Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

Joni Carino SuniCopyright:

Available Formats

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

Joni Carino SuniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

Joni Carino SuniCopyright:

Available Formats

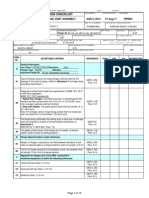

SAUDI ARAMCO ID/PIEU - 14- May 2018 - REV. 2018.03.00 (Standards Cutoff -March 31, 2018) Rev. 2018.03.

Rev. 2018.03.00 31-Mar-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Control of Welding Consumables - Plant Piping

SAIC-W-2032 14-May-18 WELD-

(Site Storage, Handling, Conditioning & Issuance)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

Tanajib Gas Plant Project - ISF Package 13 10-09003-0006 RTCC

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General Requirements

An approved procedure exists that has incorporated the following:

A) SAIC-W-2009 Checklist (Procedure for Welding Consumables)

Sch. Q,

B) SAIC-W-2010 Checklist (Receiving Inspection of Consumables)

Attachment VI

A1 C) SAIC-W-2032 Checklist (Control of Welding Consumables)

Tables

D) SATR-W-2009 - Rod Oven Calibration (Storage, Bake, Portable)

(Procedure)

E) SATR-W-2010 - Welding Consumable Issuance Record

F) SATR-W-2020 - Recv Insp Detail Form & QC log (Consumables)

Personnel involved in handling, storage, conditioning, issuance & controls

of welding consumables are trained as described below: Sch. Q,

A) Material Controller (Receipt, Control, Storage, Handling, Issue, etc.) Attachment VI

A2

B) Welding Foreman/Supervisor (Issue, Distribution, Control, Return) Tables

C) QC Inspector (Monitors approved procedure and all activities) (Procedure)

D) Welders (Follows approved WPS for consumables received/used)

Procedure has provided details on how welding consumables are

controlled by the following but not limited to:

Sch. Q,

A) Receipt & Storage requirements - prior to issuance

Attachment VI

A3 B) Material controller- Stock control (First in, First out) & issuance

Tables

C) Requestor/User - Issue & Receiving of consumables (Daily Basis)

(Procedure)

D) Return of un-used consumables, ID system & reconditioning

Procedure is being followed by all responsible for the work.

B Storage of Welding Consumables.

Non-low hydrogen electrodes to A5.1 or A5.5 are stored in a dry SAES-W-011,

B1

environment. Attachment 1

SAES-W-011,

B2 All fluxes are stored in sealed containers in a dry environment.

Attachment 1

All electrodes & filler wires for SAW, GTAW, GMAW, & FCAW are stored SAES-W-011,

B3

in sealed containers in dry environment. Attachment 2

All electrodes and filler wires for SAW, GTAW, GMAW, and FCAW that SAES-W-011,

B4

have visible rusting or contamination are discarded. Attachment 2

GTAW filler metals have either AWS/ASME identification or the

SAES-W-011

B5 manufacture's identification marked on each individual rod, by the

Para. 6.3

manufacture, with flags, stencils or stamps.

C Handling & Conditioning of Electrodes

Storage ovens have continuous power supply during working and non- SAES-W-011,

C1

working hours or days (nights and weekends). Attachment 1

Storage and Re-bake ovens have calibrated Temperature Gauge. SAES-W-011,

C2

(Note 1 of SAES-W-011, Table 1) Attachment 1

Saudi Aramco: Company General Use

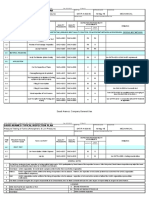

SAUDI ARAMCO ID/PIEU - 14- May 2018 - REV. 2018.03.00 (Standards Cutoff -March 31, 2018) Rev. 2018.03.00 31-Mar-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Control of Welding Consumables - Plant Piping

SAIC-W-2032 14-May-18 WELD-

(Site Storage, Handling, Conditioning & Issuance)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

Tanajib Gas Plant Project - ISF Package 13 10-09003-0006 RTCC

Portable electrode storage ovens are kept at a minimum temperature of SAES-W-011,

C3

65C. Attachment 1

Atmospheric exposure of low hydrogen electrodes shall not exceed:

a) A5.1 electrodes : 4 hours (Open to atm) / 8 hours (if continuously kept

in portable oven at 65C).

b) A5.5 (E70XX & E80XX): 2 hours (Open to atm) / 4 hours

SAES-W-011,

C4 (electrodes continuously kept in portable oven at 65C).

Attachment 1

c) Low hydrogen electrodes with strengths > E80XX: 30 mins (Opento

atm) / 1 hour (if continuously kept in portable oven at 65C)

d) S. Steel and non-ferrous electrodes: 4 hours (Open to atm)

and 8 hours if continuously kept in portable oven at 65C.

The electrodes which has exceeded the permitted atmospheric exposure

SAES-W-011,

C5 as stated in Item B7 above and electrodes with damaged hermetically

Attachment 1

sealed containers shall undergo drying prior to its ssue for welding.

Drying of electrodes was performed as follows:

A) 2 hours minimum at 260-430C for A5.1 Low-hy electrodes. SAES-W-011,

C6

B) 2 hours minimum at 370-430C for A5.5 Low-hy electrodes. Attachment 1

C) 2 hours minimum at 120-250C for SS & non-ferrous electrodes.

Electrodes are re-dried only once and marked or segregated prior to re- SAES-W-011,

C7

issue. Attachment 1

Electrodes exposed to the atmosphere for less than the permitted duration

SAES-W-011,

C8 are re-conditioned or returned to the holding oven for 4 hours at 120°C

Attachment-1

before re-issue.

Any electrodes (low hydrogen or non-low-hydrogen) and fluxes that have SAES-W-011,

C9

been wet or moist are discarded. Attachment 1&2

Opened SAW flux containers are stored continuously in ovens at 65C SAES-W-011,

C10

minimum, or at mfg's recommendation, whichever is greater. Attachment 1

Shielding gases shall conform to the requirements of AWS A5.32

Specification for Welding Shielding Gases

A) Carbon dioxide (CO2): Compressed Gas Association CGA G-6.2,

Grade H (99.8% purity) SAES-W-011

C11

B) Argon (Ar): Compressed Gas Association CGA G-11.1 Grade C (99. Para. 6.7

997% Purity) Note : AWS A5.32 Specification for Welding Shielding

Gases gases and requirement for other gas mixtures shall be submitted

to CSD for approval

D Control of Electrode Issuance and Return

A project specific procedure or method statement for electrode issuance,

Procedure

D1 receiving and return was approved by SAPMT and Inspection (PID) per

Requirement

SAIC-W-2009.

REMARKS:

ATTACHMENTS:

Attachment 1 - SAES-W-011 - Conditioning, Storage & Exposure of Consumables (Att. 1 & Att. 2)

REFERENCE DOCUMENTS:

1. SAES-W-011, Welding Requirements for On-Plot Piping, (1 January 2018)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 14- May 2018 - REV. 2018.03.00 (Standards Cutoff -March 31, 2018) Rev. 2018.03.00 31-Mar-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Control of Welding Consumables - Plant Piping

SAIC-W-2032 14-May-18 WELD-

(Site Storage, Handling, Conditioning & Issuance)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

Tanajib Gas Plant Project - ISF Package 13 10-09003-0006 RTCC

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Actual Board Profed 2022Document242 pagesActual Board Profed 2022Eunice Grace Galvez90% (10)

- Saep 321Document25 pagesSaep 321AbdullahNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNo ratings yet

- Aramco NCR FormatDocument2 pagesAramco NCR FormatMansoor BabarNo ratings yet

- SATR-W-2006 Rev 6Document1 pageSATR-W-2006 Rev 6Manoj KumarNo ratings yet

- SAIC-L-2014 Rev. 5Document10 pagesSAIC-L-2014 Rev. 5Jagadeesh PuppalaNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacoDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacojahaanNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Satip W 014 01Document12 pagesSatip W 014 01spravin231No ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection ChecklistMohammad RizwanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 Weldm4metz100% (2)

- Saudi Aramco Inspection ChecklistDocument19 pagesSaudi Aramco Inspection ChecklistIrshad IqbalNo ratings yet

- SAIC W 2069 in Process Welding InspectionDocument8 pagesSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNo ratings yet

- Saep 352 PDFDocument15 pagesSaep 352 PDFRami ElloumiNo ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 Mechanicalpravin100% (1)

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanDomie Neil Bucag SalasNo ratings yet

- SAIC-A-2008 Rev 0Document3 pagesSAIC-A-2008 Rev 0Kristine Caye DatarioNo ratings yet

- Saic W 2011rev 0Document4 pagesSaic W 2011rev 0fariboy123No ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- SAIC-W-2084 Buttering or Build-Up of JointsDocument1 pageSAIC-W-2084 Buttering or Build-Up of Jointskarioke mohaNo ratings yet

- SAIC-W-2015 Rev 7 (NDE Selection)Document17 pagesSAIC-W-2015 Rev 7 (NDE Selection)vijayachiduNo ratings yet

- Materials System SpecificationDocument11 pagesMaterials System Specificationimranb_001100% (1)

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saep 324Document13 pagesSaep 324Hansel Francis100% (4)

- Satr-W-2020Document1 pageSatr-W-2020Joni Carino SuniNo ratings yet

- Saep 1101Document50 pagesSaep 1101mathew.genesis.inspNo ratings yet

- SAIC-W-2085 Pre-Welding Inspection PDFDocument4 pagesSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaNo ratings yet

- Saudi Aramco Test ReportDocument4 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- SAIC-A-2008 Rev 6 Verify Test Medium For Hydrostatic Testing and Lay UpDocument2 pagesSAIC-A-2008 Rev 6 Verify Test Medium For Hydrostatic Testing and Lay UpAhdal NoushadNo ratings yet

- Saic-L-2010 Pmi Testing PDFDocument5 pagesSaic-L-2010 Pmi Testing PDFkarioke mohaNo ratings yet

- Saep 310Document38 pagesSaep 310paul cafeNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection Plankarthi51289No ratings yet

- 175 091300Document2 pages175 091300Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingDocument5 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingpravinNo ratings yet

- SAIC-H-2010 Rev 7Document1 pageSAIC-H-2010 Rev 7Satheesh Rama SamyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAnonymous S9qBDVky100% (1)

- SAIC-W-2039 Welder & Operator Certification Review Issuance of JCC (Job Clearance Card) & Review Performance - PipelinesDocument9 pagesSAIC-W-2039 Welder & Operator Certification Review Issuance of JCC (Job Clearance Card) & Review Performance - PipelinesilliasuddinNo ratings yet

- Saic A 2011Document8 pagesSaic A 2011jerinNo ratings yet

- 1 SATIP-L-108-01 Valve Installation-Rev 2Document15 pages1 SATIP-L-108-01 Valve Installation-Rev 2Md ShariqueNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- ARAMCO UT Inspection Checklist - SAIC-UT-2001Document6 pagesARAMCO UT Inspection Checklist - SAIC-UT-2001Anonymous hBBam1n100% (1)

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 Weldm4metzNo ratings yet

- Satip A 004 03Document3 pagesSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- Saudi Aramco Typical Inspection PlanDocument2 pagesSaudi Aramco Typical Inspection PlanMAZHARULNo ratings yet

- Welder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 WeldDocument2 pagesWelder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 Weldkarthi51289No ratings yet

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldMAZHARULNo ratings yet

- Satip G 006 0122Document10 pagesSatip G 006 0122Rijwan MohammadNo ratings yet

- SAIC-W-2006 Rev 0 PDFDocument4 pagesSAIC-W-2006 Rev 0 PDFMidhun K ChandraboseNo ratings yet

- Saudi Aramco Inspection ChecklistDocument22 pagesSaudi Aramco Inspection Checklistabdulgafoor54100% (2)

- Saic MPT 2004 Rev 0Document6 pagesSaic MPT 2004 Rev 0philipyapNo ratings yet

- Saep 323 PDFDocument8 pagesSaep 323 PDFthanga balanNo ratings yet

- SAIC-W-2032 Rev 8Document6 pagesSAIC-W-2032 Rev 8saravananmenmathiNo ratings yet

- Saic W 2032Document7 pagesSaic W 2032Carlos RamosNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistm4metzNo ratings yet

- Saic W 1308Document21 pagesSaic W 1308mathew.genesis.inspNo ratings yet

- CustomersDocument109 pagesCustomersOmar NoahNo ratings yet

- CityU Acct 23/24 Study PlanDocument1 pageCityU Acct 23/24 Study PlanCHUN HEI LUKNo ratings yet

- Geomantic Shield Generator, by Frater PyramidatusDocument12 pagesGeomantic Shield Generator, by Frater PyramidatusBrian Adam Newman (Frater Pyramidatus)No ratings yet

- Static Routing Packet TracerDocument4 pagesStatic Routing Packet Tracerfalaad64No ratings yet

- Test 2Document23 pagesTest 2Hiếu EuroNo ratings yet

- Amniotic Fluid Sludge Is Associated With Earlier Preterm Delivery and Raised Cervicovaginal Interleukin 8 ConcentrationsDocument7 pagesAmniotic Fluid Sludge Is Associated With Earlier Preterm Delivery and Raised Cervicovaginal Interleukin 8 ConcentrationsShinta Dewi WulandariNo ratings yet

- GRFN Company ProfileDocument17 pagesGRFN Company Profileenergy8001No ratings yet

- 136 Yos Online Yabanci Uyruklu Ogrenci Sinavi TR YosDocument5 pages136 Yos Online Yabanci Uyruklu Ogrenci Sinavi TR Yosusmanmughal127790No ratings yet

- Olanzapine Vs AripiprazoleDocument8 pagesOlanzapine Vs AripiprazoleDivaviyaNo ratings yet

- Physics Practical 1 PDFDocument6 pagesPhysics Practical 1 PDFMohiniraj DangeNo ratings yet

- Mooc ReportDocument16 pagesMooc ReportSparsh DhamaNo ratings yet

- PhysicalSci12 Q1 Mod4 Week7 Sources of Energy v3Document33 pagesPhysicalSci12 Q1 Mod4 Week7 Sources of Energy v3Corazon ReymarNo ratings yet

- 15EC73Document307 pages15EC73KN DEEPSHINo ratings yet

- HR - 16 Sept-1Document15 pagesHR - 16 Sept-1Ikram ChowdhuryNo ratings yet

- Australia and New ZealandDocument6 pagesAustralia and New Zealandbrunocz2No ratings yet

- Sterner Infranor 872 & 876 Series Brochure 2005Document6 pagesSterner Infranor 872 & 876 Series Brochure 2005Alan MastersNo ratings yet

- 5.5 KW Diesel DC GeneratorDocument5 pages5.5 KW Diesel DC GeneratorCoordinador RanMauNo ratings yet

- Wooden Mallet Plans - WoodArchivistDocument4 pagesWooden Mallet Plans - WoodArchivistErics100% (1)

- GIW Technical Series: Cold Weather Operation and StorageDocument2 pagesGIW Technical Series: Cold Weather Operation and StorageTravis SkinnerNo ratings yet

- REOTEMP INSTRUMENTS Product Drawing Thermowell, (Limited Space) With: - Threaded Process Connection - Straight ShankDocument1 pageREOTEMP INSTRUMENTS Product Drawing Thermowell, (Limited Space) With: - Threaded Process Connection - Straight ShankInsertec LtdaNo ratings yet

- MATH 8 Lesson Plan CODocument3 pagesMATH 8 Lesson Plan COSerdnelem Rhodz MacedaNo ratings yet

- Armitage1995 - Methods AR PDFDocument28 pagesArmitage1995 - Methods AR PDFNicolas CopernicNo ratings yet

- Safety Data Sheet CCM Polymers SDN BHD (363880-D)Document10 pagesSafety Data Sheet CCM Polymers SDN BHD (363880-D)Bo'im ZadNo ratings yet

- Share KhanDocument10 pagesShare KhangautammandalNo ratings yet

- Alcatel Omnipcx Enterprise: VPN OverflowDocument42 pagesAlcatel Omnipcx Enterprise: VPN OverflowAriel BecerraNo ratings yet

- P Block ElementsDocument16 pagesP Block Elementsprakharsample150% (1)

- Physics Experiment Report (Iv) Basic Physics "Oscillation Mathematics"Document8 pagesPhysics Experiment Report (Iv) Basic Physics "Oscillation Mathematics"JkanthNo ratings yet

- Mission Green Sept 2017Document1 pageMission Green Sept 2017Robert OkandaNo ratings yet

- 15MPE1019Document12 pages15MPE1019Polumuri RamanaNo ratings yet