Cat Payload Kit Electrical System For Medium Wheel Loaders: Harness and Wire Electrical Schematic Symbols

Cat Payload Kit Electrical System For Medium Wheel Loaders: Harness and Wire Electrical Schematic Symbols

Uploaded by

Eddie Kelvin Isidro LauraCopyright:

Available Formats

Cat Payload Kit Electrical System For Medium Wheel Loaders: Harness and Wire Electrical Schematic Symbols

Cat Payload Kit Electrical System For Medium Wheel Loaders: Harness and Wire Electrical Schematic Symbols

Uploaded by

Eddie Kelvin Isidro LauraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Cat Payload Kit Electrical System For Medium Wheel Loaders: Harness and Wire Electrical Schematic Symbols

Cat Payload Kit Electrical System For Medium Wheel Loaders: Harness and Wire Electrical Schematic Symbols

Uploaded by

Eddie Kelvin Isidro LauraCopyright:

Available Formats

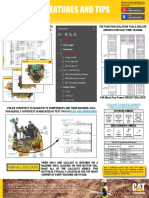

M0091383-03

March 2021 Harness And Wire Electrical Schematic Symbols

Symbols

Pressure Temperature Level Flow Circuit Breaker

Symbol Symbol Symbol Symbol Symbol

Symbols and Definitions

Fuse: A component in an electrical circuit that will open the circuit if too much current flows

through it.

Switch (Normally Open): A switch that will close at a specified point (temp, press, etc.). The

circle indicates that the component has screw terminals and a wire can be disconnected from it.

Switch (Normally Closed): A switch that will open at a specified point (temp, press, etc.).

No circle indicates that the wire cannot be disconnected from the component.

Ground (Wired): This indicates that the component is connected to a grounded wire. The

grounded wire is fastened to the machine.

Ground (Case): This indicates that the component does not have a wire connected to ground.

It is grounded by being fastened to the machine.

Cat Payload Kit

Reed Switch: A switch whose contacts are controlled by a magnet. A magnet closes the

contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch.

For Medium Wheel Loaders

Sender: A component that is used with a temperature or pressure gauge. The sender

measures the temperature or pressure. Its resistance changes to give an indication to

T

the gauge of the temperature or pressure.

Electrical System Relay (Magnetic Switch): A relay is an electrical component that is activated by electricity.

It has a coil that makes an electromagnet when current flows through it. The

electromagnet can open or close the switch part of the relay.

CPK: 962H: 950K: 972H:

C551-UP N4A1-UP R4A1-UP GTA1-UP Solenoid: A solenoid is an electrical component that is activated by electricity. It has a

SSA1-UP FER1-UP WLA1-UP coil that makes an electromagnet when current flows through it. The electromagnet

950GC: M3G1-UP J5M1-UP LCC1-UP can open or close a valve or move a piece of metal that can do work.

M5K1-UP J6J1-UP A7D1-UP

M5T1-UP K6K1-UP NPE1-UP Magnetic Latch Solenoid: A magnetic latch solenoid is an electrical component that is

activated by electricity and held latched by a permanent magnet. It has two coils (latch and unlatch)

MAL1-UP 962K: A7G1-UP that make electromagnet when current flows through them. It also has an internal switch that places

L5S1-UP T6A1-UP A7J1-UP the latch coil circuit open at the time the coil latches.

950H: PCW1-UP FLL1-UP WXZ1-UP

N1A1-UP X4T1-UP Harness and Wire Symbols

M1G1-UP Wire, Cable, or Harness Harness Identification Letter(s):

J5J1-UP 966H: 972K: Assembly Identification: Includes (A, B, C, ..., AA, AB, AC, ...)

A6D1-UP 966K: PEM1-UP Harness Identification Letters and

K5K1-UP Harness Connector Serialization Code:

Harness Connector Serialization

MXL1-UP RYF1-UP PBG1-UP Z4W1-UP The "C" stands for "Connector" and the

Codes (see sample).

number indicates which connector in the

JLX1-UP A6J1-UP TFS1-UP AG-C4 L-C12 harness (C1, C2, C3, ...).

TAL1-UP NGX1-UP L-C12

111-7898 3E-5179 3E-5179

CYR1-UP 980H: Part Number: for Connector Plug 1

FMW1-UP MHG1-UP Part Number: for Connector Receptacle

BJ61-UP 980K: A8J1-UP 2

5A

BS61-UP W7K1-UP JMS1-UP

Plug Receptacle Component

NEP1-UP PF81-UP Pin or Socket Number Fuse (5 Amps) 9X-1123 Part Number

KZL1-UP Deutsch connector: Typical representation

1 325-AG135 PK-14

P8B1-UP of a Deutsch connector. The plug contains all

Harness identification code:

2 sockets and the receptacle contains all pins. Wire Gauge*

This example indicates wire group 325,

wire 135 in harness "AG". Wire Color

1 Sure-Seal connector: Typical representation

of a Sure-Seal connector. The plug and receptacle *Wire gauge is shown in AWG (American Wire Gauge)

PUBLICATIONS.CAT.COM 2 contain both pins and sockets. but could also be shown in metric denoted with mm

© 2021 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the

“Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not

be used without permission.

(Dimensions: 34 inches x 24 inches)

M0091383-03

16 Page,

CAN A DATA LINK HARNES

572-2124

CIRCUIT DESCRIPTION TABLE

Model: 5403761 UPDATES.DGM

J-C1

J-C1 CIRCUIT # DESCRIPTION

3E-3370

3E-3370

CONNECT A-C22 TO EXISTING 14 POSN SERVICE 1641-A181 GN 4672859 101 UNSWITCHED BATTERY (+)

A F711-J1 YL-18 A

14 TO 9 POSITION SERVICE PORT ADAPTER PORT OR TO 14 TO 9 POSN ADAPTER 1640-A182 WH/GN 4672859 C-C6 A105 +8V SENSOR SUPPLY

B F712-J2 GN-18 B

REQUIRED FOR MACHINES M5K1-UP 1639-A180 OR 4672859 1552273

R-C2 R-C1 A-C22 C C 200 MAIN CHASSIS

1638-A179 WH/OR 4672859 101-C014 RD-18-GXL 1

8T8735 4518019 4518020 C2 5 5 USB DEVICE GND

N961-C015 OR-18-TXL 2

A 101-R10 RD-18-GXL 200-R11 BK-18-GXL A A 200-A110 BK-18-GXL N958-C017 PK-18-TXL 3 RS232 TO PRINTER C260 USB DEVICE SHLD

B 200-R11 BK-18-GXL 101-R10 RD-18-GXL B B 101-A75 RD-18-GXL 1641-A181 GN 4672859 4 E271 300mA SINK 3 (HORN RELAY)

C F711-R15 YL-18-GXL C C F711-A44 YL-18-GXL 1640-A182 WH/GN 4672859

CONNECTS TO EXSISTING 200-C016 BK-18-GXL 5

E272 300mA SINK 2

D 944-R12 OR-18-GXL F712-R14 GN-18-GXL D D F712-A45 GN-18-GXL 1639-A180 OR 4672859

MACHINE SERVICE 6

E 945-R13 BR-18-GXL E E 1638-A179 WH/OR 4672859 E273 300mA SINK 1

CONNECTOR

F F712-R14 GN-18-GXL A749-R16 WH-18-GXL F F A749-A311 WH-18-GXL 308 / 390 KEY SWITCH INPUT

G F711-R15 YL-18-GXL A750-R17 PK-18-GXL G G A750-A305 PK-18-GXL A-C10

1907612 F527 USB DEVICE VBUS

H A750-R17 PK-18-GXL 944-R12 OR-18-GXL H H 944-A221 OR-18-TXL

J A749-R16 WH-18-GXL 945-R13 BR-18-GXL J J 945-A222 BR-18-GXL 1 C-C7 F528 USB DEVICE D+

K K CBL-A3 2 1552267 F529 USB DEVICE D-

L L 1641-A181 GN 4672859 3 F711-019 YL-18-GXL A

A749 ATA DATA LINK 1 (+)

M M 1640-A182 WH/GN 4672859 CBL-A2 4 F712-C021 GN-18-GXL B CAN “A”

N N 1639-A180 OR 4672859 1634-A175 WH/OR 4672859 5 C A750 ATA DATA LINK 1 (-)

P P 1638-A179 WH/OR 4672859 1635-A176 OR 4672859 6 ETHERNET 1 F711 PRIM. J1939 DATALINK +

1636-A178 WH/GN 4672859 7 PRODUCT LINK

F712 PRIM. J1939 DATALINK -

1637-A177 GN 4672859 8

9 944 CAT DATA LINK 1 (+)

A-C32 10 945 CAT DATA LINK 1 (-)

1552267 11

M906 PWM 1 (ROD END PRESSURE)

A F711-A257 YL-18-GXL 12

M907 PWM 2 (HEAD END PRESSURE)

CAN A JUMPER 1 B F712-A258 GN-18-GXL

A-C6 C-C3 101-C09 RD-18-TXL M908 PWM 3 (LIFT POS)

C C-C1

1552273 3E3382 101-C014 RD-18-GXL

CBL-A4 CBL-C3 4832762 M909 PWM 4 (TILT POS)

1642-A183 WH/OR 4672859 1 1 1642-C05 WH/OR 4672859 200-C10 BK-18-TXL

A-C33 200-C016 BK-18-GXL 1 N958 RS232 RECEIVE 2 (PRINTER)

1643-A184 OR 4672859 2 2 1643-C06 OR 4672859 2

1552267 3 ETHERNET 3 DISPLAY 3 308-C11 YL-18-TXL N961 RS232 TRANSMIT 2 (PRINTER)

3

A F711-A254 YL-18-GXL 4 4

4 U921 SW TO GND 1

CAN A JUMPER 2 B F712-A253 GN-18-GXL 1645-A185 GN 4672859 5 5 1645-C07 GN 4672859 U922 SW TO GND 2

308-C11 YL-18-TXL 5

C 1644-A186 WH/GN 4672859 6 6 1644-C08 WH/GN 4672859 N961-C015 OR-18-TXL 1643-C06 OR 4672859 6 U924 SW TO GND 4 (STORE SWITCH)

N958-C017 PK-18-TXL 1642-C05 WH/OR 4672859 7

A-C9 X998 DIGITAL SENSOR RETURN

1645-C07 GN 4672859 8

CBL-A1 3447617 Y959 SEC J1939 DATALINK +

1644-C08 WH/GN 4672859 9

F527-A166 RD 3447617 1

10

F529-A162 WH 3447617 2

CBL-C3 Y960 SEC J1939 DATALINK -

11

F528-A163 GN 3447617 3 USB - NOT USED 1634 ETHERNET 1 (PRODUCT LINK)

12

C255-A165 BK 3447617 4

13 1635 ETHERNET 1 (PRODUCT LINK)

C260-A164 SH 3447617 5 F711-C020 YL-18-GXL F711-C12 YL-18-TXL

F711-019 YL-18-GXL 14 1636 ETHERNET 1 (PRODUCT LINK)

C-C4 15

A-C25 1637 ETHERNET 1 (PRODUCT LINK)

1552273 16

3E3382 F712-C022 GN-18-GXL F712-C021 GN-18-GXL 1638 ETHERNET 2 (EXISTING SERVICE PORT)

17

CAN A TERM RES 1 A-C29 101-A168 RD-18-GXL 1 1 101-C09 RD-18-TXL F712-C13 GN-18-TXL

134-2540 1552267 18 1639 ETHERNET 2 (EXISTING SERVICE PORT)

200-A167 BK-18-GXL 2 2 200-C10 BK-18-TXL 19

A F711-A309 YL-18-GXL 390-A169 YL-18-GXL 3 DISPLAY 3 308-C11 YL-18-TXL 1640 ETHERNET 2 (EXISTING SERVICE PORT)

20

B F712-A308 GN-18-GXL 4 PWR/GND/CAN 4

21 DISPLAY 1641 ETHERNET 2 (EXISTING SERVICE PORT)

C F711-A174 YL-18-GXL 5 5 F711-C020 YL-18-GXL 22 1642 ETHERNET 3 (DISPLAY)

F712-A172 GN-18-GXL 6 6 F712-C022 GN-18-GXL 1642-C05 WH/OR 4672859

23 1643 ETHERNET 3 (DISPLAY)

CAN B TERM RES 1 A-C8 1643-C06 OR 4672859

24

134-2540 1552267 A-C12 1645-C07 GN 4672859 1644 ETHERNET 3 (DISPLAY)

25

A Y959-A64 YL-18-GXL 4518019 1644-C08 WH/GN 4672859 26 1645 ETHERNET 3 (DISPLAY)

B Y960-A56 GN-18-GXL 200-A110 BK-18-GXL A

27 1654 ETHERNET 4 (NEW SERVICE PORT)

C 101-A75 RD-18-GXL B

28

F711-A255 YL-18-GXL C 1655 ETHERNET 4 (NEW SERVICE PORT)

29

F712-A252 GN-18-GXL D

30 1656 ETHERNET 4 (NEW SERVICE PORT)

SQUARE A-C2 E

4832761 31 1657 ETHERNET 4 (NEW SERVICE PORT)

494-6473 A749-A311 WH-18-GXL F

32

RS232 DTR 2 1 A750-A305 PK-18-GXL G SERVICE PORT 1808 BROADR REACH 3

33

2 944-A155 OR-18-GXL H (CAN A) 34

1809 BROADR REACH 3

RS232 GND 2 3 945-A158 BR-18-GXL J

35 1810 BROADR REACH 2

RS232 RXD 2 4 CBL-A7 K

101-A01 RD-18-GXL 101-C09 RD-18-TXL 36 1811 BROADR REACH 2

RS232 TXD 2 5 101-A168 RD-18-GXL 1657-A187 GN 4672859 L

200-C10 BK-18-TXL 37

6 200-A142 BK-18-GXL 1656-A188 WH/GN 4672859 M

38

7 200-A167 BK-18-GXL 1655-A189 OR 4672859 N

39

8 390-A169 YL-18-GXL 1654-A190 WH/OR 4672859 P

40

9 944-A155 OR-18-GXL

F711-C12 YL-18-TXL 41

10 945-A158 BR-18-GXL

A-C19 F712-C13 GN-18-TXL 42

11 F711-A174 YL-18-GXL 43

12 F712-A172 GN-18-GXL 4900571

CBL-A5 44

13 F712-A252 GN-18-GXL 1808-A191 WH/BU 4896290 1 BROADR REACH 3

14 F711-A255 YL-18-GXL 1809-A192 BU 4896290 2

15

16 A-C20

17 4900571

CBL-A6

BROADR-REACH 6- 18

101-A01 RD-18-GXL 1810-A193 WH/BU 4896290 1 BROADR REACH 2

BROADR-REACH 6+ 19 101-A168 RD-18-GXL 1811-A194 BU 4896290 2

BROADR-REACH 4+ 20 200-A142 BK-18-GXL

BROADR-REACH 4- 21 200-A167 BK-18-GXL A-C5 C-C5

22 3E3376 1552272

390-A169 YL-18-GXL

23 944-A155 OR-18-GXL 101-A01 RD-18-GXL 1 1 101-C014 RD-18-GXL

24 945-A158 BR-18-GXL N961-A140 OR-18-TXL 2 RS232-2 PRINTER OUT 2 N961-C015 OR-18-TXL

25 F711-A174 YL-18-GXL N958-A141 PK-18-TXL 3 3 N958-C017 PK-18-TXL

26 F712-A172 GN-18-GXL 200-A142 BK-18-GXL 4 4 200-C016 BK-18-GXL

27 F712-A252 GN-18-GXL

28 F711-A255 YL-18-GXL

29

30 101-A74 RD-18-GXL

31 101-A01 RD-18-GXL 101-A77 RD-18-GXL

32 101-A73 RD-18-TXL 101-A218 RD-18-GXL

33 101-A168 RD-18-GXL 101-A219 RD-18-GXL AVAILABLE POSTIONS ON BULKHEAD CONNECTORS

BROADR-REACH 2+ 34 1810-A193 WH/BU 4896290

BROADR-REACH 2- 35 1811-A194 BU 4896290

(SEE M0091381 / M0092357 / M0092359 “PROCEDURE TO INSTALL CAT PAYLOAD KIT ON CERTAIN SERIES MEDIUM WHEEL LOADERS”)

10/100 BASE-T(TXD) +2 36 1638-A179 WH/OR 4672859 200-A105 BK-18-TXL 200-A112 BK-18-GXL

10/100 BASE-T(TXD) -2 37 1639-A180 OR 4672859 200-A142 BK-18-GXL CONNECTIONS THROUGH THE

10/100 BASE-T(RXD) +2 38 1640-A182 WH/GN 4672859 200-A167 BK-18-GXL BULKHEAD CONNECTORS

10/100 BASE-T(RXD) -2 39 1641-A181 GN 4672859 200-A146 BK-14-GXL

40 200-A145 BK-18-GXL

A-C14

10/100 BASE-T(TXD) +3 41 1642-A183 WH/OR 4672859 200-A204 BK-18-GXL

2305010 4 FABRICATED “CHASSIS SENSORS”

10/100 BASE-T(TXD) -3 42 1643-A184 OR 4672859 200-A210 BK-18-GXL

HARNESS

10/100 BASE-T(RXD) +3 43 1644-A186 WH/GN 4672859 200-A211 BK-18-GXL 101-A77 RD-18-GXL 1

TILT POS

10/100 BASE-T(RXD) -3 44 1645-A185 GN 4672859 200-A112 BK-18-GXL 2

1552260 3E3370 PWM 1 / 266-2337

A105-A250 OR-18-GXL 3 J1939 SNSR - NOT USED TO A-C18 PIN 1 LOC B-4 OR-14 A OR-18 +8V

390-A68 YL-18-TXL 390-A72 YL-18-GXL X998-A251 BR-18-GXL 4

TO A-C18 PIN 5 LOC B-4 GN-14 B BK-18 GND

390-A169 YL-18-GXL Y959-A60 YL-18-GXL 5

TRIANGLE A-C3 TO T-2 WH-14 C WH-18 SIG

Y960-A50 GN-18-GXL 6

494-6473 4832762

10/100 BASE-T(TXD) +1 1 1634-A175 WH/OR 4672859 944-A220 OR-18-TXL

10/100 BASE-T(TXD) -1 2 1635-A176 OR 4672859 944-A155 OR-18-GXL

10/100 BASE-T(RXD) +1 3 1637-A177 GN 4672859 944-A221 OR-18-TXL LIFT POS

10/100 BASE-T(RXD) -1 4 1636-A178 WH/GN 4672859 1552260 3E3370 PWM 2 / 266-2337

RS232 RXD 1 5 N958-A141 PK-18-TXL 945-A223 BR-18-TXL

A-C30 X-C1 M909-X201 GN-18-GXL T-1 TO A-C18 PIN 2 LOC B-4 OR-14 A OR-18 +8V

RS232 TXD 1 6 N961-A140 OR-18-TXL 945-A158 BR-18-GXL

3E5179 1552252 TO A-C18 PIN 6 LOC B-4 GN-14 B BK-18 GND

RS232 GND 1 7 945-A222 BR-18-GXL TILT POS (PWM 1) WH-18

M909-X129 GN-18-GXL TO T-4 WH-14 C SIG

RS232 DCD 1 8 390-A72 YL-18-GXL 1 1 390-X72 YL-18-GXL SNSR IN

RS232 DTR 1 9 A105-A125 OR-18-GXL 101-A74 RD-18-GXL 2 2 101-X74 RD-18-GXL

10 A105-A126 OR-18-GXL A105-A205 OR-18-GXL 3 3 A105-X11 OR-18-GXL M909-X195 GN-18-GXL T-2

11 A105-A127 OR-18-GXL U924-A144 BK-20-TXL 4 4 U924-X144 BK-18-GXL

RS485 SHLD 12 A105-A128 OR-18-GXL M906-A132 BU-20-TXL 5 5 M906-X132 BU-18-GXL

HEAD END PRESS

13

14

A105-A205 OR-18-GXL

A105-A250 OR-18-GXL

M907-A131 GY-20-TXL

M908-A130 YL-20-TXL

6

7

CONNECT TO COMPLETER HARNESS (X) COMPLETER HARNESS

CONNECT TO A-C30

6

7

M907-X131 GY-18-GXL

M908-X130 YL-18-GXL M908-X196 YL-18-GXL T-3 237-0227 PWM 3 / 349-1178 WIRE GROUP COLOR DESCRIPTIONS

TO A-C18 PIN 3 LOC B-4 OR-14 1 +8V

RS485 TXB + 15 M909-A129 GN-20-TXL 8 8 M909-X129 GN-18-GXL LIFT POS (PWM 2) GROUND CIRCUIT

M908-X130 YL-18-GXL TO A-C18 PIN 7 LOC B-4 GN-14 2 GND

RS485 TXA - 16 E271-A202 BU-18-TXL 200-A204 BK-18-GXL 9 9 200-X75 BK-18-GXL SNSR IN TO T-6 WH-14 3 SIG

WIRES THAT HAVE SYSTEM VOLTAGE WHEN THE KEY SWITCH IS OFF

17 E272-A216 RD-18-TXL X998-A203 BR-18-GXL 10 10 X998-X14 BR-18-GXL

BROADR-REACH 5- 18 E273-A217 RD-18-TXL 200-A145 BK-18-GXL 11 11 200-X145 BK-18-GXL M908-X197 YL-18-GXL T-4

WIRES THAT HAVE SYSTEM VOLTAGE WHEN THE KEY SWITCH IS ON

BROADR-REACH 5+ 19 E271-A202 BU-18-TXL 12 12

20 F711-A44 YL-18-GXL CAT DATA LINK

RS485 RXB + 21 F711-A257 YL-18-GXL CAN DATA LINK

M907-X198 GY-18-GXL T-5 ROD END PRESS

RS485 RXA - 22 F711-A255 YL-18-GXL 237-0227 PWM 4 / 349-1178 RS-232 / RS-485 DATA LINK

HEAD END PRESS (PWM 3)

(Dimensions: 34 inches x 24 inches)

23

REMOVE SOCKET PINS FROM CONNECTOR A-C18 OR K-C1 M907-X131 GY-18-GXL TO A-C18 PIN 4 LOC B-4 OR-14 1 +8V

24 F711-A254 YL-18-GXL SNSR IN CAN DATA LINK B

AND PLUG INTO THE CAB BULKHEAD CONNECTOR TO A-C18 PIN 8 LOC B-4 GN-14 2 GND

25 F711-A34 YL-18-TXL

FOR POWER AND GROUND TO 4 CHASSIS SENSORS M907-X199 GY-18-GXL T-6 TO T-8 WH-14 3 SIG ETHERNET

TILT POS SIGNAL 26 M909-A129 GN-20-TXL F711-A259 YL-18-GXL

LOCATED AT LOC B-2

LIFT POS SIGNAL 27 M908-A130 YL-20-TXL

HEAD END PRESS SIG 28 M907-A131 GY-20-TXL F711-A259 YL-18-GXL 8V +/- COMPLETER OTHER COLOR DESCRIPTIONS

ROD END PRESS SIG 29 M906-A132 BU-20-TXL F711-A174 YL-18-GXL

K-C2 K-C1 M906-X200 BU-18-GXL T-7

30 F711-A309 YL-18-GXL A-C18

3E3388 1552264 HIGHWAYS

USB D- 31 F529-A162 3447617 1552264

ROD END PRESS (PWM 4)

USB D+ 32 F528-A163 3447617 A105-A125 OR-18-GXL 1 1 A105-K1 OR-18-GXL 1 M906-X132 BU-18-GXL

SNSR IN

2 A105-K2 OR-18-GXL 2

M0091383-03

33 F712-A45 GN-18-GXL A105-A126 OR-18-GXL 2

BROADR-REACH 1+ 34 F712-A258 GN-18-GXL A105-A127 OR-18-GXL 3 SNSR 8V +/- 3 A105-K3 OR-18-GXL 3 M906-X310 BU-18-GXL T-8

BROADR-REACH 1- 35 F712-A252 GN-18-GXL A105-A128 OR-18-GXL 4 CONNECT TO 4 A105-K4 OR-18-GXL 4

X998-A117 BR-18-GXL COMPLETER HARNESS (K) 5 X998-K5 BR-18-GXL 5

10/100 BASE-T(TXD) +5 36 5

6 X998-K6 BR-18-GXL 6

CALLOUT FORMAT IF APPLICABLE

10/100 BASE-T(TXD) -5 37 F712-A253 GN-18-GXL X998-A118 BR-18-GXL 6

MACHINE ECM POWER / GROUND SPLICES

10/100 BASE-T(RXD) +5 38 F712-A35 GN-18-TXL X998-A119 BR-18-GXL 7 7 X998-K7 BR-18-GXL 7

8 X998-K8 BR-18-GXL 8 Callout Number Component

10/100 BASE-T(RXD) -5 39 F712-A260 GN-18-GXL X998-A120 BR-18-GXL 8

NOTE: A

(Machine Location from (52) VALVE GP - CONTROL Name

40 Component Locations Table)

USB SHLD 41 C260-A164 SH 3447617 F712-A260 GN-18-GXL

390-X214 YL-18-GXL T-13 FROM J1 PIN 1 OF MACHINE ECM 138-1234 Part Number

USB VBUS 42 F527-A166 RD 3447617 F712-A172 GN-18-GXL

390-X72 YL-18-GXL KEY SWITCH IN

USB GND 43 C255-A165 BK 3447617 F712-A308 GN-18-GXL

USB GND 44 SYMBOL DESCRIPTION ABBREV COLOR

390-X215 YL-18-GXL T-14 (TO J1 PIN 1 ON MACHINE ECM)

M906-A132 BU-20-TXL CIRCUIT CONNECTED RD RED

M907-A131 GY-20-TXL A-C31 WIRE AS - SPLICE FOR M5T1-UP ONLY / 199-9785

CIRCLE A-C4 2370163 L NOTE: A WH WHITE

M908-A130 YL-20-TXL NOTE: USED WHEN ONLY 3 SPACES AVAILABLE FOR SENSOR POWER CIRCUIT NOT CONNECTED

494-6473 4832763 101-X210 RD-18-GXL T-9 FROM J1 PIN 47 OF MACHINE ECM

M909-A129 GN-20-TXL 101-A219 RD-18-GXL 1

AT CONNECTOR A-C18 OR ORANGE

CAN B (-) 1 Y960-A54 GN-18-TXL U921-A206 BK-20-TXL 101-A218 RD-18-GXL 2 TO A-C18 ELECTRICAL CONNECTION TO

102-8802 155-2270 101-X74 RD-18-GXL POWER IN MACHINE STRUCTURE

CAN B (+) 2 Y959-A59 YL-18-TXL U922-A207 BK-20-TXL U921-A206 BK-20-TXL 3 PIN 3 LOC B-4 YL-18 YL YELLOW

CAN B SH 3 U924-A144 BK-20-TXL U922-A207 BK-20-TXL 4 I/O EXPANSION YL-18 1

INTERNAL ELECTRICAL CONNECTION

+8V SENSOR POWER 101-X211 RD-18-GXL T-10 (TO J1 PIN 47 ON MACHINE ECM)

CAN A (-) 4 F712-A35 GN-18-TXL 200-A211 BK-18-GXL 5 (FUTURE USE) YL-18 2

TO SURFACE OF COMPONENT PK PINK

CAN A (+) 5 F711-A34 YL-18-TXL 200-A210 BK-18-GXL 6 CONNECTORS FIELD INSTALLED

CAN A SH 6 X998-A117 BR-18-GXL E272-A216 RD-18-TXL 7 CONNECTOR BK BLACK

KEY SW 7 390-A68 YL-18-TXL X998-A118 BR-18-GXL E273-A217 RD-18-TXL 8 NOTE: A

A105-X13 OR-18-GXL T-17 FROM J1 PIN 44 OF MACHINE ECM

CDL - 8 945-A223 BR-18-TXL X998-A119 BR-18-GXL H# GY GRAY

CIRCUIT GROUPING DESIGNATION

CDL + 9 944-A220 OR-18-TXL X998-A120 BR-18-GXL

A105-X11 OR-18-GXL SENSOR POWER PU PURPLE

10 X998-A203 BR-18-GXL

11 X998-A251 BR-18-GXL ATCH WIRE, CABLE, COMPONENT

A105-X12 OR-18-GXL T-18 (TO J1 PIN 44 ON MACHINE ECM) BR BROWN

12

13 SPLICE

14 Y959-A59 YL-18-TXL Y959-A60 YL-18-GXL GN GREEN

15 Y959-A64 YL-18-GXL NOTE: A BLADE, SPADE, RING OR SCREW

X998-X15 BR-18-GXL T-19 FROM J1 PIN 45 OF MACHINE ECM TERMINAL BU BLUE

STB WAKE-UP 16

RS232 RXD 3 17 Y960-A54 GN-18-TXL Y960-A50 GN-18-GXL

X998-X14 BR-18-GXL SENSOR RETURN

RS232 TXD 3 18 Y960-A56 GN-18-GXL

RS232 GND 3 19 X998-X16 BR-18-GXL T-20 (TO J1 PIN 45 ON MACHINE ECM)

BROADR-REACH 3- 20 1809-A192 4896290

NOTE: A

1808-A191 4896290

HARNESS ASSEMBLIES

BROADR-REACH 3+ 21

22

SEALED

SPLICE

SW TO GND 3 23 NOTE: A

200-X212 BK-18-GXL T-11 115-8109

FROM J1 PIN 57 OF MACHINE ECM Do not operate or work on this product unless you have

SW TO GND 2 24 U922-A207 BK-20-TXL

IDENT PART NO CHG DESCRIPTION

16 Page,

SW TO GND 1 25 U921-A206 BK-20-TXL read and understood the instruction and warnings in the

26 200-X145 BK-18-GXL GROUND IN

relevant Operation and Maintenance Manuals and

27

28 A 540-3761 03 CORE CPK 200-X213 BK-18-GXL T-12 (TO J1 PIN 57 OF MACHINE ECM) relevant service literature. Failure to follow the instruc-

300 mA SINK 3 29 E271-A202 BU-18-TXL tions or heed the warnings could result in injury or

300 mA SINK 2

300 mA SINK 1

30

31

E272-A216 RD-18-TXL

E273-A217 RD-18-TXL X 572-0935 00 CORE COMPLETER death. Proper care is your responsibility.

32

SW TO GND 4

33

34 U924-A144 BK-20-TXL R 572-0936 00 14-9 SERVICE ADAPTER X-C11

3E3370

STORE SWITCH

263-1493

SW TO GND WAKE-UP 35

K 572-0937 00 POWER COMPLETER A WH

+ BTRY 36 101-A73 RD-18-TXL

U924-X144 BK-18-GXL B BR

- BTRY 37 200-A105 BK-18-TXL

200-X75 BK-18-GXL C BK

38

10/100 BASE-T(TXD) +4

10/100 BASE-T(TXD) -4

39

40

1654-A190 WH/OR 4672859

1655-A189 OR 4672859

C 549-7831 02 DISPLAY

10/100 BASE-T(RXD) +4 41 1656-A188 WH/GN 4672859

10/100 BASE-T(RXD) -4 42 1657-A187 GN 4672859

43

R-TERM/STB 44

THIS SCHEMATIC IS FOR THE CAT PAYLOAD KIT ELECTRICAL SYSTEM

MEDIA NUMBER: M0091383-03

SCHEMATIC PART NUMBER: 573-1863, CHANGE: 00, VERSION: -

Components are shown installed on a fully operable machine with the key and engine off, transmission shifter

in neutral and with parking brake set.

Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations.

Refer to the Parts Manual using a specific serial number prefix in SIS before ordering parts from this schematic.

You might also like

- Bomag BF 800 CDocument41 pagesBomag BF 800 Cdouahchia rachedNo ratings yet

- White 1477/1488/1499 Sewing Machine Instruction ManualDocument34 pagesWhite 1477/1488/1499 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- 4.07 Deswik - Ugdb For Underground MetalsDocument1 page4.07 Deswik - Ugdb For Underground MetalsDIEGO SANTIAGONo ratings yet

- ZL402C VOLVO Power Transmission SIS Online Parts CatalogDocument33 pagesZL402C VOLVO Power Transmission SIS Online Parts CatalogRtigo IdNo ratings yet

- TE254 Operation ManualDocument62 pagesTE254 Operation ManualShadow BoyNo ratings yet

- Carlisle Twin QuickFill Boosted Master Cylinder DataSheetDocument8 pagesCarlisle Twin QuickFill Boosted Master Cylinder DataSheetshaken56No ratings yet

- Avp08pt AP240HCT2 080919 CZ enDocument172 pagesAvp08pt AP240HCT2 080919 CZ envolrog.aNo ratings yet

- V2607-DI-T-E3B: Kubota 07 SeriesDocument2 pagesV2607-DI-T-E3B: Kubota 07 SeriesRodrigoThuLokithoPkmz0% (1)

- 98-05110 r1 FP Rogator 854 InstallDocument18 pages98-05110 r1 FP Rogator 854 InstallJulio CRNo ratings yet

- Torque Spec MetricDocument6 pagesTorque Spec MetricLukman 92No ratings yet

- MC 100 Cargador de ExplosivosDocument8 pagesMC 100 Cargador de ExplosivosWiwa Hernandez Donoso100% (1)

- Manual Partes Trascabo 966G (Parte 2)Document577 pagesManual Partes Trascabo 966G (Parte 2)David NahNo ratings yet

- GenspaDocument373 pagesGenspaJulian Andres Zancajo100% (1)

- 6042 Skytrack Transmission Service ManualDocument118 pages6042 Skytrack Transmission Service Manuallandon.palmerNo ratings yet

- Capacities (Refill) : Shutdown SIS Previous ScreenDocument4 pagesCapacities (Refill) : Shutdown SIS Previous ScreenSain MezaNo ratings yet

- D250E II/D300E II Articulated Truck Operator StationDocument1 pageD250E II/D300E II Articulated Truck Operator StationJulio EspinozaNo ratings yet

- Austoft 9000 Series en (A21)Document13 pagesAustoft 9000 Series en (A21)dgarciaNo ratings yet

- Repuestos h65Document4 pagesRepuestos h65Guido Emanuel SteinbachNo ratings yet

- Assenbly EW145BDocument20 pagesAssenbly EW145Bសុខ ប៊ុនណារ៉ង់No ratings yet

- Ausa Mixers 500RX-X1100RH-ENG PDFDocument2 pagesAusa Mixers 500RX-X1100RH-ENG PDFAsad AijazNo ratings yet

- TH407 Parts PDFDocument2 pagesTH407 Parts PDFEric Tweneboah KoduaNo ratings yet

- Tractor 5090 Freno ParqueoDocument6 pagesTractor 5090 Freno ParqueotallerNo ratings yet

- Parts Manual: MODEL: 4215HTDocument586 pagesParts Manual: MODEL: 4215HTMessi EmetievNo ratings yet

- Group 3 Swing Device: 1. StructureDocument10 pagesGroup 3 Swing Device: 1. StructureАлександр ПанкратовNo ratings yet

- Engine Model Alternator Model LL5014F Engine Build: 1306A-E87TAG4 WSDocument2 pagesEngine Model Alternator Model LL5014F Engine Build: 1306A-E87TAG4 WSGuido Emanuel SteinbachNo ratings yet

- LG933LDocument2 pagesLG933LАмурдеталь БлаговещенскNo ratings yet

- SATCO420 Parts Section-June2011Document28 pagesSATCO420 Parts Section-June2011Luis Alejandro Faris BurgosNo ratings yet

- Catalogue: Professional Power Solution For Greater Value!Document241 pagesCatalogue: Professional Power Solution For Greater Value!aldy yasiNo ratings yet

- Patg Pamg Turbo PartsDocument12 pagesPatg Pamg Turbo Parts1luckywolf0% (1)

- Case 845B - Fluids SpecificationDocument2 pagesCase 845B - Fluids SpecificationKristomiDerMarine-IngenieurNo ratings yet

- Anti-Lock Braking System: 1989-1992 Thunderbird SC ABS Systems by Duffy Floyd BackgroundDocument14 pagesAnti-Lock Braking System: 1989-1992 Thunderbird SC ABS Systems by Duffy Floyd BackgroundkousatoufikNo ratings yet

- Esquema Hidraulico 236D Cat MinicargadoraDocument2 pagesEsquema Hidraulico 236D Cat MinicargadoraBerto Rodriguez Chambi100% (1)

- Teejet 844 E Controller ManualDocument40 pagesTeejet 844 E Controller ManualВадим ПетровичNo ratings yet

- Brochure Dasa5Document16 pagesBrochure Dasa5tystar_21100% (2)

- A35DDocument6 pagesA35Dmouloud186No ratings yet

- Fuel System, Injectors & Fuel LinesDocument2 pagesFuel System, Injectors & Fuel LinesMartin Delgado Rivera100% (1)

- Massey Ferguson 6465 TRACTOR (TIER 3 Sisu Engine) Service Parts Catalogue Manual (Part Number 3906308)Document19 pagesMassey Ferguson 6465 TRACTOR (TIER 3 Sisu Engine) Service Parts Catalogue Manual (Part Number 3906308)bvk2980022100% (1)

- 819901M9 1441 Massey Ferguson MF 4225 4235 4240 Parts Catalog K37008Document1,441 pages819901M9 1441 Massey Ferguson MF 4225 4235 4240 Parts Catalog K37008Phil ThomsenNo ratings yet

- BA Sauer 90R100 H1 enDocument60 pagesBA Sauer 90R100 H1 enTecnico Carretillas Bi BatNo ratings yet

- Training Final Drives - 7 (A)Document46 pagesTraining Final Drives - 7 (A)DraganNo ratings yet

- Sb-2500D Specifications: Engine: Fume Extraction SystemDocument2 pagesSb-2500D Specifications: Engine: Fume Extraction SystemMariano David Pons Merino100% (1)

- Peças 210GDocument1,100 pagesPeças 210GFlávio da silva carvalhoNo ratings yet

- Amss 2000-215Document65 pagesAmss 2000-215Izeddin Hussein IbrahimNo ratings yet

- Toro 006Document2 pagesToro 006Eric CNo ratings yet

- 330 Fmi Boom Angle 2425 Fmi 9Document13 pages330 Fmi Boom Angle 2425 Fmi 9liva rakotondrasoaNo ratings yet

- CB-B2,5 PompaDocument2 pagesCB-B2,5 PompaÖzgür BiliciNo ratings yet

- 003 - 1150K-1650L HydraulicsDocument38 pages003 - 1150K-1650L HydraulicsCarlos PinedaNo ratings yet

- Specializzati 06430730 V01 GBDocument20 pagesSpecializzati 06430730 V01 GBionvasile2010No ratings yet

- Screed Control Gas-Conventional: Cover Sheet 4812006514 /DDocument27 pagesScreed Control Gas-Conventional: Cover Sheet 4812006514 /Dlisandro fankhauserNo ratings yet

- TIER 3 Technical Concept: Training Center Compact Engines, CologneDocument52 pagesTIER 3 Technical Concept: Training Center Compact Engines, CologneИван КумбровNo ratings yet

- 510B Backhoe Loader: Engine PerformanceDocument5 pages510B Backhoe Loader: Engine Performancebalajimettur100% (1)

- BrakeDrum Cross Reference Chart 050115Document2 pagesBrakeDrum Cross Reference Chart 050115Alejandro Quiñonez100% (1)

- KX101 PartsDocument299 pagesKX101 Partsgarethgriffiths1984No ratings yet

- JCB Wheel Loader 456 ZX: Fast FactsDocument8 pagesJCB Wheel Loader 456 ZX: Fast FactsСергій БоженкоNo ratings yet

- Axle, Rear - Hub, Planetary - Prior To P.I.N. N8F203816Document2 pagesAxle, Rear - Hub, Planetary - Prior To P.I.N. N8F203816AlejandroNo ratings yet

- Volvo f86 Spec Sheet Collection AbbyDocument18 pagesVolvo f86 Spec Sheet Collection AbbyaxelNo ratings yet

- Mo SC-36 - enDocument76 pagesMo SC-36 - enMoloide GamerNo ratings yet

- Catalogo Faro PDFDocument26 pagesCatalogo Faro PDFFILTROSNo ratings yet

- 320C TDocument24 pages320C Tปูหลน ไซไซ100% (1)

- DocumentoDocument2 pagesDocumentoAlvaro FloresNo ratings yet

- Cat 314 C ElectricoDocument2 pagesCat 314 C Electricogalvis102075% (4)

- Cab Right Side View Cab Rops View: Electrical System 324E and 329E Excavator 329E MHPUDocument8 pagesCab Right Side View Cab Rops View: Electrical System 324E and 329E Excavator 329E MHPUEddie Kelvin Isidro LauraNo ratings yet

- c15 CaterpillarDocument20 pagesc15 CaterpillarEddie Kelvin Isidro Laura75% (4)

- STTH8R06-Y: Automotive Turbo 2 Ultrafast High Voltage RectifierDocument9 pagesSTTH8R06-Y: Automotive Turbo 2 Ultrafast High Voltage RectifierEddie Kelvin Isidro LauraNo ratings yet

- 500 Ma Low-Noise LDO Regulator: Features General DescriptionDocument31 pages500 Ma Low-Noise LDO Regulator: Features General DescriptionEddie Kelvin Isidro LauraNo ratings yet

- LWD DatasheetDocument1 pageLWD DatasheetAditia FebriansyaNo ratings yet

- Teaching Aids in MathematicsDocument13 pagesTeaching Aids in MathematicsRamya PrabakaranNo ratings yet

- Stock Selection For CPR BY KGSDocument1 pageStock Selection For CPR BY KGSvvpvarunNo ratings yet

- Rail Equipment Catalogue IDDocument43 pagesRail Equipment Catalogue IDMilly Rostika PutriNo ratings yet

- Emoticons - Google SearchDocument1 pageEmoticons - Google Searchsorlaa.moonsNo ratings yet

- Management Review Is Presided and Managed byDocument4 pagesManagement Review Is Presided and Managed bymohammedNo ratings yet

- VFD Parameters Programming - SettingDocument2 pagesVFD Parameters Programming - SettingJemerald MagtanongNo ratings yet

- CSP Isc 7 - I0r0Document138 pagesCSP Isc 7 - I0r0Jose danielNo ratings yet

- CB Insights Scouting Reports AI 100 2024Document104 pagesCB Insights Scouting Reports AI 100 2024dellmonteiroNo ratings yet

- P770ZM EsmDocument116 pagesP770ZM EsmRoberto LozanoNo ratings yet

- Spray - Chapter 1 - Basic Principles PIPENETDocument54 pagesSpray - Chapter 1 - Basic Principles PIPENETMilanNo ratings yet

- Shandong Wuzheng Group Co., LTDDocument14 pagesShandong Wuzheng Group Co., LTDchtoil2020No ratings yet

- SAS94 9BF432 70079447 Win WRKSTNDocument3 pagesSAS94 9BF432 70079447 Win WRKSTNTodd MartinNo ratings yet

- Ec6513 Micorprocessor Lab ManualDocument87 pagesEc6513 Micorprocessor Lab ManualVenkata sai Prasad ChevuruNo ratings yet

- China Made The Worlds First Artificial Intelligence-Equipped Judge Gives 97 Percent of The DecisionsDocument1 pageChina Made The Worlds First Artificial Intelligence-Equipped Judge Gives 97 Percent of The Decisionsrajendra kumarNo ratings yet

- Database System ConceptsDocument53 pagesDatabase System ConceptsNavtej BhattNo ratings yet

- Unit 1 Formulation of HypothesisDocument3 pagesUnit 1 Formulation of HypothesisMuhammed Suhail N100% (1)

- Resetting The Keep Alive Memory (KAM) : Idle Air Trim Learning Modes Transmission Range Air Conditioning ModeDocument1 pageResetting The Keep Alive Memory (KAM) : Idle Air Trim Learning Modes Transmission Range Air Conditioning ModeFabio SierraNo ratings yet

- 10 Larochelle QueeringDocument15 pages10 Larochelle QueeringmimarNo ratings yet

- 1 Checklist of Common RequirementsDocument1 page1 Checklist of Common RequirementsBoyong Fajardo100% (1)

- Belzona 1391 T (Flyer)Document2 pagesBelzona 1391 T (Flyer)Bobby SatheesanNo ratings yet

- Applications of Distributed SystemsDocument35 pagesApplications of Distributed SystemsHuzaifa KhanNo ratings yet

- Lecture 3 Desiging Effective Power Point Presentation DR DineshDocument60 pagesLecture 3 Desiging Effective Power Point Presentation DR DineshGuutaa DirbabaaNo ratings yet

- DT Graphics Gcse CourseworkDocument5 pagesDT Graphics Gcse Courseworkzehlobifg100% (2)

- 02b - Product Life Cycle (From P. 36) - 21 SeptDocument40 pages02b - Product Life Cycle (From P. 36) - 21 SeptMinyan ZhuNo ratings yet

- Omotive SystemDocument22 pagesOmotive SystemPooja100% (1)

- Gift Map 022024Document1 pageGift Map 022024Rakesh T KanjniNo ratings yet

- Belete Thesis Document FinalDocument68 pagesBelete Thesis Document FinalabenuzzionNo ratings yet

- Battery Internal Resistance TesterDocument3 pagesBattery Internal Resistance TesterSYEDNo ratings yet