Rotating Equipment Measurement

Rotating Equipment Measurement

Uploaded by

Andinata SitepuCopyright:

Available Formats

Rotating Equipment Measurement

Rotating Equipment Measurement

Uploaded by

Andinata SitepuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Rotating Equipment Measurement

Rotating Equipment Measurement

Uploaded by

Andinata SitepuCopyright:

Available Formats

John Crane EAA

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE 1

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

Contents:

1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0

INTRODUCTION SOURCES OF EQUIPMENT DIMENSIONS WHERE TO TAKE DIMENSIONS RECORDING DATA MEASURING EQUIPMENT & ACCURACY MEASUREMENTS & CHECKS RETROFITS - REUSING EXISTING SEAL PARTS UPGRADES FROM GLAND PACKING DOUBLE SEALS PRE-COMMISSIONING EQUIPMENT CHECKS OTHER EQUIPMENT STUFFING BOX & SLEEVE DATA SHEET

Page

3 3 4 4 4 4 9 9 10 10 13 14

John Crane EAA

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE

Hyperlinks to points in the document:

KEY ASPECTS OF ROTATING EQUIPMENT:

Heating / Cooling Gallery

See Section 6.4

See Section 6.3.3

Access Window

See Section 6.1.1

Shaft

Nearest Obstruction

See Section 6.3.1

Direction of Rotation

See Section 6.5

PCD / Bolt Studs

See Section 6.2

Seal Chamber Bore

See Section 6.1.2

Radial Obstruction

See Section 6.3.2

Flush Connection

See Section 6.6

See Section 6.1.2

Spigot Location

John Crane EAA

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE

1.0 INTRODUCTION

Mechanical seals are not stand-alone items, but always form part of a larger rotating equipment assembly. Obviously if the seal is to function properly it is vital that the design of the seal installation is based on the correct dimensions and information covering all aspects of the rotating equipment which affect the seal. In many cases, this information is reliably available from drawings, but in some situations, there is no alternative but to take measurements of the actual equipment in the field. By their nature, rotating equipment tends to be very diverse in design; hence, it is not possible to produce a document guide covering all such designs that may be encountered in the field. Rather this document covers normal measurements for a typical centrifugal pump, but also refers to other equipment types in passing. With some field experience, it should be possible to apply the points given in this guide to other types of equipments on a case-by-case basis.

2.0 SOURCES OF EQUIPMENT DIMENSIONS

1. EQUIPMENT OEM ADVANTAGES DISADVANTAGES As the original manufacturer, the OEM must have drawings! As original manufacturing drawings these should reflect the actual equipment dimensions (but see below) May not be correct, changes may have been made in Production or on site which are not reflected on the drawing OEM often unwilling to release drawings due to a) confidentiality, b) no benefit to them, c) desire to retain seal spares business etc. The end-user may have access to drawings from the OEM or in some cases may even have made their own drawings As a customer the end-user may have more influence for obtaining OEM drawings than John Crane as a supplier Drawings may be inaccurate or incomplete Modifications may have been made to the equipment which have not been recorded For retrofits the end-user may have a seal drawing from a competitor showing seal chamber and / or the envelope dimensions of the existing sealing arrangement Easier than site measurement The competitor's drawing may contain errors (sometimes deliberate!) There may be inadequate dimensional information shown on the competitor's drawings - again this is sometimes intentional to make seal retrofitting very difficult The subject of this Guide Access to the actual equipment in which the seal will be installed ensures that any local modifications etc. that may have been made will be apparent The equipment may be running and there may be no maintenance opportunity to dismantle it for measurement purposes Careful measurement, recording and communication of dimensions by the engineer are essential - errors must be avoided! The measurement process is time-consuming

2. END-USER ADVANTAGES DISADVANTAGES

3. COMPETITOR

ADVANTAGES DISADVANTAGES

4. SITE MEASUREMENT ADVANTAGES DISADVANTAGES

John Crane EAA

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE

While the other options should be considered first, this document focuses on option no. 4 above, i.e. measurement of rotating equipment on site. This measurement is invariably carried out by John Crane personnel, either because the site engineers are too busy to do this and regard it as a seal vendor's task, or because they are unwilling to take the responsibility of measuring it themselves in case the seal ultimately does not fit!

3.0 WHERE TO TAKE DIMENSIONS - e.g. SITE / JC WORKSHOP / OTHER

For small pumps at sites close to a John Crane workshop, removing backplates or other parts of the equipment from the site for measurement purposes may sometimes be possible. This gives the advantages of being able to measure and record details in a 'controlled' manner, with more measurement equipment available and the option of making a cup of tea. However, in practice this is generally impractical either due to time constraints, remote location, large equipment, difficulties of getting a gate pass to remove the parts from site etc. Therefore, measurements will normally be taken at the site, either at the installation itself or (better) in the site Maintenance Workshop.

4.0 RECORDING DATA

Measurements taken should be recorded in a clear and concise way. This should normally be done on the John Crane Stuffing Box & Sleeve Data Sheet as shown in Section 12.0. Any aspects of the equipment not shown on the form but which are relevant can be sketched separately. Note that one practical way of recording various features of the equipment may be to use photographs (digital or Polaroid), since these can show the overall 'style' of the equipment, the positions of any obstructions, the extent of the damage to any worn components etc. The photographs can be reviewed by other engineers / draftsmen back in the office, and can be kept as a record for future reference.

5.0 MEASURING EQUIPMENT & ACCURACY

The John Crane representative should take suitable measuring equipment when attending the site, normally including a Vernier Calliper (250mm-range min.), a Micrometer and a 12" ruler. Suitable measuring equipment and accuracies are given against each of the dimensions described below. Where accurate measurement is needed and a Vernier Calliper or Micrometer is to be used, these should be periodically calibrated (typical interval 1 year for irregular use). It is sometimes thought that only Manufacturing / QC measuring equipment needs calibration, and that this is not necessary for equipment used intermittently on site. Clearly this is a fallacy, since measuring anything with uncalibrated / inaccurate equipment defeats the whole purpose of taking an 'accurate' measurement. Even for calibrated equipment, it should be remembered that a Vernier Calliper is subject to a measuring tolerance of + 0.02mm, a Micrometer to + 0.01mm. Attempting to measure anything to greater accuracy than + 0.5mm with a ruler is unacceptable practice. While greater accuracy could be achieved with bore gauges, these are usually unavailable on site and are not normally warranted for this type of work.

6.0 MEASUREMENTS & CHECKS 6.1 CRITICAL SURFACES FOR SEALING & LOCATION

The following are critical surfaces for location of seal components and for secondary sealing. Accordingly special care must be taken to ensure these elements of the equipment are properly measured / checked.

John Crane EAA

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE

1 - shaft diameter 2 - bore of seal chamber 3 - face of seal chamber

6.1.1 Shaft The shaft of the equipment sets the position of all the rotating portion of the seal assembly, either through a close clearance shaft sleeve or directly to a retainer / collar etc. It also forms part of a static or dynamic seal (e.g. sleeve o-ring / trapped gasket / secondary seal etc.). For stepped shafts, it is essential to measure all relevant diameters in the seal chamber area, both inboard and outboard of the seal. Where the design is a hooked sleeve, the position of the hooked step, the minor diameter and the keyway should all be noted. The major diameter on the shaft should have an adequate lead-in chamfer (typically 1.5mm long X 20o) to ensure that the sleeve / sleeve o-ring / secondary seal can easily be passed onto the shaft during seal installation. If this does not exist then the end-user should be asked to modify the shaft. Note should be taken of any special features existing on the shaft, for example pin or setscrew holes, threads etc., and their size and position should be recorded. NOTE: Some shaft sleeves have a high hardness (chrome steels etc.) or a hard coating (Metco, chrome oxide spray etc.) in the area of the seal. It is important to note the position of any such coatings, and to establish the shaft hardness (normally via the OEM or possibly with a hardness tester), since this would affect the holding power of setscrews (seal head or drive collar). Typical manufacturing tolerance: + 0.02 to + 0.05mm Required measurement tolerance: + 0.01mm Surface finish: 0.8m Roundness: 0.05mm TIR Preferred method of measurement: Micrometer 6.1.2 Bore of seal chamber / spigot diameter Good practice for all mechanical seals demands a radial location of the stationary element, to ensure those parts are centred relative to the shaft. For the majority of seal installations the bore of the seal

John Crane EAA

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE

chamber is used as a close clearance pilot diameter, to radially locate the stationary portion of the seal assembly. The exceptions are installations where: the radial location is taken from an OD spigot, in which case similar comments apply to that OD surface instead of the ID some cartridge seal designs are radially set through setting spacers or centralising rings (e.g. Type 5600 series etc). For either of the seal chamber bore is then less critical, since it is not used for sealing or location.

ID Spigot

OD Spigot

Where an ID spigot is used, there may be a short recess machined as a counterbore into the face of the seal chamber. In such cases this recess is intended specifically for spigotting purposes, hence should be a controlled (tight tolerance) diameter. For some seal designs, an o-ring in the bore of the seal chamber forms the static seal between the gland plate and the seal chamber. In such cases the surface finish of the seal chamber bore must be sufficient for sealing purposes (see below), and there must be an adequate lead-in chamfer to ensure the o-ring does not get cut during installation (typically 1.5mm long X 20o). Similarly, if the o-ring has to pass over any connection holes or other steps on the ID surface, these should be dressed or relieved to prevent o-ring damage during installation. Typical manufacturing tolerance: varies Required tolerance: + 0.02mm Required measurement tolerance: + 0.02 - + 0.05mm Surface finish: 0.8m Roundness: 0.05mm TIR Preferred method of measurement: Vernier 6.1.3 Face of seal chamber The face of the seal chamber is normally used as a sealing surface for either an o-ring or gasket in the seal gland plate. Although this is a static secondary seal, nevertheless it is important that the surface finish of the seal chamber face is adequate for sealing purposes. The face of the seal chamber also acts as an abutment for the gland plate, hence must be square to the shaft to prevent any misalignment of the stationary seal assembly. Surface finish: 0.8m Squareness to shaft: TIR 0.005mm per 10mm of seal chamber bore

6.2 BOLT STUD / PCD

The bolt PCD is a critical piece of information; any errors made in recording this could be expensive and time-consuming (or even impossible!) to rectify, and would inevitably be damaging to the John Crane reputation. The diameter across from the outside of one stud to the outside of the diametrically opposite stud should be measured using a Vernier Calliper. A measurement should then be taken from the inside of

John Crane EAA

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE

the studs. The mean of these 2 dimensions should then be taken and this considered as the PCD. With 4 studs, this should be checked with the opposing pair of studs to ensure the figure is the same! The angle of the bolt positions should be noted, e.g. TDC and 90o positions, 45oC positions, special positions / non-standard angle etc. In the latter case, it may be necessary to 'construct' the positions of the bolt studs by taking several measurements. NOTE: there is often a wide tolerance on the actual positions of bolt studs; hence, even for orthodox bolt positions it is still worth constructing the position as a check. The bolt stud extension should be measured, since this will limit the section of the seal gland plate or require replacement longer studs. This dimension should be measured from the end face of the seal chamber to the end of the threaded portion of the stud. Note that for seal retrofits the thickness of the existing gland plate can also be used as a guide to allowable envelope dimensions. Typical manufacturing tolerance: + 0.2 - 0.5mm Required measurement tolerance: + 0.2mm Preferred method of measurement: Vernier

6.3 OBSTRUCTIONS

Most seal selections and designs are constrained by the available space in the seal chamber. This problem is compounded in a growing number of upgrades to double seal installations in older equipments, resulting from greater emphasis on emissions/ reliability / safety etc.

Access Window typical endview of seal chamber:

Nearest Axial Obstruction (bearing housing)

Nearest Radial Obstruction (bearing bracket)

Drain Hole

The major constraints facing the seal supplier are as follows: 6.3.1 Axial The most important axial obstruction to consider is the distance to the bearing housing. This is variously referred to as the N.O. (Nearest Obstruction) or the F.O.B. (First OBstruction). This restricts the length of the seal assembly outboard of the seal chamber. It is normally impossible to increase this distance, because the bearing position will be fixed as part of the original design. Therefore, the only way to make more space available would be to machine back the surface of the seal chamber. However, this is unpopular with end-users due to the difficulties of making the modification, and because it is an irreversible process. Note that the distance to the nearest obstruction at the shaft may be less than at a larger diameter, due to the inclusion of a bearing deflector. Typical build tolerance: + 0.5mm Required measurement tolerance: + 1mm Preferred method of measurement: Vernier or ruler

John Crane EAA

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE

6.3.2 Radial Radial obstructions typically include bearing brackets or other features limiting the design of the seal installation. These can affect the gland plate OD, the size and position of tapped connections for flushing / quenching etc. Thought must also be given to the 'ergonomics' of the seal design, for example the space available for tightening of setscrews, removal of setting spacers etc. The positions of any obstructions should be 'constructed' by taking various measurements relative to the face of the seal chamber, the shaft, the bearing housing etc. Bearing bracket designs will be vary depending on the individual equipment, however typical configurations include those shown on the Stuffing Box and Sleeve Data Sheet. Typical manufacturing tolerance: + 0.5mm Required measurement tolerance: + 1mm Preferred method of measurement: Vernier or ruler For retrofitting projects, the competitors' seal components are a reliable guide to acceptable seal envelope dimensions, since they have already been installed in the available space. Therefore, by measuring the OD of the existing gland plate, the overall length of the existing sleeve etc., it is safe to conclude that these dimensions will be less than the radial or axial obstructions. 6.3.3 Access Windows Where the seal assembly may have to pass through an access window, this will be a constraint on the overall dimensions of the seal. Similarly, if a seal is to be fitted from the coupling side of the equipment, the DBSE (Distance Between Shaft Ends) should be noted, since with the coupling removed this dimension will limit the overall length of the seal.

6.4 COOLING / HEATING GALLERIES

Some pumps may have galleries around the seal chamber for the purposes of heating or cooling the pump. These are usually evident from the tapped heating (steam) or cooling (water) connections running into the pump casing. The position of these connections and pipes may obstruct the area around the seal, and limit the size / design of the seal installation. NOTE: Where modifications are being proposed to older equipment (e.g. re-bore of seal chamber) with galleries fitted, careful thought must be given to whether the modification is practical. Decreasing the wall thickness of the casing will affect the integrity of the pressure casing. Therefore, any such situations should be referred to the OEM and / or end-user, and John Crane should never take the responsibility for the modification alone.

6.5 DIRECTION OF SHAFT ROTATION

The direction of shaft rotation is critical for seal designs that include: unidirectional spiral grooves (e.g. Type 2800 series, Type 28 series, Type 28SC, Type 28ST, Type 285 etc.); where there is any likelihood of prolonged reverse rotation a bi-directional seal design should be considered. axial flow pumping scrolls 'handed' springs (John Crane Flexibox product range) tangential connections The direction of shaft rotation (CW / CCW) should be checked on site by reference to any / all of the following: pump data sheets physical pump (there will normally be an arrow on the bearing housing or pumping casing) orientation of discharge volute on pump existing seal parts which may have tangential flushing connections or 'handed' designs

John Crane EAA

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE

site operators The direction of shaft rotation should be recorded as from the motor side. Note that conventionally an API pump will rotate CW while an ANSI pump will rotate CCW, as seen from the motor side. TO BE CHECKED.

6.6 PIPING & UTILITIES

For installations that will have ancillary connections such as API Plan 11 flushing, Plan 62 quenching etc., provisions for these supplies must be checked. This includes checking whether a tapping is provided on the pump discharge for flush recirculation. If on a retrofit project an existing sealant system or heat exchanger is to be used, then the size / location / capacity etc. must be noted, and the piping circuit sketched to include rough overall dimensions, fittings, orifices, and pipe diameters. As above, the position of any obstructions should be noted carefully, so that the seal can be designed for straightforward piping access. The utilities themselves should also be checked, including external flushing pressure and flow rate (API Plan 32) N2 pressure (API Plan 53), steam pressure (API Plan 62), cooling water pressure / temperature / flow etc.

6.7 CORROSION / EROSION / CAVITATION etc.

Any evidence of corrosion / erosion / cavitation to any parts of the pump in the area of the seal chamber should be noted and discussed with the end-user. This damage may effect seal selection, design and installation, and may necessitate replacement of affected pump parts. Such damage may also indicate problems with some aspect of pump operation that would be detrimental to seal performance; hence, it is in the interests of John Crane to get such problems resolved. In particular, any wear to Critical Surfaces for Sealing and Location (see Section 6.1) should be brought to the attention of the end-user.

7.0 RETROFITS - REUSING EXISTING SEAL PARTS

Note that in some cases the customer may request that parts of the existing competitor's seal (e.g. shaft sleeve or gland plate) be re-used, as a perceived saving in cost. However, this is frequently difficult or impossible; the dimensions of the competitor's parts may force a compromise in the John Crane seal design, and would preclude the supply of a standard cartridge seal. Apart from whether this may or may not be feasible, it also creates a problem of split responsibility for the installation, e.g. John Crane would then be expected to warranty the quality of materials and manufacture for parts not of our supply. Clearly there could be doubts over the design, the material, and any wear or corrosion in service. Therefore, this practice should be avoided unless special circumstances apply.

8.0 UPGRADES FROM GLAND PACKING

One type of retrofit of an existing sealing device is the replacement of gland packing. For older equipments that are being fitted with mechanical seals for the first time, the following key points should be noted: A mechanical seal will usually need more space than the gland packing, however the space available in a stuffing box (both radial and axial) will be very limited and not intended to accommodate a seal (see Section 6.3 Obstructions). Due to this space limitation, it is often necessary to reuse the flush connection that normally exists already in the stuffing box; hence, it is important to record the size, axial position, angle and orientation of this connection. NOTE: the axial position of the connection relative to the face of the stuffing box is particularly important, since the effectiveness of the flushing liquid in cooling the seal faces will depend on this.

John Crane EAA

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE

10

Flush Connection Stuffing Box

It is quite possible that wear on the shaft or the face of the seal stuffing box may have taken place from the gland packing installation (see below). Any such wear should be noted and recorded. This may affect the type of seal design used, and in extreme cases may necessitate substantial modification and / or replacement of parts of the rotating equipment before a seal could be installed.

Worn Shaft

Worn Face of Stuffing Box

The gland packing follower will typically have been tightened using only 2 gland bolts / studs, however for even tightening of a seal gland plate 4 bolt studs are recommended. Therefore, the feasibility of adding in 2 more bolt studs to the face of the seal chamber should be considered.

9.0 DOUBLE SEALS

The main issues to be considered with double seals are as follows: The seal installation will need more axial (and possibly radial) space than a single seal; hence, the position of the nearest obstructions is particularly important (see Section 6.3 Obstructions). There may be a need for a barrier or buffer fluid connection in the pump casing. This may exist from a previous seal or gland packing installation; otherwise, provision would need to be made to provide this.

10.0 PRE-COMMISSIONING EQUIPMENT CHECKS

Prior to commissioning of the rotating equipment, the points given below should be always checked (normally by the end-user). However if these can be checked at an earlier stage during measurement of the seal chamber, this would allow more time to rectify any problems with bearings / alignment / shaft ovality etc. The readings taken should be checked against the published limits for the seal AND those for the equipment itself. If actual equipment tolerances exceed these limits, this must be discussed with the end-user / OEM as appropriate, to prevent possible seal problems which would result.

John Crane EAA

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE

11

pre-com missioning surface finish & dim ensional check equipment checks

- 1. dimensions and surface finishes

1.5 LG x 2 0 C ha m fer 0.8

0.8

Figure #1 check the shaft and seal chamber dimensions and surface finishes as noted

pre-com missioning surface finish & d im ension al check equipment checks

- 2. shaft ru nout

T urn th e sh aft by hand N ote m easure ment on dia l in dica tor

Figure # 2 measure the shaft r unout at the seal location - the maximum value should not exceed 0.05m m FIM

John Crane EAA

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE

12

pre-com missioning surface finish & dim ensional check equipment checks

- 3. axial float

Mo ve shaft in axial d irectio n b y hand N ote m easurement on dial ind icato r

Figure # 3 the m aximum value should not exceed 0.08mm FIM - remove any sharp edges or burrs on the shaft over w hich the seal sleeve m ust pass

pre-commissioning equipment checks surface finish & dimensional check

- 4. squareness

Turn the shaft by hand Note measurement on dial indicator

Figure #4 the maximum value should not exceed 0 005 per 10mm of seal chamber bore diameter FIM

John Crane EAA

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE

13

11.0 OTHER TYPES OF EQUIPMENT

This Guide is based around a standard centrifugal pump configuration, since these are the most common equipments encountered in the field. However, for other equipments (e.g. agitators, fans, blowers, steam turbines etc.) similar guidelines apply in most cases. These together with an understanding of the seal type to be installed should ensure that the right measurements and checks are made.

11.1 AGITATORS

For agitators the driver unit (motor ' gearbox) may not be removed for seal installation, as this is a time-consuming process. Rather the maintenance procedure may involve the coupling only being removed, and the seal then installed through an access window. The dimensions of the access window are frequently small and restrict the overall envelope dimensions of the seal. If this is not taken into consideration then the result can be an expensive seal that finally cannot even be installed!

Access Window

Shaft runout and vibration levels on agitators are invariably higher than for a pump, because the equipment is larger and alignment less precise. These should be discussed on site, and axial and radial shaft float should be measured if practical. If the equipment is running then it should be possible to qualitatively assess the shaft movement and vibration, e.g. 'normal', 'high' etc. Vibration levels at the area of the seal can be recorded if suitable measurement equipment is available. Where an integral radial bearing is required in the seal cartridge, the necessary load figures are needed to correctly size the bearing. These may be available from site data sheets or the OEM, or in the case of a retrofit the size / specification of the existing bearing should be noted.

11.2 STEAM TURBINES

For steam turbine retrofits (Type 28ST seals) it is common to find that the equipment on which the seal will be installed is old, and that corrosion has occurred on the casing and / or shaft. This can include steam cuts where the casing material has been eroded by gradual steam leakage over a long period. In some cases this is likely to affect secondary sealing and pilot locations, and can be so severe that there is no option but to request major equipment repairs or replacement before the seal can be reliably installed. These aspects should be checked well in advance of seal installation if at all possible. The alternative is that the customer must be prepared to expect some 'surprises' when the turbine is opened for seal installation, and to carry out necessary repairs in a short time frame. The OEM should be involved in this process if possible.

John Crane EAA

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE

14

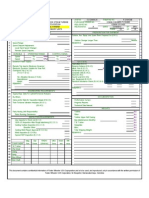

12.0 STUFFING BOX & SLEEVE DATA SHEET (2 pages)

John Crane Mechanical seals Engineered Sealing Systems JC reference :____________ Pump type :____________ Pump model :____________ Date :____________ Measure by:____________

Stuffing Box and Sleeve Data Sheet

PCD

See spigot detail

Note: - Irrelevant dimensions and details to be marked as X.

Viewing from A, the End View. Indicate which type of layout. SPECIAL Mark location

45

Indicate which method - if needed Mark location of flush and quench connection Connection size: _____

Number of studs:_____ Boss Counterbore Stud size:_____ Scallop Slot Spigot detail dimension

Available area for sealing

Option 1

Option 2

Option 3 Sheet 1 of 2

John Crane EAA

GUIDE TO MEASUREMENT OF ROTATING EQUIPMENT

INTERNAL TO JOHN CRANE - NOT TO BE RELEASED TO EXTERNAL PARTIES WITHOUT PERMISSION

PAGE

15

John Crane Mechanical seals Engineered Sealing Systems

JC reference :____________ Pump type :____________ Pump model :____________ Date :____________ Measure by:____________

Stuffing Box and Sleeve Data Sheet

Sketch and dimension sleeve detail

Sketch and dimension keyway detail

Feel free to scribble or sketch any relevant information

Sheet 2 of 2

Original Document drafted by Nigel Jenkins

You might also like

- Ford Think Service Manual - Section 2 ChassisDocument41 pagesFord Think Service Manual - Section 2 ChassisDennis Jason AntiNo ratings yet

- Rotating Equipment Codes and StandardsDocument2 pagesRotating Equipment Codes and StandardsWong Da100% (11)

- Skin Effect Current Tracing - Installation Manual PDFDocument27 pagesSkin Effect Current Tracing - Installation Manual PDFYoung-seok Hwang100% (1)

- Car Dolly Illustrsated Parts DiagramDocument36 pagesCar Dolly Illustrsated Parts DiagramMike Wienhold100% (4)

- Jphil Bolting and Unbolting Procedure Rev 1Document21 pagesJphil Bolting and Unbolting Procedure Rev 1Mark Darrel AranasNo ratings yet

- Overview of Rotating Equipment PDFDocument96 pagesOverview of Rotating Equipment PDFAiyappa Devraj100% (8)

- Rotating Equipment Reliability PDFDocument8 pagesRotating Equipment Reliability PDFAmal Ka100% (1)

- Rotating Equipment Chapter 6Document19 pagesRotating Equipment Chapter 6Mohamad Sleiman100% (1)

- Introduction To Jig & Fixture Design by KempsterDocument54 pagesIntroduction To Jig & Fixture Design by Kempstersk9145100% (10)

- Green WallDocument11 pagesGreen WallMilan LončarNo ratings yet

- Installation Guidelines - Rotating EquipmentDocument18 pagesInstallation Guidelines - Rotating EquipmentSherif Adel100% (5)

- Guide To Measure Rotating EquipmentDocument18 pagesGuide To Measure Rotating EquipmentMDRNo ratings yet

- Rotating Equipment Knowledge2Document20 pagesRotating Equipment Knowledge2SingSareblakKanaManah100% (1)

- Rotating Equipment Study Material - GEDPDocument15 pagesRotating Equipment Study Material - GEDPahmdeidNo ratings yet

- Rotating Equipment Start Up Operation Maintenance TroubleshootingDocument4 pagesRotating Equipment Start Up Operation Maintenance TroubleshootingGhulam MurtazaNo ratings yet

- Standard Overhauling Procedure of Single Stage Horizontal Centrifugal PumpDocument3 pagesStandard Overhauling Procedure of Single Stage Horizontal Centrifugal PumpNilesh Gohel100% (1)

- Rotating Equipment Chapter 3 PumpsDocument125 pagesRotating Equipment Chapter 3 PumpsMamdouhAlhanafy100% (4)

- Rotating Equipment (Driven Items)Document292 pagesRotating Equipment (Driven Items)Faisal Dilbagh100% (1)

- Pump Maintenance Procedures 1Document7 pagesPump Maintenance Procedures 1Shraddha Raut100% (1)

- Mechanical Workshop Presenters: Chris Akpan & Adeboye ODocument143 pagesMechanical Workshop Presenters: Chris Akpan & Adeboye OAnie EkpenyongNo ratings yet

- Introduction To Rotating Equipment MaintenanceDocument456 pagesIntroduction To Rotating Equipment MaintenanceJShearer97% (62)

- Reverse Dial Indicator MethodDocument14 pagesReverse Dial Indicator MethodvinothenergyNo ratings yet

- Mechanical Seals Failure, Causes and Its RemediesDocument26 pagesMechanical Seals Failure, Causes and Its RemediesFaruque Khan Yumkhaibam100% (10)

- Training On Alignment of Rotating EquipmentDocument21 pagesTraining On Alignment of Rotating EquipmentJayant SagadeNo ratings yet

- PUMP TrainingDocument130 pagesPUMP TrainingTirta Budiawan100% (9)

- 03b3 - Equipment (Rotating Pumps)Document34 pages03b3 - Equipment (Rotating Pumps)John Lexmar LeynesNo ratings yet

- Steam Turbine Inspection Bhel PDFDocument26 pagesSteam Turbine Inspection Bhel PDFReda Nari100% (1)

- Pump Maintenance PDFDocument9 pagesPump Maintenance PDFkamel100% (1)

- Recip. Compressor TestingDocument10 pagesRecip. Compressor TestingS DasNo ratings yet

- 04 Rotating Equipment PDFDocument82 pages04 Rotating Equipment PDFViswanathPvNo ratings yet

- Siemens Rotating Machinery GuideDocument191 pagesSiemens Rotating Machinery GuideSathish Kumar100% (1)

- Pump and Compressor 2Document52 pagesPump and Compressor 2SaravananRamasamy100% (5)

- Pump MaintenanceDocument83 pagesPump MaintenanceSiva Kumar Tutika100% (3)

- Rim and Face - Alignment KnowledgeDocument19 pagesRim and Face - Alignment Knowledgevj kumar100% (2)

- Rotating EquipmentDocument235 pagesRotating EquipmentpraSHANT2331100% (5)

- Vertical PumpsDocument27 pagesVertical Pumpsmersium100% (2)

- Mechanical Seal Products and Services CatalogueDocument64 pagesMechanical Seal Products and Services Cataloguetankerstar100% (2)

- Mechanical Seal Presentation (2009)Document28 pagesMechanical Seal Presentation (2009)LelosPinelos123100% (6)

- Condition Monitoring For Steam Turbines Part IIDocument31 pagesCondition Monitoring For Steam Turbines Part IIidigiti100% (1)

- Mechanical Seal PresentationDocument48 pagesMechanical Seal Presentationsathesh100% (8)

- Recip. Comp ECDPDocument51 pagesRecip. Comp ECDPSkydriver Paul100% (1)

- Top 5 Rotating Equipment Engineer Interview Questions With AnswersDocument8 pagesTop 5 Rotating Equipment Engineer Interview Questions With Answerswinarnob100% (1)

- Centrifugal Pump InspectionDocument33 pagesCentrifugal Pump InspectionAbhi Nandana100% (1)

- Api 611 5Th Edition General " Purpose Steam Turbine Existing TurbineDocument1 pageApi 611 5Th Edition General " Purpose Steam Turbine Existing TurbineAlejandro GilNo ratings yet

- IndusInd Bank LEGEND Credit Card NewDocument1 pageIndusInd Bank LEGEND Credit Card Newrushikesh.fundsutraNo ratings yet

- Mechanical Seal ReplacementDocument21 pagesMechanical Seal ReplacementshahjahanhashimaliNo ratings yet

- EQPT-02-21 Pipe Strain For Rotating EquipmentDocument2 pagesEQPT-02-21 Pipe Strain For Rotating EquipmentAmanSharmaNo ratings yet

- Overhaul of Centrifugal Gas CompressorDocument61 pagesOverhaul of Centrifugal Gas CompressorAvinash Kulkarni100% (1)

- Centrifugal Compressor TestingDocument9 pagesCentrifugal Compressor TestingEnergy 2Green100% (1)

- JHON CRANE 2152037 Barrier FluidsDocument19 pagesJHON CRANE 2152037 Barrier Fluidstotalquality100% (3)

- Centrifugal PumpsDocument30 pagesCentrifugal PumpsNitish NairNo ratings yet

- Centrifugal Pump MaintenanceDocument32 pagesCentrifugal Pump Maintenancemersium100% (3)

- ChecklistDocument2 pagesChecklistdassayevNo ratings yet

- Visual Inspection of Large Electric GeneratorsDocument31 pagesVisual Inspection of Large Electric GeneratorskknifNo ratings yet

- JIG For ESP E - CE-RDE Installation (User Manual) - XNKS - Rev.01Document20 pagesJIG For ESP E - CE-RDE Installation (User Manual) - XNKS - Rev.01greensupply.salesNo ratings yet

- Installation, Operation and Maintenance of Airflex@ CM Marine ClutchDocument12 pagesInstallation, Operation and Maintenance of Airflex@ CM Marine Clutchaiyubi2No ratings yet

- Manufacturing Sun Cartridge Cavities: Tooling CheckDocument5 pagesManufacturing Sun Cartridge Cavities: Tooling CheckxxshNo ratings yet

- DOP 202 - Rev 2Document83 pagesDOP 202 - Rev 2Fernando AybarNo ratings yet

- 18 Visual InspectionDocument31 pages18 Visual InspectionanilscoobNo ratings yet

- Manual Rosemount Annubar Flowmeter Series Part 3 en 88154 PDFDocument4 pagesManual Rosemount Annubar Flowmeter Series Part 3 en 88154 PDFeduryuNo ratings yet

- DOP 206 - Rev 4Document12 pagesDOP 206 - Rev 4Fernando AybarNo ratings yet

- Xerox Workcenter 123,128,133Document1,176 pagesXerox Workcenter 123,128,133González Oviedo GabrielNo ratings yet

- Overhead SetDocument5 pagesOverhead SetHussain AhmedNo ratings yet

- Vertical and Horizontal Recirculator Packages: Form 120-200 IOM (MAR 2010)Document44 pagesVertical and Horizontal Recirculator Packages: Form 120-200 IOM (MAR 2010)botaratoNo ratings yet

- DesignSpark Mechanical GuidebookDocument94 pagesDesignSpark Mechanical Guidebookcipiripi14100% (1)

- 11-5k Annular BOP Operation Manual-Shaffer TypeDocument19 pages11-5k Annular BOP Operation Manual-Shaffer TypeDaniel RinconNo ratings yet

- M SP2000 en PDFDocument54 pagesM SP2000 en PDFChia Sze KiatNo ratings yet

- Freightliner Coronado Maintenance ManualDocument10 pagesFreightliner Coronado Maintenance Manualdaryl100% (36)

- Massey Ferguson 7465 TRACTOR Service Parts Catalogue Manual (Part Number 1637443)Document15 pagesMassey Ferguson 7465 TRACTOR Service Parts Catalogue Manual (Part Number 1637443)bvk2980022No ratings yet

- Bolts, Screw, Nut - Terminology and Nomenclature. ISO1891 - 1979 (E - F - R)Document66 pagesBolts, Screw, Nut - Terminology and Nomenclature. ISO1891 - 1979 (E - F - R)tkcn tvNo ratings yet

- Design of Pelletizing Machine (Balling Disc) : January 2015Document5 pagesDesign of Pelletizing Machine (Balling Disc) : January 2015VIETBKA GAMEPlAYNo ratings yet

- Breakaway Coupling DrawingDocument2 pagesBreakaway Coupling DrawingpmwtechnicaldeptNo ratings yet

- Piping JointsDocument25 pagesPiping JointstowiwaNo ratings yet

- Automatic Recognition of FastenersDocument35 pagesAutomatic Recognition of FastenersMarios KNo ratings yet

- Wellhead Systems Rod AccessoriesDocument18 pagesWellhead Systems Rod Accessoriesbuat unduhNo ratings yet

- Model E180 CatalogDocument2 pagesModel E180 CatalogThomas StempienNo ratings yet

- Massey Ferguson MF 187 COMBINE Parts Catalogue Manual Instant DownloadDocument27 pagesMassey Ferguson MF 187 COMBINE Parts Catalogue Manual Instant Downloadgabeaden26No ratings yet

- PD 6705-3 - 2009Document28 pagesPD 6705-3 - 2009Pedro Baltazar100% (1)

- Nordlock DimensionsDocument16 pagesNordlock DimensionsAce Industrial SuppliesNo ratings yet

- 200WX Owner's Guide and Installation InstructionsDocument24 pages200WX Owner's Guide and Installation InstructionscristianocalheirosNo ratings yet

- Tajima TFGN 2007.06Document79 pagesTajima TFGN 2007.06alsubhantraders937No ratings yet

- 2.thread GaugesDocument28 pages2.thread GaugesAshlin SreedharNo ratings yet

- Fundermax Exterior Technic 2011gb Web PDFDocument88 pagesFundermax Exterior Technic 2011gb Web PDFarchpavlovicNo ratings yet

- Arduped PDFDocument17 pagesArduped PDFPrakash Duraisamy100% (1)

- LHM 420Document432 pagesLHM 420Mohamed El Gamal100% (1)

- MK Factory EquipmentDocument152 pagesMK Factory EquipmentironalejanNo ratings yet

- Build A Better Stirling Engine PDFDocument15 pagesBuild A Better Stirling Engine PDFseo tolhuinNo ratings yet

- Price ListDocument24 pagesPrice ListMark O'NeillNo ratings yet

- Week 15 Hardware and IronmongeryDocument45 pagesWeek 15 Hardware and IronmongeryShiela marie De guiaNo ratings yet

- Mesc 772701.002.1Document1 pageMesc 772701.002.1mb.pipingNo ratings yet