Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mech

Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mech

Uploaded by

karthi51289Copyright:

Available Formats

Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mech

Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mech

Uploaded by

karthi51289Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mech

Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mech

Uploaded by

karthi51289Copyright:

Available Formats

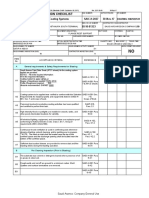

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.

00 30-Apr-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

1. Use Section A for General Requirement Checks per Data Sheet.

2. Use Section B for Environmetal Condition Checks

before work. 3. Use Section C for QC checks

Note as referenced

on applications as listed. Production work

is now ready to begin. Procedure & Data Sheets are available at site.

Use Form SATR-B-2001 & 2002.

A General Requirements (Material & Data Sheet Instructions)

Application shall be made in strict accordance with the manufacturer's

SAES-B-006 Para

A1 guidelines regarding ambient temperature, storage temperature,

8.2.3

materials, proportioning, and mixing.

Each paint container shall be clearly marked in accordance with SAES-H-001,

A2

09-SAMSS-060. Para. 6.2.3

Coatings which have exceeded the shelf life given in the Saudi Aramco

Data Sheet (see definition in SAES-H-101) shall be set aside and must SAES-H-001,

A3

not be used unless written authorization to the contrary is given by the Para. 6.2.5

Consulting Services Department.

Materials are stored upright & covered on site (canvas or tarp) per

SAES-H-001,

A4 manufacturer’s instructions with temporary storage periods at site not

Para. 6.2.1

exceeding 14-day storage rule per SAES-H-100, Para. 6.2.

Opened containers are examined for skinning, gelling, sludge & leakage. SAES-H-001,

A5 Containers & materials not in good condition are not used. Leaking Para. 6.2.4 &

containers are set aside & not used. (SAES-H-100, Sect 6). 9.1.2

Mixing operations, follow material specific data sheet instruction

(volumes, ratios, etc) in accordance with manufacturer guidelines.

Note 1: As needed, mat'ls have been heated to proper

SAES-B-006

A6 application temperature (usually about 27-30 °C) prior to spray

Para. 8.2.3

applications. Note 2: As needed, materials have

been heated for the specified time (usually for 24-48 hours) prior to spray

applications.

Equipment for spray applications is available and acceptable. Air SAES-H-102,

A9

movers in place to allow proper ventillation as required. Para 4

Steel surfaces that are to be insulated per 8.3, fireproofed with

cementitious materials or covered with intumescent or other proprietary

fireproofing such as lightweight concrete, shall be coated in accordance SAES-B-006

A10

with SAES-H-101, APCS-1B. Section 8.4

The surface preparation and coating system specified shall be referenced

on all applicable construction drawings.

B Weather, Preparation & Cleaning (*API Pub. 2218 as referenced in SAES-B-006 Para. 3.2)

Saudi Aramco: Company General Use

Weather is dry, temperature (metal, ambient) is moderate, humidity is low

to medium, & winds are not strong. Proper conditions exist.

Weather forecast is known & prep is based on winds & temps,

etc:

A) Wind is not strong enough to blow sand, salt spray, or other foreign

matter onto the surface being painted. SAES-B-006

B1

B) Wind is not strong enough to cause dry spray or to otherwise seriously Section 3.2

disturb the spray pattern applied by the spray gun.

C) Substrate temperature is above 10°C & within the temperature limits

listed by the manufacturer on the applicable Data Sheet.

D) Substrate temperature is less than 3°C above dew point & in limits

listed by the manufacturer on the applicable data sheet.

Material Staging area is organized and clean and permits proper & safe SAES-B-006

B2

mixing of coating matls for intumescent fireproofings. Section 3.2

Covering of work areas is properly done to prevent foreign matter

SAES-B-006

B3 (dust/sand) embedment & fouling of intumescent coatings.

Section 3.2

As required, total encapsulation & use of dehumidifying equipment SAES-B-006

B4

provides environmental conditions to meet manufacturer guidelines. Section 3.2

Overspray protection covering of work areas (plastic sheets, tarps, SAES-B-006

B5

masking tape, etc) is completed. Section 3.2

Surfaces are clean (no sand, dust, etc) after abrasive blasting.

Cleanliness (white glove test) shows all fines & dust removed. SAES-H-001,

B6

SSPC/cleaning method and profile, as applicable, is acceptable. Section 8.4

Airless spray equipment shall not be operated if any of the pressure SAES-H-102 Para

B7

system components is not in good condition. 4.4.5.9

Pressure Hoses used in applications meet specific requirements:

A) Hose material (pressure rating) is correct for

application.

B) Hose condition (free of cuts, damage) is safe and good.

SAES-H-102 Para

B11 C) Pressure Fittings (correct rating)

4.4.5.5.

are in good condition.

Identify sources of leakage on equipment set-up.

Benzene, gasoline, carbon tetrachloride, and chlorinated hydrocarbons SAES-H-102 Para

B12

with low threshold limit values (less than 20) shall not be used. 4.4.3

Sufficient material is available near pump to ensure continuity of the

application (intumescent mastics are applied at right temperature). SAES-B-006

B13

Staging areas are orderly & maintained with storage above grade and Section 3.2

operations are properly covered to prevent contamination.

C Quality Control

QC Equipment Kit is available as follows for coating applications:

1) Applicable Data Sheets (APCS, SA Data Sheet, Mfg Data

Sheet)

2) QC Equipment Check Sheet (SAES-H-100, Attachment "B")

3) In-Process Inspection Sheet (SAES-H-100, Attachment "C")

4) Anchor Pattern Measurement (Press-O-film tape)

5) Wet Film Thickness Gage (for application range)

6) Dry Film Thickness Gage (for application range)

SAES-H-001,

C1 7) High Intensity Lighting as needed

Attachment A

8) Coveralls, Lint-Free Gloves, Rubber-Soled Shoes/Covers (PPE)

9) Thermometer for Air Temperature

10) Humidity Gage or Sling Psychrometer

11) Contact Thermometer for Metal Temperature

12) Sharp Knife (Knife tests)

13) Hypodermic Needle Pressure Gage

14) SSPC PA2, "Paint Thickness Measurement" (Banana gage, etc)

All items have current calibration stickers as applicable

Drawings are checked & areas to be treated are easily identifiable & SAES-B-006 Para

C2

supported by drawings. Application limits are clearly identified. 3.2

QC equipment listed in SAES-H-001, Attachment A is on site for SAES-H-001

C3

inspection of surface preparation (profile) & coatings application. Para 10

Saudi Aramco: Company General Use

Quality Control Equipment Check Sheet (Att. B) is completed prior to SAES-H-001,

C4

job start-up (any work) & signed by contractor & SA. Para 10.2

In-process Inspection Sheet (Att. C) is completed/signed daily by SAES-H-001,

C5

contractor. SA initials each asterisk item & work is controlled. Para 10.2.3

Paints/Coatings & Equipment Log (Att. D) is completed/signed by SAES-H-001,

C6

coating contractor & verified/signed by inspection & SA. Para 10.2.4

REMARKS: *Always use latest approved revision of B-Std, not the Cut-off stds.

REFERENCE DOCUMENTS:

1. SAES-B-006, Fireproofing for Plants, (16 April, 2017)

2. SAES-H-001, Coating Selection and Application Requirements for Industrial Plants and Equipment (21 February 2018)

3. SAES-H-102, Safety Requirements for Coating Applications (29 October 2017)

4. API Publication 2218 - Fireproofing Practices in Petroleum & Petrochemical Processing Plants Latest Edition

ATTACHMENTS: N/A

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- MSME DeclarationDocument1 pageMSME DeclarationpavanNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Refractory Installation Procedure SAIC-N-2018 25-May-05 MechDocument4 pagesSaudi Aramco Inspection Checklist: Review of Refractory Installation Procedure SAIC-N-2018 25-May-05 MechAnonymous S9qBDVky100% (1)

- Saic H 2024Document2 pagesSaic H 2024usmanNo ratings yet

- Saic H 1002Document4 pagesSaic H 1002NASIR SYEDNo ratings yet

- SAIC-H-2032 Rev 7Document4 pagesSAIC-H-2032 Rev 7Satheesh Rama SamyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 30-Apr-13 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 15-Nov-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 15-Nov-17 MechAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic B 2005Document4 pagesSaic B 2005Muhammad Ikram QurashiNo ratings yet

- Saic H 2011Document2 pagesSaic H 2011Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 15-Nov-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 15-Nov-17 MechAbdul HannanNo ratings yet

- Saic H 1003Document4 pagesSaic H 1003NASIR SYEDNo ratings yet

- Saic H 2011Document2 pagesSaic H 2011zuknesedriNo ratings yet

- Saic-H-2028Document11 pagesSaic-H-2028mominNo ratings yet

- Liquid CoatingsDocument12 pagesLiquid CoatingsSUNIL RAJPUTNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 Mechkarthi51289No ratings yet

- Saic H 2014Document2 pagesSaic H 2014Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 Mechkarthi51289No ratings yet

- ChecklistDocument7 pagesChecklistIkram SyedNo ratings yet

- Saic B 2004Document2 pagesSaic B 2004tayyab aliNo ratings yet

- Saic H 2015Document4 pagesSaic H 2015jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 1-Nov-09 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistSardar Muhamad RashidNo ratings yet

- SAIC-H-2060 Rev 4Document3 pagesSAIC-H-2060 Rev 4Anonymous 4e7GNjzGWNo ratings yet

- Saic D 2016Document2 pagesSaic D 2016Shahzad HussainNo ratings yet

- Saic D 2016Document2 pagesSaic D 2016razzak.me.enggNo ratings yet

- SAIC-H-2029Document10 pagesSAIC-H-2029rehan hussainNo ratings yet

- Saic D 2023Document2 pagesSaic D 2023razzak.me.enggNo ratings yet

- Saic H 1003Document3 pagesSaic H 1003Afzal HussainNo ratings yet

- Saudi Aramco Inspection Checklist: 1-Dec-06 Mech-Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008Document2 pagesSaudi Aramco Inspection Checklist: 1-Dec-06 Mech-Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008ரமேஷ் பாலக்காடுNo ratings yet

- Saic-H-2027Document3 pagesSaic-H-2027momin0% (1)

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document2 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanNo ratings yet

- Saic H 1003Document2 pagesSaic H 1003Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection ChecklistMainuddin AliNo ratings yet

- SAIC-H-1003 Rev 7 (Final)Document4 pagesSAIC-H-1003 Rev 7 (Final)ryann mananquilNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document8 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanNo ratings yet

- SAIC-H-1002 - Coatings and Repair Materials Receiving, InspectionDocument2 pagesSAIC-H-1002 - Coatings and Repair Materials Receiving, InspectionzuknesedriNo ratings yet

- Saic H 1003Document3 pagesSaic H 1003Anish V NairNo ratings yet

- SAIC-H-1002 Rev 7 (Final)Document2 pagesSAIC-H-1002 Rev 7 (Final)ryann mananquilNo ratings yet

- SAIC N 2034 InspofRepairstoExtErosResistRefractInst EL RevDocument3 pagesSAIC N 2034 InspofRepairstoExtErosResistRefractInst EL RevAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistphilipyap100% (1)

- Saic B 2014Document5 pagesSaic B 2014mohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khan100% (1)

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- SAIC-H-2026 Coating Equipment InspectionDocument3 pagesSAIC-H-2026 Coating Equipment Inspectionqq343923571No ratings yet

- Saic A 2025Document3 pagesSaic A 2025tayyab aliNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saic D 2003Document3 pagesSaic D 2003tayyab aliNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistphilipyapNo ratings yet

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- Saic H 2023Document2 pagesSaic H 2023Anish V NairNo ratings yet

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechAbdul HannanNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 InstDocument17 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 Instkarthi51289No ratings yet

- TWAD - Hdpe Certificate - 75231 Sudhakar 90mmDocument2 pagesTWAD - Hdpe Certificate - 75231 Sudhakar 90mmkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 3-Jul-18Document5 pagesSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 3-Jul-18karthi51289No ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 Mechkarthi51289No ratings yet

- 0625 - s22 - QP - 4 (Extended) 1 PDFDocument16 pages0625 - s22 - QP - 4 (Extended) 1 PDFJoey DingNo ratings yet

- Wa815 / Za815 Websphere Application Server V8.5.5 Performance TuningDocument11 pagesWa815 / Za815 Websphere Application Server V8.5.5 Performance TuningBi BôngNo ratings yet

- New OXE Features Introduced in OXE R12.4/M5.204.2.b/M5.204.7.cDocument51 pagesNew OXE Features Introduced in OXE R12.4/M5.204.2.b/M5.204.7.clocuras34100% (1)

- Woodward Governor'S Troubleshooting and Rectification: A Case On Jamuna Fertilizer Company PerspectiveDocument0 pagesWoodward Governor'S Troubleshooting and Rectification: A Case On Jamuna Fertilizer Company PerspectiveSofiane HalimiNo ratings yet

- Are Edtech Valuations in A Bubble?: June 2021Document23 pagesAre Edtech Valuations in A Bubble?: June 2021S1626No ratings yet

- Equalizador de Linea ArrisDocument4 pagesEqualizador de Linea ArrisMaria RodriguezNo ratings yet

- Merchandising OperationsDocument27 pagesMerchandising OperationsAbegail Lheani GuiaNo ratings yet

- Experian Corporate Report: Particulars of The Subject Provided by YouDocument6 pagesExperian Corporate Report: Particulars of The Subject Provided by YouIman AzimNo ratings yet

- Financial Statement AnalysisDocument5 pagesFinancial Statement AnalysisShane Tabunggao100% (1)

- PALFINGER MARINE Product Brochure 2015Document1 pagePALFINGER MARINE Product Brochure 2015Hugo Vco RvaNo ratings yet

- Band A 聽力模擬考 簡體 listening test (simplified)Document12 pagesBand A 聽力模擬考 簡體 listening test (simplified)Simon AllenNo ratings yet

- Overview and Present Status of Technical Textiles in IndiaDocument34 pagesOverview and Present Status of Technical Textiles in IndiaRohit SinghNo ratings yet

- Kurzweil K2000 Display UpgradeDocument12 pagesKurzweil K2000 Display UpgradeDana OsbornNo ratings yet

- PetroHRA Guideline Rev1 Jan2017Document239 pagesPetroHRA Guideline Rev1 Jan2017Luciana GarciaNo ratings yet

- Organizational Restructuring of MPLS NOCDocument2 pagesOrganizational Restructuring of MPLS NOCVIKRANTNo ratings yet

- Ijfeat: Application of Electrostatic Precipitator in Cement PlantDocument7 pagesIjfeat: Application of Electrostatic Precipitator in Cement PlantElwathig BakhietNo ratings yet

- Electronic Engineering General KnowledgeDocument2 pagesElectronic Engineering General KnowledgeYisel Perez Ortiz100% (1)

- Yeast ExperimentDocument2 pagesYeast ExperimentJames Knowell0% (1)

- Atita EngineDocument36 pagesAtita EngineSara AzamNo ratings yet

- ST 720 ST 726 High Range Conductivity Temperature Sensor DataSheetDocument3 pagesST 720 ST 726 High Range Conductivity Temperature Sensor DataSheetSujith Panikkadan unnikrishnanNo ratings yet

- Causation Statham ReviewDocument2 pagesCausation Statham ReviewMilan MatejicNo ratings yet

- GSM Based Fault Monitoring SystemDocument23 pagesGSM Based Fault Monitoring SystemSanjana Singh100% (1)

- Warehouse Management Systems and Logistics ManagementDocument1 pageWarehouse Management Systems and Logistics ManagementSanjay RamuNo ratings yet

- Geo Certificate rf2-2021 Tensar Re500Document9 pagesGeo Certificate rf2-2021 Tensar Re500samiNo ratings yet

- International StrategyDocument34 pagesInternational StrategymanicatewatiaNo ratings yet

- Liquid Vapor Equilibrium Evaporation CondensationDocument1 pageLiquid Vapor Equilibrium Evaporation CondensationNurulThaqifah BaharumNo ratings yet

- DBA Cipriano Catherine Kris - Article Review Mang InasalDocument10 pagesDBA Cipriano Catherine Kris - Article Review Mang InasalRosel CIprianoNo ratings yet

- I Arrive For My Interview With Chloe Kelling and IDocument7 pagesI Arrive For My Interview With Chloe Kelling and IKellyNo ratings yet

- Assembling, Simulating, and Recording Robot Videos As An Effort To Motivate Middle School Students and Teachers of Science in Bengkulu ProvinceDocument11 pagesAssembling, Simulating, and Recording Robot Videos As An Effort To Motivate Middle School Students and Teachers of Science in Bengkulu ProvinceIAES International Journal of Robotics and AutomationNo ratings yet