SSH/14040/Main Contract Works 099600 / 1 Document III High-Performance Coatings

SSH/14040/Main Contract Works 099600 / 1 Document III High-Performance Coatings

Uploaded by

Hussain GodhrawalaCopyright:

Available Formats

SSH/14040/Main Contract Works 099600 / 1 Document III High-Performance Coatings

SSH/14040/Main Contract Works 099600 / 1 Document III High-Performance Coatings

Uploaded by

Hussain GodhrawalaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

SSH/14040/Main Contract Works 099600 / 1 Document III High-Performance Coatings

SSH/14040/Main Contract Works 099600 / 1 Document III High-Performance Coatings

Uploaded by

Hussain GodhrawalaCopyright:

Available Formats

SECTION 099600

HIGH-PERFORMANCE COATINGS

PART 1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and

Supplementary Conditions and Division 01 Specification Sections, apply to

this Section.

1.2 SUMMARY

A. Section includes surface preparation and the application of high-

performance coating systems not limited to following substrates:

1. Exterior Substrates:

a. Concrete, vertical and horizontal surfaces.

b. Concrete masonry units (CMUs).

c. Steel.

d. Galvanized metal.

e. Portland cement plaster (stucco).

2. Interior Substrates:

a. Concrete, vertical and horizontal surfaces.

b. Concrete masonry units (CMUs).

c. Steel.

d. Galvanized metal.

e. Wood.

f. Gypsum board.

g. Plaster.

B. Related Requirements:

1. Section 051200 "Structural Steel Framing" for shop priming of

structural steel with primers specified in this Section.

2. Section 055213 "Pipe and Tube Railings" for shop priming pipe and

tube railings with coatings specified in this Section.

3. Section 099113 "Exterior Painting" for general field painting.

4. Section 099123 "Interior Painting" for general field painting.

1.3 REFERENCES

A. The minimum standards for products specified in this section shall be

including as under but not limited to the following. Except as otherwise

SSH/14040/Main Contract Works 099600 / 1 Document III

High-Performance Coatings

specified herein, perform work in accordance with specifications, codes and

standards cited therein, and their latest editions, revisions, applicable

addenda and supplements. Where there is conflict between the referenced

standards the most stringent of the conditions/requirements shall be

applicable.

B. American Society of Testing and Materials:

1. ASTM D 523 - Standard Test Method for Specular Gloss.

2. ASTM C 672 - Standard Test Methods for Scaling

Resistance of Concrete Surfaces Exposed to

Deicing Chemicals.

3. ASTM D 412 - Standard Test Method for Vulcanised Rubber,

Thermoplastic Rubber and Thermoplastic

Elastromers for Elongation.

4. ASTM D 653 - Standard Test Methods for Water Vapour

Transmission of Organic Coating Films.

C. British Standard

1. BS 476-7 - Fire Tests on Building Materials and

Structures. Methods of test to determine the

classification of the surface spread of flame of

products.

2. BS EN ISO 12944 - Corrosion protection of steel structures by

protective paint systems

D. Surface Preparation Standards

1. SSPC – SP1 - Solvent Cleaning: Society for Protective

Coatings.

2. SSPC – SP2 - Hand Tool Cleaning: Society for Protective

Coatings.

3. SSPC – SP3 - Power Tool Cleaning: Society for Protective

Coatings.

4. SSPC – SP6 - Commercial Blast Cleaning Procedures.

5. SSPC – SP10 - Near White Blast Cleaning Procedure.

E. All applicable local codes, regulations, etc of Authorities having Jurisdiction.

Note: Contractor shall note that he shall keep copies of all of the referenced

standards on the site and shall provide the Engineer copy of the

requested referenced standards as and when requested.

SSH/14040/Main Contract Works 099600 / 2 Document III

High-Performance Coatings

1.4 DEFINITIONS

A. MPI Gloss Level 5: 35 to 70 units at 60 degrees, according to ASTM D 523.

B. MPI Gloss Level 6: 70 to 85 units at 60 degrees, according to ASTM D 523.

C. MPI Gloss Level 7: More than 85 units at 60 degrees, according to

ASTM D 523.

1.5 ACTION SUBMITTALS

A. Product Data: For each type of product. Include preparation requirements

and application instructions.

1. Include printout of current "MPI Approved System" for each product

category of substrates specified.

2. Indicate VOC content.

B. Samples for Initial Selection: For each type of topcoat product indicated.

C. Samples for Verification: For each type of coating system and each color

and gloss of topcoat indicated.

1. Submit Samples on rigid backing, 200 mm square.

2. Apply coats on Samples in steps to show each coat required for

system.

3. Label each coat of each Sample.

4. Label each Sample for location and application area.

D. Product List: Cross-reference to coating system and locations of application

areas. Use same designations indicated on Drawings and in schedules.

Include color designations.

1.6 MAINTENANCE MATERIAL SUBMITTALS

A. Furnish extra materials, from the same product run, that match products

installed and that are packaged with protective covering for storage and

identified with labels describing contents.

1. Coatings: 5 percent, but not less than 3.8 L of each material and color

applied.

1.7 QUALITY ASSURANCE

A. Coverage Rate: for liquid applied coatings, calculate the quantity of material

needed for the work in accordance with manufacturer’s printed instructions.

Submit calculations for Engineer’s approval. Divide the areas to be coated

and allocate the appropriate quantity of coating material for each area.

SSH/14040/Main Contract Works 099600 / 3 Document III

High-Performance Coatings

B. Mockups: Apply mockups of each coating system indicated to verify

preliminary selections made under Sample submittals and to demonstrate

aesthetic effects and set quality standards for materials and execution.

1. Engineer will select one surface to represent surfaces and conditions

for application of each coating system.

a. Wall and Ceiling Surfaces: Provide samples of at least 10 sq. m.

b. Other Items: Engineer will designate items or areas required.

2. Final approval of color selections will be based on mockups.

a. If preliminary color selections are not approved, apply additional

mockups of additional colors selected by Engineer at no added

cost to Owner.

3. Approval of mockups does not constitute approval of deviations from

the Contract Documents contained in mockups unless Engineer

specifically approves such deviations in writing.

4. Subject to compliance with requirements, approved mockups may

become part of the completed Work if undisturbed at time of

Substantial Completion.

1.8 DELIVERY, STORAGE, AND HANDLING

A. Store materials not in use in tightly covered containers in well-ventilated

areas with ambient temperatures continuously maintained at not less than 7

deg C.

1. Maintain containers in clean condition, free of foreign materials and

residue.

2. Remove rags and waste from storage areas daily.

1.9 FIELD CONDITIONS

A. Apply coatings only when temperature of surfaces to be coated and ambient

air temperatures are between 10 and 35 deg C.

B. Do not apply coatings when relative humidity exceeds 85 percent; at

temperatures less than 3 deg C above the dew point; or to damp or wet

surfaces.

C. Do not apply exterior coatings in rain, fog, or mist.

1.10 WARRANTY

A. General Warranty: The special warranty specified in this Article shall not

deprive the Employer of other rights the Employer may have under other

provisions of the Contract Documents and shall be in addition to, and run

SSH/14040/Main Contract Works 099600 / 4 Document III

High-Performance Coatings

concurrent with, other warranties made by the Contractor under

requirements of the Contract Documents.

B. Warranty in accordance with MPI Painting Manual requirements shall

warrant that all painting work has been performed in accordance with MPI

Painting Manual requirements. Contractor and Manufacturer are jointly and

severally liable and shall repair or replace paint coatings that fail within the

specified warranty period. Contractor and Manufacturer shall reimburse the

Employer for the cost of material and labor. Failures include, but are not

limited to:

1. Peeling or blistering of paint film.

2. Cracking of pain film.

3. Crazing of pain film

4. Efflorescence.

5. Change in colour.

6. Staining.

7. Patchiness of sheen or colour.

C. Warranty Period for Paint Coatings: 5 years from the date of Substantial

Completion.

D. Warranty Period for Structural Steel Paint Coatings: Twenty (20) years from

the date of Substantial Completion life till first maintenance.

PART 2 - PRODUCTS

2.1 MANUFACTURERS

A. Products: Subject to compliance with requirements, available products that

may be incorporated into the Work include, the following manufacturers

(though not limited to) are acceptable and products listed in the Exterior High-

Performance Coating Schedule or Interior High-Performance Coating

Schedule for the coating category indicated.

1. Jotun Paints

Tel: 2228 0699

2. Hempel Paint

Tel: 2481 3366

3. GTC Paint Co. Ltd.

Tel: 2484 6550

4. Kuwait Paint Company

Tel: 2483 2557

5. MPC Paints

Tel: 24814025/6

SSH/14040/Main Contract Works 099600 / 5 Document III

High-Performance Coatings

6. Sigma Paints

2.2 PAINT, GENERAL

A. MPI Standards: The minimum performance requirements for the products

specified in this specification section are MPI standards. All Products for

which MPI standards are specified shall comply with the respective MPI

standard for that product. Contractor shall provide necessary evidence from

the paint manufacturer, to the Engineer to confirm that the products he is

supplying on the project comply with all MPI requirements for that product.

Contractor however need not provide any MPI certificate for the products he

is supplying on the project.

2.3 HIGH-PERFORMANCE COATINGS, GENERAL

A. General

1. All paint materials shall have good flowing and brushing properties and

shall dry or cure free of blemishes, sags, air entrapment, etc.

2. Where required, paints and coatings shall meet flame spread and

smoke developed ratings designated by local authorities.

B. Equipment

1. Painting and Decorating Equipment: to best trade standards for type of

product and application.

2. Spray Painting Equipment: of ample capacity, suited to the type and

consistency of paint or coating being applied and kept clean and in

good working order at all times.

C. Mixing and Tinting

1. Unless otherwise specified herein or pre-approved, all paint shall be

ready-mixed and pre-tinted. Re-mix all paint in containers prior to and

during application to ensure break-up of lumps, complete dispersion of

settled pigment, and color and gloss uniformity.

2. Paste, powder or catalyzed paint mixes shall be mixed in strict

accordance with manufacturer's written instructions.

3. Where thinner is used, addition shall not exceed paint manufacturer's

recommendations. Do not use kerosene or any such organic solvents

to thin water-based paints.

4. If required, thin paint for spraying according in strict accordance with

paint manufacturer's instructions. If directions are not on container,

obtain instructions in writing from manufacturer and provide copy of

instructions to Consultant.

D. Material Compatibility:

1. Materials for use within each paint system shall be compatible with one

another and substrates indicated, under conditions of service and

SSH/14040/Main Contract Works 099600 / 6 Document III

High-Performance Coatings

application as demonstrated by manufacturer, based on testing and

field experience.

2. For each coat in a paint system, products shall be recommended in

writing by topcoat manufacturers for use in paint system and on

substrate indicated.

3. Products shall be of same manufacturer for each coat in a coating

system.

E. VOC Content: Provide materials that comply with VOC limits of authorities

having jurisdiction.

F. Colors: Unless otherwise indicated as selected by Engineer from

manufacturer's full range.

2.4 BLOCK FILLERS

A. Block Filler, Latex, Interior/Exterior: MPI#4.

1. A waterborne, high solids, emulsion type pigmented coating with

bridging and filling properties for interior or exterior concrete masonry

units, for the purpose of filling the surface for subsequent applications

of paint. Application by brush, roller or airless spray. Rolling or

backrolling must be done to ensure proper filling of voids.

B. Block Filler, Epoxy : MPI #116.

1. A solvent based, two component, epoxy, high solids coating for

unfilled, interior and exterior block surfaces that are to be coated with a

chemically resistant finish. Resistant to water, alkalis, chemicals and

solvents. Application is predominantly by roller or brush.

2.5 INTERIOR PRIMERS/SEALERS

A. Primer/Sealer, Latex, Interior: MPI #50.

1. White, pigmented, waterborne latex sealer used on new interior plaster,

concrete and gypsum wallboard surfaces that are subsequently painted

with latex or alkyd finish coat(s). It shall reduce the porosity of the

substrate for finish coats. Do not use on wood or previously painted

surfaces

B. Interior Alkyd Primer/ Sealer: MPI #45

1. Solvent based alkyd type, pigmented primer/sealer for new interior

wood, plaster and porous surfaces, and also for areas previously

painted with flat paints. Use for new and repainting work in residential

and commercial buildings. Topcoats specified with this sealer include

conventional alkyd and latex paints. Application methods include

brushes, rollers, and airless and conventional spray equipment.

SSH/14040/Main Contract Works 099600 / 7 Document III

High-Performance Coatings

C. Wood- Knot Sealer: White shellac or other sealer recommended in writing by

manufacturer for this purpose.

2.6 METAL PRIMERS

A. Primer, Zinc-Rich, Inorganic: MPI #19.

1. Inorganic based anticorrosive primer for steel that is exposed to severe

industrial or marine environments. For exterior exposures, use an

epoxy intermediate coat with an aliphatic polyurethane finish (MPI #72)

to maximize service life. Recommended surface preparation is SSPC

SP 10 near White Blast for most applications and SSPC SP 5 White

Metal Blast for aggressive industrial and marine locations. Application

methods will primarily be airless and conventional spray equipment, but

brushes or rollers may be used for small detail or touch-up work.

B. Primer, Epoxy, Anti-Corrosive, for galvanized metal: MPI #101.

1. Solvent based, two component, epoxy - polyamide type, anticorrosive

primer for exterior and interior, ferrous and galvanized metal surfaces.

Specified for use over new, cleaned metals and as a spot primer or full

coat over previous epoxy coatings that have been properly prepared

with hand, power tool or abrasive blasting cleaning methods.

Application methods will include using brushes, rollers, and airless and

conventional spray.

2.7 WOOD PRIMERS AND STAINS

A. Primer Sealer, Alkyd, Interior, MPI # 45.

1. Solvent based, alkyd type, pigmented primer/sealer for new interior

wood, plaster and porous surfaces, and also for areas previously

painted with flat paints. . Application methods include brushes, rollers,

and airless and conventional spray equipment

2.8 EPOXY COATINGS

A. Epoxy, Gloss: MPI #77.

1. Solvent based, gloss, two-component epoxy/polyamide coating

specified for wall and floor surfaces in moderate to heavy traffic

commercial and moderate industrial environments. It shall be resistant

to incidental splash and spillage of dilute (5%) sulfuric acid, (15%)

hydrochloric acid, (20%) sodium hydroxide, gasoline and heavy duty

cleaners and detergents. Use as a self-priming material on smooth, low

porosity concrete, masonry and wood surfaces. This epoxy shall be

suitable for application at temperatures ranging from 15 to 40 degrees

C and a maximum relative humidity of 80%. Application is generally by

spray, but in areas where spray is impractical, a brush or roller may be

SSH/14040/Main Contract Works 099600 / 8 Document III

High-Performance Coatings

used.

B. Epoxy, High-Build, Low Gloss: MPI #108.

1. Two component epoxy, high solids, low gloss coating for use on interior

or exterior concrete, masonry and primed metal surfaces. Metal

surfaces may be primed with conventional epoxy primers, epoxy zinc

rich primers or inorganic zinc rich primers. For increased durability, this

product may be top coated with epoxy or polyurethane enamels.

2.9 POLYURETHANE COATINGS

A. Polyurethane, Two-Component, Pigmented, Gloss (Gloss Level 6):

MPI #72.

1. Solvent based, two-component polyurethane, pigmented coating with a

gloss finish for interior or exterior brick, block, concrete, plaster, wood

and metal surfaces, where abrasion, weathering, chemical and solvent

resistance is required. Primarily applied by spray, but can be applied by

brush or roller in small areas.

2.10 SOURCE QUALITY CONTROL

A. Testing of Coating Materials: Owner reserves the right to invoke the

following procedure:

1. Owner will engage the services of a qualified testing agency to sample

coating materials. Contractor will be notified in advance and may be

present when samples are taken. If coating materials have already

been delivered to Project site, samples may be taken at Project site.

Samples will be identified, sealed, and certified by testing agency.

2. Testing agency will perform tests for compliance with product

requirements.

3. Owner may direct Contractor to stop applying coatings if test results

show materials being used do not comply with product requirements.

Contractor shall remove noncomplying coating materials from Project

site, pay for testing, and recoat surfaces coated with rejected materials.

Contractor will be required to remove rejected materials from

previously coated surfaces if, on recoating with complying materials,

the two coatings are incompatible.

PART 3 - EXECUTION

3.1 EXAMINATION

A. Examine substrates and conditions, with Applicator present, for compliance

with requirements for maximum moisture content and other conditions

affecting performance of the Work.

SSH/14040/Main Contract Works 099600 / 9 Document III

High-Performance Coatings

B. Maximum Moisture Content of Substrates: When measured with an

electronic moisture meter as follows:

1. Concrete: 12 percent.

2. Masonry (CMUs): 12 percent.

3. Wood: 15 percent.

4. Gypsum Board: 12 percent.

5. Plaster: 12 percent.

C. Gypsum Board Substrates: Verify that finishing compound is sanded

smooth.

D. Plaster Substrates: Verify that plaster is fully cured.

E. Verify suitability of substrates, including surface conditions and compatibility,

with existing finishes and primers.

F. Proceed with coating application only after unsatisfactory conditions have

been corrected.

1. Application of coating indicates acceptance of surfaces and conditions.

3.2 PREPARATION

A. Comply with manufacturer's written instructions and recommendations in

"MPI Architectural Painting Specification Manual" applicable to substrates

and coating systems indicated.

B. Remove hardware, covers, plates, and similar items already in place that are

removable and are not to be painted. If removal is impractical or impossible

because of size or weight of item, provide surface-applied protection before

surface preparation and painting.

1. After completing painting operations, use workers skilled in the trades

involved to reinstall items that were removed. Remove surface-applied

protection if any.

C. Clean substrates of substances that could impair bond of coatings, including

dust, dirt, oil, grease, and incompatible paints and encapsulants.

1. Remove incompatible primers and reprime substrate with compatible

primers or apply tie coat as required to produce coating systems

indicated.

D. Concrete Substrates: Remove release agents, curing compounds,

efflorescence, and chalk. Do not coat surfaces if moisture content or

alkalinity of surfaces to be coated exceeds that permitted in manufacturer's

written instructions.

1. Clean surfaces with pressurized water. Use pressure range of 10 350

to 27 580 kPa at 150 to 300 mm.

SSH/14040/Main Contract Works 099600 / 10 Document III

High-Performance Coatings

2. Abrasive blast clean surfaces to comply with SSPC-SP 7/NACE No. 4.

E. Masonry Substrates: Remove efflorescence and chalk. Do not coat surfaces

if moisture content, alkalinity of surfaces, or alkalinity of mortar joints

exceeds that permitted in manufacturer's written instructions.

1. Clean surfaces with pressurized water. Use pressure range of 690 to

4140 kPa at 150 to 300 mm.

F. Steel Substrates: Remove rust, loose mill scale, and shop primer if any.

Clean using methods recommended in writing by paint manufacturer[.] but

not less than the following:

1. SSPC-SP 7/NACE No. 4, "Brush-Off Blast Cleaning."

2. SSPC-SP 11, "Power Tool Cleaning to Bare Metal."

3. SSPC-SP 6/NACE No. 3, "Commercial Blast Cleaning."

4. SSPC-SP 10/NACE No. 2, "Near-White Blast Cleaning."

5. SSPC-SP 5/NACE No. 1, "White Metal Blast Cleaning."

G. Shop-Primed Steel Substrates: Clean field welds, bolted connections, and

areas where shop paint is abraded. Paint exposed areas with the same

material as used for shop priming to comply with SSPC-PA 1 for touching up

shop-primed surfaces.

H. Galvanized-Metal Substrates: Remove grease and oil residue from

galvanized sheet metal by mechanical methods to produce clean, lightly

etched surfaces that promote adhesion of subsequently applied coatings.

I. Aluminum Substrates: Remove loose surface oxidation.

J. Wood Substrates:

1. Scrape and clean knots. Before applying primer, apply coat of knot

sealer that is recommended in writing by topcoat manufacturer for

coating system indicated.

2. Sand surfaces that will be exposed to view and dust off.

3. Prime edges, ends, faces, undersides, and backsides of wood.

4. After priming, fill holes and imperfections in the finish surfaces with filler

that is recommended in writing by topcoat manufacturer for coating

system indicated. Sand smooth when dried.

3.3 APPLICATION

A. Apply high-performance coatings according to manufacturer's written

instructions and recommendations in "MPI Architectural Painting

Specification Manual."

1. Use applicators and techniques suited for coating and substrate

indicated.

SSH/14040/Main Contract Works 099600 / 11 Document III

High-Performance Coatings

2. Coat surfaces behind movable equipment and furniture same as similar

exposed surfaces. Before final installation, coat surfaces behind

permanently fixed equipment or furniture with prime coat only.

3. Coat backsides of access panels, removable or hinged covers, and

similar hinged items to match exposed surfaces.

4. Do not apply coatings over labels of independent testing agencies or

equipment name, identification, performance rating, or nomenclature

plates.

B. Tint each undercoat a lighter shade to facilitate identification of each coat if

multiple coats of the same material are to be applied. Tint undercoats to

match color of finish coat, but provide sufficient difference in shade of

undercoats to distinguish each separate coat.

C. If undercoats or other conditions show through final coat, apply additional

coats until cured film has a uniform coating finish, color, and appearance.

D. Apply coatings to produce surface films without cloudiness, spotting,

holidays, laps, brush marks, runs, sags, ropiness, or other surface

imperfections. Produce sharp glass lines and color breaks.

3.4 FIELD QUALITY CONTROL

A. Dry Film Thickness Testing: Owner may engage the services of a qualified

testing and inspecting agency to inspect and test coatings for dry film

thickness.

1. Contractor shall touch up and restore coated surfaces damaged by

testing.

2. If test results show that dry film thickness of applied coating does not

comply with coating manufacturer's written recommendations,

Contractor shall pay for testing and apply additional coats as needed to

provide dry film thickness that complies with coating manufacturer's

written recommendations.

3.5 CLEANING AND PROTECTION

A. At end of each workday, remove rubbish, empty cans, rags, and other

discarded materials from Project site.

B. After completing coating application, clean spattered surfaces. Remove

spattered coatings by washing, scraping, or other methods. Do not scratch

or damage adjacent finished surfaces.

C. Protect work of other trades against damage from coating operation. Correct

damage to work of other trades by cleaning, repairing, replacing, and

recoating, as approved by Engineer, and leave in an undamaged condition.

D. At completion of construction activities of other trades, touch up and restore

damaged or defaced coated surfaces.

SSH/14040/Main Contract Works 099600 / 12 Document III

High-Performance Coatings

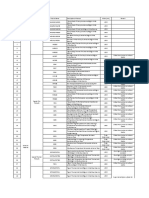

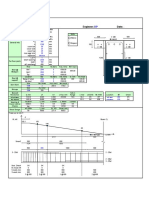

3.6 EXTERIOR HIGH-PERFORMANCE COATING SCHEDULE

A. Concrete Substrates, Vertical Surfaces:

1. Pigmented Polyurethane over epoxy, MPI EXT 3.1M:

a. Prime Coat: Epoxy, cold-cured, gloss, MPI #77.

b. Intermediate Coat: Epoxy, cold-cured, gloss, MPI #77.

c. Topcoat: polyurethane, two component solvent based,

pigmented, MPI #72.

B. Concrete Substrates, Horizontal Surfaces:

1. For horizontal surfaces with vehicular traffic refer to division 07, Section

“Traffic Coating”

C. Steel Substrates (Including Structural Steel):

1. Pigmented Polyurethane over Inorganic Zinc-Rich Primer and High-

Build Epoxy System, MPI EXT 5.1L:

a. Prime Coat: Primer, zinc-rich, inorganic, MPI #19.

b. Intermediate Coat: Epoxy, high-build, low gloss, MPI #108.

c. Topcoat: Polyurethane, two-component, pigmented, gloss (Gloss

Level 6), MPI #72.

a. Second Topcoat: Polyurethane, two-component, pigmented,

gloss (Gloss Level 6), MPI #72.

D. Galvanized-Metal Substrates:

1. Pigmented Polyurethane System, MPI EXT 5.3L:

a. Prime Coat: Primer, epoxy, anti-corrosive, for metal, MPI #101.

b. Intermediate Coat: Polyurethane, two-component, pigmented,

gloss (Gloss Level 6), MPI #72.

c. Topcoat: Polyurethane, two-component, pigmented, gloss (Gloss

Level 6), MPI #72.

3.7 INTERIOR HIGH-PERFORMANCE COATING SCHEDULE

A. Concrete Substrates, Vertical Surfaces:

1. Epoxy System, MPI INT 3.1C:

a. Prime Coat: Epoxy, gloss, MPI #77.

b. Intermediate Coat: Epoxy, gloss, MPI #77.

c. Topcoat: Epoxy, gloss, MPI #77.

B. Concrete Substrates, Horizontal Surfaces.

SSH/14040/Main Contract Works 099600 / 13 Document III

High-Performance Coatings

1. For horizontal surfaces with vehicular traffic refer to division 07, Section

“Traffic Coating”.

2. Epoxy System, MPI INT 3.2C:

a. Prime Coat: Epoxy, gloss, MPI #77.

b. Intermediate Coat: Epoxy, gloss, MPI #77.

c. Topcoat: Epoxy, gloss, MPI #77.

C. CMU Substrates:

1. Epoxy System, MPI INT 4.2F:

a. Block Filler: Block filler, latex, interior/exterior, MPI #4.

b. Intermediate Coat: Epoxy, gloss, MPI #77.

c. Topcoat: Epoxy, gloss, MPI #77.

D. Steel Substrates (Including Structural Steel):

1. High-Build Epoxy System, MPI INT 5.1P:

a. Prime Coat: Primer, zinc-rich, epoxy, MPI #20.

b. Intermediate Coat: Epoxy, high-build, low gloss, MPI #108.

c. Topcoat: Epoxy, high-build, low gloss, MPI #108.

E. Galvanized-Metal Substrates:

1. Epoxy System, MPI INT 5.3D:

a. Prime Coat: Primer, epoxy, anti-corrosive, for metal, MPI #101.

b. Intermediate Coat: Epoxy, gloss, MPI #77.

c. Topcoat: Epoxy, gloss, MPI #77.

2. Pigmented Polyurethane System:

a. Prime Coat: Primer, epoxy, as recommended in writing by

topcoat manufacturer.

b. Intermediate Coat: Polyurethane, two-component, pigmented,

gloss (Gloss Level 6), MPI #72.

c. Topcoat: Polyurethane, two-component, pigmented, gloss (Gloss

Level 6), MPI #72.

F. Gypsum Board and Plaster Substrates:

1. Epoxy System, MPI INT 9.2E:

a. Prime Coat: Primer sealer, latex, interior, MPI #50.

b. Intermediate Coat: Epoxy, gloss, MPI #77.

c. Topcoat: Epoxy, gloss, MPI #77.

END OF SECTION

SSH/14040/Main Contract Works 099600 / 14 Document III

High-Performance Coatings

You might also like

- Purpose: Method Statement - Raised Access Flooring / Cavity FlooringDocument7 pagesPurpose: Method Statement - Raised Access Flooring / Cavity Flooringajit karandikar100% (1)

- SECTION 09 96 00 High Performance Coatings GeneralDocument8 pagesSECTION 09 96 00 High Performance Coatings Generalraja qammarNo ratings yet

- 2260Document16 pages2260rayNo ratings yet

- Construction Painting Short VersionDocument17 pagesConstruction Painting Short Versionjack.simpson.changNo ratings yet

- SECTION 07 8123 Intumescent Fireproofing Part 1 General 1.01 Section IncludesDocument4 pagesSECTION 07 8123 Intumescent Fireproofing Part 1 General 1.01 Section IncludesStephen KokoNo ratings yet

- prEN 1555 - 2 - EDocument18 pagesprEN 1555 - 2 - ETeodosio ZapanaNo ratings yet

- 09 91 00 PDFDocument17 pages09 91 00 PDFSyed mohammed rasikNo ratings yet

- High PerformanceDocument12 pagesHigh PerformanceAhmed hafezNo ratings yet

- Resin Epoxy SpecsDocument4 pagesResin Epoxy Specsmanpower.ccorecoNo ratings yet

- Polyurethane Coating Specification Steel PipeDocument11 pagesPolyurethane Coating Specification Steel PipeDaniel Barni HulbertNo ratings yet

- 09 91 00 PaintingDocument16 pages09 91 00 PaintingWagih NabihNo ratings yet

- Section 09910 PaintingDocument13 pagesSection 09910 PaintingMØhãmmed ØwięsNo ratings yet

- Painting For Structural Steel: SECTION 09972Document8 pagesPainting For Structural Steel: SECTION 09972kuganNo ratings yet

- Polyurethane Lining and Coating Specification Water Welded JointsDocument12 pagesPolyurethane Lining and Coating Specification Water Welded JointsSurajit SahaNo ratings yet

- Related SpecsDocument13 pagesRelated SpecsAhmed GhariebNo ratings yet

- Paint SpecDocument6 pagesPaint SpechuasNo ratings yet

- Section 09680 CarpetDocument7 pagesSection 09680 CarpetMØhãmmed ØwięsNo ratings yet

- Project Specification: Exterior PaintingDocument6 pagesProject Specification: Exterior PaintingSoumojit SamantaNo ratings yet

- Joint Sealants - MSTDocument9 pagesJoint Sealants - MSTwafikmh4No ratings yet

- Caltrain Standard Section 9900 Painting and CoatingDocument9 pagesCaltrain Standard Section 9900 Painting and CoatingVincent DiepNo ratings yet

- Section 230713 - Duct InsulationDocument7 pagesSection 230713 - Duct Insulationmattar2007No ratings yet

- Gypsum Board SpecDocument5 pagesGypsum Board SpecAbdul LatheefNo ratings yet

- 23 07 13 Duct InsulationDocument11 pages23 07 13 Duct InsulationSaif SaadNo ratings yet

- Section 09720 Wall CoveringsDocument4 pagesSection 09720 Wall CoveringsMØhãmmed ØwięsNo ratings yet

- Wood DeckingDocument4 pagesWood DeckingDee Jay VillanuevaNo ratings yet

- Section 078200 - Board FireproofingDocument5 pagesSection 078200 - Board FireproofingWENDING HUNo ratings yet

- Section 09900Document15 pagesSection 09900Im ChinithNo ratings yet

- Section 035440 - Cement-Based ScreedDocument11 pagesSection 035440 - Cement-Based ScreedWENDING HUNo ratings yet

- 01/31/2018 DESIGN No. 016626 SECTION 03733 Concrete Repair Work Part 1 - General 1.01 Description of WorkDocument13 pages01/31/2018 DESIGN No. 016626 SECTION 03733 Concrete Repair Work Part 1 - General 1.01 Description of WorkDino HodzicNo ratings yet

- SECTION 09900 PaintingDocument11 pagesSECTION 09900 PaintingEng CivilNo ratings yet

- Section 03050-Concrete Materials and Methods - R3Document19 pagesSection 03050-Concrete Materials and Methods - R3MØhãmmed ØwięsNo ratings yet

- Section 07920 Joint SealantsDocument7 pagesSection 07920 Joint SealantsMØhãmmed ØwięsNo ratings yet

- SECTION 07 24 00 Exterior Insulation and Finish SystemsDocument12 pagesSECTION 07 24 00 Exterior Insulation and Finish SystemsJuanPaoloYbañezNo ratings yet

- Exterior Painting With MPIDocument9 pagesExterior Painting With MPIPachara ChomchalaoNo ratings yet

- Construction PaintingDocument21 pagesConstruction Paintingjack.simpson.changNo ratings yet

- Spec 079219 - Acoustical Joint SealantsDocument5 pagesSpec 079219 - Acoustical Joint Sealantsداروین پرزNo ratings yet

- Section 07141 Cold Fluid Applied WaterproofingDocument6 pagesSection 07141 Cold Fluid Applied WaterproofingMØhãmmed ØwięsNo ratings yet

- Special Provision To Specal Specification Marine StructuresDocument47 pagesSpecial Provision To Specal Specification Marine StructuresRodolfoMarínNo ratings yet

- 03930-Concrete Repair-Rev.0 PDFDocument16 pages03930-Concrete Repair-Rev.0 PDFMithun UdayanarayanaNo ratings yet

- Section 09940 METAL PAINTINGDocument14 pagesSection 09940 METAL PAINTINGIm ChinithNo ratings yet

- Spec 092400 (Plastering Works)Document11 pagesSpec 092400 (Plastering Works)Ayman BadrNo ratings yet

- Project Standard Specification: Duct Insulation 15081 - Page 1/11Document11 pagesProject Standard Specification: Duct Insulation 15081 - Page 1/11adel rihanaNo ratings yet

- Key IWS CoatingDocument6 pagesKey IWS Coatingfaisal hanifNo ratings yet

- Trespa Section Phenolic Wall PanelsDocument5 pagesTrespa Section Phenolic Wall PanelsJura OkrešaNo ratings yet

- Volume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Document8 pagesVolume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Ahmad Saadeldin100% (1)

- SECTION 07180 Traffic Coatings Part 1 General: 1 Inch 4 by 8 InchesDocument6 pagesSECTION 07180 Traffic Coatings Part 1 General: 1 Inch 4 by 8 InchesMoath AlhajiriNo ratings yet

- Section 32 1716 Manufactured Traffic-Calming DevicesDocument3 pagesSection 32 1716 Manufactured Traffic-Calming DevicesAnees RahmanNo ratings yet

- 09 9100 PainitingDocument13 pages09 9100 PainitingMohammed FasilNo ratings yet

- Specification For Painting-Piping & EquipmentDocument21 pagesSpecification For Painting-Piping & EquipmentAlvin Smith100% (2)

- CTEM Sheet Membrane WaterproofingDocument18 pagesCTEM Sheet Membrane WaterproofingHamza MamiNo ratings yet

- Insulation SpecsDocument13 pagesInsulation SpecsMuhammad GoudaNo ratings yet

- 04 22 23.13couDocument9 pages04 22 23.13couAlfredo Robles GonzalezNo ratings yet

- Va 09 51 00Document16 pagesVa 09 51 00Hana KaedeNo ratings yet

- Specification Beneath Slab Gas Vapor BarrierDocument5 pagesSpecification Beneath Slab Gas Vapor BarrierBaugh Graphic Design100% (1)

- 096723-Resinous Floor SpecsDocument7 pages096723-Resinous Floor SpecsGhayas JawedNo ratings yet

- CsiDocument9 pagesCsiyamanta_rajNo ratings yet

- Section 09220 Portland Cement PlasterDocument9 pagesSection 09220 Portland Cement PlasterMØhãmmed ØwięsNo ratings yet

- Metal Roofing Master SpecificationDocument11 pagesMetal Roofing Master Specificationnick.lee0602No ratings yet

- Epoxy Floor Scope of Work and Specifications Bid - Fy170058Document9 pagesEpoxy Floor Scope of Work and Specifications Bid - Fy170058Bishop GilbertNo ratings yet

- Barrisol SpecificationDocument4 pagesBarrisol SpecificationAdhi DharmaNo ratings yet

- Section - 03 35 00 - Polished Concrete FinishingDocument4 pagesSection - 03 35 00 - Polished Concrete FinishingEliseo LagmanNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Building Regulations in KuwaitDocument10 pagesBuilding Regulations in KuwaitHussain GodhrawalaNo ratings yet

- Material Inspection Request (MIR) : Project Title Engineer Contract No. Contractor IR Number Revision DateDocument1 pageMaterial Inspection Request (MIR) : Project Title Engineer Contract No. Contractor IR Number Revision DateHussain GodhrawalaNo ratings yet

- KIMMCO ISOVER-TDS-COMFORT SA Slab 100Document2 pagesKIMMCO ISOVER-TDS-COMFORT SA Slab 100Hussain Godhrawala100% (2)

- Techdata Index HG-merged-merged WITH APPROVALS - Pagenumber PDFDocument69 pagesTechdata Index HG-merged-merged WITH APPROVALS - Pagenumber PDFHussain GodhrawalaNo ratings yet

- Method Statement KOM HG - 01Document15 pagesMethod Statement KOM HG - 01Hussain GodhrawalaNo ratings yet

- CV For Project EngineerDocument2 pagesCV For Project EngineerHussain GodhrawalaNo ratings yet

- Thomas Cook Thailand PackageDocument10 pagesThomas Cook Thailand PackageHussain GodhrawalaNo ratings yet

- CatalogueDocument3 pagesCatalogueChristian AlmengorNo ratings yet

- Standards: European Standard EN 10025Document4 pagesStandards: European Standard EN 10025Ishwarya SrikanthNo ratings yet

- Prefab CONSTRUCTIONDocument47 pagesPrefab CONSTRUCTIONAnushka KhatriNo ratings yet

- Data Sheets Metaltite Metal Seated Ball Valves Data Sheet KTM en en 5196424Document12 pagesData Sheets Metaltite Metal Seated Ball Valves Data Sheet KTM en en 5196424molinachNo ratings yet

- Sika PDS E Sika CrackstopDocument2 pagesSika PDS E Sika Crackstoplwin_oo2435No ratings yet

- HDPE Tender DocumentDocument4 pagesHDPE Tender Documentabhijithaval100% (1)

- All QuestionDocument38 pagesAll QuestionEhsan KhanNo ratings yet

- Heat Treatment: YSS Cold Work Tool Steel SLD-MAGICDocument6 pagesHeat Treatment: YSS Cold Work Tool Steel SLD-MAGICtaknevNo ratings yet

- Swagelok Manifold PDFDocument18 pagesSwagelok Manifold PDFSyahirul AlimNo ratings yet

- Hart Union-Dielectric Technical Data Sheet PDFDocument2 pagesHart Union-Dielectric Technical Data Sheet PDFRahmat RiskiNo ratings yet

- D1.6-2017 (First Proof) (Received 03-15-2017) 251Document1 pageD1.6-2017 (First Proof) (Received 03-15-2017) 251mrNo ratings yet

- Payment Schedule FNLDocument2 pagesPayment Schedule FNLAndrew ArahaNo ratings yet

- Lam Install GuideDocument10 pagesLam Install GuideEli MatucadNo ratings yet

- Sohar Refinery Improvement Project Daily Field Welding Control Sheet SHR-FRM-QUA-120XDocument1 pageSohar Refinery Improvement Project Daily Field Welding Control Sheet SHR-FRM-QUA-120XibrahimNo ratings yet

- Concrete Beam DesignDocument4 pagesConcrete Beam DesignpetersiglosNo ratings yet

- Watts Radiant Manifolds Catalog En-20100519Document19 pagesWatts Radiant Manifolds Catalog En-20100519Pexheat.comNo ratings yet

- BS10 Table eDocument1 pageBS10 Table eGopuk KNo ratings yet

- BEMO Installation Guide - V1-2018Document91 pagesBEMO Installation Guide - V1-2018Anonymous wzuyBcNo ratings yet

- Blank Labour RatesDocument3 pagesBlank Labour RatesRajendra Kumar GoudaNo ratings yet

- 37 - Pole Connector Non Seal Bedienungsanleitung eDocument2 pages37 - Pole Connector Non Seal Bedienungsanleitung eAlper KandemirNo ratings yet

- Materials For Cryogenic Service - Engeering Properties of Aus - Decrypté PDFDocument50 pagesMaterials For Cryogenic Service - Engeering Properties of Aus - Decrypté PDFGOUAREF SAMIRNo ratings yet

- Combined TDS STDs PDFDocument160 pagesCombined TDS STDs PDFmohammadNo ratings yet

- CES 1 DMU Effect of Carbon Content On Properties of Plain Carbon SteelsDocument6 pagesCES 1 DMU Effect of Carbon Content On Properties of Plain Carbon SteelsShakbullahNo ratings yet

- Iron and SteelDocument22 pagesIron and SteelAmarendra Hassan100% (3)

- Kontakt 42 Processing Aids - NBRDocument20 pagesKontakt 42 Processing Aids - NBRPritam KarNo ratings yet

- Hilti Direct Fastening SystemsDocument17 pagesHilti Direct Fastening Systemsbharathanin100% (1)

- Taking Off Internal Floor Finishes-Example (Updated200421)Document6 pagesTaking Off Internal Floor Finishes-Example (Updated200421)faizsyam01No ratings yet

- Indian Standard Zinc Fourth Revision) : Ingot - Specification (Document6 pagesIndian Standard Zinc Fourth Revision) : Ingot - Specification (kkemparajuNo ratings yet