Válvula Control de Bomba - CLAVAL

Válvula Control de Bomba - CLAVAL

Uploaded by

Jose CabanaCopyright:

Available Formats

Válvula Control de Bomba - CLAVAL

Válvula Control de Bomba - CLAVAL

Uploaded by

Jose CabanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Válvula Control de Bomba - CLAVAL

Válvula Control de Bomba - CLAVAL

Uploaded by

Jose CabanaCopyright:

Available Formats

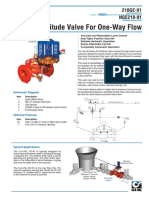

MODEL 60-19

Booster Pump Control Valve

with High Capacity Pilot System

• Designed for Larger Sized Pump Stations

• Low Head Loss

• Built-in Check Valve

• Opening and Closing Rates Separately Adjusted

• Proven Reliable Design

The Cla-Val Model 60-19 Pump Control Valve is a pilot-operated valve

designed for installation on the discharge of booster pumps to elimi-

nate pipeline surges caused by the starting and stopping of the pump.

The pump starts against a closed valve. When the pump is started,

the solenoid control is energized and the valve begins to open slowly,

gradually increasing line pressure to full pumping head. When the

pump is signaled to shut-off, the solenoid control is de-energized and

the valve begins to close slowly, gradually reducing flow while the

pump continues to run. When the valve is closed, a limit switch as-

sembly, which serves as an electrical interlock between the valve and

the pump, releases the pump starter and the pump stops.

Should a power failure occur, a built-in lift-type check valve closes

the moment flow stops, preventing reverse flow regardless of solenoid

or diaphragm assembly position.

Schematic Diagram CS3

Item Description

3 2

1

1 100-03 Powercheck Main Valve

2

2 CS3M Solenoid Control

3 102E 3-Way Valve

3B

6A

3A

4 CVS-1 Shuttle Valve

COM. N.C.

5 X105LCW Switch Assembly

N.O.

6 CV Flow Control 5

Optional Features

B

B

Item Description

A X46A Flow Clean Strainer

6B

B CK2 Isolation Valve

INLET OUTLET

P X141 Pressure Gauge

B

Y X43 “Y” Strainer

A 1 A

PC PC-22D Pump Control Panel

2

B

4

Y Y

Typical Installation

CLA-VAL

Install Model 60-19 valve as shown. Flexible conduit

Pump

52-03/652-03

should be used for electrical connections to the solenoid Surge Anticipator

control and the limit switch. A Model 52-02/652-03 Surge Valve

Anticipator Valve is recommended for power failure pro-

tection.

Discharge to

Atmosphere

Note: For optimum operation of built-in check feature, in-

stallation must be with valve stem vertically up. CLA-VAL 60-19

Isolation Valve

Booster Pump

The Model 60-19 is for 250mm and larger valves or

Control Valve

when the pressure is above 300 psi.

Discharge To

System

Pressure Ratings (Recommended Maximum Pressure - psi) Materials

Pressure Class Component Standard Material Combinations

Valve Body & Cover

Flanged Threaded

Body & Cover Ductile Iron Cast Steel Bronze

ANSI 150 300 End‡ 100-03 Available Sizes 250 - 400mm 250 - 400mm 250 - 400mm

Grade Material

Standards* Class Class Details

Disc Retainer & Cast Iron Cast Steel Bronze

ASTM A536 Ductile Iron B16.42 250 640 400 Diaphragm Washer

ASTM A216-WCB Cast Steel B16.5 285 720 400 Trim: Disc Guide, Bronze is Standard

Seat & Cover Bearing Stainless Steel is Optional

UNS 87850 Bronze B16.24 225 500 400 Disc Buna-N® Rubber

Diaphragm Nylon Reinforced Buna-N® Rubber

Note: * ANSI standards are for flange dimensions only.

Stem, Nut & Spring Stainless Steel

Flanged valves are available faced but not drilled.

‡ End Details machined to ANSI B2.1 specifications. For material options not listed, consult factory.

Valves for higher pressure are available; consult factory for details Cla-Val manufactures valves in more than 55 different alloys.

B (Diameter)

100-03 J

Threaded &

Flanged K

X

C Y

(MAX)

Inlet Outlet

Z

G E F

GG FF

GGG

A

Inlet D

DD

AA DDD

AAA

60-19 Series Dimensions (mm)

Valve Size (mm) 250 300 350 400

A Threaded — — — —

AA 150 ANSI 756 864 991 1051

AAA 300 ANSI 790 902 1029 1105

B Diameter 600 711 832 902

C Maximum 594 744 816 889

D Threaded — — — —

DD 150 ANSI 378 432 495 526

DDD 300 ANSI 395 451 514 552

E 235 273 321 394

F 150 ANSI 203 241 267 298

FF 300 ANSI 222 260 292 324

G Threaded — — — —

GG 150 ANSI 219 349 378 399

GGG 300 ANSI 236 368 397 419

H NPT Body Tapping 1.00 1.00 1.00 1.00

J NPT Cover Center Plug 1.00 1.25 1.50 2.00

K NPT Cover Tapping 1.00 1.00 1.00 1.00

Stem Travel 71 86 102 114

Approx. Ship Weight (kgs) 426 760 1116 1406

Approx. X Pilot System 762 940 1041 1092

Approx. Y Pilot System 508 559 610 660

Approx. Z Pilot System 508 559 610 660

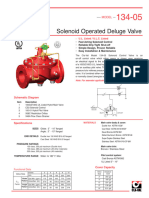

Sequence Of Operation

A A A

H H H

G B G B G B

E E E

D D D

C C C

B F B B F

F

Pump Off... Starting Cycle... Stopping Cycle...

With pump off, static line pressure is Starting switch closes, pump starts, solenoid control Starting switch opens, solenoid control A de-

transmitted through strainer F, shuttle valve A energizes and shifts allowing fluid from three-way energizes and shifts, pump continues to run.

C, solenoid control A, three way valve B, and valves G and B to drain to atmosphere. High High pressure fluid from the pump is directed

speed control E to the chamber above the pressure fluid from pump enters strainer B and shifts above the diaphragm through three-way valve

diaphragm, thus holding the valve shut. shuttle valve C, which always supplies the highest B to close the valve.

pressure from either strainer B or F. High pressure The valve closes slowly as fluid from the lower

fluid is transmitted to the lower diaphragm chamber diaphragm chamber is gradually released to

If power failure occurs when valve is open, through three-way valve G and opens the valve. atmosphere through speed control D and three-

the built-in check valve J closes immediately The opening speed of the valve is controlled by way valve G.

to prevent reverse flow. speed control E, which limits the rate fluid is relieved When the valve closes fully, the limit switch H

from above the diaphragm to drain. shuts off the pump.

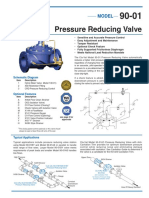

Model 60-19 Flow Chart Uses 100-03 Powercheck Main Valve

Angle Valve Sizes (mm) 250 300 350 Valve Sizing

Sizing Model 60-19 Booster Pump Control Valves is

Globe Valve Sizes (mm) 250 300 350 400

similar to sizing non-modulating type valves. Simply

100

select the smallest size valve that will handle the

80

60

pump output at an acceptable head loss for the

application.

40

Pressure Drop — psi

30

20

Do not oversize. Oversizing a Booster Pump

Control Valve will nullify its ability to prevent surges

10

8

caused by the starting and/or stopping of the pump.

6

Maximum flow values are given in the selection table

4

above. For further information on flow characteristics

3

of this valve, see the 100-03 engineering data sheet.

2

Drain Provisions

1

3 5 10 20 30 40 60 80 100 200 500 1000 2000 5000 10,000 20,000 50,000

Each time the valve opens or closes, water is

Flow Rate gpm (water)

discharged from the solenoid exhaust port, the

amount varying with the valve size. Provisions

should be made for the disposal of this water.

Liquid Volume Displaced from Diaphragm Chamber When Valve Opens or Closes Exhaust tube must be free of any back pressure.

Provide an air gap between the solenoid exhaust

Sizes (Inches) 250 300 350 400

tube and drain facility.

60-19 (gallons) 2.51 4.00 6.50 9.57

Cla-Val offers the most complete line of automatic

660-19 (gallons) 1.26 2.51 4.00 6.50

control valves for virtually any type of pump control

system available.

Please call your Cla-Val regional office or sales

agent for complete design assistance. Our goal is to

provide the best automatic control valve solution for

each application.

60-19 100-03 Pattern: Globe (G), Angle (A), End Connections: Threaded (T), Flanged (F) Indicate Available Sizes

Valve

Selection mm 250 300 350 400

Pattern G, A G, A G, A G, A

Main Valve

100-03

End Detail F F F F

Suggested Maximum 309 442 530 694

Flow

(Liters/Sec) Maximum

387 549 664 863

Intermittent

100-03 Series is the full internal port Powercheck.

Pilot System Specifications Solenoid Control Specifications

Temperature Range

Water to 180°F Max Body: 6, 12, 24, 120, 240 - DC

Materials Brass ASTM B283 Others available.

Standard Pilot System Materials Enclosure: Max. operating pressure differential:

Pilot Control: Low Lead Bronze

NEMA Type 1,2,3,3S,4,4X 200 psi

Trim: Stainless Steel Type 303

general purpose watertight Coil:

Rubber: Buna-N® Synthetic

Rubber NEMA Type 6,6P,7,9 Insulation molded Class F

Optional Pilot System Materials watertight explosion proof Watts AC 6

Pilot Systems are available with available. AC Volt Amps Inrush 30

optional Aluminum, Stainless Steel

or Monel materials.

Voltages: AC Volt Amps Holding 16

110, 220 - 50 Hz AC Watts DC 10.6

24, 120, 240, 480 - 60 Hz AC

Wiring Diagram Auto Off Hand

Auto-Off-Hand = Selector Switch

L2

L1 SW1

1CR = Relay, DPST Normally Open

A 3CR3

1CR

2CR = Relay, DPST Normally Open H

3CR = Relay, TPST Normally Open

SW1 = Switch, Remote Start, Automatic 1CR

SW2 = Switch, SPDT, Valve Limit Switch

PVS

Connect to N.C. Terminal 1CR 3CR1

PVS = Pilot Valve Solenoid

2CR

M = Pump Motor Starter N.C. 2CR

COM.

Note: SW2 and PVS supplied by Cla-Val. All other electrical items

3CR

supplied by customer. SW2 is included in the X105L switch assembly SW2

which is mounted on the pump control valve cover.

N.O.

3CR2

Shown In Pump Off Position

2CR

M

For simplified field wiring, see Model PC-1 Pump Control Panel Data Sheet.

When Ordering, Please Specify:

1. Catalog No. 60-19 2. Valve Size 3. Pattern -Globe or Angle 4. Pressure Class 5. Trim Material

6. Electrical Selection 7. Desired Options 8. When Vertically Installed (Flow Direction)

CLA-VAL 1701 Placentia Ave • Costa Mesa CA 92627 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com

Cla-Val 2021 • Printed in USA • Specifications subject to change without notice.

© Copyright

E-60-19 Metric (R-02/2021)

You might also like

- EN - WMF5000S+ - Event and Error ListDocument39 pagesEN - WMF5000S+ - Event and Error Listjair100% (1)

- Danfoss Sem Safe Section Valve Deluge Pipe SystemDocument5 pagesDanfoss Sem Safe Section Valve Deluge Pipe SystemYusuf ÖğrenNo ratings yet

- Xarios 350 ОписаниеDocument2 pagesXarios 350 ОписаниеzalupakozlaNo ratings yet

- Cla ValDocument4 pagesCla ValBanupriya BalasubramanianNo ratings yet

- Oil Pump Type Ale Gear Sizes 35-55: ALE Oil Pump Incorporates A Blocking Solenoid Valve Fitted With A Built-InDocument2 pagesOil Pump Type Ale Gear Sizes 35-55: ALE Oil Pump Incorporates A Blocking Solenoid Valve Fitted With A Built-Inmochammad RezaNo ratings yet

- E69001 PRV ClavalDocument4 pagesE69001 PRV ClavalPlanner CyberNo ratings yet

- 7.5. Cla-Val E-650-01Document4 pages7.5. Cla-Val E-650-01sigithvacNo ratings yet

- 90 01KO Data Sheet USDocument4 pages90 01KO Data Sheet USAngga ArdanaNo ratings yet

- Suntec Oil Pump ALE GBDocument2 pagesSuntec Oil Pump ALE GBkikokiko KarimNo ratings yet

- ALgbDocument2 pagesALgbOlivier MontagueNo ratings yet

- Válvula Reductora de Presión PDFDocument4 pagesVálvula Reductora de Presión PDFPaola LopezNo ratings yet

- Surge Anticipation ValveDocument4 pagesSurge Anticipation ValveMathiTwadCNo ratings yet

- CAT - Feedwater Protection SystemDocument11 pagesCAT - Feedwater Protection SystemMurli RamchandranNo ratings yet

- Piston and Bladder Type Safety Note: Applications: Hydraulic AccumulatorsDocument3 pagesPiston and Bladder Type Safety Note: Applications: Hydraulic AccumulatorsconimecNo ratings yet

- Series 100 ValvesDocument36 pagesSeries 100 ValvesCarlos Rovello GandoNo ratings yet

- Pressure Reducing Control Valve: Model: KVS - 801GDocument3 pagesPressure Reducing Control Valve: Model: KVS - 801GThúy VyNo ratings yet

- Pressure Relief & Surge Anticipator Valve: ModelDocument4 pagesPressure Relief & Surge Anticipator Valve: ModelZamfiroiu BogdanNo ratings yet

- Pompe Combustibil As - Carte TehnicaDocument2 pagesPompe Combustibil As - Carte TehnicaLucian UrsuNo ratings yet

- Kuriauto C505ECO Brochure-EnDocument2 pagesKuriauto C505ECO Brochure-EnIman Faisal0% (1)

- Val Aliv 0.75-20881504aDocument4 pagesVal Aliv 0.75-20881504aJulio VizacarraNo ratings yet

- 134-AZ DelugeDocument3 pages134-AZ DelugechanseshpNo ratings yet

- Oil Pump Type Aj Gear Sizes 4-6: ApplicationsDocument2 pagesOil Pump Type Aj Gear Sizes 4-6: Applicationsr_cristiNo ratings yet

- Valve Body Unit 1. General: Chassis - A750E and A750F Automatic Transmissions CH-46Document4 pagesValve Body Unit 1. General: Chassis - A750E and A750F Automatic Transmissions CH-46Maxi Sardi100% (1)

- SM-12 - RexrothDocument18 pagesSM-12 - RexrothVEERAMANI100% (1)

- Pressure Reducing Valve: ModelDocument4 pagesPressure Reducing Valve: ModeltorqueuNo ratings yet

- CV STM Sec 4 - Startup AdjDocument26 pagesCV STM Sec 4 - Startup AdjBams ArifinNo ratings yet

- Solenoid Control Valve: Installation / Operation / MaintenanceDocument2 pagesSolenoid Control Valve: Installation / Operation / Maintenanceahmsa.morsyNo ratings yet

- Pressure Reducing Valve: ModelDocument4 pagesPressure Reducing Valve: ModelTiam Yee YongNo ratings yet

- Model Sheet 115 - 25 Terminal 9 - 20Document2 pagesModel Sheet 115 - 25 Terminal 9 - 20Gusukuma JGNo ratings yet

- Differential Pressure Valve E-250-01Document3 pagesDifferential Pressure Valve E-250-01Navin RamnauthNo ratings yet

- Hyd PDFDocument90 pagesHyd PDFRamon CasillasNo ratings yet

- Rate of Flow and Fuel Shut Off Valve: ModelDocument2 pagesRate of Flow and Fuel Shut Off Valve: Modelanon_867776278No ratings yet

- Universal Service Pump Type Au V - Gear Size 47Document2 pagesUniversal Service Pump Type Au V - Gear Size 47mochammad RezaNo ratings yet

- Valve ActuatorsDocument32 pagesValve ActuatorsAntoine lazarus MaomyNo ratings yet

- I 769N PreactionDocument46 pagesI 769N Preactiondemdiin100% (1)

- Modulating Float Valve: ModelDocument4 pagesModulating Float Valve: ModelGus HdezNo ratings yet

- Singer Valve 106 206 F Type 4 IOM Operation GuideDocument4 pagesSinger Valve 106 206 F Type 4 IOM Operation GuideSijo JoyNo ratings yet

- Wellcast - PRVDocument8 pagesWellcast - PRVAnkur darjiNo ratings yet

- Cla-Val Electronic Control ValvesDocument6 pagesCla-Val Electronic Control ValvesArelysSotilloNo ratings yet

- Directional Control ValvesDocument7 pagesDirectional Control ValvesrabbitpummNo ratings yet

- SSV Control System SHUT DOWN VALVEDocument12 pagesSSV Control System SHUT DOWN VALVEglobal3tNo ratings yet

- Model 115-3: Digital Electronic Control ValveDocument36 pagesModel 115-3: Digital Electronic Control ValveBruno GonçalvesNo ratings yet

- Spek PompaDocument2 pagesSpek PompaYand's PermanaNo ratings yet

- Chapter 10 Rev 3 Rod ChangingDocument13 pagesChapter 10 Rev 3 Rod ChangingAnonymous 340A7vnwV1No ratings yet

- CLA-VAL Control ValveDocument4 pagesCLA-VAL Control ValvesuedasNo ratings yet

- 50B-4KG1/2050B-4KG1: Pressure Relief ValveDocument2 pages50B-4KG1/2050B-4KG1: Pressure Relief ValveEduardo CastilloNo ratings yet

- 26brake ValveDocument26 pages26brake ValveAlexander Mugabe100% (1)

- Control ValvesDocument22 pagesControl ValvesGoher IqbalNo ratings yet

- Pressure Reducing Valve: ModelDocument4 pagesPressure Reducing Valve: Modelguangyu LuNo ratings yet

- Rate of Flow Non-Surge Check Valve: ModelDocument2 pagesRate of Flow Non-Surge Check Valve: ModelAndrzej BąkałaNo ratings yet

- Pressure Reducing Valve: ModelDocument4 pagesPressure Reducing Valve: ModelSaad KhNo ratings yet

- Training Tail Lift Technology Mod 4 Signs & Symbols enDocument19 pagesTraining Tail Lift Technology Mod 4 Signs & Symbols enArmin PatelNo ratings yet

- Pump Type Aj: This Is A General Specification Leaflet For Specific Applications Not Covered Herein, Contact SuntecDocument2 pagesPump Type Aj: This Is A General Specification Leaflet For Specific Applications Not Covered Herein, Contact Suntecbobi gorgievskiNo ratings yet

- Fordson Major Systeme HydrauliqueDocument23 pagesFordson Major Systeme HydrauliqueNicolas100% (1)

- Bfe API 6a ValvesDocument32 pagesBfe API 6a ValvesAldo P WicaksanaNo ratings yet

- Mustang Series M113-21 or M6113-21 (Globe), M1113-21 or M61113-21 (Angle) Installation InstructionsDocument2 pagesMustang Series M113-21 or M6113-21 (Globe), M1113-21 or M61113-21 (Angle) Installation InstructionsWattsNo ratings yet

- ChecktronicDocument12 pagesChecktronicYaslin Maria Marquez HernandezNo ratings yet

- Part 4 Hydraulic Control Principle and ParametersDocument22 pagesPart 4 Hydraulic Control Principle and ParametersrohanNo ratings yet

- Pressure Relief & Pressure Sustaining Valve: ModelDocument4 pagesPressure Relief & Pressure Sustaining Valve: ModelKevin E JodiNo ratings yet

- Types of Valves in Piping: Types of Valves - Tables to estimate man hours of assemblyFrom EverandTypes of Valves in Piping: Types of Valves - Tables to estimate man hours of assemblyNo ratings yet

- MSS Mar 1000023967 011Document3 pagesMSS Mar 1000023967 011fvj20056No ratings yet

- Presentation 3Document42 pagesPresentation 3Hubab AhmadNo ratings yet

- Chapter 3 - Examples and Exercises (Part II) NewDocument7 pagesChapter 3 - Examples and Exercises (Part II) NewtemesgenNo ratings yet

- A Comprehensive and Systematic Modelling Tool For Natural Gas Value Chain Greenhouse Gas Emissions QuantificationDocument7 pagesA Comprehensive and Systematic Modelling Tool For Natural Gas Value Chain Greenhouse Gas Emissions QuantificationniezhenggangNo ratings yet

- SST Class 10 NotesDocument1 pageSST Class 10 NotesGOWTHAM CHANDRA SAGAR M. SNo ratings yet

- Joule-Thomson EffectDocument4 pagesJoule-Thomson EffectRandomNo ratings yet

- SOP For FlushingDocument5 pagesSOP For Flushingmoms2No ratings yet

- The Lived Experiences of Shs Students Without Electricity at HomeDocument17 pagesThe Lived Experiences of Shs Students Without Electricity at HomeRex NaqueNo ratings yet

- DF4 - Inflow Performance RelationshipDocument11 pagesDF4 - Inflow Performance Relationshipadnan0307No ratings yet

- Nexon EV MAX BrochureDocument18 pagesNexon EV MAX BrochureNitish Singh JMSNo ratings yet

- Methods of Train Authorisations & Signalling ClearanceDocument10 pagesMethods of Train Authorisations & Signalling ClearanceAyanda MdluliNo ratings yet

- Cat WSCWDC-3Document92 pagesCat WSCWDC-3Giang Nguyễn HươngNo ratings yet

- ME ESE Mains Paper I (2024) PG 592Document17 pagesME ESE Mains Paper I (2024) PG 592Tripathi 70No ratings yet

- For Posting 0917. Resolution No. 13 S024 With AnnexesDocument281 pagesFor Posting 0917. Resolution No. 13 S024 With AnnexesAnnNo ratings yet

- Answer Key 2019Document21 pagesAnswer Key 2019Abhinav TiwariNo ratings yet

- ÉSECÈ Group - Steam Boiler - Mar12 ENGDocument4 pagesÉSECÈ Group - Steam Boiler - Mar12 ENGDiego Otero Rodríguez100% (1)

- MedicalOilLessScrollSpec Rev5Document5 pagesMedicalOilLessScrollSpec Rev5Roger BustosNo ratings yet

- Guntner Heat Exchangers: ... Keep(s) Your QualityDocument8 pagesGuntner Heat Exchangers: ... Keep(s) Your QualityDimas TorrealbaNo ratings yet

- Embedded Generation Project - Final Report v1Document270 pagesEmbedded Generation Project - Final Report v1shehan.defonsekaNo ratings yet

- F758-95 (Reapproved 2000)Document6 pagesF758-95 (Reapproved 2000)trangonkdNo ratings yet

- Company / Customer:: AddressDocument6 pagesCompany / Customer:: Addresstan datNo ratings yet

- A Novel Solar HP With PVTDocument21 pagesA Novel Solar HP With PVTmuhammad.arslanNo ratings yet

- Installation Manual 64883Document60 pagesInstallation Manual 64883diegolaurapira100% (1)

- Brosur - NP GasluxDocument4 pagesBrosur - NP GasluxYudiNo ratings yet

- Ms For Repair of LR TankDocument6 pagesMs For Repair of LR Tankdadz mingiNo ratings yet

- G.Paul Richter - JT9D-7A (SP) JET ENGINE PERFORMANCE DETERIORATION TRENDSDocument24 pagesG.Paul Richter - JT9D-7A (SP) JET ENGINE PERFORMANCE DETERIORATION TRENDSАлександр ТумановNo ratings yet

- JPS78-171 - Operaional Experience and PerformanceDocument5 pagesJPS78-171 - Operaional Experience and Performancecarlosalberto.camargoNo ratings yet

- Lighting LayoutDocument1 pageLighting LayoutMichael Joshua MacasarteNo ratings yet