ManualTPSD 1

ManualTPSD 1

Uploaded by

pailis2002Copyright:

Available Formats

ManualTPSD 1

ManualTPSD 1

Uploaded by

pailis2002Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

ManualTPSD 1

ManualTPSD 1

Uploaded by

pailis2002Copyright:

Available Formats

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

MODEL TPSD

BATTERY CHARGER

TruPowerSource

CPN 102755 17650 11/07

ECN/DATE 16816 - 08/05 16701 - 02/05 15349-01-05/02 15010 10/01

ISSUE DATE: 14491 2/01

106 BRADROCK DRIVE DES PLAINES, IL. 60018-1967 (847) 299-1188 FAX: (847) 299-3061

INSTRUCTION DRAWING NUMBER: 1 OF 18

P25-

LTPSD-1

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

IMPORTANT SAFETY INSTRUCTIONS

1. 2. 3. 4. 5. 6. 7. SAVE THESE INSTRUCTIONS. This manual contains important safety and operating instructions. Before using this equipment, read all instructions and cautionary markings on (1) unit, (2) battery, and (3) product using the battery.

CAUTION: To reduce risk of injury and/or damage to the batteries, use only the type of batteries specified on the charger nameplate. Do not expose equipment to rain or snow. Do not operate equipment if it has received a sharp blow, been dropped, or otherwise damaged in any way; take it to a qualified serviceman. Do not disassemble this unit; take it to a qualified serviceman when service or repair is required. Incorrect reassembly may result in a risk of electric shock or fire.

To reduce risk of electric shock, disconnect this unit from the a.c. supply, batteries and loads before attempting any maintenance or cleaning. Turning off controls will not reduce this risk. WARNING RISK OF EXPLOSIVE GASES

a. b. Working in the vicinity of a battery is dangerous. Some batteries generate explosive gases during normal battery operation. For this reason, it is of utmost importance that each time before using this unit, you read this manual and follow the instructions To reduce risk of battery explosion, follow these instructions and those published by the battery manufacturer and manufacturer of any equipment you intend to use in the vicinity of the battery. Review cautionary marking on all products. Someone should be within range of your voice or close enough to come to your aid when you work near a battery. Have plenty of fresh water and soap nearby in case the battery electrolyte contacts skin, clothing, or eyes. Wear complete eye protection and clothing protection. Avoid touching eyes while working near a battery. If the battery electrolyte contacts skin or clothing, wash immediately with soap and water. If the electrolyte enters the eye, immediately flood the eye with running cold water for at least ten (10) minutes and get medical attention immediately. Never smoke or allow a spark or flame in vicinity of a battery. Be extra cautious, DO NOT drop metal onto a battery. It might spark or short-circuit the battery or cause an explosion. Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a battery. A battery can produce a short-circuit current high enough to weld these items causing severe burns. NEVER charge a frozen battery. Do not use battery charger for charging dry-cell batteries that are commonly used with home appliances. These batteries may burst and cause injury to person or damage to property. If it is necessary to remove the battery connections, always remove grounded terminal from the battery first. Make sure all loads are disconnected and unit is off, so as not to cause an arc. Be sure the area around the battery is well ventilated while the battery is being charged. When cleaning battery terminals, be careful to keep corrosion from coming in contact with eyes. Study all the battery manufacturers specific precautions such as removing or not removing cell caps while charging, recommended rates of charge, and maintenance procedures. Follow the battery manufacturer's recharging instructions. Never place this unit directly above the standard flooded battery. Gases from the battery will corrode and damage equipment. A sealed maintenance free or valve regulated lead acid (VRLA) may be placed below this equipment. Never allow the battery electrolyte to drip on this unit when reading the specific gravity or filling the battery. Do not operate this unit in a closed-in area or restrict ventilation in any way. Do not set any battery on top of this unit.

8.

PERSONAL PRECAUTIONS:

a. b. c. d. e. f. g. h. i.

9.

PREPARING TO CHARGE

a. b. c. d. e. a.

10. UNIT LOCATION

b. c. d.

11. D.C. CONNECTION PRECAUTIONS

Connect and disconnect d.c. output cables only after setting all of this unit's switches to off position and removing a.c. input supply. Do not pull on output cables when disconnecting charger from battery. 12. GROUNDING INSTRUCTIONS This battery charger should be connected to a grounded, metal, permanent wiring system; or an equipment grounding conductor should be run with circuit conductors and connected to equipment-grounding terminal or lead on battery charger. Connections to battery should comply with all local codes and ordinances.

2 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

RECEIVING INSTRUCTIONS AND GENERAL EQUIPMENT INFORMATION

CAUTION: To ensure safe installation and operation, the information given in the instruction manual should be read and understood before installing or using the equipment.

RECEIVING INSTRUCTIONS

Unpacking and Inspection: Examine the shipping crate upon arrival. If there is obvious damage, describe on the receiving documents. Within a few days after delivery, the equipment should be uncrated and carefully inspected for hidden damages. When removing packaging material, be careful not to discard any equipment, parts, or manuals. If any damage is detected you should: 1. File a claim with the carrier within five (5) days. 2. Send a copy of the claim to La Marche Mfg. Co. 3. Call La Marche Mfg. For a RETURN MATERIAL AUTHORIZATION NUMBER.

Failure to properly file a claim for shipping damages, or provide a copy of the claim to La Marche Mfg., may void warranty service for any physical damages reported for repair.

HANDLING

WARNING: Equipment can be very heavy, and top-heavy. Use adequate manpower or equipment for handling. Until the equipment is securely mounted, care must be used to prevent the equipment from being accidentally tipped over.

NOMENCLATURE PLATES

Each piece of La Marche Mfg. Equipment shipped is identified by part number on the nomenclature plate.

ADJUSTMENTS

All equipment is shipped from the factory fully checked and adjusted. Do not make any adjustments unless the equipment has been powered-up and the settings have been determined to be incorrect.

SPARE PARTS

To minimize downtime during installation or normal service, it is advisable to purchase spare fuses, circuit boards and other recommended components. Please refer to the list of recommended spare parts and their La Marche Mfg. Part numbers included with the instruction manual. It is recommended that spare fuses be ordered for all systems. To order spare parts, please contact La Marche Mfg. (847)-299-1188 during business hours and ask for the Parts Department.

3 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

1.0

The La Marche Model TPSD is a controlled ferroresonant float charger designed to power a load while charging a battery. The Model TPSD is a filtered and may be used without a battery. The all solid state electronic control circuit provides excellent line-load voltage regulation, current limiting, and a power failure relay with light and Form C contacts.

GENERAL

The Model TPSD is available in a wide range of single and three phase a.c. input voltages, with 24 volt, 48 volt and 130 volt d.c. outputs in output currents ranging from 6 to 200 amps.

2.0

The TPSD series rectifiers provide separate voltage adjustments for floating or equalizing lead or nickel cadmium cells. The float or equalize mode of operation is selected by a switch located on the front of the rectifier. The factory settings are as follows: FLOAT VOLTAGE EQUALIZE VOLTAGE 2.33 volts/cell (Lead) 2.27 volts/cell (VRLA) 1.55 volts/cell (N.C.)

OUTPUT RATINGS 2.1 D.C. VOLTAGE

2.17 volts/cell (Lead) 1.40 volts/cell (N.C.) 2.25 volts/cell (VRLA)

2.2

VOLTAGE RANGE

FLOAT

2.12 - 2.3 volts/cell +/- .1 volts (Lead) (VRLA) 1.39 - 1.45 volts/cell +/- .1 volts (N.C.)

2.25 - 2.40 volts/cell +/- .1 volts (Lead) (VRLA) 1.5 - 1.60 volts/cell +/- .1 volts (N.C.)

EQUALIZE

2.3

OUTPUT CURRENT

6, 12, 20, 25, 30, 35, 50, 75, 100, AMPS 12Vdc, 24Vdc, 48Vdc, or 130Vdc 75, 100, 150, 200 AMPS

Single Phase Inputs

Three Phase Inputs

24Vdc, 48Vdc, or 130Vdc

Steady state output voltage remains within +/- % of rated voltage for any load current from no load to full load and for input voltages within the rated range. Single phase units are 30Mv. RMS and three phase units are 100Mv. RMS - 32 DBRN C message weighting on units 48 volts or less. The mean time between failure (MTBF) in excess of 175,000 hours at 50 degrees C.

2.4 2.5 2.6

REGULATION FILTERING

MEAN TIME BETWEEN FAILURE

4 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

3.0

Taps are provided for nominal single phase a.c. input voltages of 120/208/240 Vac, with an a.c. input voltage range of +/-10% of nominal. The 75 and 100 amp units are rated for three phase inputs and available in 208/ 240 or 480 Vac inputs.

INPUT RATINGS 3.1 A.C. VOLTAGE

3.2 3.3

INPUT FREQUENCY RANGE INPUT CURRENT

57 to 63 Hz. (60 HZ nominal) 47 to 57 HZ. (50 HZ nominal)

(Refer to TPSD SPECIFICATION SHEET INCLUDED IN MANUAL)

4.0 5.0

(Refer to TPSD SPECIFICATION SHEET INCLUDED IN MANUAL)

TYPICAL ELECTRICAL SPECIFICATIONS STANDARD FEATURES 5.1 INPUT PROTECTION:

AC BREAKER

Single Phase Units -

A two-pole circuit breaker opens both sides of the a.c. service for 120-208 or 240 on single phase models, 50 amps or less. For 120Vac input only phase side is opened with a.c. breaker.

Three Phase Units -

A three-pole circuit breaker opens all three legs of the a.c. service.

A two pole d.c. breaker is provided on all 50 amp or less units.

5.2

OUTPUT PROTECTION:

Current limiting is adjustable from 50% to 115% of rated load, limits the d.c. output current. Factory set at 115% of rated output.

5.3

STATUS/ALARM INDICATORS

Alarm Relays

Dual Form C contacts are rated for 28 v.d.c. at 2 amperes for the low current, low d.c. voltage, high d.c. voltage, high voltage shutdown, positive ground, summary and negative ground. All alarms have adjustable time delay on energize.

A.C. ON Indicator

A green light emitting diode (LED) indicator illuminates to indicate a.c. voltage is present to the rectifier.

High-Voltage Alarm Indicator

A red LED indicator blinks to indicate that rectifier output has exceeded the preset high-voltage set point. This alarm condition will also trigger the summary failure alarm contacts.

5 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

Low-Voltage Alarm Indicator

A red LED indicator blinks to indicate that the rectifier output has dropped below a preset voltage set point. This alarm will also trigger the summary failure alarm contacts. Low voltage alarm stays on until output voltage rises above a preset value.

Low-current Alarm Indicator

A red LED indicator illuminates to indicate that the rectifier output current has fallen below .5% of rectifier rated d.c. output. This alarm may also trigger the summary failure alarm contacts provided YES is selected in the calibration routine if low current is a failure condition. Low current alarm stays alarmed until output current rises above preset value.

Summary Fail Alarm Indicator

A red LED illuminates to indicate that a failure has occurred which may disable the rectifier. The conditions which will produce a summary failure indication include: low current*, low output voltage, a.c. failure*, ground detections* or high output voltage. 2 form C contacts are provided for connection of external alarms. * - Low current, a.c. failure, and ground detection may be unselected for summary alarm condition.

Float Indicator

A green LED illuminates to indicate that the rectifier is in the float mode of operation.

Equalize Indicator

A yellow LED illuminates to indicate that the rectifier is in the equalize mode of operation.

Ground Detection Indicator and Switch

A red solid light indicates a negative ground. A flashing light indicates a positive ground. A test switch is provided, to test lights only. NOTE: ALL ALARMS HAVE RELAYS FOR CUSTOMER CONNECTIONS (SEE SCHEMATIC) This rectifier will parallel with any other La Marche Model TPSD Charger. A load sharing circuit is provided on the terminal board. When connected, two (2) or more La Marche TPSD units are forced to share the load equally within +/- 5%. Individual unit outputs must be greater than 15% of rated output. Output current will gradually increase after the rectifier is initially turned on reducing current surges. This rectifier may be connected to a battery which is heavily discharged and recharge it without clearing any protective devices while powering d.c. loads. Digital meter is standard on TPSD for d.c. volts and d.c. amps. These cases are designed for wall, floor and rack mounting. See cabinet dimensions sheet for more information.

5.4 5.5

PARALLELING

LOAD SHARING

5.6 5.7 5.8 5.9

CURRENT WALK IN

EMERGENCY RESTORATION METERS

MOUNTING

6 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

6.0

0-50 degrees C (32-122 degrees F)

ENVIRONMENTAL RATINGS 6.1 OPERATING AMBIENT TEMPERATURE

6.2 6.3 6.4 STORAGE TEMPERATURE HUMIDITY SHOCK

40 to +85 degrees C (-40 to +185 degrees F)

This rectifier is capable of operating in an ambient relative humidity range of 0-95% (non-condensing). The rectifier in its shipping container, withstands shock developed when one edge of the container is dropped six (6) inches while the opposite edge is resting on the ground, or it is dropped two (2) inches on any surface without any physical damage or degradation of the electrical performance. The rectifier in its shipping container, withstands vibration encountered in shipping without physical damage or degradation of the electrical performance. This rectifier is capable of operation at altitudes to 10,000 feet at an ambient temperature of up to +40 degrees C. The unit should be mounted so that ventilating openings are not blocked and air entering the cabinet does not exceed 122 degrees F. Heat Baffles It may be necessary to use a baffle plate between the rectifier and other heat producing equipment. Audible noise is not greater than 65 DBA measured at 5 feet from any surface on the unit enclosure.

6.5 6.6 6.7

VIBRATION ALTITUDE

VENTILATION

6.8

AUDIBLE NOISE

7.0

Table 2 lists the a.c. input and the d.c. output minimum wire size requirements. At distances exceeding 10 feet, the d.c. wire size should be chosen to keep the voltage difference between the units d.c. output terminals and the battery at less than volt when the unit is fully loaded. See Section 7.6 for POWER CABLING FORMULAS. The total loop length is twice the distance from the wiring point to the unit. These wire sizes are based on those recommended in the National Electric Code Table 310-16 for copper wire at 75 degrees C conductor temperature operating in an ambient of 30 degrees C. For higher operating temperatures refer to the derating factors in the National Electric Code Table 310-16. This terminal should be connected to an earth ground. The size of the conductor is based on National Electric Code Table 250-95 for copper wire at 75 degrees C. (See Table #2 for recommended wire sizes.) Install the rectifier so that the flow of air through the ventilators is not obstructed.

INSTALLATION INFORMATION 7.1 MINIMUM WIRE SIZES

7.2

NATIONAL CODES

7.3 7.4

FIELD GROUND TERMINAL MOUNTING

7 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

7.5

WIRE SIZE TABLE

The following section may be used to calculate the wire size requirements for wire lengths in excess of 10 ft. (Refer to TABLE 3)

CMA= CROSS SECTION OF WIRE IN CIRCULAR MILS. A = CURRENT DRAIN IN AMPERES. LF = CONDUCTOR LOOP FEET.

7.6

POWER CABLING FORMULAS

MAX AMP= MAXIMUM ALLOWABLE CURRENT FOR A GIVEN VOLTAGE DROP (IN AMPERES). AVD = ALLOWABLE VOLTAGE DROP. COPPER WIRE (KS5482-01) WIRE SIZE REQUIRED CMA = (A*LF*K) / AVD CURRENT CAPACITY (IN AMPS) - (SEE TABLE 3) MAX AMPS = (CMA* AVD)/(LF*K) K = 11.1 CONSTANT FACTOR FOR COMMERCIAL (TW TYPE)

8 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

8.0

Terminal blocks are provided for connecting the a.c. input and d.c. output. A ground wire must be connected to the units case ground.

ELECTRICAL CONNECTIONS & FIELD WIRING

8.1 A.C. INPUT

Make sure that the input source is the same voltage and frequency as that which is marked on the nameplate of the rectifier. The wire size and distribution fusing should be adequate for the nameplate input current of the rectifier plus the overload current (usually 10%-15% higher than the nominal rating). An adequate earth ground lead should be connected to the terminal marked GROUND or GND. Be sure the transformer taps are set for the correct a.c. input. unit. An a.c. input tap setting card is located inside the

Make sure that a.c. power is off at the main a.c. breaker box before installation begins.

Make sure that the battery voltage, which is being connected to the rectifier, matches the rectifiers output voltage. The negative wire from the battery must be connected to the terminal marked NEGATIVE or NEG and the positive wire from the battery must be connected to the terminal marked POSITIVE or POS on the rectifier. To prevent the d.c. output fuse from blowing when connecting the battery, connections to the power supply and batteries should be done in the following order (single power supply). 1. 2. 3. 4. 5. Connect a.c. input line to the terminal block provided. Be sure the a.c. circuit breaker is off. *****OBSERVE PROPER POLARITY!*****

8.2

D.C. OUTPUT

Observe the polarity of the battery cables and the rectifier output. Connect the negative battery cable to the negative rectifier output terminal. Energize the unit by turning the a.c. breaker to the ON position. This will charge the capacitors inside the power supply and eliminate heavy arcing when the remaining battery cable is connected. After approximately one (1) minute, turn off the power supply and immediately connect the remaining battery cable. Connect the loads. Turn the a.c. breaker to the ON position again and the rectifier will commence charging the batteries and powering the load.

Provisions for remote d.c. voltage sensing are provided. To use the remote sensing circuit remove the wire from the positive d.c. output terminal to the RS+ terminal strip. Connect a #14 gauge wire from the RS+ terminal to the positive battery terminal. Remote sensing leads should be fused 2 amp maximum fuse. Caution: The polarity of the sensing is critical. Check and verify the polarity carefully.

8.3

REMOTE VOLTAGE SENSING

When the load sharing terminal (LS) on the (TS) terminal strip is connected, multiple units are forced to share the load current within +/- 5%. Individual unit outputs must be greater than 15% of the rated current output. #16 gauge wire can be used for loadsharing. NOTE: If only one unit picks up the load, momentarily put the unit with no load into the equalize mode, and then back to the float mode. The units should share load equally. Form C contacts are provided which indicate an a.c. power failure. The contacts are rated at 60Va at 125 Vdc or a.c.

8.4

LOAD SHARING

8.5

ALARM CONNECTIONS

9 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

9.0

When all connections have been made, place the units a.c. breaker in the on position. If there is an optional d.c. breaker place it in the ON position. Verify the output voltage, output current, and the alarm and status lights to be sure the unit is operating properly. If the unit is not operating correctly check the connections again and read Section 13, TROUBLE SHOOTING.

OPERATION 9.1 START UP

10.0 ADJUSTMENTS 10.1 CURRENT LIMIT ADJUSTMENT

The current limit adjustment is factory set at approximately 115% of rated d.c. output current. The adjustment provides a means of changing the rectifier current limit between 50-115% of rated output. Turning the adjustment, which is located on the unit front panel, clockwise lowers the current limit; turning counterclockwise raises the current limit. CAUTION: CURRENT LIMIT MUST NOT EXCEED 115%. OF RATED OUTPUT CURRENT.

The float adjustment is factory set at 2.17 volts/cell (Lead) (VRLA) or 1.4 volts/cell (N.C.). Turning the adjustment, which is located on the front door of the unit, clockwise raises the float voltage (the F/E switch must be in the float position). The adjustable range is as follows: Equalize/Select Switch: 2.12-2.3 volts/cell +/- .1 Volts (Lead) (VRLA) 1.39-1.45 volts/cell +/- .1 Volts (N.C.)

10.2

FLOAT ADJUSTMENT

This switch is located on the unit front panel. When the unit defaults to float, the rectifier will maintain the battery at the voltage level which was preset by the Float potentiometer adjustment and at the same time maintain the load up to the rectifiers rated output. The equalize adjustment is factory set at 2.33 volts/cell (Lead) (VRLA) or 1.55 volts/cell (N.C.). Turning the adjustment, which is located on the front panel of the unit, clockwise raises the equalize voltage (the F/E switch must be in the equalize position). The adjustable range is as follows: 2.25-2.4 volts/cell +/- .1 Volts (Lead) (VRLA) 1.5 - 1.6 volts/cell +/- .1 Volts (N.C.) In the equalize position, the rectifier will maintain the battery at the voltage level preset by the Equalize potentiometer adjustment and at the same time maintain the load up to the rectifiers rated output.

10.3

EQUALIZE ADJUSTMENT

11.0 ALARM LIGHTS AND SET POINTS 11.1 Alarm Lights

Alarm lights are located on the front of the unit.

A.C. On:

The LED illuminates when a.c. power is applied to rectifier and a.c. breaker is in the ON position.

Summary Alarm:

The LED illuminates on low voltage, high voltage, or low d.c. current. **(Provided LDCA is selected as a summary alarm condition Factory set YES) The summary alarm can also be programmed to include a.c. power failure.

10 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

Float-Equalize Light:

The proper LED will illuminate, indicating which charge mode the rectifier is operating in. An LED blinks when rectifier or battery voltage exceeds a predetermined adjustable level. The factory setting is 2.45 volts/cell (Lead) (VRLA) or 1.6 volts/cell (N.C.). The HVSD is factory set at 2.5 volts/cell (Lead) (VRLA) or 1.65 volts/cell (N.C.). For the HVSD circuit to operate, it will be necessary to have a d.c. load or battery on the rectifiers output. When the d.c. voltage exceeds the setting, the high voltage/HVSD LED will be on solid indicating high voltage shutdown.

11.2 11.3

HIGH VOLTAGE

HIGH VOLTAGE SHUTDOWN (HVSD)

CAUTION: Do not exceed the system voltage . Increase the rectifiers output voltage to the desired set point. When the rectifier output reaches the predetermined setting, the high voltage shutdown will activate the shunt trip on the a.c. circuit breaker causing the breaker to trip which turns off the unit. To reset unit, push reset button and turn on a.c. breaker.

The LED illuminates when rectifier or battery voltage falls below a predetermined adjustable level. The factory setting is 2 volts/cell (Lead) (VRLA) or 1.2 volts/cell (N.C.). The LED will stay on until the d.c. voltage recovers to an adjustable preset level. The differential between the low voltage alarm setting and the voltage required to turn off the alarm is factory set at 8%. This can be field reset. Consult factory for procedure. The L.E.D. illuminates when the rectifier output current goes below a preset value and stays on until the current goes above a preset value. Turning the adjustment, which is located on the front door of the unit, clockwise raises the float voltage. For adjustable range see Section 2.2.

11.4

LOW VOLTAGE/DIFFERENTIAL (DIFF)

11.5 11.6

LOW CURRENT

FLOAT ADJUSTMENT:

In the float position, the rectifier will maintain the battery at the voltage level which was preset by the Float potentiometer adjustment and at the same time maintain the load up to the rectifiers rated output.

Equalize/Select Switch:

This switch is located on the unit front panel. It is a momentary switch. In the up position, the unit can be selected for either float or equalize operation. In the down position to DCV, DCA, timer mode or Equalize hours can be selected. Also, switch used to set into calibration modes. Turning the adjustment, which is located on the front panel of the unit, clockwise raises the equalize voltage. For adjustable range see Section 2.2. In the equalize position, the rectifier will maintain the battery at the voltage level preset by the Equalize potentiometer adjustment and at the same time maintain the load up to the rectifiers rated output.

11.7

EQUALIZE ADJUSTMENT:

11 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

12.0 ALARMS AND AUTOMATIC EQUALIZE TIMER

THE UNIT HAS EIGHT (8) ALARMS FOR CUSTOMER HOOKUP:

1. & 2.) A high & low dc alarms with "LED" lights (2) & relays. These alarms are preset at 2.45Vpc high and 2 Vpc low. 3.) A low dc current alarm "LED" & relay will indicate if the output current is below the factory preset level. (1% of d.c. shunt, 100% rating) 4.) A high voltage shutdown LED lights if the dc voltage exceeds 2.5 Vpc.. If the voltage remains above 2.5 Vpc for 20 seconds, the high voltage circuit will trip the ac input breaker turning off the unit. 5.) A summary alarm LED & relay will indicate if you have low voltage and low current or high voltage shutdown condition.

CAUTION: THE MAXIMUM CONTACT RATINGS FOR THE ABOVE RELAYS ARE: 6.) 7.) 8.) A.c. Power failure relay. A positive LED light FLASHING and relays indicate a positive ground. A negative LED light SOLID and relays indicate a negative ground.

MAX. SWITCHED CURRENTMAX. SWITCHED VOLTAGEMAX. SWITCHED POWER2A AC OR DC 150Vdc OR 125Vac 30W OR 62.5Va

CHECK THE UNIT SCHEMATIC FOR CUSTOMER ALARM RELAY HOOKUP.

TO CHECK OR CHANGE THE ALARM SETTINGS, push the equalize switch to equalize and hold for five (5) seconds. The display will indicate CAL then the low current. LED will blink and the display will indicate the low current alarm setting. The next reading will be the low current turn off setting. In five (5) seconds, the display will switch to the next alarm setting and that alarm LED will blink automatically. TO RESET THE ALARMS, use the equalize select switch. in the up position the set voltage will rise. down position lowers the alarm setting. to end the calibrate mode let sequence go through to say save - yes. TO CHECK OR CHANGE THE ALARM DELAY SETTINGS, have the equalize select switch in select position. hold for 20 seconds. the digital display will indicate calibration in seconds and the alarm light will be blinking. the display will show the next alarm delay time automatically. TO RAISE OR LOWER THE SETTING AGAIN, use the equalize select switch to raise or lower the same way as when changing the alarm settings. to end the delay calibration let the sequence go through to say save yes. TIME DELAY ADJUSTMENTS FROM 0 TO 255 SECONDS ON ALL ALARMS AND TIMER MODE.

FACTORY SETTING FOR ALARMS AND TIMER MODE LOW DC VOLTAGE 5 SECONDS HIGH DC VOLTAGE 5 SECONDS HIGH VOLTAGE SHUTDOWN 20 SECONDS LOW DC CURRENT 5 SECONDS TIMER MODE 30 SECONDS for Mode 4 HIGH VOLTAGE SHUTDOWN WORKS WHEN A HIGH VOLTAGE SHUTDOWN CONDITION EXISTS ALONG WITH THE PRESENCE OF DC CURRENT HIGHER THAN THE LOW DC CURRENT ALARM SETTING.

12.1

ADJUSTMENTS & SET POINTS

12 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

The equalize timer assembly is a microprocessor based electronic timer which is capable of being field programmed for different timing mode and length of time cycles. The equalize cycle can be set from 1-144 hours in one hour increments. The mode of the standard version can be selected for 1-144 hours standard timer, 7 day, 14 day, or 30 day equalize cycles. (For example, a 7 day timer will automatically equalize every 7 days for the # of hours selected.) Unless otherwise specified the equalize timer is factory set for MODE 0, with an 8 hours equalize charge. (See MODE 0 operation) To change equalize hours, hold equalize select switch in equalize for 5 seconds and CAL is displayed. Display will scroll through alarms and show settings, equalize hours will display change hours by using select switch. The timer consists of a yellow equalize "LED" and equalize select switch. The "LED" indicates that an equalize cycle is in process. The equalize select switch is used to start or stop the equalize cycle. To start a cycle the switch is pressed, the equalize "LED" will illuminate and the internal timers will reset. If the switch is pressed again the equalize cycle will be terminated and the unit will return to float operation. To check or change Timer Modes, push and hold equalize switch for 5 seconds, now in the cal alarm adjustment section. The display will scroll, showing each alarm & settings until the timer mode "LED" (the bottom "LED") starts to flash, and the digital display shows P? (?= Mode 0,1,2,3,or 4). To change mode use equalize select switch. Toggle "up" rises and "down" lowers setting. This is the standard timer mode. If the unit is put in equalize, the timer will switch the charger into the equalize mode and the equalize "LED" will indicate. The timer will automatically return the charger to the float mode when the equalize cycle is complete. The number of hours of equalize charge is determined by setting the switch that controls the equalizing hours. Switch the equalize switch again to cancel the equalize cycle. Mode 0 is manually operated. This mode of operation automatically starts an equalize cycle every 7 days. The length of this cycle is again determined by the timer setting. After the equalize period the timer will wait for another 7 days and then restart. This mode of operation automatically starts an equalize cycle every 14 days. The length of this cycle is again determined by the timer setting. After the equalize period the timer will wait for another 14 days and then restart. This mode of operation automatically starts an equalize cycle every 30 days. The length of this cycle is again determined by the timer setting. After the equalize period the timer will wait for another 30 days and then restart.

This mode of operation automatically starts an equalize cycle when the d.c. voltage drops below the low voltage setting for 30 seconds or longer. The battery voltage must rise above 2.01 to activate this mode.

12.2

ELECTRONIC EQUALIZE TIMER

12.3

TIMER MODES

MODE 0 - DISPLAY indicates P0

MODE 1 - DISPLAY indicates P1

MODE 2 - DISPLAY indicates P2

MODE 3 - DISPLAY indicates P3

MODE 4 - DISPLAY indicates P4

13 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

13.0 TROUBLESHOOTING

Troubleshooting should be performed only by trained service personnel or experienced electricians. Equipment:

CAUTION: Hazardous a.c. and d.c. voltages are present within the rectifier cabinet.

The only equipment required is a multimeter for voltage or resistance readings and analog ohmmeter On servicing new equipment, before setting up any complicated testing or jumping to any conclusions, give the unit a general inspection. Check the following:

13.1

GENERAL INSPECTION

1. Check d.c. output cables, connections, battery type, and number of battery cells with rectifier rating. 2. Check unit specifications with customer order. 3. Check input connections, input voltage and line breaker size. 4. Check for shipping damage, loose connections, broken wires, etc. 5. Certain failures can be caused by defective batteries and customer loads; make sure batteries and loads are free from defects.

NOTE: If the problem is found to be located in the printed circuit boards, the board should be replaced. No attempt should be made to repair circuit boards in the field. Information you should have when calling in for troubleshooting assistance:

13.2

SERVICE INFORMATION

1. 2. 3. 4. 5.

Equipment model number and serial number. The actual a.c. input voltage. The d.c. output voltage with and without the battery. Result of the check of a.c. breaker and d.c. output fuse. The actual d.c. output current and voltage when measured with battery and load connected to rectifier.

13.3

SYMPTOMS & CAUSES

Possible Cause:

1. 2. 3. 4. 5.

13.3.1 A.C. Breaker trips.

Wrong a.c. input voltage. The a.c. input taps on power transformer set incorrectly. (See schematic wiring diagram) An a.c. to d.c. short or a.c. or d.c. short to ground (see ground short circuit test). High d.c. output voltage. Check battery voltage for proper number of cells. Check control fuse on alarm interface board. Float/Equalize voltage potentiometers not set properly. (See Float/Equalize adjustment procedure for proper voltage setting.) Disconnect battery and loads from rectifier output terminals, put F/E switch in the float position, and apply a.c. input voltage to rectifier. If d.c. voltage raises above 2.5 v.p.c., circuit regulator assembly or informer option may be defective. Check for shorted power diodes or diode modules (SD1). (See diode troubleshooting page) H.V. shutdown improperly set, too low, informer option. Open gate or wire on triac TR-1.

6. 7. 8.

14 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

13.3.2 Open D.C. Fuse or breaker.

Possible Cause:

1. 2. 3. 4. 5. 6. Shorted power diode or diode module (repair/replace as required). Shorted battery cells or customer equipment. Shorted output cables. Capacitors not precharged. Shorted C3 capacitors. Loose connections on the d.c. fuse.

13.3.3 Charger operates but output voltage/current is low.

Possible Cause:

1. 2. 3. 4. 5. 6. 7. Float/Equalize voltage potentiometers not set correctly (see float/equalize adjustment procedure for proper voltage setting). Check power diodes or diode modules and triac (see diode and triac troubleshooting procedure). Control assembly is defective. (Replace as required) Defective display. Unit in current limit. Resonating capacitor open. Defective shunt.

13.3.4 Charger operates but output voltage is high.

Possible Cause:

1. 2. 3. Float/Equalize voltage pots not set correctly (see float/equalize adjustment procedure for proper voltage setting). Circuit regulator assembly S2A-205S is defective. Open gate on triac TR-1.

13.3.5 Ground and short circuit test.

A simple ohmmeter check can be performed to check the unit for a short to ground, primary to secondary breakdown, a.c.-d.c. short, or d.c. ground. Before installation of a new unit, the above checks should be made before installing. If a short of this type is suspected on a unit in service, check as follows: 1. 2. 3. Disconnect a.c. input power to the unit. Disconnect the d.c. battery and loads from the rectifier. Set ohmmeter scale on ohms scale RX100. Measure from one terminal of the input to one terminal of the output. Meter should not indicate. If the meter reads full scale deflection, this indicates an ac-dc short. During shipping, an a.c. wire may rub against the d.c. lugs, terminals, etc. and cause a short. These problems may be eliminated by being very careful in inspecting the wiring to make certain the a.c. wires are not touching the d.c. wiring. Check the input terminals to ground and check the output terminals ground. If the meter indicates full scale deflection, a wire is touching a metal part of the rectifier. Look for wires that are near any metal part and inspect for possible breakdown caused by shipping. The heatsink of the diodes and the control unit are insulated from ground through the mounting legs.

4.

13.4

The procedure for checking the triac is as follows:

TROUBLESHOOTING AND REPLACING THE TRIAC

On the analog ohmmeter, set the switches on ohms, d.c., and Rx10,000 scale. Disconnect the triac to be checked. Using an ohmmeter, measure the resistance between main terminals, MT1 and MT2 in both directions. A good device will indicate open circuit in both directions, a low resistance indicates a shorted device. Set analog ohmmeter to Rx100 scale.

15 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

To check for a shorted triac gate lead, measure the resistance between gate (GATE) lead and main terminal MT1. A reading of zero ohms in both directions indicates a shorted gate. A reading of infinity in both directions indicates an open gate and the triac should be replaced. A good device should have resistance in both directions, but not zero ohms.

13.5

The procedure for checking a silicon diode is as follows:

TROUBLESHOOTING AND REPLACING POWER SILICON DIODES / MODULES

1. 2. 3.

On the analog ohmmeter, set the switches on ohms, d.c., and Rx100 scale.

4. 5.

Isolate one end of the diode by disconnecting the wires attached to the nipple (or pigtail) end of the diode (only one end of the diode must be disconnected). On a diode module, both of the outside leads must be disconnected. Clip one lead of the ohmmeter to the anode lead of the diode. Clip the other ohmmeter lead to the cathode. Note the ohmmeter reading. Then reverse the leads to the diode. Again, note the ohmmeter reading. If the diode is good, the meter will indicate a high resistance in one direction and a low resistance with the leads reversed. If the diode is shorted, the meter will read full scale, or zero (O) resistance with the leads in either direction. If the diode is open, the ohmmeter needle will not indicate or it will show infinite resistance in either direction, indicating an open circuit. All diodes must be checked in the event that more than one diode is defective. If the diode is defective, remove the defective diode from the heatsink and replace with a new diode.

When checking capacitors be sure all a.c. power is turned off and battery is disconnected from unit. Check capacitors with d.c. voltmeter to see that d.c. voltage is at near -0- volts, then short circuit capacitor. Momentarily short circuit the capacitor leads to assure complete discharge. Connect the meter test leads to the capacitor leads or terminals and observe indicated resistance. A good capacitor will indicate an initial low resistance and gradually increase as the capacitor charges. The final resistance of a good capacitor is usually several hundred thousand ohms approaching a megohm.

13.6

CHECKING CAPACITORS

Initial high resistance approaching infinity indicates an open capacitor. Initial and continued low resistance readings indicate a shorted capacitor.

When ordering replacement parts, drawings, or schematics, always give model number, serial number and a.c. input voltage.

16 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

General Maintenance Procedure

Yearly

1. 2. 3. 4. Blow out rectifier/inverter with a low-pressure air hose. Make sure all connections are tight. Perform a visual check on all internal components. Check front panel meters and alarms for accuracy.

4th Year

REPEAT ABOVE WITH THE ADDITION OF:

1. Check relay contacts for pitting or corrosion. 2. Check capacitors for leakage.

7th Year

REPEAT ALL, WITH THE ADDITION OF:

1. Filter, resonating capacitors and control relays should be replaced.

10th Year

REPEAT ALL WITH THE ADDITION OF: (except replacing capacitors, they should be replaced every 7 years)

1. Check magnetics, components and wiring for signs of excessive heat.

17 OF 18

MODEL TPSD - INSTRUCTIONS AND TROUBLESHOOTING INFORMATION

MANUFACTURERS WARRANTY

All La Marche Manufacturing Co. equipment has been thoroughly tested and found to be in proper operating condition upon shipment from the factory and is warranted to be free from any defect in workmanship and material that may develop within one year from date of purchase. In addition to the standard one (1) year warranty, La Marche warrants its magnetics and power diodes on a parts replacement basis only for four (4) more years under normal use. Any part or parts of the equipment (except fuses, d.c. connectors and other wear-related items) that prove defective within a one (1) year period shall be replaced without charge providing such defect, in our opinion, is due to faulty material or workmanship and not caused by tampering, abuse, misapplication or improper installation. Magnetics and power diodes are warranted for five (5) years after date of purchase. During the last four (4) years of this five (5) year warranty period, the warranty covers parts replacement only, and no labor or other services are provided by La Marche, nor is La Marche obligated to reimburse the owner or any other person for work performed. Should a piece of equipment require major component replacement or repair during the first year of the warranty period, these can be handled in one of two ways: 1. The equipment can be returned to the La Marche factory to have the inspections, parts replacements and testing performed by factory personnel. Should it be necessary to return a piece of equipment or parts to the factory, the customer or sales representative must obtain authorization from the factory. If upon inspection at the factory, the defect was due to faulty material or workmanship, all repairs will be made at no cost to the customer during the first year. Transportation charges or duties shall be borne by purchaser. 2. If the purchaser elects not to return the equipment to the factory and wishes a factory service representative to make adjustments and/or repairs at the equipment location, La Marche's field service labor rates will apply. A purchase order to cover the labor and transportation cost is required prior to the deployment of the service representative. In accepting delivery of the equipment, the purchaser assumes full responsibility for proper installation, installation adjustments and service arrangements. Should minor adjustments be required, the local La Marche sales representative should be contacted to provide this service only. All sales are final. Only standard LaMarche units will be considered for return. A 25% restocking fee is charged when return is factory authorized. Special units are not returnable. In no event shall La Marche Manufacturing Co. have any liability for consequential damages, or loss, damage or expense directly or indirectly arising from the use of the products, or any inability to use them either separately or in combination with other equipment or materials, or from any other cause. In addition, any alterations of equipment made by anyone other than La Marche Manufacturing Co. renders this warranty null and void. La Marche Manufacturing Co. reserves the right to make revisions in current production of equipment, and assumes no obligation to incorporate these revisions in earlier models. The failure of La Marche Manufacturing Co. to object to provisions contained in customers' purchase orders or other communications shall not be deemed a waiver of the terms or conditions hereof, nor acceptance of such provisions. The above warranty is exclusive, supersedes and is in lieu of all other warranties, expressed or implied, including any implied warranty of merchantability or fitness. No person, agent or dealer is authorized to give any warranties on behalf of the Manufacturer, nor to assume for the Manufacturer any other liability in connection with any of its products unless made in writing and signed by an official of the manufacturer.

18 OF 18

You might also like

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- KCGG Relay ManualDocument284 pagesKCGG Relay Manualmfulk3100% (1)

- User Manual-GS Series Hybird Inverter PDFDocument27 pagesUser Manual-GS Series Hybird Inverter PDFKristhian Quintero0% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- EnerGenius - Battery Charger NRG24-10-HC - Technical Manual - SENSDocument27 pagesEnerGenius - Battery Charger NRG24-10-HC - Technical Manual - SENSpevare100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleFrom EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleNo ratings yet

- B. F. Skinner - Upon Further Reflection - (1987)Document212 pagesB. F. Skinner - Upon Further Reflection - (1987)NB100% (11)

- A31Document15 pagesA31lookb6No ratings yet

- A36d SeriesDocument33 pagesA36d Seriesmarcostgn2024No ratings yet

- A75DE ManualDocument20 pagesA75DE ManualJohnTPNo ratings yet

- Model: A36F - 3 Phase - Instructions and TroubleshootingDocument21 pagesModel: A36F - 3 Phase - Instructions and TroubleshootingmohammedNo ratings yet

- Transformadores FGWilsonDocument12 pagesTransformadores FGWilsonBruno MarianoNo ratings yet

- LG Flatron l204wt Lm62b SMDocument27 pagesLG Flatron l204wt Lm62b SMgeofaxxxxxxNo ratings yet

- Carregador CCL Sentinel 150Document8 pagesCarregador CCL Sentinel 150José Da Silva MataNo ratings yet

- MANUALrev Fviewing 1Document12 pagesMANUALrev Fviewing 1saleossNo ratings yet

- Service Manual Type MCAG 14, 34 High Stability Circulating Current RelaysDocument28 pagesService Manual Type MCAG 14, 34 High Stability Circulating Current RelaysIsmir Pobric100% (2)

- Sentinal 150 Battery ChargerDocument8 pagesSentinal 150 Battery ChargersarkaftNo ratings yet

- IBM Think Vision L170 Srvice ManualDocument28 pagesIBM Think Vision L170 Srvice Manualpocachurio0% (1)

- 32lg30rac 32lg32r 32lg33r 32lg34r Chassis Lp81aDocument24 pages32lg30rac 32lg32r 32lg33r 32lg34r Chassis Lp81adrdr61No ratings yet

- Windsor Spirit Manual-PartsDocument18 pagesWindsor Spirit Manual-PartsNestor Marquez-Diaz100% (1)

- Color Monitor: Service ManualDocument35 pagesColor Monitor: Service Manualmoshu_85No ratings yet

- LG cl86 Chassis Chassis fwd42v1 SM PDFDocument62 pagesLG cl86 Chassis Chassis fwd42v1 SM PDFAdrian EGNo ratings yet

- Sunpax 5500w 5 5kw Hybrid Inverter ManualDocument25 pagesSunpax 5500w 5 5kw Hybrid Inverter ManualMehmet AkbalNo ratings yet

- LG L194WTDocument29 pagesLG L194WTqxbgwhvuNo ratings yet

- 48 kHIPEPTZInstMan050GBv2 1-1Document86 pages48 kHIPEPTZInstMan050GBv2 1-1Vlad VasiliuNo ratings yet

- Service Manual Type MRSU 04 Rotor Earth Fault RelayDocument24 pagesService Manual Type MRSU 04 Rotor Earth Fault RelayRinda_RaynaNo ratings yet

- MVAJ053Document38 pagesMVAJ053Yusof BasriNo ratings yet

- Cargador de Baterias GuardianDocument8 pagesCargador de Baterias GuardianCleto Delacruz LopezNo ratings yet

- Om 2020 PDFDocument52 pagesOm 2020 PDFAchmad GunawanNo ratings yet

- LG Flatron l1753t l1953t-sfs Chassis Lm72a (ET)Document31 pagesLG Flatron l1753t l1953t-sfs Chassis Lm72a (ET)robermdeaNo ratings yet

- Apollo True Sinewave Inverter Manual 11-11-09Document34 pagesApollo True Sinewave Inverter Manual 11-11-09goga_russianNo ratings yet

- L196WTQ-S, BFQ eDocument30 pagesL196WTQ-S, BFQ eadisistemsNo ratings yet

- Color Monitor: Service ManualDocument36 pagesColor Monitor: Service ManualBorcan CristiNo ratings yet

- Lcd+Lg+Flatron+l1753t Chasis+Lm57bDocument34 pagesLcd+Lg+Flatron+l1753t Chasis+Lm57bIsrael AlexanderNo ratings yet

- Commissioning Instructions Novar 315 Capacitor Controller For Power Factor CorrectionDocument20 pagesCommissioning Instructions Novar 315 Capacitor Controller For Power Factor CorrectionRinda_RaynaNo ratings yet

- Starting & Charging System: SectionDocument28 pagesStarting & Charging System: Sectionfrank1220uNo ratings yet

- R8033C MvtiDocument28 pagesR8033C MvtiRinda_RaynaNo ratings yet

- P34x - Application Guide PDFDocument210 pagesP34x - Application Guide PDFchidambara_2013No ratings yet

- KCGG Kceg Service ManualDocument284 pagesKCGG Kceg Service Manualisola_zhou100% (1)

- Color Monitor: Service ManualDocument36 pagesColor Monitor: Service ManualelistefanNo ratings yet

- MVTP Manual GB PDFDocument22 pagesMVTP Manual GB PDFVikash Kumar PrasadNo ratings yet

- 7 2kw Series Hybrid Solar Inverter ManualDocument35 pages7 2kw Series Hybrid Solar Inverter Manualshaktisingh24No ratings yet

- LG FLATRON Monitor W1752T Service ManualDocument26 pagesLG FLATRON Monitor W1752T Service ManualNunu Bagja SetiaNo ratings yet

- Pow Hvm6 2m 48v N Hybrid Inverter ManualDocument39 pagesPow Hvm6 2m 48v N Hybrid Inverter ManualCandra ErwinantoNo ratings yet

- Heavy Duty Battery Boosters / ChargersDocument15 pagesHeavy Duty Battery Boosters / ChargersJohann SGNo ratings yet

- LG 32LT360C Ld2ac Led LCDDocument38 pagesLG 32LT360C Ld2ac Led LCDAnderson Azevedo MarquesNo ratings yet

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Oil Mill Machinery & Equipments: For More Information VisitDocument10 pagesOil Mill Machinery & Equipments: For More Information VisitRizwanSaifiNo ratings yet

- So Lesson Plan 2 TechnologyDocument22 pagesSo Lesson Plan 2 Technologyapi-309886906No ratings yet

- Brand - PositioningDocument39 pagesBrand - PositioningDo Thanh ThangNo ratings yet

- Study Guide - Exam 70-761Document20 pagesStudy Guide - Exam 70-761jelopezz100% (1)

- Yealink Firmware Failed - Dead Handset: WhirlpoolDocument1 pageYealink Firmware Failed - Dead Handset: WhirlpoolCineto TelecomunicacionesNo ratings yet

- Price List Royu Electrical MARCH 2024 Issue 1Document16 pagesPrice List Royu Electrical MARCH 2024 Issue 1jayanonymous0923No ratings yet

- ED224910Document66 pagesED224910asiofokihazNo ratings yet

- Condensate Extraction Pump (CEP)Document12 pagesCondensate Extraction Pump (CEP)mudrijasm50% (2)

- Ethical and Regulatory Aspects of Clinical Research BASICSDocument2 pagesEthical and Regulatory Aspects of Clinical Research BASICSRicardo SantamaríaNo ratings yet

- Tanap Lesson LearnedDocument124 pagesTanap Lesson LearnedserdarNo ratings yet

- Unit 2 City LifeDocument9 pagesUnit 2 City LifegiangNo ratings yet

- EVlink Home - EVH4S07N2Document2 pagesEVlink Home - EVH4S07N2Amzon JumardiNo ratings yet

- Addition of Two PolynomialDocument5 pagesAddition of Two Polynomialajay_anavNo ratings yet

- Reference Green Blue Infrastructure Guidelines Feb17Document76 pagesReference Green Blue Infrastructure Guidelines Feb17ssajith123No ratings yet

- You Me and The RainDocument24 pagesYou Me and The RainNicole AlvarezNo ratings yet

- Electronic Dartboard Owner's Manual and Game InstructionsDocument17 pagesElectronic Dartboard Owner's Manual and Game InstructionsChu Chuito TachinNo ratings yet

- Training Plan 10k Beginner v2Document4 pagesTraining Plan 10k Beginner v2BrooksRunning0% (1)

- Optics 04 00039 v2Document13 pagesOptics 04 00039 v2nikitajoshi345No ratings yet

- Speaking IIDocument3 pagesSpeaking IITEOH EAK SOONNo ratings yet

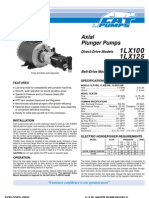

- 1LX100 SchematicDocument4 pages1LX100 Schematicab5951No ratings yet

- Golden Golden Job Card Rev 1.0Document9 pagesGolden Golden Job Card Rev 1.0Kholis JaimonNo ratings yet

- Assignment 3C. Health Education PlanDocument3 pagesAssignment 3C. Health Education PlanDanielle Audrey BanNo ratings yet

- White Paper - Data Warehouse Project ManagementDocument32 pagesWhite Paper - Data Warehouse Project ManagementDavid Walker100% (2)

- AutoCAD Electrical JIC Admin Course Syllabus SampleDocument3 pagesAutoCAD Electrical JIC Admin Course Syllabus Samplefadapow4uNo ratings yet

- Server LogDocument6,178 pagesServer LogRizki PrtmNo ratings yet

- Calc 14 - 03Document50 pagesCalc 14 - 03Roshan CharaghNo ratings yet

- 5f10da7c11cd3476cccd9a19 - C7H 6X4 Modern Ejector TruckDocument3 pages5f10da7c11cd3476cccd9a19 - C7H 6X4 Modern Ejector TruckKattie ValerioNo ratings yet

- Expro RBI Expert Group HandbookDocument26 pagesExpro RBI Expert Group HandbookJavier RivasNo ratings yet

- Structured Packing BrochureDocument12 pagesStructured Packing BrochureMoad Bouzida100% (1)