DTC P2138 App Sensor DTC P2138 App Sensor Component Description

DTC P2138 App Sensor DTC P2138 App Sensor Component Description

Uploaded by

Phyo KyawOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DTC P2138 App Sensor DTC P2138 App Sensor Component Description

DTC P2138 App Sensor DTC P2138 App Sensor Component Description

Uploaded by

Phyo KyawCopyright:

Available Formats

DTC P2138 APP SENSOR

DTC P2138 APP SENSOR PFP:18002

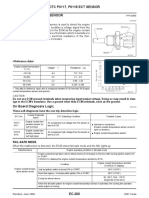

Component Description UBS00NMK

The accelerator pedal position sensor is installed on the upper end

of the accelerator pedal assembly. The sensor detects the accelera-

tor position and sends a signal to the ECM.

Accelerator pedal position sensor has two sensors. These sensors

are a kind of potentiometers which transform the accelerator pedal

position into output voltage, and emit the voltage signal to the ECM.

In addition, these sensors detect the opening and closing speed of

the accelerator pedal and feed the voltage signals to the ECM. The

ECM judges the current opening angle of the accelerator pedal from

these signals and controls the throttle control motor based on these

signals.

PBIB1741E

Idle position of the accelerator pedal is determined by the ECM

receiving the signal from the accelerator pedal position sensor. The ECM uses this signal for the engine oper-

ation such as fuel cut.

CONSULT-II Reference Value in Data Monitor Mode UBS00NML

Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

● Ignition switch: ON Accelerator pedal: Fully released 0.5 - 1.0V

ACCEL SEN 1

(Engine stopped) Accelerator pedal: Fully depressed 4.2 - 4.8V

● Ignition switch: ON Accelerator pedal: Fully released 0.5 - 1.0V

ACCEL SEN 2*

(Engine stopped) Accelerator pedal: Fully depressed 4.2 - 4.8V

● Ignition switch: ON Accelerator pedal: Fully released ON

CLSD THL POS

(Engine stopped) Accelerator pedal: Slightly depressed OFF

*: Accelerator pedal position sensor 2 signal is converted by ECM internally. Thus, it differ from ECM terminal voltage.

On Board Diagnosis Logic UBS00NMM

This self-diagnosis has the one trip detection logic.

NOTE:

If DTC P2138 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643. Refer to

EC-466, "DTC P0643 SENSOR POWER SUPPLY" .

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

● Harness or connector

(APP sensor 1 and 2 circuit is open or

Accelerator pedal position Rationally incorrect voltage is sent to ECM shorted.)

P2138 (TP sensor circuit is shorted.)

sensor circuit range/per- compared with the signals from APP sensor 1

2138

formance and APP sensor 2. ● Accelerator pedal position sensor 1 and 2

● Electric throttle control actuator

(TP sensor)

FAIL-SAFE MODE

When the malfunction is detected, ECM enters fail-safe mode and the MIL lights up.

Engine operating condition in fail-safe mode

The ECM controls the electric throttle control actuator in regulating the throttle opening in order for the idle position to be within +10

degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal condition.

So, the acceleration will be poor.

Revision: July 2005 EC-562 2006 Titan

DTC P2138 APP SENSOR

DTC Confirmation Procedure UBS00NMN

A

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION: EC

Before performing the following procedure, confirm that battery voltage is more than 8V at idle.

WITH CONSULT-II

1. Turn ignition switch ON. C

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and let it idle for 1 second.

D

4. If DTC is detected, go to EC-565, "Diagnostic Procedure" .

SEF058Y

WITH GST G

Follow the procedure “WITH CONSULT-II” above.

Revision: July 2005 EC-563 2006 Titan

DTC P2138 APP SENSOR

Wiring Diagram UBS00NMO

BBWA1709E

Revision: July 2005 EC-564 2006 Titan

DTC P2138 APP SENSOR

Specification data are reference values and are measured between each terminal and ground.

CAUTION: A

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER- EC

WIRE

MINAL ITEM CONDITION DATA (DC Voltage)

COLOR

NO.

Sensor power supply C

47 Y [Ignition switch: ON] Approximately 5V

(TP sensor)

[Engine is running]

Sensor ground

82 B/R ● Warm-up condition Approximately 0V D

(APP sensor 1)

● Idle speed

[Engine is running]

Sensor ground

83 G/W ● Warm-up condition Approximately 0V E

(APP sensor 2)

● Idle speed

Sensor power supply

90 L [Ignition switch: ON] Approximately 5V

(APP sensor 1) F

Sensor power supply

91 W/R [Ignition switch: ON] Approximately 5V

(APP sensor 2)

[Ignition switch: ON] G

● Engine: Stopped 0.25 - 0.50V

Accelerator pedal position ● Accelerator pedal: Fully released

98 G/R H

sensor 2 [Ignition switch: ON]

● Engine: Stopped 2.0 - 2.5V

● Accelerator pedal: Fully depressed

I

[Ignition switch: ON]

● Engine: Stopped 0.5 - 1.0V

Accelerator pedal position ● Accelerator pedal: Fully released

106 BR/W J

sensor 1 [Ignition switch: ON]

● Engine: Stopped 4.2 - 4.8V

● Accelerator pedal: Fully depressed K

Diagnostic Procedure UBS00NMP

1. CHECK GROUND CONNECTIONS L

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer to EC-156, "Ground Inspection" . M

BBIA0354E

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

Revision: July 2005 EC-565 2006 Titan

DTC P2138 APP SENSOR

2. CHECK APP SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect accelerator pedal position (APP) sensor harness

connector.

2. Turn ignition switch ON.

BBIA0361E

3. Check voltage between APP sensor terminal 7 and ground with

CONSULT-II or tester.

Voltage: Approximately 5V

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

PBIB2070E

3. CHECK APP SENSOR 2 POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ON.

2. Check voltage between APP sensor terminal 6 and ground with

CONSULT-II or tester.

Voltage: Approximately 5V

OK or NG

OK >> GO TO 8.

NG >> GO TO 4.

PBIB2069E

4. CHECK APP SENSOR 2 POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between APP sensor terminal 6 and ECM terminal 91.

Refer to Wiring Diagram.

Continuity should exist.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit in harness or connectors.

Revision: July 2005 EC-566 2006 Titan

DTC P2138 APP SENSOR

5. CHECK APP SENSOR 2 POWER SUPPLY CIRCUIT-III A

Check harness for short to power and short to ground, between the following terminals

ECM terminal Sensor terminal Reference Wiring Diagram

EC

47 Electric throttle control actuator terminal 2 EC-557

91 APP sensor terminal 6 EC-564

OK or NG C

OK >> GO TO 6.

NG >> Repair short to ground or short to power in harness connectors.

D

6. CHECK THROTTLE POSITION SENSOR

Refer to EC-569, "Component Inspection" .

E

OK or NG

OK >> GO TO 12.

NG >> GO TO 7.

F

7. REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1. Replace the electric throttle control actuator. G

2. Perform EC-83, "Throttle Valve Closed Position Learning" .

3. Perform EC-85, "Idle Air Volume Learning" .

H

>> INSPECTION END

8. CHECK APP SENSOR GROUND CIRCUIT FOR OPEN AND SHORT I

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector. J

3. Check harness continuity between ECM terminal 82 and APP sensor terminal 1, ECM terminal 83 and

APP sensor terminal 3.

Refer to Wiring Diagram. K

Continuity should exist.

4. Also check harness for short to ground and short to power.

L

OK or NG

OK >> GO TO 9.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

M

9. CHECK APP SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 106 and APP sensor terminal 2, ECM terminal 98 and

APP sensor terminal 5.

Refer to Wiring Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 10.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

Revision: July 2005 EC-567 2006 Titan

DTC P2138 APP SENSOR

10. CHECK ACCELERATOR PEDAL POSITION SENSOR

Refer to EC-569, "Component Inspection" .

OK or NG

OK >> GO TO 12.

NG >> GO TO 11.

11. REPLACE ACCELERATOR PEDAL ASSEMBLY

1. Replace the accelerator pedal assembly.

2. Perform EC-83, "Accelerator Pedal Released Position Learning" .

3. Perform EC-83, "Throttle Valve Closed Position Learning" .

4. Perform EC-85, "Idle Air Volume Learning" .

>> INSPECTION END

12. CHECK INTERMITTENT INCIDENT

Refer to EC-150, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

>> INSPECTION END

Revision: July 2005 EC-568 2006 Titan

DTC P2138 APP SENSOR

Component Inspection UBS00NMQ

ACCELERATOR PEDAL POSITION SENSOR A

1. Reconnect all harness connectors disconnected.

2. Turn ignition switch ON.

3. Check voltage between ECM terminals 106 (APP sensor 1 sig- EC

nal), 98 (APP sensor 2 signal) and ground under the following

conditions.

C

Terminal Accelerator pedal Voltage

106 Fully released 0.5 - 1.0V

(Accelerator pedal position

sensor 1) Fully depressed 4.2 - 4.8V D

98 Fully released 0.25 - 0.5V

(Accelerator pedal position

sensor 2) Fully depressed 2.0 - 2.5V E

MBIB0023E

4. If NG, replace accelerator pedal assembly and go to next step.

5. Perform EC-83, "Accelerator Pedal Released Position Learning" .

F

6. Perform EC-83, "Throttle Valve Closed Position Learning" .

7. Perform EC-85, "Idle Air Volume Learning" .

Removal and Installation UBS00NMR G

ACCELERATOR PEDAL

Refer to ACC-3, "ACCELERATOR CONTROL SYSTEM" .

H

Revision: July 2005 EC-569 2006 Titan

You might also like

- Volvo S40 2.0d 2008 Problem - Volvo Owners Club ForumDocument4 pagesVolvo S40 2.0d 2008 Problem - Volvo Owners Club Forumalrahij8No ratings yet

- Codigod ToyotaDocument6 pagesCodigod Toyotamarquin84100% (1)

- #1-Sist. de Dirección Electrónica Kia Rio 1.4Document3 pages#1-Sist. de Dirección Electrónica Kia Rio 1.4Daniel rodriguez alayoNo ratings yet

- Sentra 2004 Inmo PDFDocument20 pagesSentra 2004 Inmo PDFtipo3331100% (2)

- P0748Document3 pagesP0748kreyhonNo ratings yet

- Cen Tech 60581 PDFDocument24 pagesCen Tech 60581 PDFLucian LeonteNo ratings yet

- MAP HeliomarDocument1 pageMAP HeliomarUbiratan LoureiroNo ratings yet

- Xtrail P2135Document9 pagesXtrail P2135Dircios100% (3)

- Coil Wiring Diagram and TestDocument1 pageCoil Wiring Diagram and TestPhyo Kyaw100% (2)

- IOT RaspberryPiDocument26 pagesIOT RaspberryPiNeet BuddiesNo ratings yet

- Nissan Versa p0118 Ect SensorDocument7 pagesNissan Versa p0118 Ect SensorDirciosNo ratings yet

- Diagnostico Parte 1 MalibuDocument161 pagesDiagnostico Parte 1 MalibuHugo Armando Escamilla LozanoNo ratings yet

- Codigo P076aDocument6 pagesCodigo P076aOscar VillaseñorNo ratings yet

- ECM PINOUT Chevrolet-Sail-1 PDFDocument2 pagesECM PINOUT Chevrolet-Sail-1 PDFJULIO OROZCONo ratings yet

- Mirage 2017Document97 pagesMirage 2017Cesar MVNo ratings yet

- Nissan Sentra ECMDocument11 pagesNissan Sentra ECMSalvador Manuel Rocha CastilloNo ratings yet

- HYUNDAI A4AF3, A4BF3 (Accent 2000-2007, Matrix 2003 ) 4 SPEED FWD With Lock Up (Electronic Control)Document4 pagesHYUNDAI A4AF3, A4BF3 (Accent 2000-2007, Matrix 2003 ) 4 SPEED FWD With Lock Up (Electronic Control)FelipeNo ratings yet

- Transfer Case OverhaulDocument223 pagesTransfer Case OverhaulMartin FilionNo ratings yet

- Actron CP9087Document88 pagesActron CP9087Saul Valerio Loyola100% (1)

- Ec Harness ConectorDocument15 pagesEc Harness ConectorHawkar SuleimanNo ratings yet

- Libro 2004 Nissan SentraDocument57 pagesLibro 2004 Nissan SentraMichael MorenoNo ratings yet

- DTC Fallas Caja Automatica OptraDocument64 pagesDTC Fallas Caja Automatica OptraFernando Jordan BarretoNo ratings yet

- Corvette C6 BCM ModulDocument12 pagesCorvette C6 BCM Modulcougar350_723411783No ratings yet

- Manual Sensor EgrDocument10 pagesManual Sensor EgrIradier JaramilloNo ratings yet

- Chery Grand Tiggo5 DiagDocument1 pageChery Grand Tiggo5 DiagAlfredo PerezNo ratings yet

- P0405-96 P0406-96 Taken From 2KD Manual - To Be CheckedDocument4 pagesP0405-96 P0406-96 Taken From 2KD Manual - To Be CheckedBiniyam BekeleNo ratings yet

- MOTOR Selectline 10 PDFDocument1 pageMOTOR Selectline 10 PDFXavier Moreno100% (1)

- Control Module X1Document3 pagesControl Module X1Data TécnicaNo ratings yet

- Fusibles Ecosport 2004 Al 2007Document4 pagesFusibles Ecosport 2004 Al 2007Adrian sarmientoNo ratings yet

- T TC014 06Document2 pagesT TC014 06mario100% (1)

- FedWorldReport PDFDocument1,177 pagesFedWorldReport PDFHugo Bañuelos100% (2)

- Diagramas ECT y AT Motor 2GR-FE Camry 2007Document16 pagesDiagramas ECT y AT Motor 2GR-FE Camry 2007Gregory MarchanNo ratings yet

- Nissan-Sentra 2017 EN Diagrama Electrico 834bbb46e3Document64 pagesNissan-Sentra 2017 EN Diagrama Electrico 834bbb46e3sisteterrNo ratings yet

- Motronic M5.9.2 Component DifferencesDocument8 pagesMotronic M5.9.2 Component DifferencesIonel AlexandruNo ratings yet

- OptraDocument37 pagesOptraMario Alfredo Castro EscobarNo ratings yet

- Diagramas Con La Funciones de Los Pines de Las ComputadorasDocument18 pagesDiagramas Con La Funciones de Los Pines de Las ComputadorasMarco Fernando Castellanos ChauranNo ratings yet

- Solenoid Valve QR512E-1707023Document3 pagesSolenoid Valve QR512E-1707023adinxNo ratings yet

- Pinout 2 F150Document1 pagePinout 2 F150Vicent JesusNo ratings yet

- Pinout N46 Bosch MEV9 ADAMO MotorsportDocument2 pagesPinout N46 Bosch MEV9 ADAMO MotorsportRaphael MangwiroNo ratings yet

- BRC Sequent - 24Document15 pagesBRC Sequent - 24Kimba PaneNo ratings yet

- 2014 Kia Forte Koup EX 2014 Kia Forte Koup EX: System Wiring Diagrams System Wiring DiagramsDocument1 page2014 Kia Forte Koup EX 2014 Kia Forte Koup EX: System Wiring Diagrams System Wiring DiagramsAndy Cevallos100% (1)

- Can Bus de Chery Orinoco M11Document2 pagesCan Bus de Chery Orinoco M11Jimmy Quise LlamoccaNo ratings yet

- DTC P0053 Ford ExplorerDocument1 pageDTC P0053 Ford ExplorerORLANDONo ratings yet

- 2002 Camaro 5.7 PCM PinoutsDocument5 pages2002 Camaro 5.7 PCM PinoutsSilvanaNo ratings yet

- Varias Señales de CAM y CRANK SincronizadasDocument21 pagesVarias Señales de CAM y CRANK SincronizadasYulys Diaz0% (1)

- 2sa2018 - SMD Marking BW4Document5 pages2sa2018 - SMD Marking BW4julio montenegro100% (1)

- Diagnostic Guideline 4F23 For Chery v1Document97 pagesDiagnostic Guideline 4F23 For Chery v1Julio Zapata100% (2)

- Schematic Diagrams: Abs Connector Input/OutputDocument2 pagesSchematic Diagrams: Abs Connector Input/Outputgerber damianNo ratings yet

- Atx FLCDocument52 pagesAtx FLCWin CardonaNo ratings yet

- Computer Data Lines CircuitDocument1 pageComputer Data Lines CircuitPedroPalotes100% (1)

- ECM PINOUT Chevrolet Sail PDFDocument2 pagesECM PINOUT Chevrolet Sail PDFoswill bravo100% (1)

- Caja de Realy OptraDocument5 pagesCaja de Realy OptraVicent JesusNo ratings yet

- Rav4 1azDocument11 pagesRav4 1azaltlwb500100% (1)

- Installation Guide: Fuller Automated Transmissions October 2007Document68 pagesInstallation Guide: Fuller Automated Transmissions October 2007Cristian Paul Bolimbo PalgaNo ratings yet

- (TM) Ssangyong Manual de Taller Ssangyong Actyon 2013 en Ingles (1) - 301-400Document100 pages(TM) Ssangyong Manual de Taller Ssangyong Actyon 2013 en Ingles (1) - 301-400LUIS HERNANDONo ratings yet

- Sephia 1995 1.6LDocument46 pagesSephia 1995 1.6Lmiguel harciaNo ratings yet

- 2019 Chevrolet Camaro V6-3.6L Vehicle Powertrain Management Diagrams Electrical - Interactive Color (Non OE) Engine Controls - Page 1 of 8Document5 pages2019 Chevrolet Camaro V6-3.6L Vehicle Powertrain Management Diagrams Electrical - Interactive Color (Non OE) Engine Controls - Page 1 of 8HelioEynerPrudencioCarreraNo ratings yet

- 2004 Nissan QuestDocument320 pages2004 Nissan QuestMarcelino LopezNo ratings yet

- 1997 Nissan Altima Owners ManualDocument203 pages1997 Nissan Altima Owners Manualacramk100% (12)

- Caja Automatica Optra Ingles-Libre 1Document50 pagesCaja Automatica Optra Ingles-Libre 1Plinio SuarezNo ratings yet

- DTC P2138 App Sensor DTC P2138 App Sensor Component DescriptionDocument9 pagesDTC P2138 App Sensor DTC P2138 App Sensor Component DescriptionAndres AriasNo ratings yet

- Engine Control System QR Service Information DTC p2138 App SensorDocument8 pagesEngine Control System QR Service Information DTC p2138 App SensorEvander Leon RoblesNo ratings yet

- DLC Circuit TroubleshootingDocument1 pageDLC Circuit TroubleshootingPhyo KyawNo ratings yet

- Inspection of Isc Valve - Toyota Supra MK3 90 RepairDocument1 pageInspection of Isc Valve - Toyota Supra MK3 90 RepairPhyo KyawNo ratings yet

- Engine ControlDocument19 pagesEngine ControlPhyo KyawNo ratings yet

- Mohsin DocumentationDocument96 pagesMohsin Documentationch.shahzad juttNo ratings yet

- Athan Setup LogDocument12 pagesAthan Setup LogSafet DaljacNo ratings yet

- How To Use and Setup Wyze V3 For Frigate Person Detection NVRDocument4 pagesHow To Use and Setup Wyze V3 For Frigate Person Detection NVRPatrick PadgettNo ratings yet

- RSM Business Process Re EngineeringDocument145 pagesRSM Business Process Re EngineeringRajendra Swarup Mathur100% (1)

- Air Span As3030Document2 pagesAir Span As3030petrosrnashNo ratings yet

- Errors in Measurements and Its Propogation PDFDocument19 pagesErrors in Measurements and Its Propogation PDFPiyush GuptaNo ratings yet

- Parallel Computing Simply in Depth by Ajit Singh PDFDocument125 pagesParallel Computing Simply in Depth by Ajit Singh PDFazuanr830No ratings yet

- Optimization of Power System Problems: Mahmoud Pesaran Hajiabbas Behnam Mohammadi-Ivatloo EditorsDocument386 pagesOptimization of Power System Problems: Mahmoud Pesaran Hajiabbas Behnam Mohammadi-Ivatloo EditorsGonzaloNo ratings yet

- Cloud AWS Systems ArchitectDocument2 pagesCloud AWS Systems Architectdhilip kumarNo ratings yet

- 80 0062 00 MO RevHDocument62 pages80 0062 00 MO RevHLeonardo Quevedo100% (1)

- Integrating Academic Excellence With Biblical: Truth Produce A God Fearing IndividualDocument23 pagesIntegrating Academic Excellence With Biblical: Truth Produce A God Fearing IndividualBenjamin Codilla Gerez, Jr.No ratings yet

- SAD Lect 3 Step1Document3 pagesSAD Lect 3 Step1Dhanushka MadhushankaNo ratings yet

- Mini Hi-Fi System: Owner'S ManualDocument40 pagesMini Hi-Fi System: Owner'S ManualNelson BarreraNo ratings yet

- Serial Num Resume Number Candidate Name Candidate Gender GraduationDocument3 pagesSerial Num Resume Number Candidate Name Candidate Gender GraduationPrakhar NigamNo ratings yet

- Lab 14: Using TSK For Network and Host: Because Teaching Teaches Teachers To TeachDocument16 pagesLab 14: Using TSK For Network and Host: Because Teaching Teaches Teachers To TeachHenry WiliamNo ratings yet

- Documentation On Machine Learning Solutions in A CarDocument71 pagesDocumentation On Machine Learning Solutions in A CarSree ReddyNo ratings yet

- Ga07 Knapsack ProblemDocument15 pagesGa07 Knapsack ProblemIoachim DipseNo ratings yet

- Powerline 500 Wifi Access PointDocument2 pagesPowerline 500 Wifi Access PointAriel Martinez NNo ratings yet

- Installation Manual: R410A Split SeriesDocument14 pagesInstallation Manual: R410A Split Serieswarick mNo ratings yet

- LSMW Inp ZPM PM MeqDocument33 pagesLSMW Inp ZPM PM MeqErBikasKumarPathakNo ratings yet

- Oracle Fusion General NotesDocument14 pagesOracle Fusion General NotesDevaraj Narayanan100% (1)

- SOLID PrinciplesDocument17 pagesSOLID PrinciplesMohaMed RebinNo ratings yet

- TULUNanDocument11 pagesTULUNanIven Rey B. TañaraNo ratings yet

- Screenshot 2024-01-25 at 11.47.33 AMDocument46 pagesScreenshot 2024-01-25 at 11.47.33 AM8b6m8fvnrvNo ratings yet

- BiosDocument70 pagesBiosMatias MasterNo ratings yet

- MSME DataBankDocument2 pagesMSME DataBankburadasateeshNo ratings yet

- Integration Points Project Management and Accounting and Other AX 2012 ModulesDocument12 pagesIntegration Points Project Management and Accounting and Other AX 2012 Modulessantosh tripathiNo ratings yet

- Gaussian OptimizationDocument8 pagesGaussian OptimizationMark Cliffton BadlonNo ratings yet