Korando

Korando

Uploaded by

Ichraf AouiniCopyright:

Available Formats

Korando

Korando

Uploaded by

Ichraf AouiniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Korando

Korando

Uploaded by

Ichraf AouiniCopyright:

Available Formats

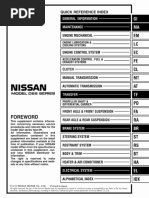

SECTION INDEX

SERVICE

MANUAL FRONT MATTER 0A

KORANDO GENERAL INFORMATION 0B

ENGINE 1

SUSPENSION 2

FOREWORD DRIVE LINE/AXLE 3

This manual includes procedure for mainte-

nance, adjustment, service operation and re- BRAKES 4

moval and installation of components.

All information, illustrations and specifications

contained in this manual are based on the latest TRANSMISSION 5

product information available at the time of

manual approval.

The right is reserved to make changes at any STEERING 6

time without notice.

HVAC

(HEATING, VENTILATION, 7

AND AIR CONDITIONING)

DAEWOO MOTOR CO., LTD.

RESTRAINTS 8

INCHON, KOREA

BODY AND ACCESSORIES 9

Downloaded from www.Manualslib.com manuals search engine

PERSONAL INJURY CAUTION

Appropriate service methods and proper repair procedure are essential

for the safe, reliable operation of all motor vehicles, as well as for the

personal safety of the person doing the repair. There are many

variations in procedures, techniques, tools and parts for servicing

vehicles, as well as in the skills of the people doing the work. This

manual cannot possibly anticipate all such variations and provide advice

or precautions for each. Anyone who deviates from the instructions

provided in this manual must ensure their own safety and preserve

the safety and integrity of the vehicle. The following list contains general

precautions that should always be followed while working on a vehicle.

• Safety stands are required whenever a procedure calls for

underbody work.

• Do not smoke when you work on a vehicle.

• To prevent serious burns, do not touch any hot metal parts.

• Set the parking brake when you work on the vehicle.

• Turn the ignition switch OFF unless a procedure states

otherwise.

• The engine may operate only in a well-ventilated area.

• Avoid moving parts when the engine is running.

• Safety glasses must be worn for eye protection.

Downloaded from www.Manualslib.com manuals search engine

KORANDO

Service Manual

FOREWORD

This manual includes procedures for maintenance, adjustment, service operations, and re-

moval and installation of components for the KORANDO vehicle.

When reference is made in this manual to a brand name, number, or specific tool, an equiva-

lent product may be used in place of the recommended item.

All information, illustrations and specifications contained in this manual are based on the latest

product information available at the time of publication approval. The right is reserved to make

changes at any time without notice.

Daewoo Motor Company, Limited

Overseas Technical Service Department

391-9 Chong Chon-2 Dong, Pu Pyung-Gu,

Inchon, Korea

Tel : 82-32-509-4161 ~ 4164

Fax : 82-32-509-4160

E-mail : m8610452@dwmc.co.kr

m9610883@dwmc.co.kr

Daewoo Motor Company, Limited

All rights Reserved

No part of this publication may be reproduced, stored in any retrieval system or transmitted, in

any form or by any means, including but not limited to electronic, mechanical, photocopying,

recording or otherwise, without the prior written permission of Daewoo Motor Company, Lim-

ited

Downloaded from www.Manualslib.com manuals search engine

TABLE OF CONTENTS

Section 0A Front Matter Section 5 Transmission

Section 5A Automatic Transmission

Section 0B General Information

Section 5B Manual Transmission

Section 1 Engine Section 5C Clutch

Section 1A1 M162 General Engine Information Section 5D1 Transfer Case (Part Time 4480)

Section 1B1 M162 Engine Mechanical Section 5D2 Transfer Case (TOD)

Section 1D1 M162 Engine Cooling

Section 6 Steering

Section 1E1 M162 Engine Electrical

Section 6A Power Steering System

Section 1F1 M162 Engine Controls

Section 6E Steering Wheel and Column

Section 1G1 M162 Engine Intake & Exhaust

Section 1A2 M161 General Engine Information Section 7 HVAC (Heating, Ventilation & Air

Section 1B2 M161 Engine Mechanical Conditioning)

Section 1D2 M161 Engine Cooling Section 7B/C Manual Control/Semiauto Tempera-

ture Control Heationg, Ventilation,

Section 1E2 M161 Engine Electrical

and Air Conditioning System

Section 1F2 M161 Engine Controls

Section 7D Full Automatic Temperature Control

Section 1G2 M161 Engine Intake & Exhaust Heationg, Ventilation, and Air Condi-

Section 1A3 OM600 General Engine Information tioning System

Section 1B3 OM600 Engine Mechanical

Section 8 Restraints

Section 1D3 OM600 Engine Cooling

Section 8A Seat Belts

Section 1E3 OM600 Engine Electrical

Section 8B Supplemental Restraint System

Section 1F3 OM600 Engine Controls

(SRS)

Section 1G3 OM600 Engine Intake & Exhaust

Section 9 Body and Accessories

Section 2 Suspension

Section 9A Body Wiring System

Section 2A Suspension Diagnosis

Section 9B Lighting Systems

Section 2B Wheel Alignment

Section 9D Wipers/Washer Systems

Section 2C Front Suspension

Section 9E Instrumentation/Driver Information

Section 2D Rear Suspension

Section 9F Audio

Section 2E Tires and Wheels

Section 9H Seats

Section 3 Drive Line / Axle Section 9L Glass and Mirrors

Section 3A Front Drive Axle Section 9N Front and Under Body

Section 3C Propeller Shaft Section 9O Bumpers and Fenders

Section 3D Rear Drive Axle Section 9P Doors

Section 9Q Roof

Section 4 Brakes

Section 9R Body Front End

Section 4A Hydraulic Brakes

Section 9T Remote Keless Entry and Anti-Theft

Section 4B Master Cylinder System

Section 4C Power Booster Section 9U Control Units and System

Section 4D Front Disc Brakes Section 9V Switches

Section 4E Rear Disc Brakes Section 9W Immobilizer System

Section 4F Antilock Brake System

Section 4G Parking Brakes

Downloaded from www.Manualslib.com manuals search engine

KORANDO

SERVICE MANUAL

ISSUED BY

OVERSEAS TECH. SERVICE

DAEWOO MOTOR CO., LTD.

391-9 CHONG CHON-2DONG, PU PYUNG-GU,

INCHON, KOREA

TELEPHONE : 82-32-509-4161~4164

FACSIMILE : 82-32-509-4160

Downloaded from www.Manualslib.com manuals search engine

ENGINE

CONTENTS

SECTION 1A1 M162 GENERAL ENGINE INFORMATION

SECTION 1B1 M162 ENGINE MECHANICAL

SECTION 1D1 M162 ENGINE COOLING

SECTION 1E1 M162 ENGINE ELECTRICAL

SECTION 1F1 M162 ENGINE CONTROLS

SECTION 1G1 M162 ENGINE INTAKE & EXHAUST

SECTION 1A2 M161 GENERAL ENGINE INFORMATION

SECTION 1B2 M161 ENGINE MECHANICAL

SECTION 1D2 M161 ENGINE COOLING

SECTION 1E2 M161 ENGINE ELECTRICAL

SECTION 1F2 M161 ENGINE CONTROLS

SECTION 1G2 M161 ENGINE INTAKE & EXHAUST

SECTION 1A3 OM600 GENERAL ENGINE INFORMATION

SECTION 1B3 OM600 ENGINE MECHANICAL

SECTION 1D3 OM600 ENGINE COOLING

SECTION 1E3 OM600 ENGINE ELECTRICAL

SECTION 1F3 OM600 ENGINE CONTROLS

SECTION 1G3 OM600 ENGINE INTAKE & EXHAUST

Downloaded from www.Manualslib.com manuals search engine

SUSPENSION

CONTENTS

SECTION 2A SUSPENSION DIAGNOSIS

SECTION 2B WHEEL ALIGNMENT

SECTION 2C FRONT SUSPENSION

SECTION 2D REAR SUSPENSION

SECTION 2E TIRES AND WHEELS

Downloaded from www.Manualslib.com manuals search engine

DRIVE LINE / AXLE

CONTENTS

SECTION 3A FRONT DRIVE AXLE

SECTION 3C PROPELLER SHAFT

SECTION 3D REAR DRIVE AXLE

Downloaded from www.Manualslib.com manuals search engine

BRAKE

CONTENTS

SECTION 4A HYDRAULIC BRAKES

SECTION 4B MASTER CYLINDER

SECTION 4C POWER BOOSTER

SECTION 4D FRONT DISC BRAKES

SECTION 4E REAR DISC BRAKES

SECTION 4F ANTILOCK BRAKE SYSTEM

SECTION 4G PARKING BRAKE

Downloaded from www.Manualslib.com manuals search engine

TRANSMISSION

CONTENTS

SECTION 5A AUTOMATIC TRANSMISSION

SECTION 5B MANUAL TRANSMISSION

SECTION 5C CLUTCH

SECTION 5D1 TRANSFER CASE (PART TIME 4408)

SECTION 5D2 TRANSFER CASE (TOD)

Downloaded from www.Manualslib.com manuals search engine

STEERING

CONTENTS

SECTION 6A POWER STEERING SYSTEM

SECTION 6E STEERING WHEEL AND COLUMN

Downloaded from www.Manualslib.com manuals search engine

HVAC (HEATING, VENTILATION &

AIR CONDITIONING)

CONTENTS

SECTION 7B/C MANUAL CONTROL/SEMIAUTO

TEMPERATURE CONTROL

HEATING, VENTILATION, AND

AIR CONDITIONING SYSTEM

SECTION 7D FULL AUTOMATIC

TEMPERATURE CONTROL

HEATING, VENTILATION, AND

AIR CONDITIONING SYSTEM

Downloaded from www.Manualslib.com manuals search engine

RESTRAINTS

CONTENTS

SECTION 8A SEAT BELTS

SECTION 8B SUPPLEMENTAL RESTRAINT

SYSTEM (SRS)

Downloaded from www.Manualslib.com manuals search engine

BODY AND ACCESSORIES

CONTENTS

SECTION 9A BODY WIRING SYSTEM

SECTION 9B LIGHTING SYSTEM

SECTION 9C HORNS

SECTION 9D WIPERS/WASHER SYSTEM

SECTION 9E INSTRUMENTATION/DRIVER INFORMATION

SECTION 9F AUDIO SYSTEM

SECTION 9G INTERIOR TRIM

SECTION 9H SEATS

SECTION 9L GLASS AND MIRRORS

SECTION 9M EXTERIOR TRIM

SECTION 9N FRAME AND UNDERBODY

SECTION 9O BUMPERS AND FASCIAS

SECTION 9P DOORS

SECTION 9Q ROOF

SECTION 9R BODY FRONT END

SECTION 9T REMOTE KEYLESS ENTRY AND ANTI-THEFT

SYSTEM

SECTION 9U CONTROL UNITS AND SYSTEM

SECTION 9V SWITCHES

SECTION 9W IMMOBILIZER SYSTEM

Downloaded from www.Manualslib.com manuals search engine

SECTION 0B

GENERAL INFORMATION

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 0B-1 While Operating the Vehicle . . . . . . . . . . . . . 0B-12

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . 0B-1 At Each Fuel Fill . . . . . . . . . . . . . . . . . . . . . . 0B-12

Vehicle Dimensions and Weights . . . . . . . . . . 0B-5 At Least Twice A Month . . . . . . . . . . . . . . . . 0B-12

Standard Bolts Specifications . . . . . . . . . . . . . 0B-6 At Least Monthly . . . . . . . . . . . . . . . . . . . . . . 0B-12

Maintenance and Repair . . . . . . . . . . . . . . . 0B-7 At Least Twice a Year . . . . . . . . . . . . . . . . . . 0B-12

Maintenance and Lubrication . . . . . . . . . . . . . 0B-7 Each Time The Oil is Changed . . . . . . . . . . . 0B-13

Normal Vehicle Use . . . . . . . . . . . . . . . . . . . . . 0B-7 At Least Annually . . . . . . . . . . . . . . . . . . . . . 0B-13

Explanation of Scheduled Maintenance Recommended Fluids and Lubricants . . . . . 0B-14

Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0B-7 General Description and System

Scheduled Maintenance Charts Operation . . . . . . . . . . . . . . . . . . . . . . . . 0B-15

(Gasoline Engine) . . . . . . . . . . . . . . . . . . . . . 0B-8 General Repair Instructions . . . . . . . . . . . . . 0B-15

Scheduled Maintenance Charts Vehicle Identification Number System . . . . . . 0B-16

(Diesel Engine) . . . . . . . . . . . . . . . . . . . . . . 0B-10 Vehicle Lifting Procedures . . . . . . . . . . . . . . 0B-19

Owner Inspections and Services . . . . . . . 0B-12

SPECIFICATIONS

TECHNICAL DATA

Performance-Manual Transaxle

Application 661LA 662NA 662LA 2.0L DOCH 2.3L DOCH 3.2L DOCH

Maximum Speed (Km/h) 140 137 148 154 165 176

Minimum Turning Radius (m) 5.8 5.8 5.8 5.8 5.8 5.8

Performance-Autumatic Transaxle

Application 661LA 662NA 662LA 2.3L DOCH 3.2L DOCH

Maximum Speed (Km/h) 140 137 140 160 170

Minimum Turning Radius (m) 5.8 5.8 5.8 5.8 5.8

Downloaded from www.Manualslib.com manuals search engine

0B-2 GENERAL INFORMATION

Engine

Application 661LA 662NA 662LA 2.0L DOCH 2.3L DOCH 3.2L DOCH

Engine Type 4Cylinder 5Cylinder 5Cylinder 4Cylinder 4Cylinder 6Cylinder

DIESEL DIESEL DIESEL GASOLINE GASOLINE GASOLINE

Bore (mm) 89 89 89 89.9 90.9 89.9

Stroke (mm) 92.4 92.4 92.4 78.7 88.4 84

Total Displacement (cc) 2299 2874 2874 1998 2295 3199

Compression Ratio 22:1 22:1 22:1 9.6:1 10.4:1 10:1

Maximum Power (ps/rpm) 101/4000 95/4000 120/4000 135/5500 149/5500 222/5500

Maximum Torque (kg.m/rpm) 21.5/2400 19.6/2400 25.5/2400 19.3/4000 22.4/4000 31.6/3750

Ignition System

Application 2.0L DOHC 2.3L DOHC 3.2L DOHC

Ignition Type Distributorless ignition

Ignition Timing (BOTH) 6°± 2° 6°± 2° 8°± 2°

Ignition Sequence 1-3-4-2 1-3-4-2 1-5-3-6-2-4

Spark Plug Gap (mm) 0.8 ± 0.1 0.8 ± 0.1 0.8 ± 0.1

Spark Plug Maker Bosch, Chapion, Beru

Spark Plug Type F8DC4(BOSCH)

C11YCC(CHAMPION)

14F8DU4(BERU)

Clutch - Manual Type

Application 661LA 662NA 662LA 2.0L DOHC 2.3L DOHC 3.2L DOHC

Type Single Dry Diaphram

Outside Diameter (mm) 225 225 240 225 225 240

Inside Diameter (mm) 150 150 150 150 150 155

Thickness 9.2 9.2 9.2 9.2 9.2 9.3

Fluid Common use :Brake Fluid

Manual Transmission

Application 661LA 662NA 662LA 2.0L DOHC 2.3L DOHC 3.2L DOHC

Maker TREMEC TREMEC TREMEC TREMEC TREMEC TREMEC

Type or Model T5 T5 T5 T5 T5 T5

Gear Ratio : 1st 3.969 3.969 3.969 3.969 3.969 3.969

2nd 2.341 2.341 2.341 2.341 2.341 2.341

3rd 1.457 1.457 1.457 1.457 1.457 1.457

4th 1.000 1.000 1.000 1.000 1.000 1.000

5th 0.851 0.851 0.851 0.851 0.851 0.851

Reverse 3.705 3.705 3.705 3.705 3.705 3.705

Final Drive Ratio 4.55 4.55 4.27 4.89 4.55 3.73

Oil Capacity (L) 3.4 3.4 3.4 3.4 3.4 3.4

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION 0B-3

Auto Transmission

Application 661LA 662LA 2.3L DOHC 3.2L DOHC

Maker BTRA BTRA BTRA BTRA

Type or Model M74 4WD M74 4WD M74 4WD M74 4WD

Gear Ratio : 1st 2.741 2.741 2.741 2.741

2nd 1.508 1.508 1.508 1.508

3rd 1.000 1.000 1.000 1.000

4th 0.708 0.708 0.708 0.708

Reverse 2.429 2.429 2.429 2.429

Final Drive Ratio 5.38 4.89 5.86 4.89

Oil Capacity (L) 9 9 9 9

Brake

Application Specifications

Booster Size non-ABS 8inch + 9inch

ABS 5.0 7inch + 8inch

ABS 5.3 8inch + 9inch

Master Cylinder Diameter (mm) f 25.4

Booster Ratio 5.6 : 1

Front Brake : Disc Type Ventilated

Rear Brake : Disc Type Solid

Tire and Wheel

Application Specifications

Standard Tire Size P235/75 R15, 255/70 R15

Standard Wheel Size 7JJ ´ 15

Inflation Pressure At Full Lode

P235 / 75 : Front 30 Psi

Rear 30 Psi

P255 / 75 : Front 30 Psi

Rear 30 Psi

Steering System

Application Specifications

Gear Type RACK & PINION

Wheel Alignment:

Front : Toe-in 0 - 4 mm

Front : Caster 2°30’ ± 30’

Front : Camber 0° ± 30’

Oil Capacity 1L

Downloaded from www.Manualslib.com manuals search engine

0B-4 GENERAL INFORMATION

Suspension

Application Specifications

Front Type Double Wishbone

Rear Type 5 - Link

Fuel System

Application Specifications

Fuel Pump Type Electric Motor Pump

Fuel Capacity 70 L

Lubricating System

Lubricating Type 661LA 662NA 662LA 2.0L DOHC 2.3L DOHC 3.2L DOHC

Oil Pump Type External Gear pump

Oil Filter Type Combination(Full & Part) Full Flow

Oil Capacity (L) (Including Oil Filter) 8.0 9.0 9.5 7.2 7.5 8.2

Cooling System

Cooling Type 661LA 662NA 662LA 2.0L DOHC 2.3L DOHC 3.2L DOHC

Coolant Capacity (L) 9.5-10 10.5 10.5 - 11 10.5 10.5 11.3

Radiator Type Forced Circulation

Water Pump Type Centrifugal

Electric System

Application 661LA 662NA 662LA 2.0L DOHC 2.3L DOHC 3.2L DOHC

Battery (MF) 12V - 90AH

Generator 75A 75A 75A 75A 115A 115A

Starter 2.2kw 2.2kw 2.2kw 1.2kw 1.2kw 1.7kw

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION 0B-5

VEHICLE DIMENSIONS AND WEIGHTS

Vehicle Dimensions

Application Application

Overall Length (mm) 4330

Overall Width (mm) 1841

Overall Height (mm) 1840

Wheel Base (mm) 2840

Tread : Front (mm) 1510

Rear (mm) 1520

Vehicle Weights

Application 661LA 662NA 662LA 2.0L DOHC 2.3L DOHC 3.2L DOHC

Manual : Curb Weight (kg) 1790 1810 1830 1790 1790 1840

Gross Vehicle Weight (kg) 2515 2515 2515 2515 2515 2515

Automatic : Curb Weight (kg) 1810 1815 1850 - 1810 1860

Gross Vehicle Weight (kg) 2515 2515 2515 - 2515 2515

Passenger Capacity 5 5 5 5 5 5

Downloaded from www.Manualslib.com manuals search engine

0B-6 GENERAL INFORMATION

STANDARD BOLTS SPECIFICATIONS

Torque (N·m / Ib-in)

Bolt* Standard Limit

4T 7T 9T 4T 7T 9T

M3 ´ 0.5 0.5 N·

·m 0.9 N··m 1.3 N·

·m 0.7 N··m 1.2 N·

·m 17 N··m

(4.5 lb-in) (8 lb-in) (12 lb-in) (6.3 lb-in) (11 lb-in) (15 lb-in)

M4 ´ 0.7 1.2 N·

·m 2.0 N··m 3.0 N·

·m 1.6 N··m 2.6 N·

·m 4.0 N·

·m

(11 lb-in) (18 lb-in) (27 lb-in) (14 lb-in) (23 lb-in) (36 lb-in)

M5 ´ 0.8 2.4 N·

·m 4.0 N··m 5.6 N·

·m 3.1 N··m 5.2 N·

·m 7.6 N·

·m

(22 lb-in) (36 lb-in) (50 lb-in) (28 lb-in) (47 lb-in) (68 lb-in)

M6 ´ 1.0 4.0 N·

·m 6.7 N··m 9.7 N·

·m 5.4 N··m 9.0 N·

·m 12.7 N· ·m

(36 lb-in) (60 lb-in) (87 lb-in) (49 lb-in) (81 lb-in) (114 lb-in)

M8 ´ 1.25 8.6 N·

·m 15.7 N· ·m 22.5 N··m 12.7 N· ·m 20.6 N··m 30.4 N· ·m

(77 lb-in) (12 lb-in) (17 lb-in) (9 lb-in) (15.2 lb-in) (22 lb-in)

M10 ´ 1.25 18.6 N··m 32.3 N· ·m 46.0 N··m 25.5 N· ·m 42.1 N··m 60.8 N· ·m

(14 lb-in) (24 lb-in) (34 lb-in) (19 lb-in) (31 lb-in) (31 lb-in)

M10 ´ 1.5 18.6 N··m 30.4 N· ·m 44.1 N··m 24.5 N· ·m 41.2 N··m 58.8 N· ·m

(14 lb-in) (22 lb-in) (33 lb-in) (18 lb-in) (30 lb-in) (44 lb-in)

M12 ´ 1.25 34.3 N··m 56.8 N· ·m 82.3 N··m 45.0 N· ·m 75.5 N··m 107.8 N· ·m

(25lb-in) (42 lb-in) (61 lb-in) (33 lb-in) (56 lb-in) (80 lb-in)

M12 ´ 1.75 32.3 N··m 53.9 N· ·m 77.4 N··m 43.1 N· ·m 71.5 N··m 98.0 N· ·m

(24 lb-in) (40 lb-in) (57 lb-in) (32 lb-in) (53 lb-in) (73 lb-in)

M14 ´ 1.5 54.0 N··m 89.2 N· ·m 127.4 N· ·m 71.6 N· ·m 117.6 N· ·m 166.6 N· ·m

(40 lb-in) (66 lb-in) (94 lb-in) (53 lb-in) (87 lb-in) (123 lb-in)

M16 ´ 1.5 81.3 N··m 107.8 N· ·m 196.0 N· ·m 107.8 N· ·m 186.2 N· ·m 264.6 N· ·m

(60 lb-in) (80 lb-in) (145 lb-in) (80 lb-in) (138 lb-in) (196 lb-in)

M18 ´ 1.5 117.6 N· ·m 196.0 N· ·m 284.2 N· ·m 156.8 N· ·m 264.6 N· ·m 372.4 N· ·m

(87 lb-in) (145 lb-in) (210 lb-in) (116 lb-in) (196 lb-in) (276 lb-in)

M20 ´ 1.5 166.6N· ·m 274.4 N· ·m 392.0 N· ·m 215.6 N· ·m 362.6 N· ·m 519.4 N· ·m

(123 lb-in) (203 lb-in) (290 lb-in) (160 lb-in) (268 lb-in) (384 lb-in)

M22 ´ 0.5 225.4N· ·m 372.4 N· ·m 529.2 N· ·m 294.0 N· ·m 490.0 N· ·m 705.6 N· ·m

(167 lb-in) (276 lb-in) (392 lb-in) (218 lb-in) (362 lb-in) (522 lb-in)

M24 ´ 1.5 284.2 N· ·m 480.2 N· ·m 686.0 N· ·m 382.2 N· ·m 637.0 N· ·m 921.2 N· ·m

(210 lb-in) (355 lb-in) (508 lb-in) (283 lb-in) (471 lb-in) (682 lb-in)

M24 ´ 2.0 274.4 N· ·m 460.6 N· ·m 666.4 N· ·m 372.4 N· ·m 617.4 N· ·m 891.8 N· ·m

(203 lb-in) (341 lb-in) (493 lb-in) (276 lb-in) (457 lb-in) (660 lb-in)

*Diameter ´ pitch in millimeters

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION 0B-7

MAINTENANCE AND REPAIR

MAINTENANCE AND LUBRICATION

NORMAL VEHICLE USE Fuel Filter Replacement

The maintenance instructions contained in the Replace the engine fuel filter every.

maintenance schedule are based on the assumption l Gasoline Engine : 60,000km (36,000 miles)

that the vehicle will be used for the following reasons: l Diesel Engine : 45,000km (24,000 miles)

l To carry passengers and cargo within the limitation

Spark Plug Replacement

of the tire inflation prassure. Refer to “Tire and Wheel”

in section 2E. Replace spark plugs with same type.

l To be driven on reasonable road surfaces and within l Type : BOSCH : F8DC4

legal operating limits. BERU : 14F-8DU4

Champion : C11YCC

EXPLANATION OF SCHEDULED l Gap : 0.8 ± 0.1 mm

MAINTENANCE SERVICES Spark Plug Wire Replacement

The services listed in the maintenance schedule are Clean wires and inspect them for burns, cracks or other

further explained below. When the following maintenance damage. Check the wire boot fit at the Distributor and at

services are performed, make sure all the parts are the spark plugs. Replace the wires as needed.

replaced and all the necessary repairs are done before Brake System Service

driving the vehicle. Always use the proper fluid and

Check the disc brake pads or the drum brake linings.

lubricants. Check the pad and the lining thickness carefully.

Engine Oil and Oil Filter Change Tire and Wheel Inspection and Rotation

Always use above the API SH grade or recommended

Check the tires for abnormal wear or damage. To

engine oil. equalize wear and obtain maximum tire life, rotate the

Engine Oil Viscosity tires. If irregular or premature wear exists, check the

Engine oil viscosity (thickness) has an effect on fuel wheel alignment and check for damaged wheels. While

economy and cold weather operation. Lower viscosity the tires and wheels are removed, inspect the brakes.

engine oils can provide better fuel economy and cold

weather performance; however, higher temperature Tire Rotation (Left-hand Drive Type)

weather conditions require higher viscosity engine oils

for satisfactory lubrication. Using oils of any viscosity

other than those viscosities recommended could result

in engine damage.

Cooling System Service

Drain, flush and refill the system with new coolant. Refer

to “Recommended Fluids And Lubricants” in this section.

Air Cleaner Element Replacement

Clean the air cleaner element every.

l Gasoline Engine : 15,000km (10,000 miles)

l Diesel Engine : 10,000km (6,000 miles)

Replace the air cleaner element every .

l Gasoline Engine : 60,000km (36,000 miles)

l Diesel Engine : 30,000km (18,000 miles)

Replace the air cleaner more often under dusty

conditions

Downloaded from www.Manualslib.com manuals search engine

0B-8 GENERAL INFORMATION

SCHEDULED MAINTENANCE CHARTS (GASOLINE ENGINE)

Engine

MAINTENANCE INTERVAL Kilometers or time in months, whichever comes first

x1,000 km 1 15 30 45 60 75 90 105 120

MAINTENANCE

ITEM Months - 12 24 36 48 60 72 84 96

Drive belt I I I I I I I I I

Engine oil & filter (1) (3) I R R R R R R R R

Cooling system hose & connections I I I I I I I I I

Engine coolant (3) I I I I R I I I R

Fuel filter (2) - - - - R - - - R

Fuel line & connections I I I I I I I I I

Air cleaner (2) I I I R I I R

Ignition timing I I I I I I I I

Spark plugs - I R I R I R I R

Charcoal canister & vapor lines - - - I - - I - -

Chart Symbols:

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R - Replace or change.

(1) If vehicle is operated under severe condition : short distance driving, extensive idling or driving in dusty condition. Change

engine oil and the filter every 7,500 km or 6 months, whichever comes first.

(2) More frequent maintenance is required if under dusty driving condition.

(3) Refer to “Recommended fluids and lubricants”.

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION 0B-9

Chassis and Body

MAINTENANCE INTERVAL Kilometers or time in months, whichever comes first

x1,000 km 1 15 30 45 60 75 90 105 120

MAINTENANCE

ITEM Months - 12 24 36 48 60 72 84 96

Exhaust pipes & mountings - I I I I I I I I

Brake/Clutch fluid (3)(4) - I R I R I R I R

Parking brake/Brake pads F & R (5) - I I I I I I I I

Brake line & connections (including booster) I I I I I I I I I

Manual transmission oil (3) I I I R I I R I I

Clutch & brake pedal free play - I I I I I I I I

Front & Rear Differential Fluid (3) I I I R I I R I I

Transfer case fluid I I I R I I R I I

Automatic transmission fluid (MB W4A040) (6) I I I R I I R I

Automatic transmission fluid (BTRA M74) I I I I I I I I I

Chassis & underbody bolts & nuts tight/secure I I I I I I I I I

Tyre condition & inflation pressure I I I I I I I I I

Wheel alignment (7) Inspect & ADJUST when abnormal condition is noted

Steering wheel & linkage I I I I I I I I

Power steering fluid & lines* (3) I I I I I I I I

Drive shaft boots I I I I I I I I

Seat belts, buckles & anchors I I I I I I I I I

Lubricate locks, hinges & bonnet latch I I I I I I I I

Chart Symbols :

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R - Replace or change.

(3) Refer to “Recommended fluids and lubricants”.

(4) Change the brake / clutch fluid every 15,000 km if the vehicle is mainly driven under severe conditions:

- Driving in hilly or mountainous terrain, or

- Towing a trailer frequently

(5) More frequent maintenance is required if under severe condition : short distance driving, extensive idling, frequent low -

speed operation in stop-and-go traffic or driving in dusty condition.

(6) Change automatic transaxle fluid and filter every 75,000 km if the vehicle is mainly driven under severe conditions.

- In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or

- In hilly or mountainous terrain, or

- When doing frequent trailer towing, or

- Uses such as found in taxi, police or delivery service.

(7) If necessary, rotate and balance wheels.

Downloaded from www.Manualslib.com manuals search engine

0B-10 GENERAL INFORMATION

SCHEDULED MAINTENANCE CHARTS (DIESEL ENGINE)

Engine

MAINTENANCE INTERVAL

x1,000 km 1 10 20 30 40 50 60 70 80 90 100

MAINTENANCE

ITEM Months - 6 12 18 24 30 36 42 48 54 60

Drive belt I I I I I I I I I I I

Engine oil & fillter (1) (3) R R R R R R R R R R R

Cooling system hose & connections I I I I I I I I I

Engine coolant (3) I R I

Fuel filter (2) R R

Fuel line & connections I I I I I I I I I I I

Glow plug I I I R I

Pre - fuel filter I I I I I I I I I I

Air cleaner (2) I I R I I R I I R I

Ignition timing (see NOTE 1) I I I I I I I I I I

NOTE 1 : Injection Timing :

Adjust as required :

- When excessive smoke is visible (black or white)

- Poor performance/economy

Chart Symbols:

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R - Replace or change.

(1) If vehicle is operated under severe condition : short distance driving, extensive idling or driving in dusty condition, change

engine oil every 5,000km or 3 months, whichever comes first.

(2) More frequent maintenance is required if under dusty driving conditing.

(3) Refer to “Recommended fluids and lubricants”.

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION 0B-11

Chassis and Body

MAINTENANCE INTERVAL Kilometers or time in months, whichever comes first

x1,000 km 1 10 20 30 40 50 60 70 80 90 100

MAINTENANCE

ITEM Months - 6 12 18 24 30 36 42 48 54 60

Exhaust pipes & mountings I I I I I I I I I I

Brake/clutch fluid (3) (4) I I I R I I R I I R I

Parking brake/Brake pads (F & R) (5) I I I I I I I I I I

Brake line & connections (including booster) I I I I I I I I I I

Manual transmission fluid (3) I I I I R I I I I R

Clutch & brake pedal free play I I I I I I I I I I

F & R Differential fluid (3) I I I I I R I I I I R

Transfer case fluid (3) I I I I R I I I I R

Automatic transmission fluid (BTRA M74) (6) I I I I I I I I I I

Chassis & underbody bolts & nuts tight/secure I I I I I I I I I I I

Tyre condition & inflation pressure I I I I I I I I I I I

Wheel alignment (7) Inspect & ADJUST when abnormal condition is noted

Steering wheel & linkage I I I I I I I I I I

Power steering fluid & lines* (3) I I I I I I I I I I

Drive shaft boots I I I I I I I I I I I

Seat belts, buckles & anchors I I I I I I I I I I I

Lubricate locks, hinges & bonnet latch I I I I I I I I I I I

Chart Symbols :

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R - Replace or change.

(3) Refer to “Recommended fluids and lubricants”.

(4) Change the brake / clutch fluid more regularly if the vehicle is mainly driven under severe conditions :

- Driving in hilly or mountainous terrain, or

- Towing a trailer frequently

(5) More frequent maintenance is required if under severe condition : short distance driving, extensive idling, frequent low -

speed operation in stop-and-go traffic or driving in dusty condition.

(6) Change automatic transmission fluid every 70,000 km if the vehicle is mainly driven under severe conditions.

- In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or

- In hilly or mountainous terrain, or

- When doing frequent trailer towing, or

- Uses such as found in taxi, police or delivery service.

(7) If necessary, rotate and balance wheels.

Downloaded from www.Manualslib.com manuals search engine

0B-12 GENERAL INFORMATION

5. Add oil, if needed, to keep the oil level above the

OWNER INSPECTIONS lower mark. Avoid overfilling the engine, since this

AND SERVICES may cause engine damage.

6. Push the indicator all the way back down into the

engine after taking the reading.

WHILE OPERATING THE VEHICLE If you check the oil level when the oil is cold, do not run

the engine first. The cold oil will not drain back to the

Horn Operation pan fast enough to give a true oil level reading.

Blow the horn occasionally to make sure it works. Check Engine Coolant Level and Condition

all the button locations.

Check the coolant level in the coolant reservoir tank

Brake System Operation and add coolant if necessary. Inspect the coolant.

Be alert for abnormal sounds, increased brake pedal Replace dirty or rusty coolant.

travel or repeated puling to one side when braking. Also, Windshield Washer Fluid Level

if the brake warning light goes on, or flashes, something

may be wrong with part of the brake system. Check the washer fluid level in the reservoir. Add fluid if

necessary.

Exhaust System Operation

Be alert to any changes in the sound of the system or AT LEAST TWICE A MONTH

the smell of the fumes. These are signs that the system Tire And Wheel Inspection and Pressure

may be leaking or overheating. Have the system

inspected and repaired immediately.

Check

Check the tire for abnormal wear or damage. Also check

Tires, Wheels and Alignment Operation for damaged wheels. Check the tire pressure when the

Be alert to any vibration of the steering wheel or the tires are cold (check the spare also, unless it is a

seats at normal highway speeds. This may mean a wheel stowaway). Maintain the recommended pressures. Refer

needs to be balanced. Also, a pull right or left on a to “Tire and Wheel” is in section 0B.

straight, level road may show the need for a tire pressure

adjustment or a wheel alignment. AT LEAST MONTHLY

Steering System Operation Light Operation

Be alert to changes in the steering action. An inspection Check the operation of the license plate light, the

is needed when the steering wheel is hard to turn or headlights (including the high beams), the parking lights,

has too much free play, or is unusual sounds are noticed the fog lights, the taillight, the brake lights, the turn

when turning or parking. signals, the backup lights and the hazard warning flasher.

Headlight Aim Fluid Leak Check

Take note of the light pattern occasionally. Adjust the Periodically inspect the surface beneath the vehicle for

headlights if the beams seem improperly aimed. water, oil, fuel or other fluids, after the vehicle has been

parked for a while. Water dripping from the air

AT EACH FUEL FILL conditioning system after use is normal. If you notice

A fluid loss in any (except windshield washer) system fuel leaks or fumes, find the cause and correct it at once.

may indicate a problem. Have the system inspected and

repaired immediately. AT LEAST TWICE A YEAR

Power Steering System Reservoir Level

Engine Oil Level

Check the power steering fluid level. Keep the power

Check the oil level and add oil if necessary. The best

steering fluid at the proper level. Refer to Section 6A,

time to check the engine oil level is when the oil is warm.

Power Steering System.

1. After stopping the engine, wait a few minutes for the

oil to drain back to the oil pan. Brake Master Cylinder Reservoir Level

2. Pull out the oil level indicator (dip stick). Check the fluid and keep it at the proper level. A low

3. Wipe it clean, and push the oil level indicator back fluid level can indicate worn disc brake pads which may

down all the way. need to be serviced. Check the breather hole in the

reservoir cover to be free from dirt and check for an

4. Pull out the oil level indicator and look at the oil level open passage.

on it.

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION 0B-13

Weather-Strip Lubrication AT LEAST ANNUALLY

Apply a thin film silicone grease using a clean cloth.

Lap and Shoulder Belts Condition and

EACH TIME THE OIL IS CHANGED Operation

Inspect the belt system including: the webbing, the

Brake System Inspection buckles, the latch plates, the retractor, the guide loops

This inspection should be done when the wheels are and the anchors.

removed for rotation. Inspect the lines and the hoses

for proper hookup, binding, leaks, cracks, chafing, etc. Movable Head Restraint Operation

Inspect the disc brake pads for wear. Inspect the rotors On vehicles with movable head restraints, the restraints

for surface condition. Inspect other brake parts, the must stay in the desired position.

parking brake, etc., at the same time. Inspect the brakes

Spare Tire and Jack Storage

more often if habit or conditions result in frequent braking.

Be alert to rattles in the rear of the vehicle. The spare

Steering, Suspension and Front Drive Axle tire, all the jacking equipment, and the tools must be

Boot And Seal Inspection securely stowed at all times. Oil the jack ratchet or the

Inspect the front and rear suspension and the steering screw mechanism after each use.

system for damaged, loose or missing parts, signs of Key Lock Service

wear or lack of lubrication. Inspect the power steering

Lubricate the key lock cylinder.

line and the hoses for proper hookup, binding, leaks,

cracks, chafing, etc. Clean and inspect the drive axle Body Lubrication Service

boot and seals for damage, tears or leakage. Replace Lubricate all the body door hinges including the hood,

the seals if necessary. the fuel door, the rear compartment hinges and the

Exhaust System Inspection latches, the glove box and the console doors, and any

folding seat hardware.

Inspect the complete system (including the catalytic

converter if equipped). Inspect the body near the exhaust Underbody Flushing

system. Look for broken, damaged, missing, or out-of- Flushing the underbody will remove any corrosive

position parts as well as open seams, holes, loose materials used for ice and snow removal and dust control.

connections, or other conditions which could cause heat At least every spring clean the underbody. First, loosen

buildup in the floor pan or could let exhaust fumes seep the sediment packed in closed areas of the vehicle. Then

into the trunk or passenger compartment. flush the underbody with plain water.

Throttle Linkage Inspection Engine Cooling System

Inspect the throttle linkage for interference or binding, Inspect the coolant and freeze protection fluid. If the fluid

damaged, or missing parts. Lubricate all linkage joints is dirty or rusty, drain, flush and refill the engine cooling

and throttle cable joints, the intermediate throttle shaft system with new coolant. Keep the coolant at the proper

bearing, the return spring at throttle valve assembly, and mixture in order to ensure proper freeze protection,

the accelerator pedal sliding face with suitable grease. corrosion protection and engine operating temperature.

Check the throttle cable for free movements. Inspect the hoses. Replace the cracked, swollen, or

Engine Drive Belts deteriorated hoses. Tighten the clamps. Clean the

outside of the radiator and the air conditioning

Inspect all belts for cracks, fraying, wear and proper

condenser. Wash the filler cap and the neck. Pressure

tension. Adjust or replace the belts as needed.

test the cooling system and the cap in order to help

Hood Latch Operation ensure proper operation.

When opening the hood, note the operation of the

secondary latch. It should keep the hood from opening

all the way when the primary latch is released. The hood

must close firmly.

Downloaded from www.Manualslib.com manuals search engine

0B-14 GENERAL INFORMATION

RECOMMENDED FLUIDS AND LUBRICANTS

Usage Capacity Fluid/Lubricant

Engine Oil 3.2L DOHC 8.2 L Quality class - API ; SH grade or above

(Change with filter) ACEA ; A2 or A3

2.3L DOHC 7.5 L MB sheet ; 229.1

Viscosity - MB sheet ; 224.1

662LA 9.5 L Quality class - API ; CG grade or above

ACEA ; B2 or B3

661LA 8.0 L MB sheet ; 228.1, 228.3,

228.5, 229.1

Viscosity - MB sheet ; 224.1

Engine Coolant 3.2L DOHC 11.3 L ALUTEC P-78

2.3L DOHC 10.5 L

662LA 10.5 - 11.0 L

661LA 9.5 - 10.0 L

Brake / Clutch Fluid Approx. 0.5L level must DOT-3 & SAE J 1703

be maintained between

MAX & MIN level

Power Steering System 1.0 L ATF DEXRON-II

Parking Brake Cable As required Grease

Hood Latch Assembly As required Grease

Hood and Door Hinges As required Spray type grease

Fuel Door Hinge

Rear Compartment Lid Hinges

Weatherstrips As required Silicone grease

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION 0B-15

l Use genuine DAEWOO parts.

GENERAL DESCRIPTION l Discard used cotter pins, gaskets, O-rings, oil seals,

AND SYSTEM OPERATION lock washers and self-locking nuts. Prepare new ones

for installation. Normal function of these parts cannot

be maintained if these parts are reused.

GENERAL REPAIR INSTRUCTIONS

l Keep the disassembled parts neatly in groups to

l If a floor jack is used, the following precautions are facilitate proper and smooth reassembly.

recommended.

l Keep attaching bolts and nuts separated, as they

l Park the vehicle on level ground, “block” the front or vary in hardness and design depending on the

rear wheels, set the jack against the frame, raise the position of the installation.

vehicle and support it with chassis stands and then

perform the service operation. l Clean the parts before inspection or reassembly.

l Before performing the service operation, disconnect l Also clean the oil parts, etc. Use compressed air to

the negative battery cable in order to reduce the make certain they are free of restrictions.

chance of cable damaged and burning due to short- l Lubricate rotating and sliding faces of parts with oil

cir cuiting. or grease before installation.

l Use a cover on the body, the seats and the floor to l When necessary, use a sealer on gaskets to prevent

protect them against damage and contamination. leakage.

l Handle brake fluid and antifreeze solution with care l Carefully observe all specifications for bolt and nut

as they can cause paint damage. torques.

l The use of proper tools, and the recommended l When service operation is completed, make a final

essential and available tools where specified, are check to be sure service was done properly and the

important for efficient and reliable performance of problem was corrected.

the service repairs.

Downloaded from www.Manualslib.com manuals search engine

0B-16 GENERAL INFORMATION

VEHICLE IDENTIFICATION NUMBER SYSTEM

* K P T L 4 B 1 B S V P 000000 *

12~17.Production Serial Number

: 000001- 999999

11.Plant Code

P : PyongTaek Plant

10.Model Year

V : 1997

W : 1998

X : 1999

Y : 2000

9. Check Digit

S : All area except North America

8. Engine Type

6 : 2295cc, In-line 4Cylinder, Gasoline (E23)

8 : 1998cc, In-line 4Cylinder, Gasoline (E20)

9 : 3199cc, In-line 6Cylinder, Gasoline (E32)

A : 2299cc, In-line 4Cylinder, Diesel (OM661)

B : 2874cc, In-line 5Cylinder, Diesel (OM662)

7. Restraint System

1 : 3-Point Safety Belt, 2 : 2-Point Safety Belt

6. Trim Level

A : Standard, B : Deluxe, C : Super Deluxe

5. Body Type

2: 3-Door, 4: 3-Door Soft Top

4. Line Models

L : Korando, LHD, R : Korando, RHD

3. Vehicle Type

T : Passenger Car, A : Truck

2. Maker ldentification : P

1. Nation : K

*. Symbol according to No.

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION 0B-17

Manufacturer’s Plate

1.Type Approval No. 2.Vehicle Identification No.

Manufacturer’s Plate Location

Diesel Engine Gasoline Engine

Downloaded from www.Manualslib.com manuals search engine

0B-18 GENERAL INFORMATION

Gasolind Engine Number Diesel Engine Number

162 993 1 0 012345 662 920 1 0 012345

Serial Number Serial Number

0 : Manual T/M 0 : Manual T/M

1 : Hydr - Auto Coupling 1 : Hydr - Auto Coupling

2 : Automatic T/M 2 : Automatic T/M

0 : Common 0 : Common

1 : Left - Hand Drive 1 : Left - Hand Drive

2 : Right - Hand Drive 2 : Right - Hand Drive

3 : KORANDO

99 : 3.2L 910 :Non-Intercooler Engine

97 : 2.3L 920 : Intercooler Engine

94 : 2.0L

661 : 2299cc

ENGINE TYPE

662 : 2874cc

Engine Number Location

IL6 3200 2300 DOHC

The engine number is stamped on the lower rear side The engine number is stamped on the upper rear left-

of the alternator. hand side of the cylinder block.

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION 0B-19

VEHICLE LIFTING PROCEDURES

To raise the vehicle, place the liffting equipment only at

the points indicated. Failure to use these precise

positions may result in permanent vehicle body

deformation.

Many dealer service facilities and service stations are

equipped with automative hoists that bear upon some

parts of the frame in order to lift the vehicle. If any other

hoist method is used, use special care to avoid damaging

the fuel tank, the filter neck, the exhaust system, or the

underbody.

Vehicle Lifting Points

Diesel Engine

The engine number is stamped on the cylinder block in

front of injection pump.

Using Jack

(Rearward of Front Tire)

Using Jack

(Forward of Rear Tire)

Downloaded from www.Manualslib.com manuals search engine

SECTION 1

ENGINE

SECTION 1A1(M162 ENGINE)

GENERAL ENGINE INFORMATION

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1A1-1 Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1A1-7

Engine Specifications . . . . . . . . . . . . . . . . . . 1A1-1 Oil Leak Diagnosis . . . . . . . . . . . . . . . . . . . . 1A1-7

Component Locator . . . . . . . . . . . . . . . . . . 1A1-3 Engine Cranking at The

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . 1A1-3 Front of Crankshaft . . . . . . . . . . . . . . . . . . 1A1-8

Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A1-4 Compression Pressure Test . . . . . . . . . . . . . 1A1-9

Performance Curve . . . . . . . . . . . . . . . . . . 1A1-5 Cylinder Pressure Leakage Test. . . . . . . . . 1A1-11

E32 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . 1A1-5 General Information . . . . . . . . . . . . . . . . . 1A1-13

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1A1-6 Cleanliness and Care . . . . . . . . . . . . . . . . . 1A1-13

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1A1-6 On-Engine Service . . . . . . . . . . . . . . . . . . . 1A1-13

SPECIFICATIONS

ENGINE SPECIFICATIONS

Application E32 Engine

Engine Model M162.993

Displacement (CC) 3199

Cylinder (Bore x Stroke) (mm) 89.9 x 84.0

Fuel Injection / Ignition System MSE 3.62S

Compression Ratio 10 : 1

Number of Cylinders 6

Camshaft Valve Arrangement DOHC

Camshaft Drive Type Chain-Driven

Max. Output (ps/rpm) 222 / 5500

Max. Torque (kg•m/rpm) 31.6 / 3750

Firing Order 1-5-3-6-2-4

Ignition Type Distributorless Double Ignition

Ignition Timing BTDC 8° ± 2°

Valve Timing Intake Open/Close ATDC 11° / ABDC 34°

Exhaust Open/Close BBDC 31° / BTDC 14°

Valve Clearance Adjustment Automatic Control

Downloaded from www.Manualslib.com manuals search engine

1A1-2 GENERAL ENGINE INFORMATION

ENGINE SPECIFICATIONS (Cont'd)

Application E32 Engine

Idle Speed (rpm) 700 ± 50

Fuel Injection Pressure (kg/cm²) 3-4

Oil Capacity (liter) 8.2

Lubrication Type Forced by Gear Pump

Oil Filter Type Full Flow with Paper Filter

Fuel Unleaded Gasoline

MSE 3.62S/3.53S (Motorsteuer Elektronik : German)

MSE : Engine Control Electronic

3.62S : 6 Cylinder Version

3.53S : 4 Cylinder Version

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A1-3

COMPONENT LOCATOR

FRONT VIEW

1 HFM Sensor 12 Intake Manifold

2 Intake Air Duct 13 Connecting Rod

3 Resonance Flap 14 Exhaust Manifold

4 Cylinder Head Cover 15 Crankshaft

5 Exhaust Camshaft 16 Engine Mounting Bracket

6 Intake Camshaft 17 Starter

7 Cylinder Head 18 Crankcase

8 Spark Plug Connector 19 Oil Pump Sprocket

9 Valve Tappet 20 Oil Strainer

10 Injector 21 Oil Pan

11 Exhaust Valve 22 Drain Plug

Downloaded from www.Manualslib.com manuals search engine

1A1-4 GENERAL ENGINE INFORMATION

SIDE VIEW

23 Camshaft Adjuster 27 Oil Pump Drive Chain

24 Cooling Fan and Viscous Clutch 28 Oil Return Pipe

25 Piston 29 Timing Chain

26 Flywheel of Drive Plate 30 Oil Pump

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A1-5

PERFORMANCE CURVE

E32 ENGINE

Downloaded from www.Manualslib.com manuals search engine

1A1-6 GENERAL ENGINE INFORMATION

SPECIAL TOOLS

SPECIAL TOOLS TABLE

000 589 10 99 01 001 589 65 09 00

Torque Wrench Socket

001 589 76 21 00 119 589 01 09 00

Compression Pressure Spark Plug Wrench

Tester

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A1-7

DIAGNOSIS

OIL LEAK DIAGNOSIS Black Light and Dye Method

Most fluid oil leaks are easily located and repaired by A dye and light kit is available for finding leaks, Refer to

visually finding the leak and replacing or repairing the the manufacturer's directions when using the kit.

necessary parts. On some occasions a fluid leak may 1. Pour the specified amount of dye into the engine oil

be difficult to locate or repair. The following procedures fill tube.

may help you in locating and repairing most leaks. 2. Operate the vehicle normal operating conditions as

Finding the Leak directed in the kit.

1. Identify the fluid. Determine whether it is engine oil, 3. Direct the light toward the suspected area. The dyed

automatic transmission fluid, power steering fluid, etc. fluid will appear as a yellow path leading to the

source.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating Repairing the Leak

temperature, park the vehicle over a large sheet Once the origin of the leak has been pinpointed and

of paper. traced back to its source, the cause of the leak must be

2.2 Wait a few minutes. determined n order for it to be repaired properly. If a

gasket is replaced, but the sealing flange is bent, the

2.3 You should be able to find the approximate

new gasket will not repair the leak. The bent flange must

location of the leak by the drippings on the

be repaired also. Before attempting to repair a leak,

paper.

check for the following conditions and correct them as

3. Visually check around the suspected component. they may cause a leak.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas that Gaskets

are hard to reach. l The fluid level/pressure is too high.

4. If the leak still cannot be found, it may be necessary l The crankcase ventilation system is malfunctioning.

to clean the suspected area with a degreaser, steam l The fasteners are tightened improperly or the threads

or spray solvent. are dirty or damaged.

4.1 Clean the area well. l The flanges or the sealing surface is warped.

4.2 Dry the area. l There are scratches, burrs or other damage to the

4.3 Operate the vehicle for several miles at normal sealing surface.

operating temperature and varying speeds. l The gasket is damaged or worn.

4.4 After operating the vehicle, visually check the l There is cracking or porosity of the component.

suspected component.

l An improper seal was used (where applicable).

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method. Seals

l The fluid level/pressure is too high.

Powder Method

l The crankcase ventilation system is malfunctioning.

1. Clean the suspected area.

l The seal bore is damaged (scratched, burred or

2. Apply an aerosol-type powder (such as foot powder)

nicked).

to the suspected area.

l The seal is damaged or worn.

3. Operate the vehicle under normal operating

conditoins. l Improper installation is evident.

4. Visually inspect the suspected component. You l There are cracks in the components.

should be able to trace the leak path over the white l The shaft surface is scratched, nicked or damaged.

powder surface to the source. l A loose or worn bearing is causing excess seal wear.

Downloaded from www.Manualslib.com manuals search engine

1A1-8 GENERAL ENGINE INFORMATION

ENGINE CRANKING AT THE FRONT OF CRANKSHAFT

Preceding Work : Removal of cooling fan

1 Vibration Damper Assembly 3 Bolt ................................................. 8.6 ± 0.9 Nm

2 Crankshaft Pulley

Notice

l Remove the negative ground cable before proceeding the work.

l Rotate the pulley in normal engine rotating direction when cranking.

Tools Required

000 589 10 99 01 Torque wrench

001 589 65 09 00 Socket

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A1-9

COMPRESSION PRESSURE TEST

1 Compression Pressure Tester 3 Adaptor

2 Diagram Sheet 4 Sealing Cone

Tools Required

001 589 76 21 00 Compression Pressure Tester

119 589 01 09 00 Spark Plug Wrench

Standard Service Data

Compression Ratio 10 : 1

Normal Engine Temperature 80°C

Normal Compression Pressure General Min. 10 bar, Max. 14 bar

Fuel Optimization Min. 6 bar, Max. 10 bar

Permissible Pressure Difference Between Individual Max. 1.5 bar

Cylinders

Downloaded from www.Manualslib.com manuals search engine

1A1-10 GENERAL ENGINE INFORMATION

Measuring Procedure

1. Warm the engine up to normal operating temperature.

2. Remove the spark plugs.

3. Place the diagram sheet to compression pressure

tester.

4. Connect the adaptor to compression pressure tester

and install it into the spark plug hole.

5. Crank the engine approx. eight revolutions by using

the start motor.

6. Compare the measurements of compression

pressure tester with the specifications.

7. Measure the compression pressure of the other

cylinders in the same way.

8. If measured value is not within the specifications,

perform the cylinder pressure leakage test.

Notice

l Discharge the combustion residues in the cylinders

before testing the compression pressure.

l Apply the parking brake before cranking the

engine.

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A1-11

CYLINDER PRESSURE LEAKAGE TEST

3 Engine Oil Filler Cap 6 Cylinder Pressure Leakage Tester with

4 Vibration Damper Connecting Hose

Permissible Pressure Leakage

At Whole Engine Max. 25 %

At Valve and Cylinder Head Gasket Max. 10 %

At Piston and Piston Ring Max. 20 %

Cylinder Number By Mark On Vibration Damper At TDC

TDC Mark OT (TDC) a (120°) b (240°)

Cylinder Number 1, 6 2, 5 3, 4

Universal Tool

Cylinder Pressure Leakage Tester Bosch, EFAW 210A

Sun, CLT 228

Downloaded from www.Manualslib.com manuals search engine

1A1-12 GENERAL ENGINE INFORMATION

Leakage Test

1. Warm the engine up to normal operating temperature.

2. Disconnect the negative battery cable.

3. Remove the spark plugs.

4. Check the coolant level by opening the coolant surge tank

cap and replenish if insufficient.

5. Open the engine oil filler cap.

6. Connect the tester to air pressure line and adjust the scale

of tester.

7. Install the connecting hose to spark plug hole.

8. Position the piston of No.1 cylinder at TDC by rotating the

crankshaft.

9. Connect the connecting hose to tester and measure the

leakage volume after blowing up 5bar of compressed air.

Notice

Measure the leakage volume in the completely opening

condition of throttle valve by pulling the acceleration cable.

10. Perform the pressure test according to the firing order.

Notice

Firing Order : 1 - 5 - 3 - 6 - 2 - 4

11. Compare the leakage pressure with the specifications.

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A1-13

GENERAL INFORMATION

CLEANLINESS AND CARE Battery cables should be disconnected before any major

work is performed on the engine. Failure to disconnect

An automobile engine is a combination of many cables may result in damage to wire harness or other

machined, honed, polished and lapped surfaces with electrical parts.

tolerances that are measured in the ten-thousanths of

an inch. When any internal engine parts are serviced, ON-ENGINE SERVICE

care and cleanliness are important. A liberal coating of

enigne oil should be applied to friction areas during Caution: Disconnect the negative battery cable

assembly, to protect and lubricate the surfaces on initial before removing or installing any electrical unit, or

operation. Proper cleaning and protection of machined when a tool or equipment could easily come in

surfaces and friction areas is part of the repair contact with exposed electrical terminals.

procedure. This is considered standard shop practice Disconnecting this cable will help prevent personal

even if not specifically stated. injury and damage to the vehicle. The ignition must

also be in LOCK unless otherwise noted.

Whenever valve train components are removed for

service, they should be kept in order. They should be Notice: Any time the air cleaner is removed, the intake

installed in the same locations, and with the same mating opening should be covered. This will protect against

surfaces, as when they were removed. accidental entrance of foreign material, which could

follow the intake passage into the cylinder and cause

extensive damage when the engine is started.

Downloaded from www.Manualslib.com manuals search engine

SECTION 1

ENGINE

SECTION 1A2(M161 ENGINE)

GENERAL ENGINE INFORMATION

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1A2-1 Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-8

Engine Specifications . . . . . . . . . . . . . . . . . . 1A2-1 Oil Leak Diagnosis . . . . . . . . . . . . . . . . . . . . 1A2-8

Component Locator . . . . . . . . . . . . . . . . . . 1A2-3 Engine Cranking At The

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-3 Front of Crankshaft . . . . . . . . . . . . . . . . . . 1A2-9

Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-4 Compression Pressure Test . . . . . . . . . . . . 1A2-10

Performance Curve . . . . . . . . . . . . . . . . . . 1A2-5 Cylinder Pressure Leakage Test. . . . . . . . . 1A2-12

E23 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-5 General Information . . . . . . . . . . . . . . . . . 1A2-14

E20 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-6 Cleanliness and Care . . . . . . . . . . . . . . . . . 1A2-14

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1A2-7 On-Engine Service . . . . . . . . . . . . . . . . . . . 1A2-14

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1A2-7

SPECIFICATIONS

ENGINE SPECIFICATIONS

Application E23 Engine E20 Engine

Engine Model M161.973 M161.943

Displacement (CC) 2295 1998

Cylinder (Bore x Stroke) (mm) 90.9 x 88.4 89.9 x 78.7

Fuel Injection / Ignition System MSE 3.53S ¬

Compression Ratio 10.4:1 9.6:1

Number of Cylinders 4 ¬

Camshaft Valve Arrangement DOHC ¬

Camshaft Drive Type Chain-Driven ¬

Max. Output (ps/rpm) 149 / 5500 135 / 5500

Max. Torque (kg•m/rpm) 22.4 / 4000 19.3 / 4000

Firing Order 1-3-4-2 ¬

Ignition Type Distributorless ¬

Ignition Timing BTDC 6° ± 2° ¬

Valve Timing Intake Open/Close ATDC 19.25° / ABDC 28.76° ATDC 13.15° / ABDC 13.57°

Exhaust Open/Close BBDC 20.62° / BTDC 15.08° BBDC 16.58° / BTDC 17.05°

Valve Clearance Adjustment Automatic Control ¬

Downloaded from www.Manualslib.com manuals search engine

1A2-2 GENERAL ENGINE INFORMATION

ENGINE SPECIFICATIONS (Cont'd)

Application E23 Engine E20 Engine

Idle Speed (rpm) 750 ± 50 ¬

Fuel Injection Pressure (kg/cm²) 3.2 - 4.2 ¬

Oil Capacity (liter) 7.5 ¬

Lubrication Type Forced by Gear Pump ¬

Oil Filter Type Full Flow with Paper Filter ¬

Fuel Unleaded Gasoline ¬

MSE 3.62S/3.53S (Motorsteuer Elektronik : German)

MSE : Engine Control Electronic

3.62S : 6 cylinder version

3.53S : 4 cylinder version

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A2-3

COMPONENT LOCATOR

FRONT VIEW

1 HFM Sensor 12 Intake Manifold

2 Intake Air Duct 13 Cylinder Head

3 Cylinder Head Cover 14 Exhaust Manifold

4 Ignition Coil 15 Dipstick Guide Tube and Gauge

5 Spark Plug Connector 16 Connecting Rod

6 Fuel Distributor 17 Crankshaft

7 Injector 18 Engine Mounting Bracket

8 Exhaust Camshaft 19 Starter

9 Intake Camshaft 20 Crankcase

10 Valve Tappet 21 Oil Pump Sprocket

11 Intake Valve 22 Oil Pan

Downloaded from www.Manualslib.com manuals search engine

1A2-4 GENERAL ENGINE INFORMATION

SIDE VIEW

23 Camshaft Adjuster 29 Oil Pump Drive Chain

24 Oil Filler Cap 30 Oil Strainer

25 Engine Hanger Bracket 31 Oil Pump

26 Cooling Fan and Viscous Clutch 32 Ring Gear and Flywheel of Drive Plate

27 Oil Filter 33 Piston

28 Timing Chain

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A2-5

PERFORMANCE CURVE

E23 ENGINE

Downloaded from www.Manualslib.com manuals search engine

1A2-6 GENERAL ENGINE INFORMATION

E20 ENGINE

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A2-7

SPECIAL TOOLS

SPECIAL TOOLS TABLE

000 589 10 99 01 001 589 65 09 00

Torque Wrench Socket

001 589 76 21 00 119 589 01 09 00

Compression Pressure Spark Plug Wrench

Tester

Downloaded from www.Manualslib.com manuals search engine

1A2-8 GENERAL ENGINE INFORMATION

DIAGNOSIS

OIL LEAK DIAGNOSIS Black Light and Dye Method

Most fluid oil leaks are easily located and repaired by A dye and light kit is available for finding leaks, Refer to

visually finding the leak and replacing or repairing the the manufacturer's directions when using the kit.

necessary parts. On some occasions a fluid leak may 1. Pour the specified amount of dye into the engine oil

be difficult to locate or repair. The following procedures fill tube.

may help you in locating and repairing most leaks. 2. Operate the vehicle normal operating conditions as

Finding the Leak directed in the kit.

1. Identify the fluid. Determine whether it is engine oil, 3. Direct the light toward the suspected area. The dyed

automatic transmission fluid, power steering fluid, etc. fluid will appear as a yellow path leading to the

source.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating Repairing the Leak

temperature, park the vehicle over a large sheet Once the origin of the leak has been pinpointed and

of paper. traced back to its source, the cause of the leak must be

2.2 Wait a few minutes. determined n order for it to be repaired properly. If a

gasket is replaced, but the sealing flange is bent, the

2.3 You should be able to find the approximate

new gasket will not repair the leak. The bent flange must

location of the leak by the drippings on the

be repaired also. Before attempting to repair a leak,

paper.

check for the following conditions and correct them as

3. Visually check around the suspected component. they may cause a leak.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas that Gaskets

are hard to reach. l The fluid level/pressure is too high.

4. If the leak still cannot be found, it may be necessary l The crankcase ventilation system is malfunctioning.

to clean the suspected area with a degreaser, steam l The fasteners are tightened improperly or the threads

or spray solvent. are dirty or damaged.

4.1 Clean the area well. l The flanges or the sealing surface is warped.

4.2 Dry the area. l There are scratches, burrs or other damage to the

4.3 Operate the vehicle for several miles at normal sealing surface.

operating temperature and varying speeds. l The gasket is damaged or worn.

4.4 After operating the vehicle, visually check the l There is cracking or porosity of the component.

suspected component.

l An improper seal was used (where applicable).

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method. Seals

l The fluid level/pressure is too high.

Powder Method

l The crankcase ventilation system is malfunctioning.

1. Clean the suspected area.

l The seal bore is damaged (scratched, burred or

2. Apply an aerosol-type powder (such as foot powder)

nicked).

to the suspected area.

l The seal is damaged or worn.

3. Operate the vehicle under normal operating

conditoins. l Improper installation is evident.

4. Visually inspect the suspected component. You l There are cracks in the components.

should be able to trace the leak path over the white l The shaft surface is scratched, nicked or damaged.

powder surface to the source. l A loose or worn bearing is causing excess seal wear.

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A2-9

ENGINE CRANKING AT THE FRONT OF CRANKSHAFT

Preceding Work : Removal of cooling fan

1 Vibration Damper Assembly 3 Bolt ................................................. 8.6 ± 0.9 Nm

2 Crankshaft Pulley

Notice

l Remove the negative ground cable before proceeding the work.

l Rotate the pulley in normal engine rotating direction when cranking.

Tools Required

000 589 10 99 01 Torque wrench

001 589 65 09 00 Socket

Downloaded from www.Manualslib.com manuals search engine

1A2-10 GENERAL ENGINE INFORMATION

COMPRESSION PRESSURE TEST

1 Compression Pressure Tester 3 Adaptor

2 Diagram Sheet 4 Sealing Cone

Tools Required

001 589 76 21 00 Compression Pressure Tester

119 589 01 09 00 Spark Plug Wrench

Standard Service Data

Compression Ratio 10.4, 9.6

Normal Engine Temperature 80°C

Normal Compression Pressure E23 Engine(e = 10.4) Min. 11 bar, Max. 15 bar

E20 Engine(e = 9.6) Min. 10.5 bar, Max. 14 bar

Permissible Pressure Difference Between Individual Max. 1.5 bar

Cylinders

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A2-11

Measuring Procedure

1. Warm the engine up to normal operating temperature.

2. Remove the spark plugs.

3. Place the diagram sheet to compression pressure

tester.

4. Connect the adaptor to compression pressure tester

and install it into the spark plug hole.

5. Crank the engine approx. eight revolutions by using

the start motor.

6. Compare the measurements of compression

pressure tester with the specifications.

7. Measure the compression pressure of the other

cylinders in the same way.

8. If measured value is not within the specifications,

perform the cylinder pressure leakage test.

Notice

l Discharge the combustion residues in the cylinders

before testing the compression pressure.

l Apply the parking brake before cranking the

engine.

Downloaded from www.Manualslib.com manuals search engine

1A2-12 GENERAL ENGINE INFORMATION

CYLINDER PRESSURE LEAKAGE TEST

3 Engine Oil Filler Cap 6 Cylinder Pressure Leakage Tester with

5 Vibration Damper Connecting Hose

Permissible Pressure Leakage

At Whole Engine Max. 25 %

At Valve and Cylinder Head Gasket Max. 10 %

At Piston and Piston Ring Max. 20 %

Cylinder Number By Mark On Vibration Damper At TDC

TDC Mark OT (TDC) UT (BDC : 180°)

Cylinder Number 1, 4 2, 3

Universal Tool

Cylinder Pressure Leakage Tester Bosch EF AW 210A

Sun, CLT 228

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A2-13

Leakage Test

1. Warm the engine up to normal operating temperature.

2. Disconnect the negative battery cable.

3. Remove the spark plugs.

4. Check the coolant level by opening the coolant surge tank

cap and replenish if insufficient.

5. Open the engine oil filler cap.

6. Connect the tester to air pressure line and adjust the scale

of tester.

7. Install the connecting hose to spark plug hole.

8. Position the piston of No.1 cylinder at TDC by rotating the

crankshaft.

9. Connect the connecting hose to tester and measure the

leakage volume after blowing up 5bar of compressed air.

Notice

Measure the leakage volume in the completely opening

condition of throttle valve by pulling the acceleration cable.

10. Perform the pressure test according to the firing order.

Notice

Firing Order : 1 - 3 - 4 - 2

11. Compare the leakage pressure with the specifications.

Downloaded from www.Manualslib.com manuals search engine

1A2-14 GENERAL ENGINE INFORMATION

GENERAL INFORMATION

CLEANLINESS AND CARE ON-ENGINE SERVICE

An automobile engine is a combination of many Caution: Disconnect the negative battery cable be-

machined, honed, polished and lapped surfaces with fore removing or installing any electrical unit, or

tolerances that are measured in the ten-thousanths of when a tool or equipment could easily come in con-

an inch. When any internal engine parts are serviced, tact with exposed electrical terminals. Disconnect-

care and cleanliness are important. A liberal coating of ing this cable will help prevent personal injury and

enigne oil should be applied to friction areas during damage to the vehicle. The ignition must also be in

assembly, to protect and lubricate the surfaces on initial LOCK unless otherwise noted.

operation. Proper cleaning and protection of machined

surfaces and friction areas is part of the repair Notice: Any time the air cleaner is removed, the intake

procedure. This is considered standard shop practice opening should be covered. This will protect against

even if not specifically stated. accidental entrance of foreign material, which could

follow the intake passage into the cylinder and cause

Whenever valve train components are removed for

extensive damage when the engine is started.

service, they should be kept in order. They should be

installed in the same locations, and with the same mating

surfaces, as when they were removed.

Battery cables should be disconnected before any major

work is performed on the engine. Failure to disconnect

cables may result in damage to wire harness or other

electrical parts.

Downloaded from www.Manualslib.com manuals search engine

SECTION 1

ENGINE

SECTION 1A3(OM600 ENGINE)

GENERAL ENGINE INFORMATION

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1A3-1 Special Tools Table . . . . . . . . . . . . . . . . . . . . 1A3-9

Engine Specifications . . . . . . . . . . . . . . . . . . 1A3-1 Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . 1A3-10

Sectional View . . . . . . . . . . . . . . . . . . . . . . 1A3-3 Oil Leak Diagnosis . . . . . . . . . . . . . . . . . . . 1A3-10

OM662LA Engine . . . . . . . . . . . . . . . . . . . . . 1A3-3 Compression Pressure Test . . . . . . . . . . . . 1A3-11

OM661LA Engine . . . . . . . . . . . . . . . . . . . . . 1A3-5 Cylinder Pressure Leakage Test . . . . . . . . . 1A3-13

Performance Curve . . . . . . . . . . . . . . . . . . 1A3-7 General Information . . . . . . . . . . . . . . . . . 1A3-15

OM662LA Engine . . . . . . . . . . . . . . . . . . . . . 1A3-7 Cleanliness and Care . . . . . . . . . . . . . . . . . 1A3-15

OM661LA Engine . . . . . . . . . . . . . . . . . . . . . 1A3-8 On-Engine Service . . . . . . . . . . . . . . . . . . . 1A3-15

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1A3-9

SPECIFICATIONS

ENGINE SPECIFICATIONS

Application OM662LA OM661LA

Engine Type Four-Stroke Diesel Four-Stroke Diesel

Displacement (CC) 2874 2299

Cylinder (Bore x Stroke) (mm) 89 x 92.4 89 x 92.4

Fuel Injection / Ignition System PES 5 M55 C320 RS 168 PES 5 M55 C320 RS 167

Compression Ratio 22:1 22:1

Number of Cylinders 5 4

Camshaft Valve Arrangement SOHC SOHC

Camshaft Drive Type Chain-Drive Chain-Drive

Max. Output (ps/rpm) 120 / 4000 101 / 4000

Max. Torque (kg•m/rpm) 25.5 / 4000 21.5 / 2400

Firing Order 1-2-4-5-3 1-3-4-2

Injection Timing BTDC 18°± 10° BTDC 18°± 10°

Valve Timing Intake Open/Close ATDC 11.33° / ABDC 17° ATDC 11.33° / ABDC 17°

(at 2mm lift) Exhaust Open/Close BBDC 28° / BTDC 15.25° BBDC 28° / BTDC 15.25°

Valve Clearance Adjustment Automatic Control Automatic Control

Downloaded from www.Manualslib.com manuals search engine

1A3-2 GENERAL ENGINE INFORMATION

ENGINE SPECIFICATIONS (Cont'd)

Application OM 662 LA OM 661 LA

Idle Speed (rpm) 720 - 820 750 - 850

Fuel Injection Pressure (bar) 135 - 143 135 - 143

Oil Capacity (liter) 8.0 - 9.5 6.5 - 8.0

Lubrication Type Forced by Gear Pump Forced by Gear Pump

Oil Filter Type Combined Full-Flow and Partial Flow Combined Full-Flow and Partial Flow

Filter Filter

Fuel Diesel Diesel

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A3-3

SECTIONAL VIEW

OM662LA ENGINE

Front View

Downloaded from www.Manualslib.com manuals search engine

1A3-4 GENERAL ENGINE INFORMATION

Side View

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A3-5

OM661LA ENGINE

Front View

Downloaded from www.Manualslib.com manuals search engine

1A3-6 GENERAL ENGINE INFORMATION

Side View

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A3-7

PERFORMANCE CURVE

OM662LA ENGINE

rpm

Downloaded from www.Manualslib.com manuals search engine

1A3-8 GENERAL ENGINE INFORMATION

OM661LA ENGINE

rpm

Downloaded from www.Manualslib.com manuals search engine

GENERAL ENGINE INFORMATION 1A3-9

SPECIAL TOOLS

SPECIAL TOOLS TABLE

000 589 10 99 01 001 589 65 09 00

Torque Wrench Socket

001 589 76 21 00 001 589 73 21 00

Compression Pressure Hand Vacuum Pump

Tester

Downloaded from www.Manualslib.com manuals search engine

1A3-10 GENERAL ENGINE INFORMATION

DIAGNOSIS

OIL LEAK DIAGNOSIS 1. Pour the specified amount of dye into the engine

oil fill tube.

Most fluid oil leaks are easily located and repaired

2. Operate the vehicle normal operating conditions

by visually finding the leak and replacing or repairing

as directed in the kit.

the necessary parts. On some occasions a fluid leak

may be difficult to locate or repair. The following 3. Direct the light toward the suspected area. The

procedures may help you in locating and repairing dyed fluid will appear as a yellow path leading to

most leaks. the source.

Finding the Leak Repairing the Leak

1. Identify the fluid. Determine whether it is engine Once the origin of the leak has been pinpointed

oil, automatic transmission fluid, power steering and traced back to its source, the cause of the leak

fluid, etc. must be determined n order for it to be repaired

properly. If a gasket is replaced, but the sealing

2. Identify where the fluid is leaking from.

flange is bent, the new gasket will not repair the

2.1 After running the vehicle at normal operating leak. The bent flange must be repaired also. Before

temperature, park the vehicle over a large attempting to repair a leak, check for the following

sheet of paper. conditions and correct them as they may cause a

2.2 Wait a few minutes. leak.

2.3 You should be able to find the approximate Gaskets

location of the leak by the drippings on the

paper. l The fluid level/pressure is too high.

3. Visually check around the suspected component. l The crankcase ventilation system is

Check around all the gasket mating surfaces for malfunctioning.

leaks. A mirror is useful for finding leaks in areas l The fasteners are tightened improperly or the

that are hard to reach. threads are dirty or damaged.

4. If the leak still cannot be found, it may be l The flanges or the sealing surface is warped.

necessary to clean the suspected area with a l There are scratches, burrs or other damage to

degreaser, steam or spray solvent. the sealing surface.

4.1 Clean the area well. l The gasket is damaged or worn.

4.2 Dry the area. l There is cracking or porosity of the component.

4.3 Operate the vehicle for several miles at l An improper seal was used (where applicable).

normal operating temperature and varying

speeds.

Seals

l The fluid level/pressure is too high.

4.4 After operating the vehicle, visually check

the suspected component. l The crankcase ventilation system is