The Resultant Is Within The Middle of One Third: Computed

The Resultant Is Within The Middle of One Third: Computed

Uploaded by

tewele brhaneCopyright:

Available Formats

The Resultant Is Within The Middle of One Third: Computed

The Resultant Is Within The Middle of One Third: Computed

Uploaded by

tewele brhaneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

The Resultant Is Within The Middle of One Third: Computed

The Resultant Is Within The Middle of One Third: Computed

Uploaded by

tewele brhaneCopyright:

Available Formats

4.

Footing Design

4.1 Material and Constants

Material Properties

fc'= 24.00 Mpa

Type of steel : Grade-60 for bar dia. greater than or equal to 20mm

fyk = 400.00 MPa

Grade-40 for bar dia. less than or equal to 20mm

fyk = 300.00 MPa

Es = 200000.00 MPa

Ec = 23515.10 MPa

4.2 Design for flexure

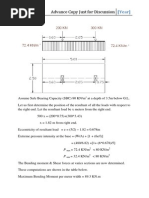

Although the wall will be supported on soil, the trapezoidal bearing stress distribution is used in the structural design of the footing.

This will produce larger upward forces acting on the toe and smaller upward forces acting on the heel, both of which are conservative.

σv=∑P/B*(1±6e/B)

When the resultant is within the middle of one third.

[AASHTO LRFD Art 11.6.3.2]

Combo Pu(KN) e(m) B(m) B/6(m) σvmaxσvmin Remark

1 439.346 0.42 3.93 0.655 183.5 40.1089

2 578.85 0.28 3.93 0.655 210.3 84.3264

The resultant is within the middle of one third

main reinforecement

For footings supporting masonry walls, the max moment is computed midway between the middle and the edge of the wall.

d= 1.181 m

q1= #### KN/m2

Mcomputed= 79.304 KNm/m

The cracking moment is given by

2

fr = 0.63 * SQRT( fc' ) = 3.09 N/mm y t= = D/2 250 mm

3 4

Icr = bD /12 = 1.042E+10 mm

M cr = fr * Icr / (y t ) = 128.60 kNm/m

1.2 * M cr = 154.32 kNm/m

The amount of reinforcement shall be adequate to develop a factored flexural resistance at least equal to the lesser of

- 1.2 times the cracking strength determined on the basis of the modlus of rubture,fr, of the concrete

- 1.33 times the moment required by the applicable strength

where load combination

Taking the minimum of the above two moment values Mu= 105.475 kNm/m

Design moment, Mu = Max(M computed,Min(1.2M cr,1.33Mu)) Ø = 0.90

Mu= 105.47 kNm/m b= 1000 mm

a= 58 fy= 400.00 N/mm2

As = Mu/(Øfy(d - a/2)) = 749 mm2 fc'= 24.00 N/mm2

a = As*fy/(0.85*fc'b) = 15 mm D= 500 mm

ρmin=0.03fc'/fy=0.0018 diam= 20 mm

Asmin=ρmin*b*d 756 mm^2 cover 50 mm

d= 420 mm

β1= 0.85

Check for maximum reinforement

rmax = 0.75*rb =

0.75*0.85*b1*(fc'/fy)*600/(600+fy) 0.02

rprovided = As/bd= 0.002 OK

As,req= 756 mm2

S=b*as/As,prov= 170.00 mm

Provide φ 20 C/C 170 As,prov= 1847.995679 mm2

Distribution reinforecemet

As,dis%=3840/srqrt(s)<=65% s= 1000 mm

As,dis%= 65%

Asdis= 1201.197191 mm2

φ= 16 mm

s= 160 mm b= 1000 mm

Provide φ 16 C/C 160 As,prov= 1256.637061 mm2

Temeperature and shear reinforecement

For members less than 1.2m millimeters thick, the area of reinforcement in each direction shall not be spaced greater than

300mm and satisfy the lesser ofAs>=0.75Ag/fy or SumAb=0.0015Ag

Ag=mm2/mm fy=Mpa 0.75Ag/fy [mm2/mm]

0.0015Ag [mm2/mm] As [mm2/mm]

500 300.00 1.25 0.75 1.25

The above steel must be distributed equally on both faces of the backwall

using dia= 12 mm

at spacing = 170 mm

Astemp= 1.330556889

ok

4. 3 Depth of Footing

A. Check depth for wide beam shear:

The nominal shear resistance, Vn, shall be determined as

Vn = Lesser of (0.25fc'bv dv ) or (0.083β√fc'bv dv ) = 335.58 kN dv = 413 mm

fc'= 24.0 Mpa

Vc=(Vn/bv dv ) = 731.9 kN/m2

shear is critical at "dv" distance from the face X=of the wall -0.013 m

qv= 210.66 KN/m2

Vacting= -2.66 KN/m

V= -6.45 KN/m2

OK

You might also like

- RC Tank Design CalculationDocument8 pagesRC Tank Design CalculationNicholas ThompsonNo ratings yet

- Open Well Staircase: 1. Design DataDocument7 pagesOpen Well Staircase: 1. Design DataEr Saroj Paudel100% (1)

- U5 - L37L38 L39 - Design Drawing Practice On Rectangular Combined Footing Numerical 2 PDFDocument8 pagesU5 - L37L38 L39 - Design Drawing Practice On Rectangular Combined Footing Numerical 2 PDFNitesh SinghNo ratings yet

- Design of Cantilever BeamDocument23 pagesDesign of Cantilever Beamjs kalyana rama85% (13)

- 2021.07.22 City Commission Miami Waterfront Design StandardsDocument71 pages2021.07.22 City Commission Miami Waterfront Design Standardsthe next miami100% (1)

- Numerical Simulation of Timber Connections With Slotted-In Stell Plates. Michael Nygaard Nonbo 2010Document106 pagesNumerical Simulation of Timber Connections With Slotted-In Stell Plates. Michael Nygaard Nonbo 2010zadadazNo ratings yet

- Flow Chart For Telecom Billing SystemDocument4 pagesFlow Chart For Telecom Billing SystemAshutosh Patil67% (3)

- Specification: Model: Hyd. Crawler (JD - 1300E) CustomerDocument14 pagesSpecification: Model: Hyd. Crawler (JD - 1300E) CustomerAsad Aijaz100% (1)

- The Resultant Is Within The Middle of One Third: ComputedDocument1 pageThe Resultant Is Within The Middle of One Third: Computedtewele brhaneNo ratings yet

- The Resultant Is Within The Middle of One Third: ComputedDocument1 pageThe Resultant Is Within The Middle of One Third: Computedtewele brhaneNo ratings yet

- Column Design2 (Final) PRINTDocument13 pagesColumn Design2 (Final) PRINTAashish MaharjanNo ratings yet

- Design of Rectangular Underground Water Tank: S S M C+ SSTDocument6 pagesDesign of Rectangular Underground Water Tank: S S M C+ SSTRatul Palodhi100% (1)

- Top Bar Slab CheckingDocument6 pagesTop Bar Slab CheckingJamie MartinezNo ratings yet

- Design Drawing Practice On Rectangular Combined Footing Numerical 2 PDFDocument8 pagesDesign Drawing Practice On Rectangular Combined Footing Numerical 2 PDFsm31No ratings yet

- Share Wall Design As Per Is 456Document2 pagesShare Wall Design As Per Is 456Sanjay RokkaNo ratings yet

- BLD 403 - Module 4Document10 pagesBLD 403 - Module 4olasunkanmi olamideNo ratings yet

- Design of Bank Building in MSECDocument82 pagesDesign of Bank Building in MSECjahanger ali SNo ratings yet

- OverhangDocument1 pageOverhangteweldeNo ratings yet

- Calculation of Slab ReinforcementDocument2 pagesCalculation of Slab ReinforcementwaquarstrNo ratings yet

- DomeDocument2 pagesDomeParshwa ConsultancyNo ratings yet

- Design of T-BeamDocument6 pagesDesign of T-BeamDineshNo ratings yet

- Concrete DesignDocument25 pagesConcrete Designgugastavo4No ratings yet

- Stringer Slab 20.08.24Document33 pagesStringer Slab 20.08.24Shindiya LalNo ratings yet

- SL No Item Cost/piece Quantity TotalDocument8 pagesSL No Item Cost/piece Quantity TotalSUNIL KUMAR K S Civil, KLEIThubballiNo ratings yet

- Basement WallDocument3 pagesBasement WallSijan AdhikariNo ratings yet

- Unit 5Document31 pagesUnit 5Nirina ArimananaNo ratings yet

- Slab 1Document16 pagesSlab 1nr.husninathirahNo ratings yet

- B1Document3 pagesB1MediksNo ratings yet

- Design of Strip Footing at Grid C-C: U U, LimDocument3 pagesDesign of Strip Footing at Grid C-C: U U, LimSujal MaharjanNo ratings yet

- Title:-One Way Slab Design Box CulvertDocument3 pagesTitle:-One Way Slab Design Box CulvertcivilceejiNo ratings yet

- Ug Tank PreviewDocument2 pagesUg Tank Previewaaditya chopadeNo ratings yet

- Grid Slab WITH BBSDocument11 pagesGrid Slab WITH BBSJyoti PatilNo ratings yet

- Combined FootingDocument4 pagesCombined FootingSakar ShresthaNo ratings yet

- Design of Flash Mixer at Kurawar - 1ADocument13 pagesDesign of Flash Mixer at Kurawar - 1AAnonymous RREG0QJWNo ratings yet

- Torsional Strength As Per 5100.5.2017: Beam DataDocument8 pagesTorsional Strength As Per 5100.5.2017: Beam DataSambhav PoddarNo ratings yet

- Canti Slab Design Is CodeDocument2 pagesCanti Slab Design Is CodeSajith JNo ratings yet

- Design For Water TankDocument9 pagesDesign For Water TankHarmeetNo ratings yet

- Desing of 200 Cubic Metre Reinforced Rectangular Clear Water Storage Tank For Rumphi Tank Geometry and DimensionsDocument23 pagesDesing of 200 Cubic Metre Reinforced Rectangular Clear Water Storage Tank For Rumphi Tank Geometry and DimensionsWjz WjzNo ratings yet

- 4.5 - Design of DRS - Simply SupportedDocument18 pages4.5 - Design of DRS - Simply Supportedron thombare100% (1)

- Design of Flash Mixer at Aron - 4DDocument10 pagesDesign of Flash Mixer at Aron - 4DSougata MondalNo ratings yet

- Design and Detailing of Steel in Combined FootingsDocument34 pagesDesign and Detailing of Steel in Combined FootingsgundulpNo ratings yet

- One Way Slab Design: 1. Calculation of LoadDocument6 pagesOne Way Slab Design: 1. Calculation of LoadSaugat ThapaNo ratings yet

- Doubly Reinforced BeamDocument19 pagesDoubly Reinforced BeamLavender HoneyNo ratings yet

- 500cubic Metre Concrete Tank DesignDocument18 pages500cubic Metre Concrete Tank DesignWjz WjzNo ratings yet

- p.k slabDocument4 pagesp.k slabVivek Patra 146No ratings yet

- Oneway Slab DesignDocument2 pagesOneway Slab DesignSajith JNo ratings yet

- Stair CaseDocument12 pagesStair Casevenkatesh19701No ratings yet

- Temple FACILITY Circular Slab DesignDocument1 pageTemple FACILITY Circular Slab Designselvakumar sNo ratings yet

- Detailed Design Design of SlabDocument4 pagesDetailed Design Design of Slabnandheeswaran rNo ratings yet

- design problem isolted footingDocument5 pagesdesign problem isolted footingabhishekratkale38No ratings yet

- Cantilever SlabDocument16 pagesCantilever SlabMukhlish Akhatar100% (1)

- Example 2 Simply Supported Beam - Flanged Section PDFDocument7 pagesExample 2 Simply Supported Beam - Flanged Section PDFWee Ren100% (2)

- Design of Strip Footing (Raft) For PM Room1Document3 pagesDesign of Strip Footing (Raft) For PM Room1Nagesh ChitariNo ratings yet

- Design of Slab: Ly/lx 2. So This Is Two Way SlabDocument6 pagesDesign of Slab: Ly/lx 2. So This Is Two Way SlabSudip ShresthaNo ratings yet

- End Cond... : Design of Stair CaseDocument6 pagesEnd Cond... : Design of Stair Caseazam1uNo ratings yet

- 3Document8 pages3Yousif R. AljNo ratings yet

- T-Beam (Slab Panel) - 28 18.37 Degree SpanDocument2 pagesT-Beam (Slab Panel) - 28 18.37 Degree Spanafifa kausarNo ratings yet

- Design of One Way SlabDocument2 pagesDesign of One Way Slabpathan is khanNo ratings yet

- Two Way SlabDocument2 pagesTwo Way Slabrukesh104No ratings yet

- Design of Slab Final 1Document24 pagesDesign of Slab Final 1Aashish MaharjanNo ratings yet

- BeamsDocument4 pagesBeamsthirangaNo ratings yet

- 35m T-Girder CMCDocument20 pages35m T-Girder CMCEngineeri TadiyosNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Chapter 7Document25 pagesChapter 7tewele brhaneNo ratings yet

- Culverts and Low Level Water CrossingsDocument9 pagesCulverts and Low Level Water Crossingstewele brhaneNo ratings yet

- Chapter 1and 2Document32 pagesChapter 1and 2tewele brhaneNo ratings yet

- Chapter - 3 and 4Document34 pagesChapter - 3 and 4tewele brhaneNo ratings yet

- Chapter 5Document41 pagesChapter 5tewele brhaneNo ratings yet

- Ed 115514Document122 pagesEd 115514tewele brhaneNo ratings yet

- Compound Curve PDF FreeDocument6 pagesCompound Curve PDF Freetewele brhaneNo ratings yet

- CH 11Document58 pagesCH 11tewele brhaneNo ratings yet

- 2.1 Preliminary Dimension: H (M) b1 (M) 2.8 A (M) T (M) B (M) b2 (M) 0.875 s2 B3 (M) 4.275 s1 D (M) B (M) Hret (M)Document1 page2.1 Preliminary Dimension: H (M) b1 (M) 2.8 A (M) T (M) B (M) b2 (M) 0.875 s2 B3 (M) 4.275 s1 D (M) B (M) Hret (M)tewele brhaneNo ratings yet

- Forecasting Road Tra Applications of Time-Series, Curve Estimation, Multiple Linear Regression, and Path Analysis ModelsDocument17 pagesForecasting Road Tra Applications of Time-Series, Curve Estimation, Multiple Linear Regression, and Path Analysis Modelstewele brhaneNo ratings yet

- The Impact of Transportation Service Quality On Customer Satisfaction: Evidence From Amhara Region, EthiopiaDocument9 pagesThe Impact of Transportation Service Quality On Customer Satisfaction: Evidence From Amhara Region, Ethiopiatewele brhaneNo ratings yet

- Statistical Analysis of The Occurrence and Severity of Crashes Involving Vulnerable Road UsersDocument8 pagesStatistical Analysis of The Occurrence and Severity of Crashes Involving Vulnerable Road Userstewele brhaneNo ratings yet

- CENG 5501, Bridge Eng'g PDFDocument73 pagesCENG 5501, Bridge Eng'g PDFtewele brhane100% (1)

- New Upstream Prep Unit 2 RevisionDocument9 pagesNew Upstream Prep Unit 2 Revisionmohamed abdallahNo ratings yet

- DLMS CLIENT Test PlanDocument73 pagesDLMS CLIENT Test Plankrkamaldevnlm4028No ratings yet

- Problem SolutionsDocument5 pagesProblem SolutionskkappaNo ratings yet

- Phraseology Problem 1Document3 pagesPhraseology Problem 1Bintang Suryadi PutraNo ratings yet

- New Chinese Style PowerPoint TemplatesDocument24 pagesNew Chinese Style PowerPoint TemplatesGeurimjaNo ratings yet

- FinalAccept7648 03022023120228 PDFDocument2 pagesFinalAccept7648 03022023120228 PDFPankaj ShuklaNo ratings yet

- 01 - Client Server ComputingDocument3 pages01 - Client Server ComputingnithyaNo ratings yet

- Chapter 7 - 'Sex and Marriage' - J. KrishnamurtiDocument8 pagesChapter 7 - 'Sex and Marriage' - J. Krishnamurtirrhhttt fghtNo ratings yet

- MCS025 Synchro-Check Module: InstallationDocument1 pageMCS025 Synchro-Check Module: Installationوسام وسامNo ratings yet

- Restriction Orifice T95500enDocument2 pagesRestriction Orifice T95500enCarlos SopasNo ratings yet

- Camera BagDocument196 pagesCamera BagLinggawatiAditopoNo ratings yet

- Personal Protective Equipment (PPE) Gloves: Standard Infection Control Precautions Literature ReviewDocument32 pagesPersonal Protective Equipment (PPE) Gloves: Standard Infection Control Precautions Literature ReviewElvira ManeteNo ratings yet

- Wireless Monitoring System For Lightweight Aircraft Landing GearDocument6 pagesWireless Monitoring System For Lightweight Aircraft Landing Gear759305169No ratings yet

- Hardy Weinberg TheoremDocument4 pagesHardy Weinberg TheoremIshwar ChandraNo ratings yet

- CV Preparation Worksheet 1Document3 pagesCV Preparation Worksheet 1Alvian CMBPNo ratings yet

- Quotation For: QKN18052143: Balai Besar Kimia Dan Kemasan (BBKK) Jakarta - KemenperinDocument1 pageQuotation For: QKN18052143: Balai Besar Kimia Dan Kemasan (BBKK) Jakarta - KemenperinFhernando ImanuelNo ratings yet

- Coordination Compounds 03 - IsomerismDocument10 pagesCoordination Compounds 03 - Isomerismsumanbesra21092007No ratings yet

- Variable DC Power Supply: Ac Machines (Lab) DescriptionDocument4 pagesVariable DC Power Supply: Ac Machines (Lab) DescriptionAmeer AliNo ratings yet

- Sap Abap Error CodeDocument12 pagesSap Abap Error CodevmuthukumaarNo ratings yet

- Thrust Vectoring - Technical SeminarDocument20 pagesThrust Vectoring - Technical SeminarNithish Jain100% (1)

- Chapter 8: Thermal Conductivity and The Mechanism of Heat TransportDocument33 pagesChapter 8: Thermal Conductivity and The Mechanism of Heat TransportConrad MonterolaNo ratings yet

- LanguagesDocument30 pagesLanguagesCarlos FausNo ratings yet

- WB p151026 NegyxjaDocument159 pagesWB p151026 NegyxjaAstrit E. SalihuNo ratings yet

- The Impact of Technology Advancement On ICT Students (Group 2 Research Paper)Document5 pagesThe Impact of Technology Advancement On ICT Students (Group 2 Research Paper)ICT 11 Lemi, Arvie Paulo D.No ratings yet

- (FREE PDF Sample) The Continuous The Discrete and The Infinitesimal in Philosophy and Mathematics John L. Bell EbooksDocument62 pages(FREE PDF Sample) The Continuous The Discrete and The Infinitesimal in Philosophy and Mathematics John L. Bell Ebooksdueskofa100% (3)

- Solution Manual For Blueprints For Writing Building Essays 1st Edition by Pam Mathis ISBN 0495802468 9780495802464Document36 pagesSolution Manual For Blueprints For Writing Building Essays 1st Edition by Pam Mathis ISBN 0495802468 9780495802464allenwoodonktbqdway100% (40)