Oi psm630 en in PDF

Oi psm630 en in PDF

Uploaded by

Costy45Copyright:

Available Formats

Oi psm630 en in PDF

Oi psm630 en in PDF

Uploaded by

Costy45Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Oi psm630 en in PDF

Oi psm630 en in PDF

Uploaded by

Costy45Copyright:

Available Formats

Operating instructions

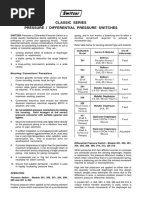

Pressure switch mechanical, model PSM-630

Fig. top: Pressure switch mechanical, model PSM-630

Fig. bottom: Pressure switch with relief valve, model PSM-630

Contents

Contents

1. General information 3

2. Model and specification 4

3. Operation 5

4. Procedure 6

5. Electrical connection 7

6. Mounting dimensions 8

© 2022 WIKA Instruments India Pvt. Ltd.,

All rights reserved.

Prior to starting any work, read the operating instructions!

Keep for later use!

2 WIKA operating instructions pressure switch mechanical, model PSM-630.

1. General information

The Pressure switch PSM-630 is primarily designed for automatic control of air

compressor and other similar control functions. Type PSM-630 is available optionally

with pressure relief valve which is used to release the locked pressure in the

compressor head for smooth operation during the next cycle. The switch breaks the

circuit when the pressure reaches the set value and makes it when pressure falls below

a pre-set value, the contacts can be used for starting and stopping of compressors.

Installation Guidelines

Isolate electrical power supply before opening the cover.

Before installation check operating pressure and temperature range as per the

information provided in page 4.

Do not exceed the stated maximum working pressure.

The measuring element will get permanently damaged if the applied pressure

exceeds the maximum working pressure.

The pressure measuring element is mounted in a metallic housing. Ensure to hold

the pressure connection hexagon with a spanner and tighten the process connector

to avoid strain on the metallic sensor housing. Ensure no stress is produced while

fitting.

Do not hold the instrument and rotate it for fixing on pressure line.

Instrument is suitable for air and water.

Bleed the system before putting into operation.

a) Mount the instrument away from sources of vibrations more than 4g.

b)

Protect against the effects of weather, example rain.

Manual ON/OFF knob – Knob should be in ON position always (contacts will be in

normally closed condition), during the process of pressure increase and decrease

instrument will work as per the set point and differential.

If this knob is in OFF position (contacts will be in normally open condition), contacts

will not change over further as per set parameters.

Knob can be positioned in OFF condition when user need to disconnect the electrical

connection temporarily at the compressor end instead of switching OFF the main

Power supply.

Fix cover properly to use manual on/off knob by tightening screw at 2 Nm of torque.

Do not mount the cover when knob is in off position.

3 WIKA operating instructions pressure switch mechanical, model PSM-630.

2. Model and specification

Permissible

Adjustable switch Maximum

Unit Setting range 1) switch point on

differential 2) working pressure

rising pressure

1 ... 5 1.7 ... 5 0.7 ... 3 8

bar 2.5 ... 11 4.3 ... 11 1.8 ... 7 15

6 ... 16 8.3 ... 16 2.3 ... 7 20

1) Switch point and reset point have to be within the setting range.

2) The difference between the switch point and the reset point is also known as switch hysteresis.

Measuring element

NBR diaphragm

Pressure connector

Die cast aluminium

Switching function

Normally closed contact

Permissible ambient temperature

-40 °C ... +70 °C

Permissible medium temperature

-20 °C ... +70 °C

Switch contacts

Double pole single throw (DPST) contact system

Triple pole single throw (TPST) contact system

Electrical rating

AC-3 16A, 230V / 440V AC

Conformity

BS:6134:1991, IEC-60947-5-1, IEC-60947-4-1, IEC-60947-1

Pressure relief valve

Only for setting range 2.5 ... 11 bar and 6 ... 16 bar

1/4" flare connection with nut

4 WIKA operating instructions pressure switch mechanical, model PSM-630.

3. Operation

Process pressure when applied to the sensing diaphragm creates a force which

opposes the force of a pre-compressed spring (Range spring). When the force due to

the diaphragm overcomes the spring force, it moves a balancing arm and in turn switch

contact changes over.

The output contacts can be used for starting and stopping of compressors.

Contact gets reset when the force of the diaphragm becomes less than that of the

spring load.

The pressure at which the contact is reset can be varied by adjusting the differential

spring.

Setpoint adjustment Differential adjustment

(-) (+)

(+) Lock Plate

(-)

Spanner Size: 8 mm Spanner Size: 8 mm

Fig.1 Fig.2

■■ Setpoint setting can be adjusted by rotating the range adjustable nut for the cut-out

pressure. Refer Fig.1. Using spanner of size 8 mm

■■ Desired cut-in pressure can be achieved by rotating the differential adjustment nut

after removing lock plate. After adjustment place lock plate back and tight the lock

screw with tightening torque of 2 Nm. Refer Fig.2

■■ The relief valve has a 1/4˝ flare connection for copper tubing. Connect to the delivery

line between compressor and check valve. Refer Fig.3

Fig.3

■■ For manual stop of compressor, rotate the knob to off position

5 WIKA operating instructions pressure switch mechanical, model PSM-630.

4. Procedure

6 7

5

1. Process con

2. TPST/DPST

3. Removable p

3 4. 2 mounting s

2 5. Switch point

6. Reset setting

7. Manual On/O

8. Option: Relie

4 4

1 8

1. Process connection 5. Switch point setting

2. TPST / DPST switch contact 6. Reset setting

3. Removable plastic cover 7. Manual On/Off knob

4. 2 mounting screws for plastic cover 8. Option: Relief valve

1. Fix the instrument to a calibration setup (comparator) with a master gauge. Apply

pressure to the instrument equal to the desired set value (cut out).

2. Adjust the range nut (5) to bring the set point close to the desired set value.

3. Rotate differential adjuster screw (6) to bring the desired differential value.

4. Rotate the range adjuster nut (5) till the contact changes over. Set value increases

when the screw is rotated clockwise and vice versa.

5. Increase and decrease the pressure to the desired set and differential value to

ensure that output contact changes over.

7. The pressure switch is now set to operate at the set value.

8. The differential value is the difference between cut-out pressure and cut-in

pressure.

The instrument adjustment is now complete.

Notes:

■■ Whenever the cut-out value is changed, the cut-in value will also change. But the

differential value remains the same.

■■ If the cut-in value is changed by adjusting the differential nut the cut-out value does

not change.

■■ Reset point = set point - differential value

6 WIKA operating instructions pressure switch mechanical, model PSM-630.

5. Electrical connection

Compressor connection with Direct on line connection of

direct on line starter compressor motor

Electrical Connection DPST

Refer the diagram and ensure that the cable is connected

to the correct terminal. Provide adequate length of wires 1 2

to avoid any strain on the terminal use cable tie.

3 4

Output contact remains closed as long as the pressure 5 6

is below cut-out value. It opens, when pressure reaches

the cutout value.

For single phase induction motor use only two poles for

phase and neutral.

N L

Recommended electrical components:

L N

Cable: 4 core, 2.5 sq.mm copper wire

Load or MS

Power supply Load or MS

Power Supply

Cable shoes: “U” type copper cable shoes with sleeves

TPST

Tightening torque of terminal and grounding screw is

2 Nm recommended. 1 2

3 4

5 6

7 WIKA operating instructions pressure switch mechanical, model PSM-630.

6. Mounting dimensions

Standard Version

ON/OFF Knob

Electrical Connections

Process Connection

Weight: approx. 500 g [18 oz]

Version with relief valve (option)

Relief Valve

Weight: approx. 550 g [20 oz]

Direct Mounting

WIKA Instruments India Pvt. Ltd.

OI-PSM-630 06/2022 - D02

Plot no B-20 and B-21, Industrial area

Site-3, Meerut Road

Ghaziabad 201003, Uttar Pradesh

Tel. +91 0120-2712134

sales@wika.co.in

www.wika.co.in

8 WIKA operating instructions pressure switch mechanical, model PSM-630

You might also like

- Error List HiabDocument2 pagesError List Hiabtsdcn100% (3)

- ABB Distribution: SF - Circuit Breaker ManualDocument28 pagesABB Distribution: SF - Circuit Breaker Manualdeepak2628100% (1)

- AWB2528-1508-User Manual EASY500-700 PDFDocument304 pagesAWB2528-1508-User Manual EASY500-700 PDFverde24No ratings yet

- Air Compressor Manual: MSL Compressor Co., LTDDocument23 pagesAir Compressor Manual: MSL Compressor Co., LTDNikolay KirovNo ratings yet

- Switzer Pres SwitchDocument5 pagesSwitzer Pres Switchanshuman singhNo ratings yet

- S W T Series Full-Automatic Computer Wire Stripping Machine Operation ManualDocument27 pagesS W T Series Full-Automatic Computer Wire Stripping Machine Operation ManualJuan G. JáureguiNo ratings yet

- Satchwell: Universal Pressure SwitchDocument4 pagesSatchwell: Universal Pressure SwitchNATHANNo ratings yet

- Maxatec MT-150 User ManualDocument15 pagesMaxatec MT-150 User Manualambr0No ratings yet

- SIG Motorized ValveDocument6 pagesSIG Motorized ValveAlexandre FerreiraNo ratings yet

- Tc-2060 Instruction Manual v0.09Document93 pagesTc-2060 Instruction Manual v0.09Herry SusiloNo ratings yet

- Delma Polaris 4Document24 pagesDelma Polaris 4nethelNo ratings yet

- Paper Cutting MachineDocument23 pagesPaper Cutting MachineManish Shetty100% (2)

- Antrieb Actuators O & M CatalogueDocument12 pagesAntrieb Actuators O & M Catalogueysr3ee6926100% (3)

- Tornatech JockeypumpDocument2 pagesTornatech Jockeypumpsafetyjulz14No ratings yet

- Dosing Pump Operational ManualDocument12 pagesDosing Pump Operational Manualalex_alexutzuuNo ratings yet

- Ounting Manual Ressure & Temperature Switches: France BelgiumDocument4 pagesOunting Manual Ressure & Temperature Switches: France BelgiumMohsen GdNo ratings yet

- BJ-03MAX ManualDocument23 pagesBJ-03MAX ManualezequielNo ratings yet

- Bulletin 836T Pressure ControlsDocument4 pagesBulletin 836T Pressure ControlsWendy CassidyNo ratings yet

- TZT 701 Installer ManualDocument16 pagesTZT 701 Installer ManualMatthew HobbsNo ratings yet

- Hat530n en ManualDocument19 pagesHat530n en Manualdario sanchezNo ratings yet

- Top Gun CUT-40MDocument9 pagesTop Gun CUT-40MTom PleysierNo ratings yet

- ZK3201 Control Panel User's ManualDocument49 pagesZK3201 Control Panel User's Manualmenale libayeNo ratings yet

- Operating Instructions Compact Piston and Diaphragm Pressure Switches Series 8000Document4 pagesOperating Instructions Compact Piston and Diaphragm Pressure Switches Series 8000Ronaldo CordeiroNo ratings yet

- IP68 Actuator With CC Spares CatalogueDocument8 pagesIP68 Actuator With CC Spares CatalogueParameswararao BillaNo ratings yet

- Kent USA Kls1840n - 2660N ElectricalDocument39 pagesKent USA Kls1840n - 2660N Electricalchidambaram kasi100% (1)

- P 6410 Ip Iom-1Document5 pagesP 6410 Ip Iom-1victorvelasquezchalcoNo ratings yet

- Indfos Differential Pressure Switches Ipsd 50Document4 pagesIndfos Differential Pressure Switches Ipsd 50Tarun BiswalNo ratings yet

- Manual Serie PL3000Document13 pagesManual Serie PL3000Anonymous j3b9ApBpNo ratings yet

- Diff. Pressure SwitchDocument3 pagesDiff. Pressure SwitchDurga PrasadNo ratings yet

- Pressure Switch in Abron Feederds-307 - GBDocument8 pagesPressure Switch in Abron Feederds-307 - GBamerNo ratings yet

- Service: ManualDocument30 pagesService: ManualFlorian LeordeanuNo ratings yet

- Pressure Transmitter 699 BA Full enDocument16 pagesPressure Transmitter 699 BA Full enJose Lorenzo ToralNo ratings yet

- Pneumatic and Electropneumatic Actuators Type 3372: Mounting and Operating Instructions EB 8313 ENDocument18 pagesPneumatic and Electropneumatic Actuators Type 3372: Mounting and Operating Instructions EB 8313 ENMagno DelmiroNo ratings yet

- Supplemental Guide: Pressure Switch ProductsDocument12 pagesSupplemental Guide: Pressure Switch Productsing_vic1No ratings yet

- Installation and Maintenance Manual Softstarters PS S 18/30 300/515Document16 pagesInstallation and Maintenance Manual Softstarters PS S 18/30 300/515Rier AteNo ratings yet

- Electrovane FiltreDocument39 pagesElectrovane FiltrepvflorinNo ratings yet

- Speed Switches: InstructionsDocument3 pagesSpeed Switches: InstructionsmuthakkerNo ratings yet

- Duct Mount Pressure Transmitter InstallationDocument4 pagesDuct Mount Pressure Transmitter InstallationShadab khanNo ratings yet

- Uai B 0214Document4 pagesUai B 0214Jose Puc ManzanillaNo ratings yet

- CamScanner 25-09-2023 14.15 (1)Document5 pagesCamScanner 25-09-2023 14.15 (1)thconstructoraambienteprimarioNo ratings yet

- PsuDocument8 pagesPsuInsan AzizNo ratings yet

- Tab 2 - Instruments OEMDocument111 pagesTab 2 - Instruments OEMJocelyn Ambar Gallardo ArismendiNo ratings yet

- RM-DPC Micro: SensorlineDocument15 pagesRM-DPC Micro: SensorlineLuis angel RamirezNo ratings yet

- HAT530N enDocument20 pagesHAT530N enRath AsypadenNo ratings yet

- BNC HT LT Mp-446 8055ia - I PlusDocument154 pagesBNC HT LT Mp-446 8055ia - I PlusseregeNo ratings yet

- Imp 100Document4 pagesImp 100ipla_mecanico359No ratings yet

- Ip - M-Pact - ENGDocument135 pagesIp - M-Pact - ENGdejanoski_aNo ratings yet

- Model: P945 Series: Weatherproof Type Pressure SwitchDocument6 pagesModel: P945 Series: Weatherproof Type Pressure SwitchHoang Mai HoaNo ratings yet

- Edda 1500 Kanepe PaketlemeDocument25 pagesEdda 1500 Kanepe PaketlemeEMRE KAAN USTA100% (1)

- Dkg-205 Automatic Mains Failure UnitDocument20 pagesDkg-205 Automatic Mains Failure UnitRafatNo ratings yet

- Hydrostatic Pump - 15HPDocument14 pagesHydrostatic Pump - 15HPMicheal Booka WhelanNo ratings yet

- CBT 6P ManualDocument27 pagesCBT 6P ManualMichael Parohinog GregasNo ratings yet

- 16B Temperature Process ControlDocument32 pages16B Temperature Process ControlbyrsNo ratings yet

- Operating Instructions: Compact AC/DC YokeDocument7 pagesOperating Instructions: Compact AC/DC YokeDiego Fernando Navia FerreyraNo ratings yet

- Data Sheet T 8384-3 EN: Type 3730-3 Electropneumatic Positioner With HART CommunicationDocument12 pagesData Sheet T 8384-3 EN: Type 3730-3 Electropneumatic Positioner With HART CommunicationThiago Rodrigo Oliveira SantosNo ratings yet

- semi-auto-strapping-machine-manual-s666Document25 pagessemi-auto-strapping-machine-manual-s666Ousséma DridiNo ratings yet

- SENTRON Switching and Protection Devices - Switch DisconnectorsDocument12 pagesSENTRON Switching and Protection Devices - Switch DisconnectorsJeyakumarNo ratings yet

- Netmostat N-1 Programmable Room Thermostat User ManualDocument15 pagesNetmostat N-1 Programmable Room Thermostat User Manualmilos.belgiumNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- md22_en_potentiometer_21.01.05.pdfDocument4 pagesmd22_en_potentiometer_21.01.05.pdfCosty45No ratings yet

- Schematic_WemosD1mini_DMX_Shield_2025-01-06Document1 pageSchematic_WemosD1mini_DMX_Shield_2025-01-06Costy45No ratings yet

- ms8221cDocument20 pagesms8221cCosty45No ratings yet

- Manual n1500 v23x K EnglishDocument8 pagesManual n1500 v23x K EnglishCosty45No ratings yet

- Quick Start Guide to Profibus DP S300 S400 S600 S700 revBDocument5 pagesQuick Start Guide to Profibus DP S300 S400 S600 S700 revBCosty45No ratings yet

- Constant Current Sources With BJTDocument5 pagesConstant Current Sources With BJTCosty45No ratings yet

- Air Condition Size Calculator (1.1.19)Document5 pagesAir Condition Size Calculator (1.1.19)Costy45No ratings yet

- How To Normalize MP3 Files To Play at The Same VolumeDocument8 pagesHow To Normalize MP3 Files To Play at The Same VolumeCosty45No ratings yet

- 500-05088-04 FlexFast - User - ManualDocument101 pages500-05088-04 FlexFast - User - Manualjuan carlosNo ratings yet

- 8DN8 GIS - CatalogueDocument19 pages8DN8 GIS - CatalogueWayne ChenNo ratings yet

- IEEE ReclosingDocument55 pagesIEEE ReclosinglearningalotNo ratings yet

- Introduction of Ring Main UnitDocument8 pagesIntroduction of Ring Main Unitfaradino100% (1)

- Peugeot 206 Owners Manual 2007Document109 pagesPeugeot 206 Owners Manual 2007Henk Veen0% (1)

- Acti9 C60NA-DC - C120NA-DC - SW60-DC - A9N61690Document3 pagesActi9 C60NA-DC - C120NA-DC - SW60-DC - A9N61690YexiongWaherNo ratings yet

- Gis 3Document16 pagesGis 3zeyadNo ratings yet

- FiretrolSeminar SADocument114 pagesFiretrolSeminar SAkr1tikalmas100% (3)

- A Report On Summer Training in North Eastern Railway, GorakhpurDocument41 pagesA Report On Summer Training in North Eastern Railway, GorakhpurVirendra Singh100% (1)

- Installation ManualDocument9 pagesInstallation ManualDenis RaudseppNo ratings yet

- Ener Con Plus ManualDocument20 pagesEner Con Plus ManualSuperhypoNo ratings yet

- Cerabar S: Service ManualDocument80 pagesCerabar S: Service ManualRotceh SeyerNo ratings yet

- Iom 07 2015 30RBM 30RBP 160 520 LRDocument52 pagesIom 07 2015 30RBM 30RBP 160 520 LRAhmadNo ratings yet

- Legrand Vela 2012-2013Document9 pagesLegrand Vela 2012-2013Dasvivide ElemirNo ratings yet

- Cruise Control PDFDocument28 pagesCruise Control PDFManuel FernandezNo ratings yet

- What Is A Motor Control CentreDocument63 pagesWhat Is A Motor Control Centreajaysitaula8478No ratings yet

- C248 Service Manual 1Document264 pagesC248 Service Manual 1Juan Manuel Lopes LopesNo ratings yet

- TD 30000r PDFDocument4 pagesTD 30000r PDFDavid Ponce GuerraNo ratings yet

- Model Railway Signal ProjectDocument1 pageModel Railway Signal Projectvinaykumarverma21No ratings yet

- EPL Lab ManualDocument74 pagesEPL Lab ManualPrince Vineeth67% (3)

- YALE (A938) ERC100VHS LIFT TRUCK Service Repair Manual PDFDocument20 pagesYALE (A938) ERC100VHS LIFT TRUCK Service Repair Manual PDFjkdmsmemmd0% (1)

- Condor Scissors Lift v2033xl SN 97070 Parts BookDocument10 pagesCondor Scissors Lift v2033xl SN 97070 Parts Bookthomas100% (50)

- ZTX Catalog 1SCC303016C0201 19-06Document32 pagesZTX Catalog 1SCC303016C0201 19-06cgramscischrammNo ratings yet

- CAB CHANGING InsrtuctionsDocument5 pagesCAB CHANGING InsrtuctionsKhajahussain SyedNo ratings yet

- TP 6113Document124 pagesTP 6113mdmglobal100% (2)

- C15 & C20 Series Inline Flow Switch: FeaturesDocument2 pagesC15 & C20 Series Inline Flow Switch: FeaturesJavier AffifNo ratings yet

- Rolling Shutters BrochureDocument21 pagesRolling Shutters Brochureabhishekseth100% (1)