G7 LEAP - Week 4 SMAW

G7 LEAP - Week 4 SMAW

Uploaded by

SHERELYN RODRIGUEZCopyright:

Available Formats

G7 LEAP - Week 4 SMAW

G7 LEAP - Week 4 SMAW

Uploaded by

SHERELYN RODRIGUEZOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

G7 LEAP - Week 4 SMAW

G7 LEAP - Week 4 SMAW

Uploaded by

SHERELYN RODRIGUEZCopyright:

Available Formats

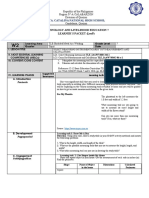

Republic of the Philippines

Region IV-A CALABARZON

Division of Quezon

STA. CATALINA NATIONAL HIGH SCHOOL

Candelaria, Quezon

TECHNOLOGY AND LIVELIHOOD EDUCATION 7

LEARNER’S PACKET (LeaP)

Learning Area TLE-Shielded Metal Arc Welding Grade Level 7

W4 Quarter Third Date

I. LESSON TITLE Check condition of Tools and Equipment

II. MOST ESSENTIAL LEARNING

Check condition of tools and Equipment TLE_IAAW7/8MT-0h-1

COMPETENCIES (MELCs)

III. CONTENT/CORE CONTENT

1.1 Functional and non-functional tools are labeled.

References: K-12 Basic Education Curriculum TLE Learning Module in

Shielded Metal Arc Work (SMAW) Grade 7 and 8, 2016

Suggested

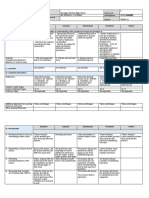

IV. LEARNING PHASES Learning Activities

Timeframe

A. Introduction Presentation

Panimula

Tools and equipment should be regularly maintained to ensure its longevity. Regular care

and maintenance will guarantee that the equipment will function properly every time.

Welding tools are expensive, and its replacement parts can be hard to find. It is important to

stick to yourregular schedule on maintenance to ensure its optimum performance at all times.

Methods of Identifying Functional and Non-Functional Tools and Equipment 1. 1.

1. Visual Inspection

It refers to the visual observation of an expert on the appearance of the tools and

equipment. The physical appearance of tools will describe such characteristics as

dullness, sharpness, dismantled parts, and uneven teeth of the cutting tools.

2.Functionality

Vibration or extra noise from the operation means problem on parts and accessories

started to develop. Is it already susceptible to wear and tear? Has it already exceeded its

service life? Has it passed the manufacturer’s quality control test? A few pieces of the

hand tools issued in the shop can be subjected for condemnation they are no longer

serviceable. Some hand tools issued for years in shops and few pieces of these can be

subjected for condemnation.

3. Performance

It is determined not only during the actual use but also after use to find out whether the

hand tools are still worth using. When there is something wrong with the performance of

either hand tools or equipment, they need an immediate repair or maintenance.

4. Service span

Hand tools are issued to shop teacher at one time. However, this must be recorded to

determine when it was received and how long the tools have been kept in the shop. A

hand tool which is too old is unsafe for both the students and workers. Such tool should

be marked defective and segregated from the good ones.

5. Power Supply (for electrically operated only)

Failure to meet the required power supply, malfunction will occur in the part of hand

tools or equipment.

6. Person involved

It refers to the technical person who has the knowledge and skills about the technology .

Procedures in Segregating and Labeling Functional and Non-Functional

Tools and Equipment

1. Conduct an inventory of tools and equipment.

2. Record the number of non-functional tools and equipment.

3. Segregate tools that are serviceable or unserviceable.

4. Report the number of tools and equipment that are non-functional but subject for

repair.

5. Label tools and equipment which are condemnable.

6. Return tools and equipment in the tool cabinet as per operating procedures

B. Development Learning task 1: LET’S INSPECT

Pagpapaunlad Direction: Write the word Functional if the tool is considered functional and write Non-

Functional if it is not. Place your answer beside the picture.

Source: K TO 12 SMAW WELDING LEARNING MODULE

C. Engagement Learning task 2: With the help oy your parents/guardian/household members, make an

Pakikipagpalihan inventory of functional and non-functional tools in your house. Write the reason for its

functionality/non-functionality.

Tools/Equipment Functional Non-functional Reason

(Check if yes) (Check if yes)

D. Assimilation Learning task 3: Venn Diagram

Direction: From Learning Task 1 of Engagement, create a Ven diagram. The left side are

functional and write side are the non-functional characteristics based on the overlapping

categories of both types.

V. ASSESSMENT Learning task 4

(Learning Activity Sheets for Direction: Choose the letter of the correct answer. Write your answer on the answer sheet.

Enrichment, Remediation or 1. Defective hand tools are kept and .

Assessment to be given on Weeks 3 A. marked as defective.

and 6) B. mixed with non-defective tools.

C. put anywhere in the shop.

D. sold in the junk shop.

2. One way of checking whether hand tools are defective or non-defective is the .

I. length of service

11. trademark of the manufacturer

111. physical appearance

A. 1 only C. 111 only

B. 11 only D. 1, 11, and 111

3. Which is determined after the operation of a hand tool is tested?

A. Service span

B. Performance

C. Physical appearance

D. Repair Maintenance

4. All defective hand tools with major defects are subjected to .

1. Repair

11. Condemnation

111. Display/sample

A. 1 only C. 111 only

B. 11 only D. 1, 11, and 111

5. Service span of a tool pertains to .

A. maintenance schedule

B. determining when the tool is acquired

C. functionality of a tool

D. defectiveness of a tool bolts

VI. REFLECTION Write your personal insights about the lesson using the prompts below.

I understand that .

I realize that .

I need to learn more about .

Prepared by : Checked by:

Sherelyn Y. Rodriguez - TI Rosemarie L. Manalo

Jennifer M. Martinez - TII Master Teacher I

Lydia C. Landicho - TIII

Email Address: stacatalinanationalhighschool@gmail.com

Telephone No. 042-585-345

You might also like

- Lesson-Plan-Tle-7-Nail Care ServicesDocument7 pagesLesson-Plan-Tle-7-Nail Care Servicesma kathrine cecille macapagalNo ratings yet

- TLIB2807B - Maintain and Use Hand Tools - Learner GuideDocument41 pagesTLIB2807B - Maintain and Use Hand Tools - Learner Guideromerofred67% (3)

- The Goodness Gorillas PresentationDocument7 pagesThe Goodness Gorillas Presentationapi-543934498No ratings yet

- SMAW7 Q1 Mod6 CheckFunct V3Document17 pagesSMAW7 Q1 Mod6 CheckFunct V3Kurt Valentine LopezNo ratings yet

- TLE Bread PastryProduction7 8 Week4Document4 pagesTLE Bread PastryProduction7 8 Week4Karen Joy Bobos CalNo ratings yet

- Tle 8 Eim q3 w4 StudentDocument10 pagesTle 8 Eim q3 w4 StudentCastillo, Warner John F.No ratings yet

- DLP-eim October 10, 2023Document4 pagesDLP-eim October 10, 2023Heyden Cyra De MesaNo ratings yet

- TLE Carpentry7-8 Weeks2-3Document5 pagesTLE Carpentry7-8 Weeks2-3Ric Jhon LoraNo ratings yet

- 4-As Sept OCT 22Document2 pages4-As Sept OCT 22Jefrey TalayNo ratings yet

- Learners Engagement Plan LEPDocument3 pagesLearners Engagement Plan LEPfrederic asejo100% (2)

- DLLHandtoolsDocument5 pagesDLLHandtoolsLuffy D. BrownsNo ratings yet

- TLE - IAEIM7 8 - q0 CLAS6 - Checking Condition of Tools and Equipment RHEA ROMERODocument14 pagesTLE - IAEIM7 8 - q0 CLAS6 - Checking Condition of Tools and Equipment RHEA ROMERORachelle CortesNo ratings yet

- Detailed Lesson Plan in TLEDocument7 pagesDetailed Lesson Plan in TLEma kathrine cecille macapagalNo ratings yet

- Lesson Plan Basic Tools and Equipment - LunaDocument5 pagesLesson Plan Basic Tools and Equipment - LunaRegine Lozano Luna100% (1)

- Eim 8 Lesson 4Document6 pagesEim 8 Lesson 4accel sillaNo ratings yet

- CG AutomotiveDocument11 pagesCG AutomotiveJame Paul GalgaoNo ratings yet

- Las Carpentry 4Document5 pagesLas Carpentry 4rachelNo ratings yet

- Y2 - Module 1 - Using Basic Hand ToolsDocument54 pagesY2 - Module 1 - Using Basic Hand ToolsMARQUE JALIPOTNo ratings yet

- TLE10 - ACP-NC-II - G10 - Q1 - Mod2 - Determine Defective Tools and Equipment According To Operation Manuals - v3Document20 pagesTLE10 - ACP-NC-II - G10 - Q1 - Mod2 - Determine Defective Tools and Equipment According To Operation Manuals - v3jhune dolawenNo ratings yet

- Dumalneg National High School: Horticulture Darell James B. Cariaga 1 Grade 7 2020 - 2021Document4 pagesDumalneg National High School: Horticulture Darell James B. Cariaga 1 Grade 7 2020 - 2021My TeacherNo ratings yet

- CapSLET FFP G7 02 NEW W1 L2Document12 pagesCapSLET FFP G7 02 NEW W1 L2Cristy Falcasantos AranjuezNo ratings yet

- Lesson Exemplar AutomotiveDocument5 pagesLesson Exemplar Automotivealonicabritanico1217No ratings yet

- DLL Q4 Epas M2Document6 pagesDLL Q4 Epas M2Tiffany PinesNo ratings yet

- DLP IN TLE Carpentry Week 2Document4 pagesDLP IN TLE Carpentry Week 2Elnie PalmaNo ratings yet

- Industrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood EducationDocument7 pagesIndustrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood Educationjayson acunaNo ratings yet

- Sept. 25-29Document5 pagesSept. 25-29Carrengil DatuNo ratings yet

- BNC Week 1Document4 pagesBNC Week 1Judith FrondaNo ratings yet

- ICT Grade 8 OctoberDocument5 pagesICT Grade 8 OctoberCJ SarsalejoNo ratings yet

- Department of Education: Republic of The PhilippinesDocument11 pagesDepartment of Education: Republic of The PhilippinesRAMON VENEZUELANo ratings yet

- Barrion DemoDocument6 pagesBarrion DemoElaine Joy Marasigan BarrionNo ratings yet

- Edited Adm Smaw m4Document22 pagesEdited Adm Smaw m4Wilfred LlapitanNo ratings yet

- Module 2 Unit 4 Use Hand ToolsDocument9 pagesModule 2 Unit 4 Use Hand ToolsLee RiaNo ratings yet

- DLL - Tle Ict Css 10 - q1 - w3Document5 pagesDLL - Tle Ict Css 10 - q1 - w3LORENZO MANALANGNo ratings yet

- G7 LEAP - Week 5 SMAWDocument3 pagesG7 LEAP - Week 5 SMAWSHERELYN RODRIGUEZNo ratings yet

- Tle 10 Agriculture Quarter 3 Week 3-4 Lesson 2: Routine Check-Up of Tools and Equipment Week 3Document12 pagesTle 10 Agriculture Quarter 3 Week 3-4 Lesson 2: Routine Check-Up of Tools and Equipment Week 3Jay Aldin Rosete100% (3)

- Learning Activity Sheet Tle 8-Css - Quarter 3 Week 3Document7 pagesLearning Activity Sheet Tle 8-Css - Quarter 3 Week 3Axel Nicerio Rovelo0% (1)

- Eim Iatools CommonDocument37 pagesEim Iatools CommonZhiany CardelNo ratings yet

- QUARTER 3, Week 5, Session 3Document6 pagesQUARTER 3, Week 5, Session 3Princess Aimie LalongisipNo ratings yet

- TLE 7 Week 2Document2 pagesTLE 7 Week 2Lorie Grace Catalogo BaguioNo ratings yet

- CG HorticultureDocument7 pagesCG HorticultureEl G. Se ChengNo ratings yet

- CG Week3 DLPCOPYDAY3 PDFDocument3 pagesCG Week3 DLPCOPYDAY3 PDFRachel CanoNo ratings yet

- Technology and Livelihood Education: Agricultural Crops ProductionDocument16 pagesTechnology and Livelihood Education: Agricultural Crops ProductionFe DelgadoNo ratings yet

- Computer System Servicing: TLE-Information and Communication TechnologyDocument14 pagesComputer System Servicing: TLE-Information and Communication TechnologyGemma MatobatoNo ratings yet

- Hard DriveDocument112 pagesHard DriveChi Chay100% (1)

- DLL Fish SeafoodDocument4 pagesDLL Fish SeafoodJenessa ReyesNo ratings yet

- Salug National High School Salug, Zamboanga Del NorteDocument4 pagesSalug National High School Salug, Zamboanga Del NorteTuyac Regañon100% (1)

- PC Hardware Servicing Learning ModuleDocument113 pagesPC Hardware Servicing Learning ModuleCAREN CADAYNo ratings yet

- TLE Grade8 AS Module6 Quarter1 Week6Document11 pagesTLE Grade8 AS Module6 Quarter1 Week6Lorie Bracia100% (1)

- CM Grade 7 Tle First QuarterDocument5 pagesCM Grade 7 Tle First QuarterJoy May SalazarNo ratings yet

- DLL - Cooperative Learning ApproachDocument5 pagesDLL - Cooperative Learning ApproachAndrea Dapiton OrillanedaNo ratings yet

- Salug National High School Salug, Zamboanga Del NorteDocument3 pagesSalug National High School Salug, Zamboanga Del NorteTuyac RegañonNo ratings yet

- Tle 10 CurmapDocument5 pagesTle 10 CurmapMelody BannohocNo ratings yet

- Poultry 9Document3 pagesPoultry 9Jefrey TalayNo ratings yet

- Hand Tools in Computer Hardware ServicingDocument5 pagesHand Tools in Computer Hardware ServicingNeniel DumanjogNo ratings yet

- LubricatingDocument4 pagesLubricatingRJLifeOfPedzNo ratings yet

- DLL - Grade 9 TLE - Wk1 - Food ProcessingDocument8 pagesDLL - Grade 9 TLE - Wk1 - Food Processingrojasmaremar1998No ratings yet

- 3rd Quarter MODULE 1 SOFT COPY Using and Maintaining Hand Tools CSSDocument15 pages3rd Quarter MODULE 1 SOFT COPY Using and Maintaining Hand Tools CSSAllona LaronaNo ratings yet

- Pla RubricsDocument89 pagesPla Rubricsapi-313716520No ratings yet

- Css Module 1Document104 pagesCss Module 1Rowena AntolijaoNo ratings yet

- A. Preparatory ActivitiesDocument3 pagesA. Preparatory ActivitiesLawrenceAducaNo ratings yet

- Facility Maintenance Series: Types of Maintenance ProgramsFrom EverandFacility Maintenance Series: Types of Maintenance ProgramsRating: 5 out of 5 stars5/5 (1)

- G7 LEAP - Week 6 SMAWDocument2 pagesG7 LEAP - Week 6 SMAWSHERELYN RODRIGUEZNo ratings yet

- G7 LEAP - Week 5 SMAWDocument3 pagesG7 LEAP - Week 5 SMAWSHERELYN RODRIGUEZNo ratings yet

- G7 LEAP - Week 3 SMAWDocument2 pagesG7 LEAP - Week 3 SMAWSHERELYN RODRIGUEZNo ratings yet

- G7 LEAP - Week 2 SMAWDocument2 pagesG7 LEAP - Week 2 SMAWSHERELYN RODRIGUEZNo ratings yet

- ReportDocument4 pagesReportSHERELYN RODRIGUEZNo ratings yet

- G7 LEAP - Week 1 SMAWDocument2 pagesG7 LEAP - Week 1 SMAWSHERELYN RODRIGUEZNo ratings yet

- Activity Sheets in TLE CSSDocument1 pageActivity Sheets in TLE CSSSHERELYN RODRIGUEZNo ratings yet

- Getting Ready Factsheet For Igcse MathsDocument4 pagesGetting Ready Factsheet For Igcse MathsMs JohnsonNo ratings yet

- 6-Venus Math Quarter 4 TestDocument2 pages6-Venus Math Quarter 4 TestEldon KingNo ratings yet

- LO5 IPR Result - Sir ValenzuelaDocument17 pagesLO5 IPR Result - Sir ValenzuelaReuel Jay ValenzuelaNo ratings yet

- Planeacion de Ingles Dias de La SemanaDocument7 pagesPlaneacion de Ingles Dias de La SemanaCristhina Yamile Gomez OrtizNo ratings yet

- Cot 1 Health Second QuarterDocument3 pagesCot 1 Health Second QuarterSandra Rae VasquezNo ratings yet

- Legal Education in IndiaDocument3 pagesLegal Education in IndiaAyushNo ratings yet

- Resignation LetterDocument2 pagesResignation Letter311009No ratings yet

- Instructional Plan in Health 1 Quarter 2 Week 8Document3 pagesInstructional Plan in Health 1 Quarter 2 Week 8jane cuestas100% (3)

- Department of Education Division of Cavite Municipality of General Mariano AlvarezDocument8 pagesDepartment of Education Division of Cavite Municipality of General Mariano Alvarezahim mahalasNo ratings yet

- MLC-Resident-Welcome-Letter (Class 002-2022)Document9 pagesMLC-Resident-Welcome-Letter (Class 002-2022)jdjfjfjfjfjjfNo ratings yet

- Ed 208 Report - Principle of Constructive Alignment - PanesDocument3 pagesEd 208 Report - Principle of Constructive Alignment - Panesanna.mary.arueta.gintoro031202No ratings yet

- Program Brief - EXL Train and Hire DriveDocument2 pagesProgram Brief - EXL Train and Hire Driveshreyansh tiwariNo ratings yet

- Individual Learning Monitoring PlanDocument2 pagesIndividual Learning Monitoring PlanAilljim Remolleno ComilleNo ratings yet

- Department of Education: Region Iii - Central Luzon Schools Division of Tarlac ProvinceDocument32 pagesDepartment of Education: Region Iii - Central Luzon Schools Division of Tarlac ProvinceMark James Diosay100% (3)

- Warning: (Secondary Teacher Education Department)Document2 pagesWarning: (Secondary Teacher Education Department)malikusman124nNo ratings yet

- Sex Address Name of Guardian Contact Number Name of Learners (Surname, First Name MI)Document25 pagesSex Address Name of Guardian Contact Number Name of Learners (Surname, First Name MI)John Paul Canlas SolonNo ratings yet

- First Words - Lesson 71Document23 pagesFirst Words - Lesson 71Shamrock3DNo ratings yet

- Tieng Anh 3 This Is My House Day La Nha Cua Toi Lesson 6Document2 pagesTieng Anh 3 This Is My House Day La Nha Cua Toi Lesson 6Key passwordNo ratings yet

- Semi-Detailed LP VolcanoDocument2 pagesSemi-Detailed LP VolcanoCherish CalachanNo ratings yet

- Class-KG-week4-week 4 APSACS Online Support Program Week4Document23 pagesClass-KG-week4-week 4 APSACS Online Support Program Week4Zeeshan JafarNo ratings yet

- UPSC CSAT 2022 Answer Key EnglishDocument1 pageUPSC CSAT 2022 Answer Key EnglishSanjeeb kumar BeheraNo ratings yet

- Field Study 1 - RevisedDocument4 pagesField Study 1 - RevisedmarfcelisNo ratings yet

- CBSE Date Sheet 2025 Class 12 PDF (Soon) @cbse - Nic.in Download CBSE 12th Exam TimeDocument20 pagesCBSE Date Sheet 2025 Class 12 PDF (Soon) @cbse - Nic.in Download CBSE 12th Exam Timengurangruru10No ratings yet

- 2023-2024 MATH 6 COT 3rd QuarterDocument7 pages2023-2024 MATH 6 COT 3rd Quarterjaneth.arponNo ratings yet

- CONCEPT PAPER For Survey or Social ResearchDocument17 pagesCONCEPT PAPER For Survey or Social ResearchMakky Drake BryleNo ratings yet

- Senior Prefect Application TemplateDocument2 pagesSenior Prefect Application TemplateOfeghaNo ratings yet

- No. Name: 14. Nanda Septiana Ayu Course Project: Classroom Management PlanDocument4 pagesNo. Name: 14. Nanda Septiana Ayu Course Project: Classroom Management PlanRaka Al MunawarNo ratings yet

- BI Y6 LP TS25 (Unit 2 - Life in The Past - LP 17-32)Document17 pagesBI Y6 LP TS25 (Unit 2 - Life in The Past - LP 17-32)Fadzil MANo ratings yet

- CambridgeBooklistPreOLevel-OLevelIII2019-20 Army PDFDocument9 pagesCambridgeBooklistPreOLevel-OLevelIII2019-20 Army PDFMuhammad AnasNo ratings yet