Calificación Termotecnica Coindustrial

Calificación Termotecnica Coindustrial

Uploaded by

Tato VargasCopyright:

Available Formats

Calificación Termotecnica Coindustrial

Calificación Termotecnica Coindustrial

Uploaded by

Tato VargasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Calificación Termotecnica Coindustrial

Calificación Termotecnica Coindustrial

Uploaded by

Tato VargasCopyright:

Available Formats

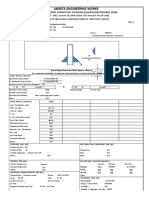

OFICINA / OBRA:

RECORD OF WELDER OR WELDER

OPERATOR QUALIFICATION TEST (WPQ) Bogotá

EBR-ODL

FECHA: 14 de Jumio de 2016

Welders Name EMILIO CHAMORRO Identificación 80,249,542 Stamp No VB

Welding Process(es) FCAW Type Semiautomatico

Identification of (WPS) followed by welder during welding of test coupon 132

Base Material(s) welded ASTM A36 1/2"

Manual or Semiautomatic variables for each process (QW-350) Actual Values Range Qualified

Backing (metal, weld metal, welded from both side flux, etc) (QW-402) Weld Metal Metal de Soldadura/Metal base

ASME P-No P1 to Asme P-No P1 (QW-403) P1 P1 Hasta P11

(X) Plate ( ) Pipe (Enter diameter) NA NA

Filler Metal Specification (SFA) Clasification (QW-404) 5,20 5.20

Filler Metal F-No F6 F6

Consumable insert for GTAW or PAW NA NA

Weld deposit thickness for each welding Process NA NA

Welding Position (1G,..5G,etc)(QW-405)

ODL S.A. 2G-3G 1G-2G-3G

Thickness of deposit Weld Metal REVISADO QA 1/2" 1"

Progression, Uphill / Downhill ASCENDENTE ASCENDENTE

Backing gas for (GTAW, PAW or GMAW; fuel gas for OFWQW-408) NA NA

GMAW transfer mode (QW-409) Por:________ NA NA

GTAW welding current type / polarity NA NA

Fecha:______

Machine Welding variables for the Process used (QW-360) NA Range Qualified

Direct/Remote visual control NA NA

Automatic Voltage control (GTAW) NA NA

Automatic joint tracking NA NA

Welding Position (1G,..5G, el (1G,5G,etc.) NA NA

Consumable Insert NA NA

Backing (metal,weld metal, welded from both sides, flux, etc) NA

GUIDE BEND TEST RESULTS . N.A.

QW-462.2 QW-462.3(a)

Guide bend test type <> QW-462.3 (b) Long R&F Results

(Side)Results<> Trans R&F Type <>

Visual Examination results (QW-302.4) ACEPTABLE

Radiographic test results (QW-304 And QW-305) REPORTE PROYINCO LTDA 07 14 Junio / 2016

(for alternative qualification of groove welds by radiography)

Filet weld-fracture test NA Length and percent of defects NA (in)

Macro test fusion NA Filled leg size .

Welding test Conducted by ING. CARLOS MERIÑO

We certify that the statements in this record are correct and that the teat coupons wew prepare, Welded

in accordance with the requirements of section IX of the ASME code

QA / QC Firma

Ing CARLOS MERIÑO

You might also like

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit Adwani0% (1)

- Welder Test Certificate - CSDocument1 pageWelder Test Certificate - CSPrathamesh Omtech100% (4)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Welder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document18 pagesWelder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)mahendraNo ratings yet

- Dowel Pin Tolerances PDFDocument4 pagesDowel Pin Tolerances PDFHenrique Marques100% (2)

- 1Document26 pages1Maribel Bihag AlcantaraNo ratings yet

- PeopleSoft Application Developer 1 Certification Study Guide - 1Z0-241Document15 pagesPeopleSoft Application Developer 1 Certification Study Guide - 1Z0-241Amanda0% (1)

- Gtaw - Inox - 6g Julio Arriagada Gallegos Constructora Laja Mayo 2023Document1 pageGtaw - Inox - 6g Julio Arriagada Gallegos Constructora Laja Mayo 2023elevacerchileNo ratings yet

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- Diamond Engineering (Chennai) PVT LTD.,: Welder Qualification Test RecordDocument1 pageDiamond Engineering (Chennai) PVT LTD.,: Welder Qualification Test Recordmangalraj900No ratings yet

- Abdul Muhid WPQRDocument1 pageAbdul Muhid WPQRChandra Bintang W.PNo ratings yet

- WPQ Asme IxDocument1 pageWPQ Asme IxEDEN GONZALEZNo ratings yet

- WPQ Format - SMAWDocument3 pagesWPQ Format - SMAWBalkishan DyavanapellyNo ratings yet

- 2 - WQT KPRDocument27 pages2 - WQT KPRSuryadev singhNo ratings yet

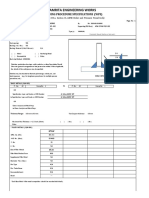

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 pagesAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- WPQ 006Document1 pageWPQ 006vinuNo ratings yet

- Welder CertificateDocument1 pageWelder CertificatePaul H TampubolonNo ratings yet

- SampleDocument5 pagesSample이훈No ratings yet

- 3.ofis-W-39 - Ofis-Wps-02aDocument3 pages3.ofis-W-39 - Ofis-Wps-02aanandNo ratings yet

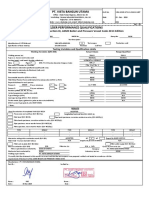

- Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionDocument1 pagePt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionHaryanto RNo ratings yet

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

- PQR (GMAW) - NotesDocument3 pagesPQR (GMAW) - Notesbibianamercado02No ratings yet

- Registro de Calificacion Del Procedimiento (PQR) : JOINTS (QW-402)Document2 pagesRegistro de Calificacion Del Procedimiento (PQR) : JOINTS (QW-402)Anonymous Xa5rkMZm9ZNo ratings yet

- WPQ Formats NEWDocument4 pagesWPQ Formats NEWMANABENDRA MAITRANo ratings yet

- Weder Qualification Test Certificates-Part 2Document7 pagesWeder Qualification Test Certificates-Part 2Avijit Debnath100% (1)

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- 385 2 Internal Gtaw+SmawDocument2 pages385 2 Internal Gtaw+Smawsubash1688No ratings yet

- Wps PQR PDFDocument35 pagesWps PQR PDFquality unifab83% (6)

- Procedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Document2 pagesProcedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Walid BdeirNo ratings yet

- 170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQDocument4 pages170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps & PQR For Valve Installation - XLSX Fix TerbaruDocument20 pagesWps & PQR For Valve Installation - XLSX Fix Terbarufebri100% (1)

- QW 483 - PQR (Gtaw+smaw) 04.01.17Document8 pagesQW 483 - PQR (Gtaw+smaw) 04.01.17Srikant GanjiNo ratings yet

- Eslam Abdelhameed Asme Ix IdDocument1 pageEslam Abdelhameed Asme Ix Idel_sharkawy2011No ratings yet

- Ananta Golui WQTDocument2 pagesAnanta Golui WQTamei.pari2014No ratings yet

- 171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQDocument4 pages171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- WPQ FormatDocument8 pagesWPQ FormatsanjaykumarmauryaNo ratings yet

- PT - SAE WPS PQR - MIGAS (PGDP) - Unlocked-2Document16 pagesPT - SAE WPS PQR - MIGAS (PGDP) - Unlocked-2Batara SinagaNo ratings yet

- WPS-46 - Gtaw & Smaw Tig + SmawDocument8 pagesWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNo ratings yet

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Document2 pagesWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (2)

- Procedure Qualification RecordDocument6 pagesProcedure Qualification RecordGaurang PandyaNo ratings yet

- 2.ofis-W-09 - Ofis-Wps-09Document4 pages2.ofis-W-09 - Ofis-Wps-09anandNo ratings yet

- Welding Procedure Specification (W.P.S) : Alstom India LimitedDocument2 pagesWelding Procedure Specification (W.P.S) : Alstom India LimitedAhmed saberNo ratings yet

- PWPS WPS PQR WPQDocument21 pagesPWPS WPS PQR WPQcsolanki658688% (8)

- 1.911.032 WPQ Smaw Astm A36Document1 page1.911.032 WPQ Smaw Astm A36Felipe Carrasco sepulvedaNo ratings yet

- WPS&PQR For PipeDocument5 pagesWPS&PQR For PipeKAMALNo ratings yet

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- 180-Smaw-Zug-Asme (Andhika Rolando-3g) - WPQDocument4 pages180-Smaw-Zug-Asme (Andhika Rolando-3g) - WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PQR (52a) ModelDocument1 pagePQR (52a) ModelSIDDHARTH BEHERAYNo ratings yet

- Proposed Piping WPS GTAW SMAWDocument2 pagesProposed Piping WPS GTAW SMAWadminNo ratings yet

- Wps For Structure Mild Steel Fillet Weld - CompressDocument2 pagesWps For Structure Mild Steel Fillet Weld - CompressAhmed saberNo ratings yet

- Welder Performance Qualifications (WPQ) (ASME Boiler and Pressure Vessel Code)Document1 pageWelder Performance Qualifications (WPQ) (ASME Boiler and Pressure Vessel Code)Edinson Herrera VasquezNo ratings yet

- REP-SA 240 GR 410S-WPQ-05, W9Document1 pageREP-SA 240 GR 410S-WPQ-05, W9Shaniraj BirajdarNo ratings yet

- U.G WPS 001Document5 pagesU.G WPS 001arefpiriNo ratings yet

- REP-SA 240 GR 410S-WPQ-05, W6Document1 pageREP-SA 240 GR 410S-WPQ-05, W6Shaniraj BirajdarNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- MycoremediationDocument23 pagesMycoremediationNeha Mhapralkar75% (8)

- Radionic Patents by Tony ScofieldDocument13 pagesRadionic Patents by Tony Scofieldboomix100% (1)

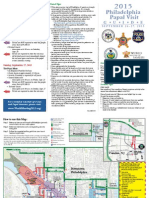

- Secret Service Pope Visit MapDocument2 pagesSecret Service Pope Visit MapPhiladelphiaMagazineNo ratings yet

- Belt Drive Numerical 1Document6 pagesBelt Drive Numerical 1Prateek riders100% (1)

- 12.stairs 3 PDFDocument1 page12.stairs 3 PDFJohnny cusoNo ratings yet

- Motor+Running Lighting+CapacitorsDocument28 pagesMotor+Running Lighting+Capacitorssokol_poleceNo ratings yet

- Srivas Prasad - Measurement of The Temperature of The Cosmic Microwave BackgroundDocument8 pagesSrivas Prasad - Measurement of The Temperature of The Cosmic Microwave BackgroundNestorr50No ratings yet

- 18EC24 Basic Electronics Notes-croppedDocument12 pages18EC24 Basic Electronics Notes-croppedArslan HEPNo ratings yet

- Test Protocol For Seat: Pull Force Gauge Push Force Gauge Straps Cast-Iron Discs For Musculation StopDocument13 pagesTest Protocol For Seat: Pull Force Gauge Push Force Gauge Straps Cast-Iron Discs For Musculation StopŠetkić SemirNo ratings yet

- PPE - 2010 Dec - Q&ADocument15 pagesPPE - 2010 Dec - Q&ACch100% (2)

- Power Transformer Condition Monitoring and Remanent Life AssessmentDocument5 pagesPower Transformer Condition Monitoring and Remanent Life AssessmentAmarinder DhimanNo ratings yet

- SingleRAN GSM UMTS LTE - New Product Introduction v2.0Document9 pagesSingleRAN GSM UMTS LTE - New Product Introduction v2.0angicar100% (3)

- B2B Sales Coverage ModelDocument14 pagesB2B Sales Coverage ModelPrabal Pratap SinghNo ratings yet

- Atlas: High Performance End MillsDocument12 pagesAtlas: High Performance End Millsmax8086No ratings yet

- JTS Standard Vertical Turbine Pumps en E00727 6 2010Document8 pagesJTS Standard Vertical Turbine Pumps en E00727 6 2010yunusisNo ratings yet

- IFU 5902159 ExoFit Harness PDFDocument20 pagesIFU 5902159 ExoFit Harness PDFValentinNo ratings yet

- Installation LogDocument2 pagesInstallation LogThọ Trần ĐứcNo ratings yet

- Umbraco Manual 7.1 - How To Create An Umbraco Website From Flat HTML FilesDocument29 pagesUmbraco Manual 7.1 - How To Create An Umbraco Website From Flat HTML FileschsNo ratings yet

- Expansion Tank Capacity Calculation SheetDocument5 pagesExpansion Tank Capacity Calculation SheetDEX TERRNo ratings yet

- Prepaid Prepaid: Thank You For Shopping On Ebay Thank You For Shopping On EbayDocument4 pagesPrepaid Prepaid: Thank You For Shopping On Ebay Thank You For Shopping On EbayArnav AgarwalNo ratings yet

- 2009-09-22 HLEOA-AG01D1-ShedsDocument2 pages2009-09-22 HLEOA-AG01D1-ShedsgeowozNo ratings yet

- It Kpi Encyclopedia PreviewDocument5 pagesIt Kpi Encyclopedia Previewshahbaz51950% (2)

- Section Three:: By: Katie MorganDocument9 pagesSection Three:: By: Katie MorganKatie-Marie MorganNo ratings yet

- DONG AH's BrochureDocument31 pagesDONG AH's BrochureMinhtien LeNo ratings yet

- Cicind: Manual For Expansion Joints and Chimney Seals An Engineering Guide JUNE 2003Document28 pagesCicind: Manual For Expansion Joints and Chimney Seals An Engineering Guide JUNE 2003Chiheb KaanicheNo ratings yet

- Failure 01042016 PDFDocument5 pagesFailure 01042016 PDFpawan kumar raiNo ratings yet