2005 Honda CR85/85RB EXPERT Owner'S Manual & Competition Handbook

2005 Honda CR85/85RB EXPERT Owner'S Manual & Competition Handbook

Uploaded by

Cons BaraguirCopyright:

Available Formats

2005 Honda CR85/85RB EXPERT Owner'S Manual & Competition Handbook

2005 Honda CR85/85RB EXPERT Owner'S Manual & Competition Handbook

Uploaded by

Cons BaraguirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

2005 Honda CR85/85RB EXPERT Owner'S Manual & Competition Handbook

2005 Honda CR85/85RB EXPERT Owner'S Manual & Competition Handbook

Uploaded by

Cons BaraguirCopyright:

Available Formats

CR85/000-023 04.12.

15 11:51 AM ページ 1

2005

Honda CR85/85RB EXPERT

OWNER’S MANUAL & COMPETITION HANDBOOK

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 2

Introduction

Congratulations on choosing your Honda CR As you read this manual, you will find

motocross motorcycle. information that is preceded by a NOTICE

symbol. This information is intended to help you

When you own a Honda, you’re part of a avoid damage to your Honda, other property, or

worldwide family of satisfied customers-people the environment.

who appreciate Honda’s reputation for building

quality into every product. Unless you are mechanically qualified and have

the proper tools, you should see your Honda

Your CR is a high performance racing dealer for the service and adjustment procedures

motorcycle that utilizes the latest motocross discussed in this manual.

technology and is intended for competition use in

sanctioned, closed-course events by experienced The official Honda Service Manual for your CR

riders only. is available (page 120). It is the same manual

your dealer uses. If you plan to do any service

Be aware that motocross is a physically on your CR beyond the standard maintenance

demanding sport that requires more than just a procedures in this manual, you will find the

fine motorcycle. To do well, you must be Service Manual a valuable reference.

excellent physical condition and be a skillful

rider. For the best results, work diligently on If you have any questions, or if you ever need a

your physical conditioning and practice special service or repairs, remember that your

frequently. Honda dealer knows your CR best and is

dedicated to your complete satisfaction.

Before riding, take time to get acquainted with

your CR and how it works. To protect your Please report any change of address or ownership

investment, we urge you to take responsibility for to your Honda dealer so we will be able to

keeping your CR well maintained. Scheduled contact you concerning important production

service is a must, of course. But it’s just as information.

important to observe the break-in guidelines, and

perform all the pre-ride and other periodic checks You may also want to visit our website at

detailed in this manual. www.honda.com.

You should also read the owner’s manual before Happy riding!

you ride. It’s full of facts, instructions, safety

information, and helpful tips. To make it easy to

use, the manual contains a table of contents, a

detailed list of topics at the beginning of each

section, and an index at the back of the book.

Introduction

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 3

A Few Words About Safety

Your safety, and the safety of others, is very important. And operating this motorcycle safely is an important responsibility.

To help you make informed decisions about safety, this manual contains a section devoted to Motorcycle Safety, as well as a number of Safety Messages

throughout the manual.

Safety Messages are preceded by a safety alert symbol and one of three signal words: DANGER, WARNING, or CAUTION.

These signal words mean:

DANGER You WILL be KILLED or SERIOUSLY HURT if you don’t follow instructions.

WARNING You CAN be KILLED or SERIOUSLY HURT if you don’t follow instructions.

CAUTION You CAN be HURT if you don’t follow instructions.

Of course, it is not practical or possible to warn you about all hazards associated with operating or maintaining a motorcycle. You must use your own good

judgement.

Safety Messages

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 4

Contents

MOTORCYCLE SAFETY................................1 Service Preparations TIPS ..................................................................99

Important Safety Information...............................2 Component Locations ........................................28 Transporting Your Motorcycle .........................100

Important Safety Precautions..........................2 Seat Removal .....................................................29 Storing Your Honda..........................................101

Important Message to Parents ........................2 Fuel Tank Removal ............................................30 You & the Environment ...................................102

Accessories & Modifications ...............................3 Subframe Removal.............................................32 Troubleshooting................................................103

Safety Label .........................................................4

Service Procedures TECHNICAL INFORMATION ...................105

OPERATING CONTROLS ..............................5 Fluid & Filters Vehicle Identification .......................................106

Component Locations ..........................................6 Fuel System ........................................................34 Specifications ...................................................107

Transmission Oil ................................................36 Torque Specifications.......................................109

BEFORE RIDING..............................................7 Coolant ...............................................................38 High Altitude Carburetor Adjustment ..............111

Are You Ready to Ride?.......................................8 Air Cleaner .........................................................40 Oxygenated Fuels .............................................112

Is Your Motorcycle Ready to Ride?.....................9 Competition Logbook.......................................113

Pre-ride Inspection..........................................9 Engine Optional Parts List............................................115

Throttle ...............................................................42 Spare Parts & Equipment .................................117

BASIC OPERATING INSTRUCTIONS .......11 Clutch System ....................................................44 Wiring Diagram................................................118

Safe Riding Precautions................................12 Spark Plug ..........................................................46

Starting & Stopping the Engine .........................13 Cylinder System .................................................47 CONSUMER INFORMATION ....................119

Preparation ....................................................13 Authorized Manuals .........................................120

Starting Procedure ........................................13 Chassis Contacting Honda.............................................121

Flooded Engine .............................................13 Suspension..........................................................52 Your Honda Dealer...........................................122

How to Stop the Engine................................14 Brakes.................................................................57 The Honda Rider’s Club (USA only) ..............123

Shifting Gears.....................................................15 Wheels ................................................................61

Break-in Guidelines ...........................................16 Tires & Tubes .....................................................62 TABLE OF CONTENTS ...............................124

Drive Chain ........................................................64

SERVICING YOUR HONDA.........................17 Expansion Chamber ...........................................67 INDEX .............................................................126

Before You Service Your Honda Additional Maintenance Procedures ..................68

The Importance of Maintenance ........................18 QUICK REFERENCE

Maintenance Safety ............................................19 Appearance Care ................................................69

Important Safety Precautions........................19

Maintenance Schedule .......................................20 ADJUSTMENTS FOR COMPETITION ......71

General Competition Maintenance ....................22 Front Suspension Adjustments...........................72

Before & After Competition Maintenance.........26 Rear Suspension Adjustments ............................80

Between Motos & Practice Maintenance .....26 Suspension Adjustments for Track

After Competition Maintenance ...................27 Conditions ..............................................84

Suspension Adjustment Guidelines....................85

Carburetor Adjustments & Tuning Tips.............88

Chassis Adjustments...........................................95

Gearing ...............................................................96

Tire Selection for Track Conditions...................97

Personal Fit Adjustments ...................................98

Contents

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 1

Motorcycle Safety

This section presents some of the most important Important Safety Information...............................2

information and recommendations to help you Important Safety Precautions..........................2

ride your CR safely. Please take a few moments Important Message to Parents ........................2

to read these pages. This section also includes Accessories & Modifications ...............................3

information about the location of the safety label Safety Label .........................................................4

on your CR.

Motorcycle Safety 1

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 2

Important Safety Information

with every additional drink. So don't drink and

Important Safety Precautions ride, and don't let your friends drink and ride Important Message to Parents

either.

Your CR can provide many years of pleasure, if Your child's safely is very important to Honda.

you take responsibility for your own safety and Keep Your Honda in Safe Condition. That's why we urge you to read this message

understand the challenges you can meet in Maintaining your CR properly is critical to your before you let any young person ride this

competitive racing. safety. A loose bolt, for example, can cause a motorcycle. Competitive riding can be fun. But

breakdown in which you can be seriously bad judgement can result in injury, and we don't

As an experienced rider, you know there is much injured. want that to happen. As a parent, you can help

you can do to protect yourself when you ride. prevent accidents by making good decisions

The following are a few precautions we consider about when and how your youngster rides this

most important. motorcycle.

Never Carry a Passenger. • Remember, this CR is designed only for

Your CR is designed for one operator only. competition use by experienced junior riders.

Carring a passenger can cause an accident in It is an operator only model, and the

which you and others can be hurt. maximum load capacity is 150 lbs. Rider

weight must not exceed this limit.

Wear Protective Gear.

Whether you’re practicing to improve your skills, • The junior rider must be fall enough to hold

or riding in competition, always wear an the motorcycle up while straddling it with

approved helmet, eye protection, and proper both feet on the ground. He or she must also

protective gear. be strong enough to pick up the motorcycle if

it is on its side.

Take Time to Get to Know Your CR.

Because every motorcycle is unique, take time to • The parent and junior rider must be fully

become thoroughly familiar with how this one familiar with the motorcycle, the motorcycle

operates and responds to your commands before controls and control functions. Both must also

placing your machine, and yourself, in Fully understand everything in this manual

competition. before riding begins.

Learn and Respect Your Limits. • For your child's safely, be sure to make

Never ride beyond your personal abilities or pre-practice and pre-race inspections, and

faster than conditions warrant. Remember that impress on the junior rider the importance of

alcohol, drugs, illness and fatigue can reduce checking all the items thoroughly before

your ability to perform well and ride safety. riding.

Don't Drink and Ride.

Alcohol and riding don't mix. Even one drink can

reduce your ability to respond to changing

conditions, and your reaction time gets worse

2 Motorcycle Safety

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 3

Important Safety Information

Accessories & Modifications

Installing non-Honda accessories, removing

original equipment, or modifying your CR in any

way that would change its design or operation,

could seriously impair your CR’s handling,

stability, and braking, making it unsafe to ride.

WARNING

Improper accessories or modifications

can cause a crash in which you can be

seriously hurt or killed.

Follow all instructions in this owner’s

manual regarding modifications and

accessories.

Motorcycle Safety 3

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 4

Safety Label

Read this label carefully and don’t remove it.

If the label comes off or becomes hard to read, contact your Honda dealer for replacement.

4 Motorcycle Safety

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 5

Operating Controls

Read this section carefully before you ride. It Component Locations ..........................................6

presents the location of the basic controls on your

CR.

Operating Controls 5

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 6

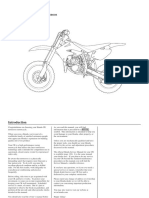

Component Locations

clutch lever

front brake lever

engine stop button

throttle grip

fuel fill cap

choke knob

fuel valve shift lever kickstarter rear brake pedal

6 Operating Controls

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 7

Before Riding

Before each ride, you need to make sure you and Are You Ready to Ride?.......................................8

your Honda are both ready to ride. To help get Is Your Motorcycle Ready to Ride?.....................9

you prepared, this section discusses how to Pre-ride Inspection .............................................9

evaluate your riding readiness, and what items

you should check on your CR.

For information about suspension, carburetor,

and other adjustment for competition, see page

71.

Before Riding 7

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 8

Are You Ready to Ride?

Before riding your CR for the first time,we

should also that you read this owner’s manual, WARNING

make sure you understand the safety messages, Not wearing a helmet increases the

and know how to operate the controls. chance of serious injury or death in a

crash.

Before each ride, it’s also important to make sure

you and your CR are both ready to ride. Be sure you always wear a helmet, eye

protection and other protective apparel

For information about suspension, carburetor, when you ride.

and other adjustments, see page 71.

Whether you’re preparing for competition or for

practice, always make sure you are.

• In good physical and mental condition

• Free of alcohol and drugs

• Wearing an approved helmet, eye protection,

and other appropriate riding gear

Although complete protection is not possible,

wearing the proper gear can reduce the chance or

severity of injury when you ride.

8 Before Riding

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 9

Is Your Motorcycle Ready to Ride?

Competitive riding can be tough on a motorcycle,

so it’s important to inspect your CR and correct Pre-ride Inspection

any problems you find before each ride. Check

the following items (page numbers are at the Check the following before each ride:

right): • Transmission oil level...................................37

• Coolant for proper level................................38

• Cooling system and hoses for condition.......39

WARNING • Spark plug for proper heat range, carbon

Improperly maintaining this motorcycle or fouling and high tension cord terminal for

failing to correct a problem before riding looseness .......................................................46

can cause a crash in which you can be • Air cleaner for condition and

seriously hurt or killed. contamination................................................40

• Clutch operation and freeplay.......................44

Always perform a pre-ride inspection • Steering head bearings and related parts

before every ride and correct any for condition..................................................68

problems. • Carburetor throttle operation ........................42

• Tires for damage or improper inflation

pressure ........................................................62

• Spokes for looseness.....................................61

• Rim locks for looseness................................61

• Front and rear suspension for proper

operation .................................................52, 53

• Front and rear brakes, check operation ........54

• Drive chain for correct slack and adequate

lubrication .....................................................64

• Drive chain guide, sliders and guide rollers

for damage or wear .......................................64

• Expansion chamber springs for damage or

lack of tension...............................................67

• Every possible part for looseness (such as

cylinder head nuts, carburetor insulator bolts,

engine mounting bolts, axle nuts, drive chain

adjusters, drive chain guide, handlebar holder

bolts, kickstarter mounting bolts and wire

harness connectors).......................68, 109, 110

Before Riding 9

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 10

10 Before Riding

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 11

Basic Operating Instructions

This section gives basic information on how to Safe Riding Precautions .....................................12

start and stop your engine as well as break-in Starting & Stopping the Engine .........................13

guidelines. Preparation ....................................................13

Starting Procedure ........................................13

Flooded Engine .............................................13

How to Stop the Engine................................14

Shifting Gears.....................................................15

Break-in Guidelines ...........................................16

Basic Operating Instructions 11

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 12

Basic Operating Instructions

Safe Riding Precautions

Before riding your CR for the first time, please

review the Important Safety Precautions

beginning on page 2 and the previous section,

titled Before Riding.

For your safety, avoid starting or operating the

engine in an enclosed area such as a garage.

Your CR’s exhaust contains poisonous carbon

monoxide gas which can collect rapidly in an

enclosed area and cause illness or death.

12 Basic Operating Instructions

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 13

Starting & Stopping the Engine

Always follow the proper starting procedure Check the transmission oil and coolant levels

described below. before starting the engine (page 37, 38). Flooded Engine

Your CR can be kickstarted with the transmission Cold Engine Starting If the engine fails to start after repeated attempts,

in gear by pulling in the clutch lever before 1. Turn the fuel valve (1) ON. it may be flooded with excess fuel. To clear a

operating the kickstarter. 2. Shift the transmission into neutral. flooded engine:

3. Pull the choke knob (2) up.

4. With closed throttle, operate the kickstarter. 1. Shift the transmission into neutral.

Preparation Starting from the top of the kickstarter stroke, 2. Push the choke knob down all the way to

kick through to the bottom with a rapid, OFF.

Make sure that the transmission is in neutral. continuous motion. 3. Open the throttle fully.

Turn the fuel valve ON. 5. After the engine starts, the choke knob should 4. While pushing the engine stop button, crank

be pushed down as soon as possible to the engine several times with the kickstarter.

prevent spark plug fouling. 5. Release the engine stop button.

Starting Procedure 6. Allow the engine to warm up for at least 2 6. Follow the Warm Engine Starting procedure.

minutes before riding off, preferably until the

Always follow the proper starting procedure side of the cylinder is very warm to the touch

described below. through your riding glove. Slowly increase

rpm and don’t blip the throttle. Warming the

engine is important to prevent cold seizures.

Warm Engine Starting

1. Turn the fuel valve ON.

2. Shift the transmission into neutral.

3. Push the choke knob down.

4. Open the throttle (1/8 – 1/4) and operate the

kickstarter.

(1) (2)

(1)

(1) fuel valve (2) choke knob

Basic Operating Instructions 13

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 14

Starting & Stopping the Engine

How to Stop the Engine

(1)

(2)

(1) throttle (2) engine stop button

Normal Engine Stop

1. Shift the transmission into neutral.

2. Turn the fuel valve OFF.

3. Lightly open the throttle (1) 2 – 3 times, and

then close it.

4. Depress and hold the engine stop button (2)

until the engine stops completely.

Failure to close the fuel valve may cause the

carburetor to overflow, fill the crankcase with

fuel and result in hard starting.

Emergency Engine Stop

To stop the engine in an emergency, press the

engine stop button.

14 Basic Operating Instructions

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 15

Shifting Gears

1. After the engine has been warmed up, the

motorcycle is ready for riding.

2. While the engine is idling, pull in the clutch

lever and depress the shift lever to shift into

1st (low) gear.

3. Slowly release the clutch lever and at the

same time gradually increase engine speed by

opening the throttle. Coordination of the

throttle and clutch lever will assure a smooth

positive start.

NOTICE

When moving off from a standing start, be careful

not to use too much throttle. The motorcycle may

"wheelie" over backwards.

4. When the motorcycle attains a moderate

speed, close the throttle, pull in the clutch

lever and shift to 2nd gear by raising the shift

lever.

5. This sequence is repeated to progressively

shift to 3rd, 4th, 5th, and 6th, (top) gear. Raise

the shift lever to shift to a higher gear and

depress it to downshift. Each stroke of the

shift lever engages the next gear is sequence.

The shift lever automatically returns to the

horizontal position when released.

Basic Operating Instructions 15

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 16

Break-in Guidelines

Help assure your CR’s future reliability and

performance by paying extra attention to how

you ride during the first operating day or 15

miles (25 km).

During this period, avoid full-throttle starts and

rapid acceleration.

This same procedure should be followed each

time when:

• piston is replaced

• rings are replaced

• cylinder is replaced

• crankshaft or crankshaft bearings are replaced

16 Basic Operating Instructions

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 17

Servicing Your Honda

Keeping your CR well maintained is absolutely Before You Service Your Honda Chassis

essential to your safety. It’s also a good way to The Importance of Maintenance ........................18 Suspension..........................................................52

protect your investment, get maximum Maintenance Safety ............................................19 Brakes.................................................................57

performance, avoid breakdowns, and have more Important Safety Precautions........................19 Wheels ................................................................61

fun. Maintenance Schedule .......................................20 Tires & Tubes .....................................................62

General Competition Maintenance ....................22 Drive Chain ........................................................64

To help keep your CR in good shape, this section Before & After Competition Maintenance.........26 Expansion Chamber ...........................................67

includes a Maintenance Schedule for required Between Motos & Practice Maintenance .....26 Additional Maintenance Procedures ..................68

servicing and step-by-step instructions for After Competition Maintenance ...................27

specific maintenance tasks. You’ll also find Appearance Care ................................................69

important safety precautions, information on oils, Service Preparations

and tips for keeping your Honda looking good. Component Locations ........................................28

Seat Removal .....................................................29

An ICM (Ignition Control Module) system is Fuel Tank Removal ............................................30

used on this motorcycle; consequently, routine Subframe Removal.............................................32

ignition timing adjustment is unnecessary. If you

want to check the ignition timing, refer to the Service Procedures

Honda Service Manual (page 122).

Fluids & Filters

Fuel System ........................................................34

Transmission Oil ................................................36

Coolant ...............................................................38

Air Cleaner .........................................................40

Engine

Throttle ...............................................................42

Clutch System ....................................................44

Spark Plug ..........................................................46

Cylinder System .................................................47

Servicing Your Honda 17

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 18

The Importance of Maintenance

Keeping your CR well-maintained is absolutely

essential to your safety. It’s also a good way to

get maximum performance during each moto.

Careful pre-ride inspections and good

maintenance are especially important because

your CR is designed to be ridden in off-road

competition.

Remember, proper maintenance is your

responsibility. Be sure to inspect your CR before

each ride and follow the Maintenance Schedule

in this section.

WARNING

Improperly maintaining this motorcycle or

failing to correct a problem before you

ride can cause a crash in which you can

be seriously hurt or killed.

Always follow the inspection and

maintenance recommendations and

schedules in this owner’s manual.

18 Servicing Your Honda

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 19

Maintenance Safety

This section includes instructions on how to • Read the instructions before you begin, and

perform some important maintenance tasks. make sure you have the tools and skills

Some of the most important safety precautions required.

follow. However, we cannot warn you of every

conceivable hazard that can arise in performing • To help prevent the motorcycle from falling

maintenance. Only you can decide whether or over, park it on a firm, level surface, using the

not you should perform a given task. optional work stand or a maintenance stand to

provide support.

WARNING • To reduce the possibility of a fire or

Failure to properly follow maintenance explosion, be careful when working around

instructions and precautions can cause gasoline. Use only a non-flammable (high

you to be seriously hurt or killed. flash point) solvent such as kerosene —not

gasoline— to clean parts. Keep cigarettes,

Always follow the procedures and sparks, and flames away from all fuel-related

precautions in this owner’s manual. parts.

Important Safety Precautions

• Make sure the engine is off before you begin

any maintenance or repairs.

This will help eliminate several potential

hazards:

Carbon monoxide poisoning from engine

exhaust. Be sure there is adequate ventilation

whenever you operate the engine.

Burns from hot motorcycle parts. Let the

engine and exhaust system cool before

touching.

Injury from moving parts. Do not run the

engine unless instructed to do so.

Servicing Your Honda 19

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 20

Maintenance Schedule

To maintain the safety and reliability of your CR, Perform the pre-ride inspection (page 9) at each

regular inspection and service is required as scheduled maintenance period.

shown in the Maintenance Schedule that follows.

Summary of Maintenance Schedule Notes and

The Maintenance Schedule lists items that can be Procedures:

performed with basic mechanical skills and hand

tools. Procedures for these items are provided in Notes:

this manual. 1. Clean after every moto for dusty riding

conditions.

The Maintenance Schedule also includes items 2. Replace every 2 years. Replacement requires

that involve more extensive procedures and may mechanical skill.

require special training, tools, and equipment. 3. Replace after the first break-in ride.

Therefore, we recommend that you have your

Honda dealer perform these tasks unless you Maintenance Procedures:

have advanced mechanical skills and the required I: inspect and clean, adjust, lubricate, or replace,

tools. Procedures for items in this schedule are if necessary

provided in a service manual available for C: clean

purchase from your dealer (page 121). L: lubricate

R: replace

Service intervals in the maintenance schedule are

expressed in terms of races and riding hours. To

avoid overlooking required service, we urge you

to develop a convenient way to record the

number of races and/or hours you ride.

If you do not feel capable of performing a given

task or need assistance, remember that your

Honda dealer knows your CR best and is fully

equipped to maintain and repair it. If you decide

to do your own maintenance, use only genuine

Honda parts or their equivalents for repair or

replacement to ensure the best quality and

reliability.

20 Servicing Your Honda

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 21

Maintenance Schedule

All items should be checked before each competition event. See your Honda dealer unless you are mechanically qualified and have the proper tools.

Damage from competition use is not covered by the Distributor's Limited Warranty on your Honda.

Perform the Pre-ride Inspection at each scheduled maintenance period.

I: Inspect and Clean, Adjust, Lubricate or Replace if necessary. C: Clean. L: Lubricate. R: Replace.

Frequency Each race Every 3 races Every 9 races

Note or about or about or about Ref. page

Item 2.5 hours 7.5 hours 22.5 hours

Throttle Operation I 42

Air Cleaner Note 1 C 40

Spark Plug I R 46

Radiator Coolant Note 2 I 38

Cooling System I 39

Cylinder Head Decarbonizing C 48

Piston and Piston Rings R 48

Piston Pin and Connecting Rod Small End Bearing R 48

Reed Valve R 49

Transmission Oil R 37

Drive Chain I, L R 64 – 66

Drive Chain Sliders I 64

Drive Chain Rollers I 65

Drive Sprocket I 66

Driven Sprocket I 66

Brake Fluid Note 2 I 58, 59

Brake Pad Wear I 60

Brake System I 57

Clutch System I 44

Control Cables I,L 68

Expansion Chamber/Silencer I 67

Suspension I 52, 53

Swingarm/Shock Linkage L 25, 53

Fork Oil Note 3 R 54

Wheels/Tires I 61, 62, 63

Nuts, Bolts, Fasteners I 68, 109, 110

Steering Head Bearing I 68

This maintenance schedule is based upon average riding condition. Machine subjected to severe use require more frequent servicing.

NOTE: 1. Clean after every moto (heat) for dusty riding conditions.

2. Replace every 2 years. Replacement requires mechanical skill.

3. Replace after the first break-in ride.

Servicing Your Honda 21

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 22

General Competition Maintenance

Perform maintenance on firm, level ground using

the optional workstand, or equivalent support.

Use genuine Honda parts or their equivalent

when servicing your CR.

Clean parts in non-flammable (high flash point)

cleaning solvent (such as kerosene) when

disassembling. Lubricate any sliding surface,

O-rings, and seals before reassembling. Grease

parts by coating or filling where specified.

After any engine disassembly, always install new

gaskets, O-rings, cotter pins, piston pin clips,

snap rings, etc. when reassembling. After

reassembly, check all parts for proper installation

and operation.

All Pre-ride Inspection Items

Refer to Pre-ride Inspection in your Owner’s

Manual, page 9.

22 Servicing Your Honda

Downloaded from www.Manualslib.com manuals search engine

CR85/000-023 04.12.15 11:51 AM ページ 23

General Competition Maintenance

Handgrips

Always use Honda Hand Grip Cement (U.S.A only) or

Honda Bond A when replacing handgrips.

Throttle Grip

Align the “∆” mark on the throttle grip with the hole

of the throttle cable guide. Left handlebar grip: Align

the top of the waffle pattern on the grip with the Air Cleaner

clutch lever as shown in the illustration. Clean and oil your air cleaner regularly because the volume

Refer to the Service Manual for installation of air able to pass through it has a great effect on

performance. Both engine performance and long term

instructions.

durability may be affected by an air cleaner that has

deteriorated and allows dirt to pass. Inspect the air cleaner

closely each time it’s serviced for evidence of small tears or

seam separation. Keep a spare air cleaner oiled and ready to

install, sealed in a plastic bag. Riding in dusty conditions

may require servicing the air cleaner or replacing it with a

pre-serviced air cleaner between motos. Be careful not to

over oil the air cleaner. While it is important to oil the air

For added security, you may choose to safety wire the cleaner thoroughly, over oiling will cause an overall rich

hand grips to the handlebar and throttle to prevent the running condition, probably more noticeable off idle and in

low rpm performance. Follow the servicing instructions in

possibility of them loosening. Position the twisted

the Maintenance section. Use Pro Honda Foam Filter Oil or

wire ends away from your palms and be sure to bend an equivalent. Be sure to grease the air cleaner flange

the wire ends well into the grip rubber so they will not where it contacts the air cleaner housing. Honda White

snag your glove. Lithium Base Grease, or an equivalent, is handy for this

because any dirt that penetrates this sealing area will show

up clearly

(page 40).

Use the Honda genuine air cleaner or an equivalent air

cleaner specified for your model.

Using the wrong Honda air cleaner or a non-Honda air

cleaner which is not of equivalent quality may cause

Throttle Control

Remove the throttle control every few rides, clean the inside

of the drum and the handlebar thoroughly, and apply a light

coating of silicone lubricant. Inspect the cable carefully for Air Cleaner Housing Sealing

kinks or other damage that may restrict throttle control in Transmission Oil Remove and reseal the air cleaner housing boot where it

any way. Move the handlebar from lock to lock to be sure Drain and replace transmission oil often to ensure the connects to the air cleaner housing with silicone sealer if

there is no cable interference. Check to be sure the top of greatest service life of the transmission and clutch. Frequent there is any doubt to its sealing integrity. Use Honda

the carburetor is screwed on tight. Make certain the throttle oil changes will also assure consistent performance of both Thread Lock or an equivalent on the attaching studs.

operation is perfect after servicing and inspecting. shifting and clutch action (page 36). Inspect the air cleaner and air intake tract regularly for signs

of deterioration or dirt penetration.

Servicing Your Honda 23

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 24

General Competition Maintenance

Gaskets Fuel Filter

Spark Plug Always use new gaskets when reassembling components. Periodically drain the fuel from the tank, remove and clean

Some non-resistor plugs may cause ignition problems. the fuel valve/filter. Replace the fuel valve O-ring if there

Refer to the recommendations elsewhere in this manual for Cylinder Removal are any signs of damage or deterioration (page 35).

specific types so you will be sure to use the proper reach Put a little grease on the cylinder mounting dowels to

and heat range. Replace periodically as specified in the prevent corrosion from dissimilar metals. The tolerances are Fuel Contamination

Maintenance Schedule (page 21). quite tight, so it’s important to keep these dowels absolutely Periodically drain the float bowl and inspect the

clean (page 47). carburetor for contamination from dirt (page 35).

Spark Plug Cap

Install a small plastic tie-wrap around the spark plug cap to

reduce any possibility of it loosening or of water

penetration.

Inlet Tract Sealing

Air leaks around the carburetor insulator and reed valve

Electrical Connectors assembly should be cured by disassembling, cleaning and

Clean electrical connectors and wrap them with electrical resealing with new gaskets and some sealing agent. Be

tape to reduce the possibility of unwanted disconnections, careful not to overtighten the mounting bolts — this is the

water shorts or corrosion. Additional corrosion protection is most common cause for leaks here. Inspect the mating

offered by using Honda Dielectric Grease on all electrical surfaces, for warpage due to over-torquing.

connections.

Ignition

Remove the alternator cover and keep it off for a few hours

after each washing to let condensation evaporate. Pull the

flywheel rotor every few rides and clean it and its crankshaft

mounting surface, the alternator stator, the ignition pulse

Engine Mounting Bolts generator pickup and the entire ignition cavity thoroughly. Pressure/Vacuum Leak-Down Test

Make sure the engine mounting bolts are tightened to the The presence of dirt between the ignition pulse generator Perform this test at regular intervals to minimize the

proper torque specification. For added peace of mind, and the flywheel makes the ignition control module possibility of engine damage from air leaks.

remove the nuts, clean the threads, and apply Honda Thread compensate to maintain the ignition curve. Cleaning dirt

Lock or an equivalent prior to torquing the nuts. from the ignition side main seal helps to prevent premature

seal wear. Close inspection of this seal can reveal a leakage

problem before engine damage occurs.

24 Servicing Your Honda

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 25

General Competition Maintenance

Swingarm Pivot Lubrication Brake Fluid Replacement Steering Head Bearings

Clean, inspect and lubricate when servicing suspension Refer to Brake Pad Wear in your Owner’s Manual, page 60. Periodically clean, inspect and regrease the steering head

linkage pivots. Be sure all of the suspension pivot seals are Brake Caliper Inspection: Be sure both the front and rear bearings — especially if wet, muddy or extremely dusty

in good condition. Use Honda Moly 60 paste (U.S.A. only) calipers are able to move freely on the caliper bracket pins. courses are encountered often.

or molybdenum disulfide paste (containing more than 40% Check pad thickness periodically and replace when

molybdenum disulfide additive). minimum thickness is reached. If the brakes fade when they

are hot, inspect the pads for glazing or damage, and replace

if necessary.

Brake Fluid Replacement: Replace the hydraulic fluid in

the brake system every two years. Replace the fluid more

frequently if you subject your brakes to severe use. Heavy

braking heats the brake fluid and it may deteriorate sooner

than expected. Any type of riding, that requires frequent use

of the brakes, such as in tight woods, can shorten the service

life of brake fluid.

Suspension Linkage Lubrication

Disassemble, clean, inspect and lubricate all pivot bearings Fork Oil/Performance

after each 7.5 hours of running time in order to maintain Disassemble, clean and inspect the fork and replace the oil

proper suspension performance and minimize component regularly. Contamination due to the tiny metal particles

wear. Use Honda Moly 60 paste (U.S.A. only) or produced from the normal action of the fork, as well as

molybdenum disulfide paste (containing more than 40% normal oil breakdown, will deteriorate the performance of

molybdenum disulfide additive). the suspension. Refer to the Honda Service Manual. Use

only Pro Honda HP Fork Oil 5W (U.S.A. only) or

equivalent which contains special additives to assure

maximum performance of your CR’s front suspension.

Frame

Because your CR is a high-performance machine, the frame

should not be overlooked as part of your overall competition

maintenance program. Periodically inspect the frame

closely for possible cracking or other damage. It makes

good racing sense.

Swingarm

Do not attempt to weld or otherwise repair a damaged swingarm.

Welding will weaken the swingarm. Water Pump Inspection Hole Spokes

After every race, check the inspection hole, located just Check spoke tension frequently between the first few rides.

Footpegs below the water pump cover on the right crankcase cover. As the spokes, spoke nuts and rim contact points seat-in, the

Worn footpeg teeth can be repaired by filing the grooves Clean away any clogged dirt or sand, if necessary. Look for spokes may need to be retightened. Once past this initial

between the teeth with a triangular-shaped file. coolant or oil leakage. Leaking coolant indicates a worn or seating-in period, the spokes should hold their tension. Still,

Be aware that filing them too sharp will reduce boot sole damaged water seal. Leaking oil indicates a bad be sure your race maintenance program includes checking

lifespan. Sharpen only the points of the teeth. Filing the transmission oil seal. If replacement is necessary, both seals spoke tension and overall wheel condition on a regular basis

grooves deeper will weaken the footpegs. Be sure the pegs should be replaced. (page 61).

are free to pivot freely and that the pivot pin retaining cotter

pins are in good condition. Nuts, Bolts, Etc

Application of a thread locking agent to essential fasteners

offers added assurance and security. Remove the nuts, clean

the threads of both the nuts and bolts, apply Honda Thread

Lock or an equivalent and tighten to the specified torque.

Servicing Your Honda 25

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 26

Before & After Competition Maintenance

alignment will also extend brake pad wear. • Be sure the fuel and oil is mixed well by

Between Motos & Practice Maintenance agitating it thoroughly before pouring pre-mix

into the fuel tank.

After practice or between motos you have a

chance to make additional checks and WARNING

adjustments.

Gasoline is highly flammable and

• Clean accumulated dirt from under the explosive. You can be burned or seriously

fenders and off the wheels, suspension injured when handling fuel.

components, hand grips, controls, and

footpegs. A stiff, nylon parts cleaning brush • Stop the engine and keep heat, sparks

works well. and flame away.

(1) • Handle fuel only outdoors.

• Check tire air pressure.

• Check spoke tension and rim lock nut security. (1) chain adjuster index marks • Wipe up spills immediately.

• Check sprocket bolt and nut security.

• Suspend the front wheel above the ground and

use the pressure release screws (2) to release

the built-up pressure (in excess of normal

atmospheric pressure: 0 psi) in the fork tubes.

This pressure is caused by normal fork action

while riding. (If you are riding at altitude,

remember that fork pressure of 0 at sea level

will increase as elevation increases.)

• Clean the sides of the drive chain with a stiff,

nylon parts-cleaning brush. Lubricate and

adjust the chain as necessary.

Do not perform maintenance while engine is (2)

running. Injury to your fingers or hands may

result.

• After adjustment, check that the chain (2) pressure release screws

adjuster index marks (1) are in the same

position on each side. This will ensure that

the rear wheel is in proper alignment and

allow maximum performance from the rear

disc brake. Maintaining proper wheel

26 Servicing Your Honda

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 27

Before & After Competition Maintenance

Routine Cleaning

After Competition Maintenance If your CR is only slightly dirty, it is best to clean

it by hand with the aid of a stiff bristled nylon

It is important to the long term performance of brush and some clean rags.

your CR to practice a consistent maintenance

program. Right after the event is a good time to Take care to prevent catching your fingers

begin your next maintenance cycle. between the chain and sprockets.

After Race Lubrication A variety of reasonably priced cleaning brushes

Apply a light coating of rust-inhibiting oil to the are available from variety, drug, food, and

drive sprocket and any steel portions of the hardware stores. Some of these brushes are

chassis or engine where the paint has worn away. extremely useful in removing dirt from the many

This will prevent rusting of the exposed metal. tight contours of the metal pieces of your CR.

Apply rust-inhibiting oil more heavily if the Avoid using stiff, abrasive brushes on the plastic

event was particularly wet or muddy. Take care or rubber parts.

to avoid spraying any oil near the disc brakes or

the disc rotors. If your CR was exposed to sea air or salt water,

rinse it as soon as possible after the event, dry it,

Remove the drive chain, clean it, and lubricate and apply a spray lubricant to all metal parts.

the chain and sprockets. Be sure the chain is

wiped clean and is dry before applying the chain If you decide to wash your CR or use cleaners,

lube. refer to Appearance Care (page 69).

Take care to prevent catching your fingers

between the chain and sprockets.

Servicing Your Honda 27

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 28

Component Locations

front brake fluid reservoir

clutch lever front brake lever

engine stop button

throttle grip

steering head

fuel tank fuel fill cap rear brake fluid reservoir

front brake hose

fuel valve

air cleaner seat

left side cover kickstarter

choke knob rear suspension

front suspension

right side cover

chain slider transmission oil

rear check bolt

brake caliper

drive chain

rear brake

pedal

shift lever chain roller

oil filler cap

chain guide slider rim lock

front brake caliper rear axle shaft

rim lock front axle shaft

chain adjuster

28 Servicing Your Honda

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 29

Seat Removal

Refer to Safety Precautions on page 19. Installation

1. Slide the seat front prong (1) onto the seat

Removal bracket (2) and the seat rear prong (3) onto

1. Remove the seat bolts (1). the tab (4) by pushing down and forward on

2. Slide the seat (2) back. the seat in each of these areas.

(1)

2. Install the seat bolts (5) and tighten them to

the specified torque:

(2)

19 lbf·ft (26 N·m, 2.7 kgf·m)

(5)

(1) (3)

(1) seat bolts

(2) seat

(2)

(4)

(1) seat front prong

(2) seat bracket

(3) seat rear prong

(4) tab

(5) seat bolts

Servicing Your Honda 29

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 30

Fuel Tank Removal

Refer to Safety Precautions on page 19. 5. Remove the seat (page 29).

6. Pull the breather tube (6) out of steering stem WARNING

Removal nut. Gasoline is highly flammable and

1. Turn the fuel valve OFF. 7. Unhook and remove the fuel tank band (7). explosive. You can be burned or seriously

2. Remove the right side shroud bolts (1). 8. Disconnect the fuel line (8) from the fuel injured when handling fuel.

3. Slide the right side shroud (2) forward. valve.

9. Remove the right and left side fuel tank • Stop the engine and keep heat, sparks

bolts/washers (9) and fuel tank. and flame away.

(2) • Handle fuel only outdoors.

• Wipe up spills immediately.

(6)

(9)

(7)

(8)

(1)

(1) right side shroud bolts

(2) right side shroud

(6) breather tube

4. Remove the left side shroud bolts (3), collar (7) fuel tank band

(4) and left side shroud (5). (8) fuel line

(9) right and left side fuel tank bolts/washers

(5)

(3)

(3)

(4)

(3) left side shroud bolts

(4) collar

(5) left side shroud

30 Servicing Your Honda

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 31

Fuel Tank Removal

Installation 6. Install the seat (page 29).

1. Install the fuel tank on the frame. 7. Install the left side shroud (5), collar (6) and

2. Tighten the right and left side fuel tank left side shroud bolts (7).

bolts/washers (1). (5)

3. Connect the fuel line (2) to the fuel valve. (7)

4. Hook the fuel tank band (3).

5. Put the breather tube (4) in the steering stem

nut.

(4)

(1)

(3) (7)

(2) (6)

(5) left side shroud

(6) collar

(7) left side shroud bolts

8. Slide the right side shroud (8) aligning the

grommet (9) of the shroud and boss (10) of

(1) right and left side fuel tank bolts/washers

(2) fuel line the fuel tank.

(3) fuel tank band 9. Tighten the shroud bolts (11).

(4) breather tube

(11)

(10)

(8)

(9)

(8) right side shroud

(9) grommet

(10) boss

(11) shroud bolts

Servicing Your Honda 31

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 32

Subframe Removal

Refer to Safety Precautions on page 19. 4. Loosen the screw (5) on the air cleaner Installation

connecting tube clamp (6). 1. Loosely attach the upper and lower ends of

Removal the subframe to the mainframe while

1. Remove the seat (page 29). connecting the air cleaner connecting tube to

2. Remove the right side cover (1) by removing (6) the carburetor.

the bolt/collar (2). 2. Tighten the screw (1) on the connecting tube

clamp (2).

(2) (2)

(5)

(1)

(5) screw

(6) connecting tube clamp (1)

5. Remove the lower subframe mounting bolts

(7) and upper subframe mounting bolt (8). (1) screw

(1) right side cover 6. Remove the subframe (9) by pulling it (2) connecting tube clamp

(2) bolt/collar straight backward.

3. Align the subframe (3) with the rear wheel

3. Remove the bolt/washer (3) and muffler (4). and install the upper subframe mounting bolt

(4) and lower subframe mounting bolts (5).

(3) 4. Tighten the upper subframe mounting bolt to

(9)

the specified torque:

(8) 16 lbf·ft (22 N·m, 2.2 kgf·m)

5. Tighten the lower subframe mounting bolts to

the specified torque:

16 lbf·ft (22 N·m, 2.2 kgf·m)

(7)

(4)

(3)

(4)

(7) lower subframe mounting bolts

(8) upper subframe mounting bolt

(3) bolt/washer (9) subframe

(4) muffler (5)

(3) subframe

(4) upper subframe mounting bolt

(5) lower subframe mounting bolts

32 Servicing Your Honda

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 33

Subframe Removal

6. Connect the silencer (6) to the expansion

chamber with the sealing rubber.

Install the rubber seal (7) with its "FR" mark (8)

facing foward.

7. Install and tighten the muffler bolt/washer (9).

(9)

(6)

(7) (8)

(6) silencer (8) "FR" mark

(7) rubber seal (9) muffler bolt/washer

8. Install the right side cover (10) and bolt/collar

(11).

(11)

(10)

(10) right side cover (11) bolt/collar

9. Install the seat (page 29).

Servicing Your Honda 33

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 34

Fuel System

Refer to Safety Precautions on page 19. Premix gasoline and oil in a ratio of 32:1. 32:1 FUEL OIL MIXING CHART

Prepare the fuel mixture in a clean container, and

shake until thoroughly mixed before filling the Fuel Oil

Fuel Recommendation fuel tank. 32 1

USE PRO HONDA HP2 2-STROKE OIL Gallons Liters Ounces cm3

Type Unleaded

(32:1) OR AN EQUIVALENT. 0.5 1.89 2.0 59

Pump Octane Number 91 (or higher) 1.0 3.78 4.0 118

1.5 5.67 6.0 177

NOTICE 2.0 7.57 8.0 237

We recommend that you use unleaded fuel

2.5 9.46 10.0 296

because it produces fewer engine deposits and Too much oil will cause excessive smoking and 3.0 11.35 12.0 355

extends the life of exhaust system components. spark plug fouling. Too little oil will cause 3.5 13.24 14.0 414

engine damage or premature wear. 4.0 15.14 16.0 473

Your engine is designed to use any gasoline that 4.5 17.03 18.0 532

has a pump octane number of 91 or higher. Vegetable oils separate from gasoline more easily 5.0 18.92 20.0 591

5.5 20.81 22.0 651

Gasoline pumps at service stations normally than mineral oils, especially in cold weather. It is 6.0 22.71 24.0 710

display the pump octane number. For advisable to use mineral oil when ambient

information on the use of oxygenated fuels, see temperatures below 32°F (0°C) are expected.

page 112.

If the gasoline-oil mixture is left standing in a

Use of lower octane gasoline can cause persistent container for a long period of time, lubricity will

“pinging” or “spark knock” (a louder rapping deteriorate. Use the mixture within 24 hours-or

noise) which, if severe, can lead to engine the time period recommended by the oil

damage. (Light pinging experienced while manufacturer.

operating under a heavy load, such as climbing a

hill, is no cause for concern.) Once an oil container is opened, the oil must be

used within one month, since oxidation may

If pinging or spark knock occurs at a steady occur.

engine speed under normal load, change brands

of gasoline. If pinging or spark knock persists,

consult your Honda dealer.

Never use stale or contaminated gasoline. Avoid

getting dirt, dust, or water in the fuel tank.

34 Servicing Your Honda

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 35

Fuel System

To service the fuel filter:

Refueling Procedure Fuel Line 1. Drain the fuel from the fuel tank into an

approved gasoline container. Disconnect the

Fuel Tank Capacity: fuel line.

1.4 US gal (5.3 x) (2) 2. Remove the fuel valve (1) by removing the

bolt (2). Wash the fuel filter (3) in high

(3) flash-point cleaning solvent.

(2)

(4)

(1)

(3)

(1) (1)

(1) fuel valve (2) fuel line

(2)

(1) fuel fill cap (3) steering stem nut 1. Check the fuel valve (1) and fuel filter for

(2) breather tube contamination.

2. Check for leaks. (1) fuel valve (3) fuel filter

1. To open the fuel fill cap (1), pull the breather 3. Check the fuel line (2) for cracks, (2) bolt (4) O-ring

tube (2) out of the steering stem nut (3). Turn deterioration, damage, or leakage. Replace the

the fuel fill cap counterclockwise and remove fuel line, if necessary. 3. Reassemble the fuel valve in the reverse order

it. 4. Check for interference between the frame and of removal. Make sure the O-ring (4) is in

2. Add fuel until the level reaches the bottom of tank and adjust if necessary. place. Install the fuel valve in the fuel tank.

the filler neck. Avoid overfilling the tank. Refill the fuel tank.

There should be no fuel in the filler neck. Attach the fuel line and turn the fuel valve to

3. Close the fuel fill cap and insert the breather Fuel Filter ON; check for leaks.

tube to the steering stem nut.

The fuel filter is included in the fuel valve

mounted on the bottom left side of the fuel tank.

WARNING Dirt accumulated in the filter will restrict the

Gasoline is highly flammable and flow of the fuel to the carburetor.

explosive. You can be burned or

seriously injured when handling fuel.

• Stop the engine and keep heat, sparks

and flame away.

• Handle fuel only outdoors.

• Wipe up spills immediately.

Servicing Your Honda 35

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 36

Transmission Oil

Refer to Safety Precautions on page 19. • Your CR does not need oil additives. Use the

Oil Recommendation recommended oil.

Using the proper oil, and regularly checking, • Do not use oils with graphite or molybdenum

adding, and changing oil will help extend the Type transmission oil or 4-stroke additives. They may adversely affect clutch

service life of the transmission and clutch. Even engine oil operation.

the best oil wears out. Changing oil helps get rid • Do not use API SH or higher 4-stroke engine

API classification SG or higher except oils

of dirt and deposits. Operating the engine with (4–stroke engine oil labeled as energy

oils displaying a circular API “energy

old or dirty oil can damage your engine. only) conserving on the circular conserving” service label on the container. They

Running the engine with insufficient oil can API service label may affect lubrication and clutch performance.

cause serious damage to the transmission.

Viscosity SAE 80W/85W

(weight) (transmission oil)

SAE 10W–40

(4-stroke engine oil)

JASO T903 MA

standard (4-stroke

engine oil only)

others without friction modifiers as

molybdenum additives

NOT RECOMMENDED OK

suggested oil* Pro Honda HP Trans oil,

Pro Honda GN4 or HP4 Other viscosities shown in the following chart

(without molybdenum may be used when the average temperature in

additives) 4-stroke engine

oil or an equivalent

your riding area is within the indicated range.

* Suggested 4-stroke engine oils are equal

performance to SJ oils that are not labeled as

energy conserving on the circular API service

label.

36 Servicing Your Honda

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 37

Transmission Oil

JASO T 903 standard

The JASO T 903 standard is an index to choose Checking & Adding Oil Replacing Transmission Oil

engine oils for 4-stroke motorcycle engines.

There are two classes: MA and MB. 1. Run the engine for three minutes, then shut it

Oil conforming to the standard has the following (1) off.

classification on the oil container. 2. Support the CR in an upright position on a

level surface.

(1) 3. Remove the oil filler cap from the right

crankcase cover.

4. Place an oil drain pan under the engine to

catch the oil. Then remove the drain bolt (1).

(2) 5. Pour the drained oil into a suitable container

(2)

and dispose of it in an approved manner (page

102).

(1) oil filler cap (2) oil check bolt

NOTICE

(1) code number of the sales company of the oil 1. Run the engine for three minutes, then shut it Improper disposal of drained fluids is harmful to

(2) oil classification off. the environment.

2. Wait three minutes after shutting off the

engine to allow the oil to properly distribute 6. After the oil has drained completely, install

itself in the clutch and transmission. the drain bolt with a new sealing washer and

3. Support the CR in an upright position on a tighten it to the specified torque:

level surface. 18 lbf·ft (25 N·m, 2.5 kgf·m)

4. Remove the oil filler cap (1) and oil check 7. Add the recommended oil:

bolt (2) from the right crankcase cover. A 0.58 US qt (0.55 x) at oil change

small amount of oil should flow out of the 8. Check the oil level by following the steps in

check bolt hole. Allow any excess oil to flow Checking & Adding Oil.

out of the check bolt hole.

5. If no oil flows out of the check bolt hole, add

oil slowly through the oil filler hole until oil

starts to flow out of the check bolt hole.

Install the oil check bolt and filler cap.

6. Repeat steps 1 - 4.

7. After inspecting the oil level or adding oil,

tighten the oil check bolt and filler cap

securely and oil check bolt to the specified

torque:

(1)

6.6 lbf·ft (9 N·m, 0.9 kgf·m)

(1) oil drain bolt

Servicing Your Honda 37

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 38

Coolant

Your CR’s liquid cooling system dissipates Increasing the concentration of antifreeze is not

engine heat through the coolant jacket that recommended because it decreases cooling WARNING

surrounds the cylinder and cylinder head. system performance. Higher concentrations of Removing the radiator cap while the

antifreeze (up to 60%) should only be used to engine is hot can allow the coolant to

Maintaining the coolant will allow the cooling provide additional protection against freezing. spray out, seriously scalding you.

system to work properly and prevent freezing, Check the cooling system frequently during

overheating, and corrosion. freezing weather. Always let the engine and radiator cool

down before removing the radiator cap.

Coolant Recommendation Checking & Adding Coolant 2. Add coolant up to the filler neck if the level is

low.

Use Pro Honda HP coolant or an equivalent high Refer to Safety Precautions on page 19. Inspect the coolant level before each outing.

quality ethylene glycol antifreeze containing A coolant loss of 0.7 - 2.0 US oz (20 - 60

corrosion protection inhibitors specifically 1. With the engine cold, remove the radiator cap cm3) through the overflow tube is normal. If

recommended for use in aluminum engines. (1) and check coolant level. The coolant level coolant loss is more than this, inspect the

Check the antifreeze container label. is correct when it is at the bottom of the cooling system.

radiator filler neck (2). Capacity:

Use only distilled water as a part of the coolant (1)

0.45 US qt (0.43 x) at disassembly

solution. Water that is high in mineral content or (2) 0.45 US qt (0.43 x) at coolant change

salt may be harmful to the aluminum engine. 3. Install the radiator cap securely.

NOTICE NOTICE

Using coolant with silicate inhibitors may cause If the radiator cap is not installed properly, it

premature wear of radiator pump seals or will cause excessive coolant loss and may result

blockage of radiator passages. Using tap water in overheating and engine damage.

may cause engine damage.

The factory provides a 50/50 solution of

antifreeze and water in this motorcycle. This

coolant solution is recommended for most (1) radiator cap (2) filler neck

operating temperatures and provides good

corrosion protection.

Decreasing the concentration of antifreeze to less

than 40% will not provide proper corrosion

protection.

38 Servicing Your Honda

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 39

Coolant

(1)

Cooling System Inspection Coolant Replacement

1. Check the cooling system for leaks (see the Refer to Safety Precautions on page 19.

Honda Service Manual for troubleshooting of

leaks). Coolant should be replaced by your Honda

2. Check water hoses (1) for cracks, dealer, unless you have the proper tools and

deterioration, and clamp bands for looseness. service data and are mechanically qualified.

3. Check the radiator mount for looseness. Refer to the official Honda Service Manual.

4. Make sure the overflow tube (2) is connected

and not clogged.

5. Check the radiator fins for clogging.

(2) (3) WARNING

6. Check the water leakage check hole (3) below Removing the radiator cap while the

the water pump for leakage. Make sure the (1) water hoses (3) water leakage check engine is hot can allow the coolant to

hole remains open. If water leaks through the (2) overflow tube hole

spray out, seriously scalding you.

check hole, the water pump seal is damaged.

If oil leaks through the check hole, the Always let the engine and radiator cool

transmission oil seal is damaged. See the down before removing the radiator cap.

Honda Service Manual or consult your Honda

dealer for replacing the water pump seal or

the transmission oil seal. Both seals should To properly dispose of drained coolant, refer to

be replaced at the same time. You & the Environment, page 102.

Servicing Your Honda 39

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 40

Air Cleaner

Refer to Safety Precautions on page 19. 4. Remove the air cleaner (3) from the air

Cleaning cleaner holder (4).

The air cleaner uses polyurethane inner and outer

pieces which can’t be separated. 1. Remove the seat (page 29). (4)

A dirty air cleaner will reduce engine power. 2. Loosen the air cleaner retaining bolt (1).

3. Remove the air cleaner assembly (2).

Proper air cleaner maintenance is very important

(2) (1)

for off-road vehicles. A dirty, water-soaked,

worn-out, or defective air cleaner will allow dirt,

dust, mud, and other impurities to pass into the (3)

engine.

Service the air cleaner more frequently if you

ride in unusually wet or dusty areas. Your Honda (1) air cleaner retaining bolt

dealer can help you determine the correct service (3) air cleaner

(4) air cleaner holder

interval for your riding conditions.

(1) 5. Wash the air cleaner in clean non-flammable

Your CR’s air cleaner has very specific

(high flash point) cleaning solvent such as

performance requirements. Use a new genuine

(1) air cleaner retaining bolt kerosene not gasoline. Then wash it in hot,

Honda air cleaner specified for your model or an

(2) air cleaner assembly soapy water, rinse well, and allow to dry

air cleaner of equal quality.

thoroughly.

The air cleaner is made in two pieces : inner

Proper air cleaner maintenance can prevent

and outer, which can't be separated.

premature engine wear or damage, expensive

6. Inspect for tears or cracks in the foam or

repairs, low engine power, poor gas mileage, and

seams of the air cleaner. Replace the air

spark plug fouling.

cleaner if it is damaged.

7. Clean the inside of the air cleaner housing.

NOTICE 8. Allow the air cleaner to dry thoroughly. After

drying, soak the air cleaner in clean Pro

Improper or lack of proper air cleaner

Honda Foam Filter Oil or an equivalent air

maintenance can cause poor performance and

cleaner oil.

premature engine wear.

Apply air cleaner oil to the entire surface, of

the air cleaner and rub it with both hands to

saturate the air cleaner with oil. Squeeze out

excess oil.

40 Servicing Your Honda

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 41

Air Cleaner

9. Apply a thin coat of Honda White Lithium NOTICE

Grease, or an equivalent, to the sealing

surface. Improper installation of the air cleaner assembly

10.Assemble the air cleaner and holder and put may allow dirt and dust to enter the engine and

the air cleaner retaining bolt through the cause rapid wear of the piston rings and cylinder.

assembly.

11.Install the assembly into the air cleaner

housing with the tab (5) facing up and tighten 12.Reinstall the seat (page 29), making sure it is

the bolt securely. securely attached.

(5)

(5) tab

Servicing Your Honda 41

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 42

Throttle

Refer to Safety Precautions on page 19. 1. Pull the rubber dust cover (2) back. Lower Adjustment

2. Loosen the upper lock nut (3) on the throttle The lower adjuster is used for major freeplay

cable mechanism. adjustment, such as after replacing the throttle

Throttle Freeplay 3. Turn the upper adjuster (4). cables or removing the carburetor. It is also used

Turning the adjuster in direction (–) will if you can not get the proper adjustment with the

RIGHT SIDE (1) decrease freeplay and turning it in direction upper adjuster.

(+) will increase freeplay. (5)

4. Tighten the upper lock nut. Return the rubber

dust cover to its normal position.

5. After adjustment, check for smooth rotation of

the throttle grip from fully closed to fully (+)

(–)

open in all steering positions.

If the adjuster is threaded out near its limit or

the correct freeplay cannot be reached, turn

the adjuster all the way in and back out one (6)

(1) throttle freeplay turn. Tighten the upper lock nut, install the

rubber dust cover and make the adjustment (7)

Inspection with the lower adjuster.

Check freeplay (1).

Freeplay: 1/8 - 1/4 in (3 - 6 mm) (5) rubber cap (+) increase

If necessary, adjust to the specified range. (6) lock nut (–) decrease

(7) adjuster

Upper Adjustment

Minor adjustments are generally made with the 1. Pull up the rubber cap (5) on the carburetor

upper adjuster. cap and loosen the lock nut (6).

2. Turn the adjuster (7) in direction (–) to

(4) decrease freeplay, and in direction (+) to

(2)

increase freeplay.

(+) 3. Tighten the lock nut.

(3)

4. Reinstall the rubber cap securely after

adjustment.

5. Operate the throttle grip to ensure that it

(–) functions smoothly and returns completely.

If you can’t get the freeplay within the specified

range, contact your Honda dealer.

(2) rubber dust cover (+)increase

(3) upper lock nut (–)decrease

(4) upper adjuster

42 Servicing Your Honda

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 43

Throttle

Throttle Inspection

(1)

(1) throttle

1. Check that the throttle assembly is positioned

properly and the securing bolts are tight.

2. Check for smooth rotation of the throttle (1)

from fully open to fully closed in all steering

positions. If there is a problem, see your

Honda dealer.

3. Inspect the condition of the throttle cables

from the throttle grip down to the carburetor.

If the cable is kinked or chafed, have it

replaced.

4. Check the cables for tension or stress in all

steering positions.

5. Lubricate the cables with a commercially-

available cable lubricant to prevent premature

rust and corrosion.

Servicing Your Honda 43

Downloaded from www.Manualslib.com manuals search engine

CR85R/024-046 04.12.15 11:52 AM ページ 44

Clutch System

Refer to Safety Precautions on page 19. Cable End Adjustment Lower Adjustment

Minor adjustments are generally made with the The lower clutch cable adjuster is used if the

cable end adjuster. upper clutch cable adjuster is threaded out near

Clutch Freeplay its limit — or the correct freeplay cannot be

obtained.

(1)

(2) (–)

(4)

(1)

(–)

(+)

(3)

(+)

(5)

(1) dust cover (+) increase

(2) lock nut (–) decrease

(1) clutch lever (3) cable end adjuster (4) lock nut (+) increase

(5) lower clutch cable adjuster (–) decrease

Inspection 1. Pull the dustcover (1) back.

Check freeplay. 2. Loosen the lock nut (2) and turn the cable end 1. Turn the cable end adjuster (3) all the way in

Freeplay: 3/8 - 13/16 in (10 - 20 mm) adjuster (3). Turning the adjuster in direction (to provide maximum freeplay).

(–) will decrease free play and turning in the 2. Loosen the lock nut (4).

If necessary, adjust to the specified range. direction (+) will increase free play. 3. Turn the lower clutch cable adjuster (5) to

Improper freeplay adjustment can cause 3. After adjustment, tighten the lock nut and obtain the specified freeplay.

premature clutch wear. install the dust cover. 4. Tighten the lock nut. Check the adjustment.