Saic-H-2027

Saic-H-2027

Uploaded by

mominCopyright:

Available Formats

Saic-H-2027

Saic-H-2027

Uploaded by

mominOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Saic-H-2027

Saic-H-2027

Uploaded by

mominCopyright:

Available Formats

SAUDI ARAMCO ID/PIEU - 30-Nov-2017- REV. 2017.09.00 (Standards Cutoff - September 30, 2017) Rev. 2017.09.

00 30-Sep-17

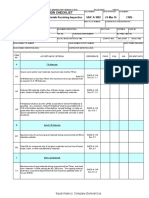

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Surface Preparation for Liquid Coating Systems SAIC-H-2027 30-Nov-17 COATING-1402522531

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

UPGRADE FIRE WATER SYSTEM AT RASTANURA SOUTH TERMINAL BI-10-01333 SAUDI ARCHIRODON COMPANY LTD

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

FLANGE REST SUPPORT

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

168-B-XA-864219-003-00-1 & 2

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

08/03/2022 09:30 AM 08/03/2022 09:30 AM SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SATIP-H-100-01 3.1

SAUDI ARAMCO INSPECTION LEVEL

W

CONTRACTOR INSPECTION LEVEL

H

NO

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General requirements & Safety Requirements for Blasting

Saudi Aramco Paint Data Sheet (APCS sheets) for the coating system

applied are provided:

NOTES: Fill in the required information:

Fill in the required information: SAES-H-101V &

Coating System to apply: APCS -3

A1 Degree of cleanliness required: SSPC SP16 SAES-H-001 Para

Profile (Roughness) required: N/A 7 & APCS Sheets

Abrasive recommended: GARNET 30/60

Coating system to be applied was verified to conform with the Selection SAES-H-001 Sec.

A2 Requirements for industrial plants and equipments listed in SAES-H- 7&

001, Sec. 7 and scope of work. Scope of Work

Personnel involved in protective coating activities has been qualified SAEP-316,

A3

and certified to perfom their task. Para. 5.1

High intensity flood or spotlights are installed in vessels, tanks, and SAES-H-001 Para

A4

other poorly illuminated locations for visibility. 6.5.3

All electrical lighting, equipment, and connections are explosion proof

SAES-H-102,

A5 conforming to National Electric Code, Class I, Div 1, Group D

Para. 4.1.2

requirements (NEC Article 500).

Continuous forced ventilation is used in confined spaces whenever

abrasive blasting, solvent cleaning, and/or painting are in progress. SAES-H-102,

A6 **NOTE: The fresh air inlet shall be located near the top of the Para. 4.2.1 &

confined space and the discharge opening shall be located near the Para. 4.2.2

bottom of the confined space.

Sufficient dust suction blowers are provided to remove dust and fine SAES-H-001 Para

A7

blasting debris during the blasting operation. 6.5.4

B Pre-Cleaning Inspection (Prior to Blasting)

The substrate was solvent or detergent cleaned where presence of oil SAES-H-001 Para

B1

or grease is observed. 6.4.1

Rough welds and cut-off are ground to a minimum radius. Weld SAES-H-001 Para

B2

Spatters and

Substrate surface laminations

temperature are removed.

is at least 3°C above the Dew point. 6.4.2

SAES-H-001 Para

B3

6.4.3

Saudi Aramco: Company General Use

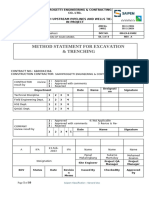

SAUDI ARAMCO ID/PIEU - 30-Nov-2017- REV. 2017.09.00 (Standards Cutoff - September 30, 2017) Rev. 2017.09.00 30-Sep-17

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Surface Preparation for Liquid Coating Systems SAIC-H-2027 30-Nov-17 COATING-1402522531

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

UPGRADE FIRE WATER SYSTEM AT RASTANURA SOUTH TERMINAL BI-10-01333 SAUDI ARCHIRODON COMPANY LTD

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

SAES-H-001 Para

B4 Nozzle pressure is 620 kPa (90 psig) measured at the nozzle side.

8.1.4

Quality of compressed air for blasting is checked at start and at mid-point

of each 8 hour shift. This is determined by performing a blotter test.

Note: Blotter test procedure.

a) Attach a piece of blotter or absorbent paper to a clip board.

b) Operate the blast system for at least 5 minutes, then allow air

SAES-H-001,

B5 flow out of the blasting nozzle at a nozzle pressure of 50 psig.

Para. 8.1.3

c) Hold the paper approx. 45-60 cm in front of the nozzle for at

least 1 minute.

d) Satisfactory results shall be no water or oil contamination on

the blotter.

e) Record time of test and result in SATR-H-2006.

Abrasive used for blasting are as per the APCS sheet, contain less than

50 PPM of sulfates & chlorides and calcium carbonate shall be 1.0% by SAES-H-100

weight. (Verified by certificates) and following limitations applied: Para 8.2.1

B6 a) Sand is not used as a blasting abrasive as prohibited by GI-0006.021. to

b) The use of reclaimed slag abrasives is prohibited. Para 8.2.3

c) The use of reclaimed garnet is permitted provided it meets the above & Para 6.3.4

requirements and a CSD-approved recycling system is utilized.

14-MAR-22 08:00 AM Surface Preparation

All personnel entering tanks or vessels after abrasive blasting wear

SAES-H-001 Para

C1 rubber-soled shoes with clean disposable covers, sweat bands and lint-

6.5.5

free gloves.

Blasted surface areas are cleaned of spent abrasive:

1) By dry brushing

SAES-H-001 Para

C2 2) By blowing down with clean, dry compressed

6.6.1

air 3) Internal surfaces shall be dry brushed and vacuum

cleaned

Calibrated gages are used for measurement of anchor profile, i.e.

thickness of Clemtex tape and anchor profile depth gage.

Note: The reference standard for profile measurement shall be the Schedule Q,

C3

Clemtex Anchor Pattern Standards. ( This does not preclude Para. 7.1

the use of other techniques providing they agree with the

reference standard) as per SAES-H-001, Para 6.6.4.

Surface cleanliness level after blasting meets the required degree of

cleanliness for the specified coating system: (Record the obtained

cleanliness level in SATR-H-2006.

Coating System Cleanliness Level

1. APCS-2A/2B/2C/2D/2E/2F/2G/2H/2I

SAES-H-001 Para

/11B/19C//27/28 ..............................................Sa-3 (SP 5)

8.1.1

C4

&

2. APCS-1A/1B/1C/1D/1E/1F/3/5A/5B/ 9/11A/12/17A

Para 8.1.3

/17A /19A/19B/20A/20B/22A/22B/26/26T.......Sa-21/2 (SP10)

3. APCS-4/6/10/23.............................................Sa-2 (SP 6)

4. APCS-7.....................................................St-2 (SP2)/St 3 (SP3)

5. APCS-11C...............................................C/S SP1,SP6. S/S SP1

6. Others:__APCS-3_______..... ..........._SSPC-SP16_____

Saudi Aramco: Company General Use

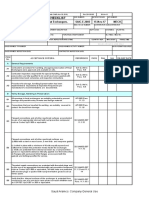

SAUDI ARAMCO ID/PIEU - 30-Nov-2017- REV. 2017.09.00 (Standards Cutoff - September 30, 2017) Rev. 2017.09.00 30-Sep-17

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Surface Preparation for Liquid Coating Systems SAIC-H-2027 30-Nov-17 COATING-1402522531

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

UPGRADE FIRE WATER SYSTEM AT RASTANURA SOUTH TERMINAL BI-10-01333 SAUDI ARCHIRODON COMPANY LTD

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Measured surface profile (Roughness) conforms with the profile specified

for the applied coating system. (Record result and attach Replica Tape on

SATR-H-2006)

APCS Coating System Specified Surface Profile

(Micrometers)

1. APCS- 1A/1B/1D/1E/2A/2B/2C/2D/4/5A/5B/6/9/

11A/12/17A/17B/22A/22B/26/26T..........40-65 Min-Max

2. APCS-26................................................40-75 Min-Max

3. APCS-2E/19C/28....................................60-100 Min-Max

4. APCS-/2F/2G/3/19A/19B/23/27/28.........65-100 Min-Max SAES-H-001 Para

C5

5. APCS-2H/2I.............................................75-100 Min-Max 8.1.1

6. APCS-1C/1F............................................25-40 Min-Max

7. APCS-7/10...............................................Not critical

8 . APCS-9..................................................25-50 Min-Max

9. APCS-11B..............................................25 Max

10. APCS-20A/20B.........................As recommended by coating Mfg

11. Others:_APCS-3_________.............19 -40 Min-Max .............

_________________

REMARKS

ATTACHMENTS:

REFERENCE DOCUMENTS:

1. SAES-H-001,Coating Selection and Application Requirements for Industrial Plants and Equipment (5 April 2016)

2. SAES-H-102: Safety requirements for Coating Applications (24 October 2012)

3. SAEP-316, Performance Qualification of Coating Personnel (31 July 2016)

4. Schedule "Q", Quality Requirements for Contractors (Project Specific)

5. G.I.-0006.021, Safety Requirements for Abrasive Blast Cleaning, (19 June 2012 )

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: HARSHAD PATIL Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

ZEESHAN Mr. SHANMUGAM GURUSWAMY

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date: MOHAMMED YASER KHAN Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Applicable Codes & Standards For Aramco Projects (Piping)Document107 pagesApplicable Codes & Standards For Aramco Projects (Piping)momin100% (11)

- UNIZIK Post UTME Past Questions and Answers.Document93 pagesUNIZIK Post UTME Past Questions and Answers.Malcom Oguji100% (1)

- Hydrostatic Testing ProcedureDocument7 pagesHydrostatic Testing Proceduremomin67% (3)

- Saic S 4057Document5 pagesSaic S 4057Engr IrfanNo ratings yet

- Non-Conformance Control ProcedureDocument12 pagesNon-Conformance Control Proceduremomin100% (2)

- Pages From SAES-H-001-19Document1 pagePages From SAES-H-001-19mohammed s fawabNo ratings yet

- Is 1570Document164 pagesIs 1570Sumit Shyamal63% (8)

- Saic-H-2028Document11 pagesSaic-H-2028mominNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 15-Nov-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 15-Nov-17 MechAbdul HannanNo ratings yet

- 09 Samss 068Document7 pages09 Samss 068AjeetKumarNo ratings yet

- Satr-H-2006 3.3Document3 pagesSatr-H-2006 3.3mominNo ratings yet

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 pagesSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliNo ratings yet

- Satip H 002 02Document10 pagesSatip H 002 02Rijwan MohammadNo ratings yet

- SATR-H-2004 Rev 7Document3 pagesSATR-H-2004 Rev 7josephNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002Sajid ShaikhNo ratings yet

- 09 SAMSS 089 (Final Draft - 2018)Document28 pages09 SAMSS 089 (Final Draft - 2018)lhanx2No ratings yet

- 09 Samss 101Document9 pages09 Samss 101GOSP3 QC MechanicalNo ratings yet

- Saep 744Document7 pagesSaep 744Anonymous 4IpmN7OnNo ratings yet

- SATIP-H-002-01 Rev 7Document4 pagesSATIP-H-002-01 Rev 7Satheesh Rama SamyNo ratings yet

- Pages From SAES-H-001-5Document1 pagePages From SAES-H-001-5mohammed s fawab100% (1)

- 09 Samss 069 PDFDocument10 pages09 Samss 069 PDFSelvakpm06100% (1)

- Inspection & Testing RequirementsDocument1 pageInspection & Testing RequirementsMuhammad RizwanNo ratings yet

- 175 091300Document2 pages175 091300Abu Anas M.SalaheldinNo ratings yet

- Satr S 4002Document1 pageSatr S 4002Noor Mohamed AzeezNo ratings yet

- SAIC-B-2003 Rev 2Document2 pagesSAIC-B-2003 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDocument2 pagesSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyNo ratings yet

- Saic D 2025Document10 pagesSaic D 2025jerinNo ratings yet

- SATIP H 002 08 Rev 4.unlockedDocument2 pagesSATIP H 002 08 Rev 4.unlockedMohamed Farhan B PositiveNo ratings yet

- SATIP-T-492-01 Ver 08Document1 pageSATIP-T-492-01 Ver 08thezaidNo ratings yet

- Satip H 002 11Document10 pagesSatip H 002 11Rauf ChaudharyNo ratings yet

- Ai Hempadur 87540 EnglishDocument2 pagesAi Hempadur 87540 EnglishAmilcar BolagNo ratings yet

- 1 SATIP-NDE-RT-01 Radiographic Testing-Rev 1Document1 page1 SATIP-NDE-RT-01 Radiographic Testing-Rev 1KirubhakarPooranamNo ratings yet

- 09 Samss 071Document6 pages09 Samss 071inatt101100% (1)

- Materials System SpecificationDocument8 pagesMaterials System SpecificationAjeetKumarNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportMoghal AliNo ratings yet

- 09 Samss 060Document4 pages09 Samss 060asimazami69No ratings yet

- Saudi Aramco Stamdard 01-SAMSS-005 Cement Mortor Lining of Steel PipeDocument5 pagesSaudi Aramco Stamdard 01-SAMSS-005 Cement Mortor Lining of Steel PipeansarimehmoodNo ratings yet

- T00-A-Dd-842201-001 - Rev DDocument17 pagesT00-A-Dd-842201-001 - Rev DNaveedNo ratings yet

- SATIP-K-001-02 Rev 7 Air-Handling UnitDocument3 pagesSATIP-K-001-02 Rev 7 Air-Handling UnitRAMAKRISHNA100% (1)

- SAIC-H-2010 Rev 7Document1 pageSAIC-H-2010 Rev 7Satheesh Rama SamyNo ratings yet

- Sigma C200a Coaltar Epoxy BaseDocument1 pageSigma C200a Coaltar Epoxy BaseBilal Ghazanfar100% (1)

- SaicDocument8 pagesSaicKhurram Shehzad100% (1)

- 1st List of Non Inspectable Materials Technical Submittals - VID Comments (OMPPD-GUPD-L-165-17)Document7 pages1st List of Non Inspectable Materials Technical Submittals - VID Comments (OMPPD-GUPD-L-165-17)Mohamed Reda Hussein SengarNo ratings yet

- Saic A 1010Document1 pageSaic A 1010Naushad AlamNo ratings yet

- Under Revision: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument1 pageUnder Revision: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualbryanNo ratings yet

- Ansi Z129 - 1 For Hazardous Industrial Chemicals - Precautionary LabelingDocument100 pagesAnsi Z129 - 1 For Hazardous Industrial Chemicals - Precautionary LabelingJuan Carlos Guerrero R0% (1)

- Awais Inspector-PaintingDocument6 pagesAwais Inspector-PaintingMohammed GaniNo ratings yet

- 12 Samss 007Document32 pages12 Samss 007Muhammad BilalNo ratings yet

- Saep 381Document17 pagesSaep 381irfan hussain100% (1)

- Materials System SpecificationDocument6 pagesMaterials System SpecificationAjeetKumarNo ratings yet

- Saic Q 1039Document4 pagesSaic Q 1039Basir AhmadNo ratings yet

- Saep 119Document11 pagesSaep 119Demac SaudNo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilSajid ShaikhNo ratings yet

- 175 011000 PDFDocument2 pages175 011000 PDFAbu Anas M.SalaheldinNo ratings yet

- Monthly Report No.-2 Coating Welspun DammamDocument5 pagesMonthly Report No.-2 Coating Welspun Dammammdsajidalam100% (1)

- 33 Self Refurbishment Method Statement Phoenix Housing Co OpDocument11 pages33 Self Refurbishment Method Statement Phoenix Housing Co OpthomasNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- 000-ZA-E-03452 Rev. A (Method Statement For Excavation & Trenching)Document10 pages000-ZA-E-03452 Rev. A (Method Statement For Excavation & Trenching)hsesupervisor01No ratings yet

- Incr - XXXDocument2 pagesIncr - XXXsadik coolsadyNo ratings yet

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- Satip S 070 01 Rev 7 (Final)Document2 pagesSatip S 070 01 Rev 7 (Final)Zuhaib Khan100% (2)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSelvakpm06No ratings yet

- Saic-H-2029Document12 pagesSaic-H-2029mominNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saic N 2026Document3 pagesSaic N 2026jerinNo ratings yet

- 0001Document1 page0001mominNo ratings yet

- Part.1 Issued For Construction (Fire Protection)Document322 pagesPart.1 Issued For Construction (Fire Protection)mominNo ratings yet

- IMS ManualDocument6 pagesIMS ManualmominNo ratings yet

- Ba090211 005Document1 pageBa090211 005mominNo ratings yet

- SOP - Permit To Work SystemDocument3 pagesSOP - Permit To Work Systemmomin100% (2)

- Management Review 2020Document2 pagesManagement Review 2020mominNo ratings yet

- Project Quality Plan (JFJS-788)Document18 pagesProject Quality Plan (JFJS-788)mominNo ratings yet

- Sep Mgse CM SCM 0031 Procedure For Valve Testing and InstallationDocument6 pagesSep Mgse CM SCM 0031 Procedure For Valve Testing and InstallationmominNo ratings yet

- Magnetic Particle Testing ProcedureDocument11 pagesMagnetic Particle Testing ProceduremominNo ratings yet

- Ba090205 001Document1 pageBa090205 001mominNo ratings yet

- Alf Piping 117 009Document6 pagesAlf Piping 117 009mominNo ratings yet

- Saudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechDocument8 pagesSaudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechmominNo ratings yet

- Mgse T Sep Sa 0029Document1 pageMgse T Sep Sa 0029mominNo ratings yet

- Saic-H-2029Document12 pagesSaic-H-2029mominNo ratings yet

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechDocument7 pagesSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Inspect Assembly of Air-Cooled Heat Exchanger ComponentsDocument12 pagesSaudi Aramco Inspection Checklist: Inspect Assembly of Air-Cooled Heat Exchanger ComponentsmominNo ratings yet

- Saudi Aramco Inspection Checklist: Re-Instatement of Air Cooled Heat Exchanger SAIC-E-2008 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Re-Instatement of Air Cooled Heat Exchanger SAIC-E-2008 15-Nov-17 MechmominNo ratings yet

- SATIP-S-060-08 Rev 8 Copper Piping FinalDocument2 pagesSATIP-S-060-08 Rev 8 Copper Piping FinalmominNo ratings yet

- Saic-H-2030Document9 pagesSaic-H-2030mominNo ratings yet

- Saudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechDocument3 pagesSaudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanmominNo ratings yet

- SATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalDocument2 pagesSATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalmominNo ratings yet

- SATIP-S-060-02 Rev 8 Electric Drinking Water Coolers FinalDocument2 pagesSATIP-S-060-02 Rev 8 Electric Drinking Water Coolers FinalmominNo ratings yet

- Andres Anal Chem CalibrationDocument5 pagesAndres Anal Chem CalibrationAndres, Andrea Lyn M.No ratings yet

- Aits 1920 Ot JeemDocument17 pagesAits 1920 Ot JeemhelloNo ratings yet

- Chemistry IPDocument9 pagesChemistry IPMOHAMED IBRAHIMNo ratings yet

- Purification & Characterisation of Organic CompoundsDocument14 pagesPurification & Characterisation of Organic CompoundsEzhil MukilNo ratings yet

- Advances in Cellulose NanomaterialsDocument39 pagesAdvances in Cellulose NanomaterialsSiamakNo ratings yet

- BGDT20019785 Report Number:: ITS Labtest Bangladesh LTDDocument3 pagesBGDT20019785 Report Number:: ITS Labtest Bangladesh LTDanwar sadatNo ratings yet

- Chemical Properties of SoilDocument74 pagesChemical Properties of SoilGenesis Joy MarbellaNo ratings yet

- Lab Report 02 PH Group 01Document4 pagesLab Report 02 PH Group 01Haniya SiddiqueNo ratings yet

- Annotated-Electron Configuration Practice - CruchetDocument4 pagesAnnotated-Electron Configuration Practice - Cruchet270121.ajNo ratings yet

- Answer: (D) Propyne Explanation: The C - C Bond Length 1.54 Å, C C Bond Length 1.34 Å and C C Bond Length 1.20 Å. Since Propyne Has A Triple Bond, Therefore It Has Minimum Bond LengthDocument4 pagesAnswer: (D) Propyne Explanation: The C - C Bond Length 1.54 Å, C C Bond Length 1.34 Å and C C Bond Length 1.20 Å. Since Propyne Has A Triple Bond, Therefore It Has Minimum Bond Lengthaibanand dasNo ratings yet

- 1-Intro GFRP-RC 08102020Document74 pages1-Intro GFRP-RC 08102020Mustufa F KanjetaNo ratings yet

- Practical Chemistry 4 PDFDocument56 pagesPractical Chemistry 4 PDFaligohardisholder101No ratings yet

- Unidad 2 - Parte 2 - Teoría Del Campo Cristalino, Espectroscopia ElectrónicaDocument63 pagesUnidad 2 - Parte 2 - Teoría Del Campo Cristalino, Espectroscopia ElectrónicaLUIS CARLOS ROMERO ZAPATANo ratings yet

- Phyl 6 Nerve Review KeyDocument4 pagesPhyl 6 Nerve Review KeyTofik MohammedNo ratings yet

- CRDDSDocument40 pagesCRDDSvaddadihatashaNo ratings yet

- UST Business Plan-CompleteDocument42 pagesUST Business Plan-Completehaytan0410No ratings yet

- CO2 LoadingDocument12 pagesCO2 LoadingMuhammad Sheraz GorayaNo ratings yet

- 9 - BICH 200-ProteinDocument21 pages9 - BICH 200-ProteinDR. ANUPAMA NAGARAJNo ratings yet

- Air Entrained ConcreteDocument10 pagesAir Entrained ConcreteanushaNo ratings yet

- MCT - Cement PaintsDocument13 pagesMCT - Cement PaintsIshika AgarwalNo ratings yet

- Chloride Attack On Concrete Structures - Cause and Prevention - TheconstructorDocument4 pagesChloride Attack On Concrete Structures - Cause and Prevention - TheconstructorAlhmohra AnselNo ratings yet

- Che 2102 Course OutlineDocument2 pagesChe 2102 Course Outlinedorcaschepkoech525No ratings yet

- Sample Paper Science - 5Document8 pagesSample Paper Science - 5Gurukul PatnaNo ratings yet

- Wool BleachingDocument59 pagesWool BleachingAbel TayeNo ratings yet

- Product Information SENSOCEL +Document2 pagesProduct Information SENSOCEL +Limiyanto TanseriNo ratings yet

- Amali 3Document9 pagesAmali 3Aiman FarhanNo ratings yet

- The Cell 3Document104 pagesThe Cell 3jandra pearlNo ratings yet

- NMAT Biology Practice Questions Set 2Document7 pagesNMAT Biology Practice Questions Set 2KisakiNo ratings yet