0 ratings0% found this document useful (0 votes)

60 viewsSF-600 TDS 2023

SF-600 TDS 2023

Uploaded by

Rajneesh RallanSF-600 is a synthetic high temperature chain lubricant formulated with synthetic base stocks and additives to resist high heat decomposition and prevent sludge or carbon buildup. It is recommended for use in tenter frame ovens, ceramics production, bakery ovens, glass production, paint curing ovens, paper manufacturing, and plywood production. Advantages include high temperature oxidation resistance, thermal stability, low volatility, and outstanding anti-wear properties.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

SF-600 TDS 2023

SF-600 TDS 2023

Uploaded by

Rajneesh Rallan0 ratings0% found this document useful (0 votes)

60 views1 pageSF-600 is a synthetic high temperature chain lubricant formulated with synthetic base stocks and additives to resist high heat decomposition and prevent sludge or carbon buildup. It is recommended for use in tenter frame ovens, ceramics production, bakery ovens, glass production, paint curing ovens, paper manufacturing, and plywood production. Advantages include high temperature oxidation resistance, thermal stability, low volatility, and outstanding anti-wear properties.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

SF-600 is a synthetic high temperature chain lubricant formulated with synthetic base stocks and additives to resist high heat decomposition and prevent sludge or carbon buildup. It is recommended for use in tenter frame ovens, ceramics production, bakery ovens, glass production, paint curing ovens, paper manufacturing, and plywood production. Advantages include high temperature oxidation resistance, thermal stability, low volatility, and outstanding anti-wear properties.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

60 views1 pageSF-600 TDS 2023

SF-600 TDS 2023

Uploaded by

Rajneesh RallanSF-600 is a synthetic high temperature chain lubricant formulated with synthetic base stocks and additives to resist high heat decomposition and prevent sludge or carbon buildup. It is recommended for use in tenter frame ovens, ceramics production, bakery ovens, glass production, paint curing ovens, paper manufacturing, and plywood production. Advantages include high temperature oxidation resistance, thermal stability, low volatility, and outstanding anti-wear properties.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

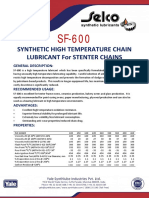

SF-600

SYNTHETIC HIGH TEMPERATURE CHAIN

LUBRICANT For STENTER CHAINS

GENERAL DESCRIPTION:

SF-600 is a high temperature lubricant which has been specifically formulated with synthetic base stocks

having unusually high temperature lubricating capability. Careful selection of additives result in a fluid which

resists high temperature decomposition and prevents the formation of sludge or carbon normally produced

by petroleum based products. This results in longer equipment life, less maintenance, better efficiency, while

costly downtime is significantly reduced.

RECOMMENDED USAGE:

SF-600 is excellent for tenter frame ovens, ceramics production, bakery ovens and glass production. It is

equally recommended for paint curing ovens, paper manufacturing, plywood production and can also be

used as a bearing lubricant in high temperature environments.

ADVANTAGES:

• Excellent high temperature oxidation resistance.

• Superior thermal stability for prolonged lubricant life.

• Extremely low volatility/less lubricant consumption.

• Outstanding anti-wear properties/reduced chain drag.

PROPERTIES:

ISO GRADE 100 150 180 220 260 320 360 400 460

Viscosity cSt @ 40°C (ASTM D-445) 100 150 180 220 260 320 360 400 460

Viscosity cSt @ 100°C (ASTM D-445) 15 20 23 27 30 34 37 40 43

Viscosity Index (ASTM D-2270) 100 145 145 150 150 150 150 150 150 148

Flash Point °F/°C (ASTM D-92) 560°/294° 300 300 300 300 300 300 300 300 300

Fire Point °F/°C (ASTM D-92) 610°/321° 332 332 332 334 334 335 335 335 335

Pour Point °F/°C (ASTM D-92) -22°/-30° -32 -32 -32 -32 -32 -31 -31 -31 -30

Auto-Ignition Point °F/°C 850°/454° 454 454 454 454 454 454 454 454 454

Four Ball Wear Test (ASTM D-4172) Scar Diameter, mm 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35

% Evaporation Loss 2 hrs @ 220°C 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1

% Evaporation Loss 2 hrs @ 250°C 1.27 1.27 1.27 1.27 1.27 1.27 1.27 1.27 1.27

Carbon Residue @ 520°C 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002

You might also like

- Esab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)Document2 pagesEsab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)RodrigoNo ratings yet

- FOB Extra Duty Gear Oil TDSW 815913 - 815914Document3 pagesFOB Extra Duty Gear Oil TDSW 815913 - 815914Elwin arifinNo ratings yet

- FOB Megaflow AW Hydraulic Oil TDSW 814637aDocument3 pagesFOB Megaflow AW Hydraulic Oil TDSW 814637aElwin arifinNo ratings yet

- Bpxe B6ctalDocument2 pagesBpxe B6ctalVusal HasanovNo ratings yet

- SynconSynROOil 68Document2 pagesSynconSynROOil 68solnyshko28110705No ratings yet

- Ficha Tecnica Castrol Hyspin AWS RangeDocument2 pagesFicha Tecnica Castrol Hyspin AWS Rangeel pro jajaja GonzalezNo ratings yet

- Optigear EP 150Document3 pagesOptigear EP 150Franklin JprstNo ratings yet

- Castrol Hyspin AWS RangeDocument2 pagesCastrol Hyspin AWS RangeVusal HasanovNo ratings yet

- Castrol Molub Alloy 860Document3 pagesCastrol Molub Alloy 860tribolasNo ratings yet

- Hyspin AWS 15Document2 pagesHyspin AWS 15nargueNo ratings yet

- Wepp bpzs8fDocument2 pagesWepp bpzs8fArthur Sanda LayukNo ratings yet

- Castrol Hyspin VG Range: DescriptionDocument2 pagesCastrol Hyspin VG Range: DescriptionBruno RussoNo ratings yet

- Nebula Igo Gear-OilDocument1 pageNebula Igo Gear-OilDidi KurniadiNo ratings yet

- RP BioMax Gear PDS 05nov2020Document2 pagesRP BioMax Gear PDS 05nov2020FERMIN ARTEAGANo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- PDS - Coastal Premium AW Hydraulic OilsDocument2 pagesPDS - Coastal Premium AW Hydraulic OilsThe DoctorNo ratings yet

- 783 - Pds-Morlina Oil SD 100Document2 pages783 - Pds-Morlina Oil SD 100JonesNo ratings yet

- 1-Royal Centurion EP Gear OilDocument3 pages1-Royal Centurion EP Gear Oilrobertoalfaro492023No ratings yet

- Gravis SP Series - INGDocument1 pageGravis SP Series - INGZeko AlzogneyNo ratings yet

- Chevron Meropa EP PDSDocument2 pagesChevron Meropa EP PDSArie'f Armand ArsyatNo ratings yet

- Turbine Oil - SpecDocument2 pagesTurbine Oil - SpecEid EeidNo ratings yet

- Grease PropertiesDocument4 pagesGrease Propertiescarlos sotoNo ratings yet

- Castrol Perfecto XDocument3 pagesCastrol Perfecto XHector Martin BarajasNo ratings yet

- Bel-Ray No-Tox Syntra Food Grade Synthetic OilDocument4 pagesBel-Ray No-Tox Syntra Food Grade Synthetic OilGiovanny MosqueraNo ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- Maker Tauro enDocument2 pagesMaker Tauro enibrahim maulanaNo ratings yet

- Aceite Castrol Tribol 290 Conveyor Lubricant 2Document2 pagesAceite Castrol Tribol 290 Conveyor Lubricant 2carlos pachecoNo ratings yet

- Epic Hydraulic Range TdsDocument2 pagesEpic Hydraulic Range Tdsapi-375685829No ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Texaco Meropa 320 Eng M0010Document2 pagesTexaco Meropa 320 Eng M0010Ady MihailaNo ratings yet

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimNo ratings yet

- Icr-6025 6027 (GP1)Document1 pageIcr-6025 6027 (GP1)duwiNo ratings yet

- Gii Turbine Oil 32 46 68 77 100Document1 pageGii Turbine Oil 32 46 68 77 100Thaer HamedeNo ratings yet

- Repsol Maker Super TauroDocument2 pagesRepsol Maker Super Tauroibrahim maulanaNo ratings yet

- Tds - Super Gear OilDocument2 pagesTds - Super Gear OilRakka HardiyantaNo ratings yet

- Product Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDocument3 pagesProduct Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDiegoNo ratings yet

- Polyurea Grease TdsDocument2 pagesPolyurea Grease TdsBanti SidhiwalaNo ratings yet

- Optimus Turbine Oil 2Document1 pageOptimus Turbine Oil 2kennethNo ratings yet

- Loctite Ea 9330 Aero-EnDocument5 pagesLoctite Ea 9330 Aero-EnbenNo ratings yet

- Epofine 740 - Finehard 5200Document4 pagesEpofine 740 - Finehard 5200Karishma PrabhuNo ratings yet

- Powerflow NZ Hydraulic Oil - 04 2021 1Document2 pagesPowerflow NZ Hydraulic Oil - 04 2021 1gatitanegra1992No ratings yet

- Omega Amide Nylon Pa CatalogueDocument5 pagesOmega Amide Nylon Pa Cataloguesoni10483No ratings yet

- PDS Drydene GearAll EP Series 0322-01Document1 pagePDS Drydene GearAll EP Series 0322-01txto2881No ratings yet

- Castrol BRAYCOTE 601 EF - Pds - Eng - Rev. 2014.08.04Document2 pagesCastrol BRAYCOTE 601 EF - Pds - Eng - Rev. 2014.08.04Massimiliano VolaNo ratings yet

- Clock Spring Diamond Wrap BrochureDocument2 pagesClock Spring Diamond Wrap BrochuremuhammadxpNo ratings yet

- Web ProductSheet DiamondWrap 2018 PDFDocument2 pagesWeb ProductSheet DiamondWrap 2018 PDFRiankwnNo ratings yet

- Tribol CH 1421 RangeDocument4 pagesTribol CH 1421 RangeNoche de EstrellasNo ratings yet

- Aw Hydraulic Oil: Applications Selection GuideDocument2 pagesAw Hydraulic Oil: Applications Selection GuideMassimiliano VolaNo ratings yet

- Renolin CLPDocument3 pagesRenolin CLPDANE80No ratings yet

- Technical Data Sheet: Synthetic Oil For Trunnion Bearings and Mining MachinesDocument1 pageTechnical Data Sheet: Synthetic Oil For Trunnion Bearings and Mining MachinesDon HowardNo ratings yet

- Product Data Sheet: Synthetic Gear OilDocument2 pagesProduct Data Sheet: Synthetic Gear OilDiegoNo ratings yet

- Magna PM 220-Pds-EngDocument2 pagesMagna PM 220-Pds-EngVusal HasanovNo ratings yet

- Castrol Tribol GR 4020 220-460 PD Tds-EnDocument3 pagesCastrol Tribol GR 4020 220-460 PD Tds-EnIulian BarbuNo ratings yet

- Pao 100Document2 pagesPao 100Антон СтепураNo ratings yet

- Molylube Extreme Pressure High Viscosity GreaseDocument4 pagesMolylube Extreme Pressure High Viscosity GreaseJaime MunozNo ratings yet

- Datasheet-Saf-2205-En-V2021-10-07 13 - 05 Version 1Document8 pagesDatasheet-Saf-2205-En-V2021-10-07 13 - 05 Version 1simone.mauriNo ratings yet

- L-CKD Heavy Duty Industrial Gear OilDocument3 pagesL-CKD Heavy Duty Industrial Gear OilDavidNo ratings yet

- HO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)Document2 pagesHO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)azimchemNo ratings yet

- Asphalt Binder Basics Specifications, History and FutureDocument40 pagesAsphalt Binder Basics Specifications, History and FutureEdmundo Jaita CuellarNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic Ceramics IIFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic Ceramics IIMihails KusnezoffNo ratings yet

- Knittol SPL TDSDocument1 pageKnittol SPL TDSRajneesh RallanNo ratings yet

- SF-600 TDS 2023Document1 pageSF-600 TDS 2023Rajneesh RallanNo ratings yet

- SG-390 TDSDocument1 pageSG-390 TDSRajneesh RallanNo ratings yet

- SG-620 TDSDocument1 pageSG-620 TDSRajneesh RallanNo ratings yet

- Haynes Tubular ProductsDocument20 pagesHaynes Tubular ProductsChristo Van Den HeeverNo ratings yet

- EIGA StandardDocument19 pagesEIGA StandardGaiu George LucianNo ratings yet

- Sigmacover™: Recoatable Epoxy SystemsDocument8 pagesSigmacover™: Recoatable Epoxy SystemsRasheedNo ratings yet

- Biomaterials Classification (Market)Document20 pagesBiomaterials Classification (Market)Aniket SinghNo ratings yet

- 2020 Y6 Timed Practice Question PaperDocument21 pages2020 Y6 Timed Practice Question Paperakdc 33No ratings yet

- Two Years Project - TopicsDocument22 pagesTwo Years Project - TopicsAbi KuttyNo ratings yet

- #03 Source RockDocument49 pages#03 Source Rockriyadi100% (1)

- Afcona - 4010 Tds EngDocument1 pageAfcona - 4010 Tds EngSamuel AgusNo ratings yet

- BP406P Medicinal Chemistry1Document30 pagesBP406P Medicinal Chemistry1Anit DubeyNo ratings yet

- Preslist Reagent Lab Pa: NO Nama Produk Merk Kemasan HargaDocument1 pagePreslist Reagent Lab Pa: NO Nama Produk Merk Kemasan Hargakartikagff:fdfgtrgrqa sariNo ratings yet

- Bakery WheatDocument10 pagesBakery WheatAVIRAL YADAVNo ratings yet

- Application Engineering Bulletin: PurposeDocument9 pagesApplication Engineering Bulletin: PurposeCesar G.No ratings yet

- Minerals & RocksDocument28 pagesMinerals & RocksLejeb TCNo ratings yet

- LDH Catalysts PDFDocument20 pagesLDH Catalysts PDFAhsan Iqbal AlamgirNo ratings yet

- True A and False B: Test PrepDocument4 pagesTrue A and False B: Test PrepChandra ReddyNo ratings yet

- The Case of The Adulterated Baking Soda2Document4 pagesThe Case of The Adulterated Baking Soda2Ash HassanNo ratings yet

- Cambridge IGCSE: Combined Science 0653/41Document20 pagesCambridge IGCSE: Combined Science 0653/41Hin Wa LeungNo ratings yet

- Fuels From Biomass: A. Demirbas, Biorefineries, © Springer 2010 33Document42 pagesFuels From Biomass: A. Demirbas, Biorefineries, © Springer 2010 33lewisNo ratings yet

- Research Paper 1:: Common Problems in Desizing & Their CountermeasuresDocument4 pagesResearch Paper 1:: Common Problems in Desizing & Their Countermeasuresn.t100% (1)

- Experiment 2: Gravimetric Analysis in SolutionDocument3 pagesExperiment 2: Gravimetric Analysis in SolutionwinfattNo ratings yet

- Introducing A New Food Grade Lubricant: 3H DirectDocument2 pagesIntroducing A New Food Grade Lubricant: 3H DirectjjgonzalezquinaNo ratings yet

- The Design and Properties of Steel CastingsDocument14 pagesThe Design and Properties of Steel CastingsCarlos Ortega JonesNo ratings yet

- Sebosan PFDocument3 pagesSebosan PFAlbertNo ratings yet

- Rubber Lining Material TypeDocument3 pagesRubber Lining Material TypeFitroh Abdul MalikNo ratings yet

- Microstructural Evolution and Change in Hardness in Type 304H Stainless Steel During Long-Term CreepDocument4 pagesMicrostructural Evolution and Change in Hardness in Type 304H Stainless Steel During Long-Term CreepOwais MalikNo ratings yet

- Applications of The Reflux Classifier On SA CoalsDocument24 pagesApplications of The Reflux Classifier On SA CoalsSenthilkumar PragasamNo ratings yet

- First Quarterly Examination Science 7Document3 pagesFirst Quarterly Examination Science 7Jorgen De Guzman-SalonNo ratings yet

- Alkene - Preparation - Physical PropertiesDocument8 pagesAlkene - Preparation - Physical Propertiesomanshtulsyan15No ratings yet

- Salt Analysis Chem Practical 2022-23 NewDocument7 pagesSalt Analysis Chem Practical 2022-23 Newanandmaurya871No ratings yet