0 ratings0% found this document useful (0 votes)

65 viewsRod - Union I Crmo 910

Rod - Union I Crmo 910

Uploaded by

Rushita SolankiUnion I CrMo 910 is a low-alloyed TIG rod that is creep resistant and suitable for welding creep resistant steels used in boilers, tanks, pipelines, and nuclear reactors. It can be used to weld steels like 1.7380 and 1.7379 and provides a weld metal with a yield strength of at least 470 MPa, tensile strength of 590 MPa, and 20% elongation. The rod is marked W CrMo2 Si / ER 90S-G and is used with argon gas and a DC polarity at a flow rate of 8-12 l/min.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Rod - Union I Crmo 910

Rod - Union I Crmo 910

Uploaded by

Rushita Solanki0 ratings0% found this document useful (0 votes)

65 views1 pageUnion I CrMo 910 is a low-alloyed TIG rod that is creep resistant and suitable for welding creep resistant steels used in boilers, tanks, pipelines, and nuclear reactors. It can be used to weld steels like 1.7380 and 1.7379 and provides a weld metal with a yield strength of at least 470 MPa, tensile strength of 590 MPa, and 20% elongation. The rod is marked W CrMo2 Si / ER 90S-G and is used with argon gas and a DC polarity at a flow rate of 8-12 l/min.

Original Description:

Union 910

Original Title

Rod.union i Crmo 910

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Union I CrMo 910 is a low-alloyed TIG rod that is creep resistant and suitable for welding creep resistant steels used in boilers, tanks, pipelines, and nuclear reactors. It can be used to weld steels like 1.7380 and 1.7379 and provides a weld metal with a yield strength of at least 470 MPa, tensile strength of 590 MPa, and 20% elongation. The rod is marked W CrMo2 Si / ER 90S-G and is used with argon gas and a DC polarity at a flow rate of 8-12 l/min.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

65 views1 pageRod - Union I Crmo 910

Rod - Union I Crmo 910

Uploaded by

Rushita SolankiUnion I CrMo 910 is a low-alloyed TIG rod that is creep resistant and suitable for welding creep resistant steels used in boilers, tanks, pipelines, and nuclear reactors. It can be used to weld steels like 1.7380 and 1.7379 and provides a weld metal with a yield strength of at least 470 MPa, tensile strength of 590 MPa, and 20% elongation. The rod is marked W CrMo2 Si / ER 90S-G and is used with argon gas and a DC polarity at a flow rate of 8-12 l/min.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

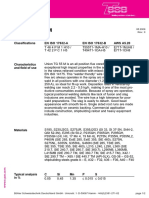

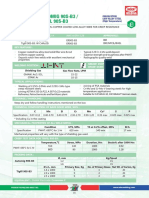

Welding consumables for creep resistant steels

Union I CrMo 910

TIG Rod, low-alloyed, creep resistant

Classifications

EN ISO 636-A EN ISO 21952-A EN ISO 21952-A AWS A5.28 / SFA-5.28

W 46 3 2Mo W CrMo2Si W MoSi ER80S-G

Characteristics and typical fields of application

Low-alloyed welding rod / wire for the welding with argon. Suitable for manufacturing creep resistant steels in boiler, tank, pipeline and

GTAW

nuclear reactor construction.

Base materials

1.7380 – 10CrMo9-10 – ASTM A335 Gr. P22

1.7379 – G17CrMo9-10 – ASTM A217 Gr. WC9

Typical analysis of the wire rod

C Si Mn Cr Mo

wt.-% 0.07 0.60 1.0 2.55 1.0

Mechanical properties of all-weld metal - typical values (min. values)

Condition Yield strength Rp0.2 Tensile strength Rm Elongation A (L0=5d0) Impact values ISO-V KV J

MPa MPa % 20 °C

a 470 590 20 80

Operating data

Shielding gas Dimension mm

I1-3 2.0 × 1000

(EN ISO 14175)

Rod marking W CrMo2 Si / ER 90S-G 2.4 × 1000

2.5 × 1000

3.0 × 1000

3.2 × 1000

Shielding gas: Ar I1 – I3. Gas flow: 8 – 12 l/min.

Polarity: DC-

Approvals

TÜV (00908), DB (42.132.41), CE

166

You might also like

- 19042016000000T - Union I CrMo 910 - Tig RodDocument1 page19042016000000T - Union I CrMo 910 - Tig RodRushita SolankiNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- 31102015000000B - Boehler E 308 H PW-FD - CWDocument1 page31102015000000B - Boehler E 308 H PW-FD - CWKARLNo ratings yet

- Datasheet BOHLER DCMS-IG TIGDocument1 pageDatasheet BOHLER DCMS-IG TIGDaniele DuarteNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- BOEHLER Q T 309L TIG RodDocument1 pageBOEHLER Q T 309L TIG RodbrayanNo ratings yet

- Union Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantDocument1 pageUnion Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantbrayanNo ratings yet

- 409Document2 pages409satish04No ratings yet

- Datasheet BOHLER NI 1-IG TIGDocument1 pageDatasheet BOHLER NI 1-IG TIGMuhammed SulfeekNo ratings yet

- 3dprint AM P22: Material TypeDocument1 page3dprint AM P22: Material TypeKara WhiteNo ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- Categorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBDocument1 pageCategorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBabhishekNo ratings yet

- L1 11991 en Thermanit 13 04 Si de en 21Document1 pageL1 11991 en Thermanit 13 04 Si de en 21k.sourenaNo ratings yet

- Datasheet FOXcore 308L T0 DG Cored WireDocument1 pageDatasheet FOXcore 308L T0 DG Cored WireAHRAKNo ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Thermanit P23Document1 pageThermanit P23Branko FerenčakNo ratings yet

- Thermanit 308 Mo 1SE3A00G 3407112 ENDocument1 pageThermanit 308 Mo 1SE3A00G 3407112 ENbrayanNo ratings yet

- L1 10913 en BOEHLER X 70 IG 2HA3510G 3376575 ENDocument1 pageL1 10913 en BOEHLER X 70 IG 2HA3510G 3376575 ENk.sourenaNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014HoangNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014Yousab CreatorNo ratings yet

- Boehler HL 75 T-MCDocument1 pageBoehler HL 75 T-MCBruno SantosNo ratings yet

- Diamondspark X80 RC-Pipe: Classifi CationsDocument1 pageDiamondspark X80 RC-Pipe: Classifi CationssajawalNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- item22-LNT 502Document1 pageitem22-LNT 502VVan TanNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- Ficha Técnica CarborodDocument1 pageFicha Técnica CarborodAndres NuñezNo ratings yet

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocument1 page11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczNo ratings yet

- Boehler EAS 4 M-IG - Tig RodDocument1 pageBoehler EAS 4 M-IG - Tig RodbrayanNo ratings yet

- Ceweld 308h TigDocument1 pageCeweld 308h TigFilipe CordeiroNo ratings yet

- 308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsDocument1 page308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsFilipe CordeiroNo ratings yet

- B Boehler X 70-IG de en 5Document1 pageB Boehler X 70-IG de en 5Jorge RushNo ratings yet

- Bohler Dcms T-MCDocument1 pageBohler Dcms T-MCFlaviu-Andrei AstalisNo ratings yet

- ceweld_-_410_nimo_-_2015-11-05Document1 pageceweld_-_410_nimo_-_2015-11-05ehsan hatamiNo ratings yet

- Datasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1Document3 pagesDatasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1szystNo ratings yet

- ceweld_-_410_-_2022-08-29 (2)Document1 pageceweld_-_410_-_2022-08-29 (2)ehsan hatamiNo ratings yet

- PDS - Bohler N ER 70 S-2 NACE PDFDocument1 pagePDS - Bohler N ER 70 S-2 NACE PDFwesley59No ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- PDS-OK Tigrod 12.61-Rev6Document2 pagesPDS-OK Tigrod 12.61-Rev6umairNo ratings yet

- Item5 LNT316LDocument1 pageItem5 LNT316LVVan TanNo ratings yet

- European Steel and Alloy Grades: S235JRG2 (1.0038)Document2 pagesEuropean Steel and Alloy Grades: S235JRG2 (1.0038)farshid KarpasandNo ratings yet

- B - Boehler DMO-IG - Ss - en - 5 PDFDocument1 pageB - Boehler DMO-IG - Ss - en - 5 PDFDimitris NikouNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- Boehler CN 22 9 N-IG DUPLEX REALINOXDocument1 pageBoehler CN 22 9 N-IG DUPLEX REALINOXRAHINE AmineNo ratings yet

- Thermanit GE-316L PDFDocument1 pageThermanit GE-316L PDFsmpoe017No ratings yet

- B_Boehler-er-80-s-ni-1-ig_ss_en_5aDocument1 pageB_Boehler-er-80-s-ni-1-ig_ss_en_5aMuhammed SulfeekNo ratings yet

- UTP A 6222 MoDocument1 pageUTP A 6222 MoKara WhiteNo ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- L1 34428 en B Boehler-AWS-ER309L Ss en 1Document1 pageL1 34428 en B Boehler-AWS-ER309L Ss en 1Edgar HornusNo ratings yet

- ISO Standards On Mech Test of MetalsDocument1 pageISO Standards On Mech Test of MetalsKiran NikateNo ratings yet

- 02112015000000B - Boehler FOX DCMS Ti - CeDocument1 page02112015000000B - Boehler FOX DCMS Ti - CeparbinaNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-2 EN 10162Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-2 EN 10162farshid KarpasandNo ratings yet