APW Technical Drafting 8 W2 3

Uploaded by

Kyle CruzAPW Technical Drafting 8 W2 3

Uploaded by

Kyle CruzRepublic of the Philippines

Department of Education

Region III – Central Luzon

Schools Division of City of Malolos Maintain Hand Tools, Drawing

Marcelo H. Del Pilar National High School

Bagong Bayan, City of Malolos, Bulacan Instruments, Equipment and

Paraphernalia

Junior High School

I. Introduction

It is the responsibility of everyone to maintain the good

8

operating condition of all the hand tools, equipment, and

paraphernalia in the workplace. Since these tools help in the

completion of the different job requirements, keeping them

well preserved will make work easier and more efficient.

II. Learning Competency/ Unit of Competency

Activity

Performance Lesson 2: Maintain Hand Tools, Drawing Instruments,

Equipment and Paraphernalia

Worksheet

III. Nominal Duration

TECHNICAL DRAFTING 8 4 Days

Maintain Hand Tools, Drawing

Instruments, Equipment and

Paraphernalia

IV. Objectives/ Learning Outcomes best friends of the architects. In this lesson, we will discuss

safety procedures in maintaining technical drafting tools.

Without the drafting tools, materials, and equipment, it will

1. Follow the standard procedures in accomplishing forms. take you a long time or it is very impossible to finish a work.

2. Check the list of hand tools, drawing instruments,

The following are the basic safety procedures in maintaining

equipment, and paraphernalia to be requested per job

requirements. tools and materials used in drafting.

3. Evaluate the condition of all the requested hand tools, Safety Procedures in Maintaining Hand Tools

drawing instruments, equipment and paraphernalia for

proper operation and safety. It is essential to take proper care of the drafting tools,

4. Follow procedures in preparing an inspection report to materials, and equipment. Below are some tips to properly use

the property custodian. and take care of them.

1. Before starting any drawing, be sure to keep the hands

V. Content/ Lesson clean and free from dirt.

2. Maintain the cleanliness of the working area, especially

Maintain Hand Tools, Drawing Instruments, Equipment the drawing table.

and Paraphernalia

3. Avoid dropping your tools and equipment.

Materials: 4. Wipe off the surface and edges of triangles and T-squares

before and after using them.

Learning Module

Video Presentation 5. Sharpen and store your pencils properly after use.

URL reference

6. Find or create an organizer where you can hang your

measuring tools.

VI. Procedure (Knowledge) 7. Have a separate container for making tools.

8. Keep your drawing sheets in a plastic tube to protect

them from dust and dirt.

Drafting is the act and discipline of composing drawings

that visually communicate how something functions or is 9. Never lend or borrow drafting tools and materials if

constructed. Similar with drawing, sketch, it has several things possible.

to be used. Drafting tools, materials, and equipment are the

10. Pencils should be sharpened whenever they show sign injuries and illnesses. Gloves, masks and goggles are usually

of dullness. worn when cleaning tools since most cleaning agents and

solutions are harmful to the human body

11. Never use the edge of T-square and triangles to cut

paper along its working edges. A slight nick at the edge will

ruin the T-square.

Listed below are examples of PPE:

12. After using the tools, instruments, and equipment,

clean them first before keeping in a safe place.

Storage and Care

Tools can be kept in anything that keeps them organized

and safe during transport.

Drawings are best stored in flat files, lateral files, round

tubes, or portfolios.

Keep your tools clean 10 - dirt will rub off them onto the Cleaning tools- are materials used to clean efficiently. It is a

drawing media. vital to clean especially when your form of employment

involves cleaning.

Procedures in cleaning, tightening and simple repair of

hand tools, drawing instruments, equipment and

paraphernalia

In doing simple repair of tools, make sure that you are

knowledgeable in doing so. Repairing tools without sufficient

skills may result to further damage or inflict injuries to the

fixer. Small repairs like tightening, sharpening, and changing

of handles may not require special skills to do. If a tool or

equipment is beyond repair, it must be disposed properly. Gripping tools- used to hold objects firmly, possibly developed

from tongs. A plier’s rivet must be well tightened to be

Before cleaning any tool, be sure to wear the proper

personal protective equipment. Personal protective equipment, able to grip properly.

commonly referred to as "PPE", is an equipment worn to

The commonly used gripping tools:

minimize exposure to hazards that cause serious workplace

Driving tool- is used to loosen and tighten screws. Its

handles must also be tightened to reduce hand

strain when turning. A loosely connected handle

will make it almost impossible to use it.

Striking tools- is used in conjunction with another tool to

effect entry. It is a very basic hand tools connecting of a

weighted head attached to hand.

Some examples of the striking tools are as follows:

Procedures in Cleaning, Tightening and Simple, Repair for

Hand tools, Equipment and Paraphernalia

Cleaning Procedures:

1. Before cleaning any tool, be sure to wear the proper

Personal Protective Equipment (PPE) ex. gloves, mask, and

goggles are usually worn when cleaning tools since most

cleaning agent and solutions are harmful to the human

body.

Lubricants- is a substance, usually introduced to reduce 2. Only use cleaning agents as prescribed by the tool or

friction between surfaces. Also be applied after equipment’s manufacturer.

tightening to reduce the friction.

3. Cleaning the tool after use is highly recommended.

4. After using a tool, clean it thoroughly with a damp cloth.

Wipe it dry with another piece of cloth before keeping it.

5. When not in use, the T-square is preferably hung by

inserting the hole to a nail (attached to a wall) at the end of

its blade.

Tightening Procedures: Malfunctions and other unplanned and unusual event may

not be eliminated, but they can surely be minimized.

1. Lubricants must be applied after tightening to avoid

rusting. Listed below are some of malfunctions and unplanned events

2. Only use the prescribed tool when tightening and loosing. when using the different tools in completing job requirements.

3. After cleaning, use an all-purpose oil to lubricate tools with 1. When the screwdriver is not properly aligned with the

adjustable part. drive of the screw’s head.

Simple Repair Procedures: This happens when using a driving tool, screws may slip

1. Work area must always be kept neat and tidy. the tip of the screwdriver. This can be minimized by

making sure that the tip of the screwdriver is well secured

2. Put oil on the movable parts of the measuring tools such as in the drive of the screw’s head. Using a screwdriver with a

zigzag ruler, calipers, dividers, and compasses to avoid magnetized tip can also help minimize this type of

stock-up. malfunction.

3. Avoid unnecessary sliding of T-square or triangles to 2. The jaws of the pliers are blunt, thus making it hard to

protect the drawing. Pick up the triangle by its tip and tilt hold on things.

the T-square blade upward slightly before moving.

This usually happens when small objects tend to fall down

4. If your tools already show signs of rust, spray the tools when being held by a gripping tool like pliers. This can be

with oil and then scrub them with steel wool or a stiff wire prevented by making sure that gripping tools have well

brush. maintained jaws that can grasp objects properly.

5. Afterwards, wash them with warm, soapy water and scrub 3. The heads of striking tools separating away from the

them again with a cloth or rag until all signs of rust are handle.

gone.

The use of striking tools also imposes a great threat if

6. All tools and equipment must be placed in a clean and dry there will be a malfunction. Common hazards can cause

place. severe injuries to anyone. To avoid this type of accident,

Common Malfunction in Hand tools, Equipment and the handle of a striking tool must be tightly attached to its

Paraphernalia head.

4. A cutting tool is not sharp enough.

Mishaps in using cutting tools are also dangerous. They Never use pliers on a screwdriver for extra leverage. Only

may arise from slippage of the material to be cut. These use wrench or screwdrivers specifically designed for

unplanned events will cause laceration and wounds to the purpose.

user. To avoid this, cutting tools must always be kept

Do not use dull blades because they require more force,

sharp.

thus are more likely to slip. Replace the blade when it

Common Faults in Using Hand Tools starts to “tear” instead of cut.

Do not increase the handle length of pliers to gain more Never leave a knife unattended with the blade exposed.

leverage. Use a larger pair of pliers or bolt cutters if

Don’t bend or apply side loads to blades by using them to

necessary.

open cans or loosen tight cover of containers. Blades are

Do not substitute pliers for a wrench when turning bolts brittle and can snap easily.

and nuts. Pliers cannot grip these items properly and might

cause a slip and create an accident.

PROCEDURES IN RECEIVING AND STORING TOOLS AND

Never use pliers as a hammer on the handle. Such abuse is MATERIALS

likely to result in cracks or breaks.

Definition of Terms:

Cut hardened wires only with pliers designed for that

Receipt - an acknowledgement document (usually tangible)

purpose.

that payment has been made.

Always cut the wires in right angle. Never rock from side to

Items (tools/ Materials) - a distinct part that can be specified

side or bend wire back and forth against the cutting edges.

separately in a group of things that could be

Never use screwdrivers as a pry bar, chisel, and punch enumerated on a list.

stirrer or scraper.

Number (No.) - an arithmetical value expressed by a word,

Never use screwdrivers with broken or worn-out handles. symbol, or figure representing a particular quantity

Screwdriver of these kinds should have tags to indicate that used in counting.

it is defective.

Quantity -the number of tools or materials.

Serviceable - being capable of service or useful.

Not Serviceable - not good enough to be used for a particular Procedures in Accomplishing the Forms

purpose.

1. Write your name as requester.

Remarks - a statement about you notice.

2. Indicate date of request.

Property Custodians - are the individuals responsible for the

3. Fill in the classification of the project and its purpose.

physical custody, care, and safekeeping over

property in their possession or under their 4. Write the number of required materials.

supervision.

5. State the condition of the materials.

Inspection- the act of looking at something closely in order to

6. Secure the approval of authorities concerned.

learn more about it, to find problems, etc. : the act

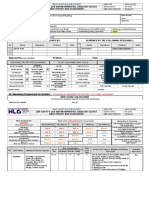

of inspecting something. A. Sample of Checklist Form:

Procedure- a step-by-step sequence of activities or course of Name: _______________________________ Date: _____________

action (with definite start and end points) that must Year and Section:____________________

be followed in the same order to correctly perform a Department: ________________________

task method. Purpose:_____________________________

Supply officer - oversees financial and management matters

relating to stock supplied or received in an

No. Tools / Materials Quantity

organization, business or company.

1. Drawing table 3

Report- an official document that gives information about 2. Pencil sharpener 5

3. Divider 2

particular subject.

Damage- problem that is caused by a mistake, wrong action.

Purchase Order (PO) – a commercial document and first official

offer issued by a buyer to a seller indicating types,

Checked by:_________Noted by:________Approved by:_______

quantities, and agreed prices for products or services.

It is used to control the purchasing of products and

services from external suppliers. Sample Evaluation Form:

Name: ______________________________ Date: 4. Take note of the receipt of the Property/ Supply Unit,

___________________ the place and the date of delivery.

Year/ Section: ______________________ 5. If there’s a required sample mentioned in perfected

Department:________________________ PO/Contract, ask for the approved sample for purposes of

Purpose:____________________________ comparison/verification.

6. After all the documents have been evaluated, proceed to

No. Tools/ Materials Quantity Remarks (Please check) the delivery site specified in the perfected PO/ Contract

and conduct inspection and testing procedure if necessary.

No. of No. of Not

Serviceable serviceable 7. Conduct physical inspection of the items delivered.

Count the items delivered and check with the required

1. Drawing table 4 3 1 quantity.

2. Pencil sharpener 8 8 0

3. Divider 5 2 3 8. Determine whether it is brand new, reconditioned or

rebuilt.

9. Take note for the obvious damage or defect in the

Checked by: ________________ Noted by:____________________ equipment.

Procedures in preparing an inspection report to the 10. Prepare the inspection report immediately after inspection

property custodian for the submission to the supply officer.

1. Upon receipt of the Request for Inspection, see to it that all

required documents are attached like the original copies of

the perfected Purchased Order/ Contract, Delivery VII. Assessment

Receipts/ Sales Invoice, and other.

Activity 1 (Knowledge)

2. Check the documents submitted as to completeness and

authenticity prior to inspection.

3. Take note of any cases of alteration erasures or other

modification in the perfected Purchase Order / Contract.

Directions: Read the procedures inside the box and match each Activity 2 (Knowledge)

with the appropriate picture. Write your answer in your

activity sheet. Directions: Choose the letter of the correct answer. Write your answer in

your activity sheet.

1. Before cleaning any tool, be sure to wear the proper Personal

1. Why does a cutting tool malfunction?

Protective Equipment.

a. It is sharp.

2. All tools and equipment must be placed in a clean and dry place.

b. It is regularly checked.

3. Lubricants must also be applied after tightening to avoid rusting.

c. It is kept well.

4. Work area must always be kept neat and tidy.

d. It is not sharp.

5. Put oil on the movable parts of the measuring tools such as zigzag

ruler, calipers, dividers, and compasses to avoid stock-up. 2. How does a gripping tool function?

a. It can hold small objects.

b. It can strike small objects.

c. It can lubricate small objects.

1. ________________________________________________________ d. It can drive small objects.

3. Why do we use driving tools?

a. to magnetize small objects

b. to loosen screws

c. to tighten screws

2. _________________________________________________________

d. all of the above

4. Why does malfunction of tools pose great threat?

a. It can cause severe injury to the user.

3. _________________________________________________________ b. It helps work easier.

c. It is just okay.

d. It is still safe.

5. How can we avoid malfunction of tools for effective performance?

4. ________________________________________________________ a. by being irresponsible

b. by preventive maintenance

c. by not checking the tools regularly

d. by leaving the tools unattended

5. _________________________________________________________

Activity 3 (Understanding)

Directions: Write / if the statement is correct, X if it is wrong. 1. Maintain the __________ in the working area, especially the

Use the activity sheet for your answer. drawing table.

2. Avoid __________ your tools and equipment.

1. Before starting any drawing, be sure to keep the hands 3. _______ off the surface and edges of triangles and T-squares

clean and free from dirt. before and after using them.

2. Maintain the cleanliness of the working area especially 4. Sharpen and store your ________ properly after use.

the drawing table. 5. Find or create an organizer where you can hang your

3. Drop your tools and equipment after using. __________tools.

4. Wipe off the surface and edges of triangles and T- 6. Have a separate container for _________ tools.

squares before and after using them. 7. Keep your drawing sheets in a plastic tube to protect them from

5. Keep and store your pencils properly after use. a ________ and dirt.

6. Before cleaning any tool, be sure to wear the proper 8. Never lend or borrow ________ tools and materials if possible.

school uniform. 9. Pencils should be sharpened whenever they show sign of

7. Throwing of tools after use is highly recommended. _________

8. Wipe dry the tool with a piece of cloth before keeping it. 10. Never use the edge of T-square and triangles to ________paper

9. When not in use, the T-square should be hung properly. along its working edges.

10. Lubricants must also be applied after tightening to 11. Never use __________ as a pry bar, chisel and punch stirrer or

prevent rusting. scraper

12. The use of ___________ also imposes a great threat if there will

be a malfunction.

Activity 4 (Understanding) 13. Blades are _______ and can snap easily.

14. Always cut ________in right angle.

Directions: Supply each blank with a correct word. Choose your 15. When using __________, screw may slip the tip of the

answer from the given words in the box. Write your screwdriver.

answer in your activity sheet.

cut wipe making striking tools dust dullness Activity 5 (Performance)

screwdriver drafting drawing tools pencils

Dropping brittle cleanliness measuring wires Look for 5 pictures of people who do cleaning, tightening

and simple repair using the tools being discussed. Cut and

paste then in your activity sheet.

You might also like

- Title: Soil Poisoning: Work Method StatementNo ratings yetTitle: Soil Poisoning: Work Method Statement10 pages

- Den-Jet Ce20-500 - Super Slim Manual - Jul 2015No ratings yetDen-Jet Ce20-500 - Super Slim Manual - Jul 201531 pages

- Technical Drafting - G7 - 8 - Week 2 Compress LASNo ratings yetTechnical Drafting - G7 - 8 - Week 2 Compress LAS13 pages

- Week 3-4 TLE - AS in MECHANICAL DRAFTINGNo ratings yetWeek 3-4 TLE - AS in MECHANICAL DRAFTING7 pages

- Lesson 2: Performing Basic Mensuration and CalculationNo ratings yetLesson 2: Performing Basic Mensuration and Calculation9 pages

- Lesson Exemplar in T.L.E Technical Drafting 8No ratings yetLesson Exemplar in T.L.E Technical Drafting 85 pages

- LO1 Prepare Drafting Materials and Tools Drawing InstrumentNo ratings yetLO1 Prepare Drafting Materials and Tools Drawing Instrument28 pages

- Curriculum/ Department/ System Description Objectives Strengths WeaknessesNo ratings yetCurriculum/ Department/ System Description Objectives Strengths Weaknesses13 pages

- DLP (Practice Occupational Health and Safety Procedures)No ratings yetDLP (Practice Occupational Health and Safety Procedures)7 pages

- Tle - Ict - CSS: Quarter 1 - Module 0: Personal Entrepreneurial Competencies (Pecs)No ratings yetTle - Ict - CSS: Quarter 1 - Module 0: Personal Entrepreneurial Competencies (Pecs)23 pages

- Lesson Plan in Technology Livelihood Education (DRAFTING)No ratings yetLesson Plan in Technology Livelihood Education (DRAFTING)8 pages

- CO Q1 TLE EPAS 7 8 Module 4 Preparing Technical DrawingsNo ratings yetCO Q1 TLE EPAS 7 8 Module 4 Preparing Technical Drawings47 pages

- Lesson 3: Mensuration and Calulation: Measuring Tools and Trade MathematicsNo ratings yetLesson 3: Mensuration and Calulation: Measuring Tools and Trade Mathematics12 pages

- Hinigaran National High School: Summative Test Modules 7,8 and 9No ratings yetHinigaran National High School: Summative Test Modules 7,8 and 92 pages

- 4 CO Q0 ICT8 Mod4 Performing Mensuration and Calculation-FinalNo ratings yet4 CO Q0 ICT8 Mod4 Performing Mensuration and Calculation-Final33 pages

- K To 12 TLE Industrial Arts - Consumer Electronics Servicing Curriculum Guide December 2013No ratings yetK To 12 TLE Industrial Arts - Consumer Electronics Servicing Curriculum Guide December 201317 pages

- ANSI Z358.1 - 2004 - Eyewash & Shower EquipmentNo ratings yetANSI Z358.1 - 2004 - Eyewash & Shower Equipment28 pages

- Change Roller Track and Change Bolt of Shoe Track CraneNo ratings yetChange Roller Track and Change Bolt of Shoe Track Crane2 pages

- Location Written By: Approved By: Date Created Last RevisionNo ratings yetLocation Written By: Approved By: Date Created Last Revision2 pages

- F07 - Course Design and Module of Instruction (Organic Agriculture)No ratings yetF07 - Course Design and Module of Instruction (Organic Agriculture)82 pages

- Material Safety Data Sheet: Ingredient Name Cas No. % WT Exposure LimitsNo ratings yetMaterial Safety Data Sheet: Ingredient Name Cas No. % WT Exposure Limits8 pages

- (Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateNo ratings yet(Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position Date5 pages

- Acido Grabador en Gel - Msds - Jade Etchant Gels1No ratings yetAcido Grabador en Gel - Msds - Jade Etchant Gels15 pages

- Treker: 4200 NT/ST, 4400 NT/ST, 4210/4410 ST Light Utility VehiclesNo ratings yetTreker: 4200 NT/ST, 4400 NT/ST, 4210/4410 ST Light Utility Vehicles62 pages