Weld Procedure Specification (WPS) : According To Asme Ix &

Weld Procedure Specification (WPS) : According To Asme Ix &

Uploaded by

Mina Roger SamyCopyright:

Available Formats

Weld Procedure Specification (WPS) : According To Asme Ix &

Weld Procedure Specification (WPS) : According To Asme Ix &

Uploaded by

Mina Roger SamyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Weld Procedure Specification (WPS) : According To Asme Ix &

Weld Procedure Specification (WPS) : According To Asme Ix &

Uploaded by

Mina Roger SamyCopyright:

Available Formats

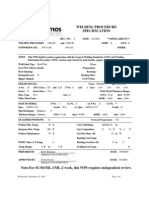

NORTHERN WELD PROCEDURE Date : 18 / 8 / 2001

BRANCH

SPECIFICATION (WPS) WPS No. : WPS 11/01 DMC

Sheet : 1 of 1

Q.A / Q.C

DEPARTMENT

ACCORDING TO ASME IX

& API 650

COMPANY NAME :BUROLLUS GAS COMPANY

PROJECT NAME : SCARAB/SAFFRON DEV.

WELDING PROCEDURE SPECIFICATION No. : WPS 11/01 DMC

REVISION NO. : 0

SUPPORTING PQR NO. : 01/98 MIDOR

TYPES ( Manual , Automatic, Semi Auto.) : Automatic

JOINTS DESIGN

5-14mm

5-14 mm

30-70mm

BASE METAL POSTWELD HEAT TREATMENT

Temperature Range : N.A

Material Spec. : A283 Time Range : N.A

Type or Grade :C Other : N.A

P No. :1

A No. :1

GAS

Thickness : 5-14MM Type of Gas or Gases : N.A

Diameter : PLATE Composition of Gas Mixture : N.A

Other : Other :

FILLER METALS ELECTRICAL CHARACTERISTICS

Current : D.C

Weld Metal Analysis A No. :1 Polarity : ELECTRODE +VE

Size of Electrode : 4.0MM

WELD FILLER METAL CURRENT VOLTAGE

Filler Metal No. :6 LAYERS Class Diam Polar. Amp. RANGE

S F A Specification : A5.17 ( mm ) range

AWS Classification : F7A2/EM12 1ST EM12 4.0 +VE 550-600 30-35

POSITION 2nd EM12 4.0 +VE 550-600 30-35

3rd

Position of Groove : 2F FILL

Weld Progression :

Other : BOTTOM-ROOF CAP

PREHEAT TECHNIQE

Interpass Cleaning :GRIND&WIRE BRUSH

Preheat Temp. ( C ) ( Min) :.N.A

String or Weave Bead : WEAVE

Interpass Temp. ( C ) ( Max.) : 250 C

Orifice or Gas Cup Size : N.A

Other :

Multipass or Single Pass : MULT.

Single or Multiple Electrodes : SINGLE

Other :

PETROJET QA / QC MGR. CLIENT REP.

JOB TITLE

NAME

DATE

SIGN.

EXHIBIT A

You might also like

- Draft WPS For Carbon Steel PipeDocument2 pagesDraft WPS For Carbon Steel Pipeabet_singkong893057% (7)

- Weekly Welder Repair Rate MonitoringDocument15 pagesWeekly Welder Repair Rate MonitoringSiddiqui Abdul Khaliq100% (1)

- Welding Procedure Specification (WPS) : According To Api 1104Document1 pageWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (2)

- Wps SawDocument2 pagesWps Sawdevendrasingh2021100% (10)

- Aluminium WPSDocument2 pagesAluminium WPSAnonymous yCpjZF1rF100% (1)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (3)

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (3)

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Welder ListDocument2 pagesWelder ListYulian Adhriansyah100% (1)

- Electrode SelectionDocument1 pageElectrode SelectionMel gibsonNo ratings yet

- DHGDocument1 pageDHGjahanNo ratings yet

- Weld Procedure Specification (WPS) : According To Asme Ix &Document1 pageWeld Procedure Specification (WPS) : According To Asme Ix &Mina Roger SamyNo ratings yet

- Weld Procedure Specification (WPS) : According To Asme Ix &Document1 pageWeld Procedure Specification (WPS) : According To Asme Ix &Mina Roger SamyNo ratings yet

- Weld Procedure Specification (WPS) : According To Asme IxDocument1 pageWeld Procedure Specification (WPS) : According To Asme IxMina Roger Samy50% (2)

- PIPING WPS and PQRDocument5 pagesPIPING WPS and PQRshibaprasad0115No ratings yet

- PQR Babbit SCDocument34 pagesPQR Babbit SCagustinusNo ratings yet

- GWAW Welding SpecificationDocument2 pagesGWAW Welding SpecificationSaurabh GuptaNo ratings yet

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)Njoku ChijiokeNo ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- PQR 3G Fcaw SF71Document3 pagesPQR 3G Fcaw SF71long phamNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- PQR FC-12-22Document2 pagesPQR FC-12-22cycsi02No ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- WPS PJBDocument7 pagesWPS PJBMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- PQR FC-19-23Document2 pagesPQR FC-19-23cycsi02No ratings yet

- PQR FC-19-23.1Document2 pagesPQR FC-19-23.1cycsi02No ratings yet

- WPS NewDocument13 pagesWPS NewMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification: Monday, April 27, 2009 Page 1 of 2Document2 pagesWelding Procedure Specification: Monday, April 27, 2009 Page 1 of 2srb metallurgNo ratings yet

- PQR PDFDocument2 pagesPQR PDFNjoku ChijiokeNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Preliminary - Welding Procedure Specification (WPS)Document1 pagePreliminary - Welding Procedure Specification (WPS)Rudi DaNo ratings yet

- WPS & PQRDocument7 pagesWPS & PQRRanjan KumarNo ratings yet

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Document3 pagesWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationWaranya Musika100% (1)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad Daniel100% (2)

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Document1 pageWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- PQR UpdatedDocument2 pagesPQR UpdatedameeruldumNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- WPS-PQR RepairDocument16 pagesWPS-PQR RepairmohammedetaNo ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationMark Jason M. BrualNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- MHC Conveying System Private Limited: JOINTS (QW-402)Document3 pagesMHC Conveying System Private Limited: JOINTS (QW-402)Lipika GayenNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Mig Welding Mastery PDFDocument31 pagesMig Welding Mastery PDFCarlos SosaNo ratings yet

- Wps Sa106 Grbeil Gtaw SmawDocument5 pagesWps Sa106 Grbeil Gtaw SmawRajmahesh DakhoreNo ratings yet

- Drawing For Lubrication MillDocument2 pagesDrawing For Lubrication MillDeepakNo ratings yet

- Accredited Compentency Assessors As of July 2022Document10 pagesAccredited Compentency Assessors As of July 2022Mark TepaceNo ratings yet

- Kiln Consumable SpareDocument2 pagesKiln Consumable SpareAMCFC BlueNo ratings yet

- Welding (Cadet Training)Document41 pagesWelding (Cadet Training)Kyaw Bhone WinNo ratings yet

- Episode 607: Specific Heat Capacity: Changes Phase From A Solid To A Liquid or Liquid To A GasDocument19 pagesEpisode 607: Specific Heat Capacity: Changes Phase From A Solid To A Liquid or Liquid To A GasMuhamadMarufNo ratings yet

- PQR Fcaw SmawDocument2 pagesPQR Fcaw SmawMIGUEL ANGELNo ratings yet

- Welding CodeDocument14 pagesWelding CodeKureiNo ratings yet

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- Weld WeightDocument10 pagesWeld WeightDivyesh PatelNo ratings yet

- Practice 6 - Questions - CSWIPDocument12 pagesPractice 6 - Questions - CSWIPravichandran0506100% (1)

- EnerVal TehniCki KatalogDocument18 pagesEnerVal TehniCki KatalogHasim BenziniNo ratings yet

- Smaw PDFDocument10 pagesSmaw PDFArizapatazoNo ratings yet

- Basic Welding Knowledge and TechniquesDocument2 pagesBasic Welding Knowledge and Techniquesapi-390592034No ratings yet

- FDLA - Fan Coil Ducto Daitsu - Rev.1 PDFDocument52 pagesFDLA - Fan Coil Ducto Daitsu - Rev.1 PDFVictor Hugo Castillo Aguirre0% (1)

- Data Film IIWDocument2 pagesData Film IIWelektromekanik 2014No ratings yet

- Eo Weld Fitting 4100e001Document11 pagesEo Weld Fitting 4100e001sandeepNo ratings yet

- Flow Temp. Controller 2 (Cased) PAC-IF031B-E: Installation ManualDocument36 pagesFlow Temp. Controller 2 (Cased) PAC-IF031B-E: Installation ManualAttila BalazsNo ratings yet

- SP, Robacta 280 (42,0415,0145), 20150716 - TOCHA 301Document18 pagesSP, Robacta 280 (42,0415,0145), 20150716 - TOCHA 301saub.maintNo ratings yet

- Ahp 2X660 (WPS) )Document17 pagesAhp 2X660 (WPS) )Hema NandhNo ratings yet

- Electrode Selection Excel ChartDocument2 pagesElectrode Selection Excel ChartHamid MansouriNo ratings yet

- E Joint Factor 2 PDFDocument1 pageE Joint Factor 2 PDFMohamed ElsayedNo ratings yet

- ITP-Steel Structure NewDocument5 pagesITP-Steel Structure NewPrasanta ParidaNo ratings yet

- BV Fillet Welding SIzeDocument5 pagesBV Fillet Welding SIzeGede Bayu AryaNo ratings yet