Ciclo Di Verniciatura: Painting Cycle Doc. No. PC 3154 Sheet 1 of 1

Ciclo Di Verniciatura: Painting Cycle Doc. No. PC 3154 Sheet 1 of 1

Uploaded by

Maffone NumerounoCopyright:

Available Formats

Ciclo Di Verniciatura: Painting Cycle Doc. No. PC 3154 Sheet 1 of 1

Ciclo Di Verniciatura: Painting Cycle Doc. No. PC 3154 Sheet 1 of 1

Uploaded by

Maffone NumerounoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Ciclo Di Verniciatura: Painting Cycle Doc. No. PC 3154 Sheet 1 of 1

Ciclo Di Verniciatura: Painting Cycle Doc. No. PC 3154 Sheet 1 of 1

Uploaded by

Maffone NumerounoCopyright:

Available Formats

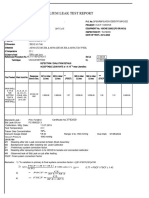

Eni E&P Document ID : Revision Index Sheet of Sheets

14202DTQR16334

Validity

Rev. 1/1

Status

Sonatrach Document ID:

CAFC-115-AQ-P-18OO20 EX-CO 01

CICLO DI VERNICIATURA Doc. No. PC 3154

Painting Cycle Sheet 1 of 1

PROPRIETA’ TECNICHE VEDI SCHEDE TECNICHE ALLEGATE

Technical Properties See attached technical sheet

PREPARAZIONE SUPERFICIE Cleanliness: ISO 8501-1 Sa 2 ½

Surface preparation Surface profile: 40 µm - 75 µm

DESCRIZIONE DEL CICLO / Cycle description

COAT PAINTING TYPE PRODUCT SUPPLIER M.D.F.T. (µm)

Primer Alkyl zinc silicate Carbozinc 11 Carboline 75 µm

Intermediate High build epoxy sealer Carboguard 890LT Carboline 75 µm

Finish High build aliphatic polyurethane Carbothane 134HP Carboline 75 µm

TOTAL MINIMUM DRY FILM THICKNESS (µm) 225 µm

FINAL COLOUR Aluminium

CONTROLLI RICHIESTI / Inspection requirements

Visual examination:100% of all surfaces; acceptance criteria: no defects

Visible surface cleanliness according to ISO 8501-1; 100% of all surfaces; acceptance criteria: in accordance with specified requirements

(Sa 2 ½ )

Absence of dust according to ISO 8502-3; spot check; acceptance criteria: max. quantity and size rating 2

2

Salt test according to ISO 8502-6 or ISO 8502-9: 4 Sample / 2000 m of fabrication; acceptance criteria: average conductivity

3 3

corresponding to ≤ 30 mg/m and max conductivity to ≤ 40 mg/ m NaC1

2

Roughness according to ISO 8503: each component or once per 10 m ; acceptance criteria: as specified in the material DS of paint

Manufacturer

Visual examination of coating: 100% of surface after each coat; acceptance criteria: no defect

Holiday detection according to ASTM D 5162; 100% Of all surfaces; acceptance criteria: no holiday

Wet film thickness according to ISO 2808 7B; Spot checks; acceptance criteria: according to materials data sheets

2

Dry film thickness according to ISO 2808 No. 6: each component or once per 10 m ; acceptance criteria: SSPC PA-2 and coating system

requirements

2

Adhesion test according to ISO 2409: each component or once per 10 m ; acceptance criteria: class 0

REMARK

Painting cycle applicable on carbon steel ball valves and hand wheel

with temperature max. 110°C according to Spec. CAFC-00-SP-MP-00NG02 B System 1

Q.C. Q.M.

2 05.04.2013 Aggiuti commenti / Added comments

S.Frazzi D.Morelli

Q.C. Q.M.

1 29.03.2013 Aggiuti commenti / Added comments

S.Frazzi D.Morelli

Q.C. Q.M.

0 28.02.2013 Prima emissione / First Issue

S.Frazzi D.Morelli

Rev: Date: Prepared: Approved: Description:

You might also like

- TR2381 Rev.7Document158 pagesTR2381 Rev.7Maffone Numerouno0% (1)

- Experiment 5 - GlycogenDocument5 pagesExperiment 5 - GlycogenGrace Aquino67% (6)

- Icpo NG En590 2704231111Document3 pagesIcpo NG En590 2704231111Nikita Novikov100% (2)

- SUMMARY PQT PT PERTAMINA (PERSERO) 15 February 2017Document15 pagesSUMMARY PQT PT PERTAMINA (PERSERO) 15 February 2017YuwantoniAl100% (1)

- Project: Tasiast Debottlenecking Project - Tailings THICKENER/4699-THK-201Document2 pagesProject: Tasiast Debottlenecking Project - Tailings THICKENER/4699-THK-201Rekhis OussamaNo ratings yet

- Sample FET To ISO 15848-1 PDFDocument4 pagesSample FET To ISO 15848-1 PDFVivi Oktavianti100% (1)

- TR1005 Rev.3Document9 pagesTR1005 Rev.3Maffone NumerounoNo ratings yet

- TR0038-3 - Valve-ActuatorsDocument49 pagesTR0038-3 - Valve-ActuatorsMaffone NumerounoNo ratings yet

- Handbook of Industrial Water TreatmentDocument6 pagesHandbook of Industrial Water TreatmentArunish Mangla0% (2)

- ch13 ProblemsDocument84 pagesch13 Problemsbrownhazel67% (6)

- Ciclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateDocument1 pageCiclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateMaffone NumerounoNo ratings yet

- Painting Cycle: Document TitleDocument8 pagesPainting Cycle: Document TitleMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateDocument1 pageCiclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateDocument1 pageCiclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Painting CycleDocument1 pageCiclo Di Verniciatura: Painting CycleMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateDocument1 pageCiclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateMaffone NumerounoNo ratings yet

- PQT - Apcotherm 800 CUI-Heeru B&R Site - IOCL LUPECH ProjectDocument5 pagesPQT - Apcotherm 800 CUI-Heeru B&R Site - IOCL LUPECH Projectbramhananda.biswas02No ratings yet

- PO SR - No.8, HEL REPORT 120004Document4 pagesPO SR - No.8, HEL REPORT 120004Agni DuttaNo ratings yet

- Aggregates Tullamore Certification 1Document9 pagesAggregates Tullamore Certification 1jesusNo ratings yet

- 44302324-PR-001_ADocument7 pages44302324-PR-001_AMustafa AdelNo ratings yet

- Borl Qap R1Document2 pagesBorl Qap R1infoNo ratings yet

- TDS of MATFLOW 20.50 - SPDocument2 pagesTDS of MATFLOW 20.50 - SPreshan champikaNo ratings yet

- CSTB Underslim ENGDocument14 pagesCSTB Underslim ENGfreddyguzman3471No ratings yet

- Ciclo Di Verniciatura: Painting CycleDocument1 pageCiclo Di Verniciatura: Painting CycleMaffone NumerounoNo ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- Inspection and Test Plan For Anode T51-T60Document10 pagesInspection and Test Plan For Anode T51-T60congvt93No ratings yet

- SKL SP2Document2 pagesSKL SP2Mangalraj MadasamyNo ratings yet

- Fahu DatasheetDocument9 pagesFahu DatasheetMustafa MandourNo ratings yet

- Sikafloor 264Document10 pagesSikafloor 264khanhNo ratings yet

- Surface Preparation - Cleanliness: ISO 8502 Dust Tape Test KitDocument1 pageSurface Preparation - Cleanliness: ISO 8502 Dust Tape Test KitElie AouadNo ratings yet

- Material Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)Document136 pagesMaterial Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)rheynavarro24No ratings yet

- Vendor Document Cover SheetDocument75 pagesVendor Document Cover Sheetmujahed_muhammedNo ratings yet

- TDS 684 Resist 86 Euk GBDocument5 pagesTDS 684 Resist 86 Euk GBNgô Trung NghĩaNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Lobatse Water Supply Master Plan - Work Package 1: Daily Field Joint Internal Lining ReportDocument2 pagesLobatse Water Supply Master Plan - Work Package 1: Daily Field Joint Internal Lining ReportvipanNo ratings yet

- WAGO 750-600enDocument6 pagesWAGO 750-600enFirmanNo ratings yet

- Sikafloor 264 PDS (CE)Document7 pagesSikafloor 264 PDS (CE)AymanNo ratings yet

- AKT Technical Information - 06.2017Document17 pagesAKT Technical Information - 06.2017brotaccristianNo ratings yet

- TDS Resist 78 (JOTUN)Document5 pagesTDS Resist 78 (JOTUN)RinoHpNo ratings yet

- Qap - DPCVDocument1 pageQap - DPCVSANDESHNo ratings yet

- Document Transmittal: SAW-CWCO-TR149 15 January 2013Document8 pagesDocument Transmittal: SAW-CWCO-TR149 15 January 2013Budi IndraNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- SP - DS LSDocument5 pagesSP - DS LSsakhr fahdNo ratings yet

- 220401 - Spotcheck-SKL-SP2-Red-Penetrant-Aerosol (2) - распознанDocument2 pages220401 - Spotcheck-SKL-SP2-Red-Penetrant-Aerosol (2) - распознанbaurzhannNo ratings yet

- Constrologix Engineering & Research Services Pvt. LTD.: Test ReportDocument1 pageConstrologix Engineering & Research Services Pvt. LTD.: Test ReportBharat KoraleNo ratings yet

- Sikafloor®-263 SLDocument6 pagesSikafloor®-263 SLHalit Baris SertbakanNo ratings yet

- Sikaflex® Pro-3 Purform® - Material SubmittalDocument34 pagesSikaflex® Pro-3 Purform® - Material SubmittalEmad El ShaerNo ratings yet

- Baltoflake: Technical Data SheetDocument6 pagesBaltoflake: Technical Data SheetSaul AntayhuaNo ratings yet

- TDS 39362 Barrier 80 X Euk GBDocument5 pagesTDS 39362 Barrier 80 X Euk GBnouzNo ratings yet

- Muki Z 2001: Technical Data SheetDocument5 pagesMuki Z 2001: Technical Data SheetIan PerdanaNo ratings yet

- Baltoflake Data SheetDocument5 pagesBaltoflake Data SheetsmnisNo ratings yet

- Paint - Technical Specification 2022-01...Document1 pagePaint - Technical Specification 2022-01...Weng Hoe ChooNo ratings yet

- Spotcheck SKC S CleanerRemover AerosolDocument3 pagesSpotcheck SKC S CleanerRemover Aerosolswapniljamdade6No ratings yet

- Procedimiento de Tratamiento de Superficies (Surface Treatment Procedure - System 1)Document3 pagesProcedimiento de Tratamiento de Superficies (Surface Treatment Procedure - System 1)Henry GelvisNo ratings yet

- TDS 11480 Pilot ACR Euk GBDocument5 pagesTDS 11480 Pilot ACR Euk GBeeng gilangNo ratings yet

- Gpti Qicl J931 Mut 004Document3 pagesGpti Qicl J931 Mut 004uselessinstaid52No ratings yet

- A MC Msi 1 CP PM Ds 001 Ace r02Document38 pagesA MC Msi 1 CP PM Ds 001 Ace r02vijender07No ratings yet

- TDS¤47884¤Jotafloor EP Coating¤Euk¤GBDocument6 pagesTDS¤47884¤Jotafloor EP Coating¤Euk¤GBkey.to.industrial.paintingNo ratings yet

- Red DN80 50 50936Document1 pageRed DN80 50 50936slimane AIT-IDIRNo ratings yet

- CERTIFICADO PLASSON PORTABRIDA 90 MMDocument1 pageCERTIFICADO PLASSON PORTABRIDA 90 MMangel rojasNo ratings yet

- 24 - 1 Core LT XLPE CableDocument9 pages24 - 1 Core LT XLPE CabledrravijainNo ratings yet

- Marker For Terminal Blocks - UCT-TM 5 - 0828734Document4 pagesMarker For Terminal Blocks - UCT-TM 5 - 0828734ibrahim abd elhadyNo ratings yet

- Vendor IR. 01-PRI-PTK-II-2024 Final Inspection. Budi - 23-02-2024.Document14 pagesVendor IR. 01-PRI-PTK-II-2024 Final Inspection. Budi - 23-02-2024.suronocaturatmojoNo ratings yet

- Public Health and Municipal Engineering Department - NelloreDocument3 pagesPublic Health and Municipal Engineering Department - Nellorejuliyet strucNo ratings yet

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- Ciclo Di Verniciatura: SpecificaDocument1 pageCiclo Di Verniciatura: SpecificaMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Technical PropertiesDocument1 pageCiclo Di Verniciatura: Technical PropertiesMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Proprietà TecnicheDocument1 pageCiclo Di Verniciatura: Proprietà TecnicheMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Painting CycleDocument1 pageCiclo Di Verniciatura: Painting CycleMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Painting CycleDocument1 pageCiclo Di Verniciatura: Painting CycleMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Painting CycleDocument1 pageCiclo Di Verniciatura: Painting CycleMaffone NumerounoNo ratings yet

- Ciclo Di VerniciaturaDocument2 pagesCiclo Di VerniciaturaMaffone NumerounoNo ratings yet

- Ciclo Di VerniciaturaDocument2 pagesCiclo Di VerniciaturaMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateDocument1 pageCiclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Painting CycleDocument5 pagesCiclo Di Verniciatura: Painting CycleMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Technical PropertiesDocument1 pageCiclo Di Verniciatura: Technical PropertiesMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Painting CycleDocument5 pagesCiclo Di Verniciatura: Painting CycleMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Technical PropertiesDocument1 pageCiclo Di Verniciatura: Technical PropertiesMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Proprietà TecnicheDocument9 pagesCiclo Di Verniciatura: Proprietà TecnicheMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Painting CycleDocument5 pagesCiclo Di Verniciatura: Painting CycleMaffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Painting CycleDocument1 pageCiclo Di Verniciatura: Painting CycleMaffone NumerounoNo ratings yet

- TR2212 Rev.5Document35 pagesTR2212 Rev.5Maffone NumerounoNo ratings yet

- TR2212 Rev.5Document35 pagesTR2212 Rev.5Maffone NumerounoNo ratings yet

- Ciclo Di Verniciatura: Painting CycleDocument7 pagesCiclo Di Verniciatura: Painting CycleMaffone NumerounoNo ratings yet

- 11544E01 - Cryogenic Test Procedure PDFDocument13 pages11544E01 - Cryogenic Test Procedure PDFMaffone Numerouno0% (1)

- Supplier Documentation Instructions: Kashagan Development Experimental ProgramDocument22 pagesSupplier Documentation Instructions: Kashagan Development Experimental ProgramMaffone Numerouno100% (2)

- TR2343 Rev.2.02Document13 pagesTR2343 Rev.2.02Maffone Numerouno100% (1)

- FS 2004 A - Rev-7Document78 pagesFS 2004 A - Rev-7Maffone NumerounoNo ratings yet

- 12.2 Acid-Base Titrations QPDocument1 page12.2 Acid-Base Titrations QPSamaira SavlaNo ratings yet

- United Kingdom Chemistry and Aerosol (UKCA) Technical DescriptionDocument86 pagesUnited Kingdom Chemistry and Aerosol (UKCA) Technical DescriptionReno ChoiNo ratings yet

- Differential Equations Question'sDocument14 pagesDifferential Equations Question'smairaNo ratings yet

- Dock RescoreDocument5 pagesDock RescoreCorinne LawrenceNo ratings yet

- 1H NMR Standard - Ylide - 0-11ppmDocument2 pages1H NMR Standard - Ylide - 0-11ppmdaniel sihyunNo ratings yet

- Blast Loading and Blast Effects On Structures - An OverviewDocument16 pagesBlast Loading and Blast Effects On Structures - An OverviewKowTeckshengNo ratings yet

- Phytochemical Screening and Antimicrobial Activity of Aqueous Stem Extract of Aloe Vera On Some Common Pathogenic BacteriaDocument8 pagesPhytochemical Screening and Antimicrobial Activity of Aqueous Stem Extract of Aloe Vera On Some Common Pathogenic BacteriaUMYU Journal of Microbiology Research (UJMR)No ratings yet

- Cleaning Validation Protocol Pantoprazole InjectionDocument8 pagesCleaning Validation Protocol Pantoprazole InjectionshashiNo ratings yet

- SDS Hydroxypropyl Methyl Cellulose (HPMC)Document8 pagesSDS Hydroxypropyl Methyl Cellulose (HPMC)Alejandra Rojas-OlivosNo ratings yet

- Class - 9 Science Powerpoint Presentation Chapter - 2 - Is Matter Around Us PureDocument85 pagesClass - 9 Science Powerpoint Presentation Chapter - 2 - Is Matter Around Us PureKANU PRIYANo ratings yet

- Narayana PTMDocument17 pagesNarayana PTMRadha KrishnaNo ratings yet

- 2 Acid Base EquilibriumDocument30 pages2 Acid Base Equilibriumu3537671No ratings yet

- US3779883 PentaDocument6 pagesUS3779883 PentaRuchita Poilkar100% (1)

- 3 MSDS Coa Dan Msds Alkohol 70%Document5 pages3 MSDS Coa Dan Msds Alkohol 70%Imelda Lorena DeviNo ratings yet

- Carboxylic Acid and Their DerivativesDocument5 pagesCarboxylic Acid and Their DerivativesShubham KumarNo ratings yet

- Science 4 - Summative Test 1 Quarter 1Document2 pagesScience 4 - Summative Test 1 Quarter 1Joy VeranoNo ratings yet

- Conversion of Glycerol To Light Olefins and Gasoline PrecursorsDocument6 pagesConversion of Glycerol To Light Olefins and Gasoline PrecursorsAnonymous Wcj4C3jNo ratings yet

- Cells Rap BlanksDocument2 pagesCells Rap BlanksEkaitz SantamariaNo ratings yet

- 10-Casting+wax PTNDocument40 pages10-Casting+wax PTNmostafa fayezNo ratings yet

- Process Overview 240108 223527Document1 pageProcess Overview 240108 223527thiago.fcouto23No ratings yet

- 14-09-2024_Sr.Super60_NUCLEUS&STERLING-BT_Jee-Main_RPTM-08&10_KEY & Sol'SDocument14 pages14-09-2024_Sr.Super60_NUCLEUS&STERLING-BT_Jee-Main_RPTM-08&10_KEY & Sol'Sadithyanda19No ratings yet

- Tugasan 3.2 (Kategori A) / Task 3.2 (Category A)Document2 pagesTugasan 3.2 (Kategori A) / Task 3.2 (Category A)ainirasibNo ratings yet

- Ijera Published PaperDocument4 pagesIjera Published PapervishalgoreNo ratings yet

- Separation Process Engineering Second Edition Safari all chapter instant downloadDocument45 pagesSeparation Process Engineering Second Edition Safari all chapter instant downloadorogobeshelNo ratings yet

- Unit4 Creep RepeatDocument30 pagesUnit4 Creep RepeatDhananjay ShimpiNo ratings yet

- SP 1173Document13 pagesSP 1173Raja Ganesan100% (1)

- Coulometry and ElectrogravimetryDocument36 pagesCoulometry and ElectrogravimetryFaiza AnsariNo ratings yet