Fiat52605 02

Fiat52605 02

Uploaded by

LucaCopyright:

Available Formats

Fiat52605 02

Fiat52605 02

Uploaded by

LucaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Fiat52605 02

Fiat52605 02

Uploaded by

LucaCopyright:

Available Formats

MATERIAL

STANDARD

PROPERTY CLASSES OF

SPECIAL SERVICE FASTENERS 52605/02

normazione Page: 1/6

Date: 02/23/2004

SUPERVISOR : RIGONI Sergio P.P.E. -- E.M.M. Ingegneria dei Materiali Tel. 35342

TMD

MANAGER : MURCHIO Lorenzo P.P.E. -- E.M.M. Ingegneria dei Materiali Tel. 32608

Code

A

Ch.

PURPOSE

To specify the characteristics and approved materials for property classes of special service

6

fasteners.

Edition

Change Date Description

--- --- 06/15/83 Edition 5 --- Property classes for R80 IND and 8 SD added; serrated flange

hexagon nuts provided in property class for R40 IND.

Approved material range widened. Layout changed. (AS)

A 01/02/83 Edition 5 --- Approved materials for R40 RCT and R50 RCT property classes

changed and note 11 added. (AS)

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES

B 06/25/85 Edition 5 --- Hardness for R40 SD property class changed (was HRB ≥ 79); new

approved materials for classes R50 SD STAB and R80 SD added. (AS) WITHOUT PRIOR WRITTEN CONSENT BY FIAT AUTO S.P.A. IN CASE OF DISPUTE

THE ONLY VALID REFERENCE IS THE ORIGINAL ITALIAN EDITION

C 11/09/87 Edition 5 --- Note 6 changed. (AS)

D May ’90 Edition 5 --- R50 SD property class approved material changed (was C40). (BM)

E Feb. ’92 Edition 5 --- Armonized with A.R. 3100.0120 and 9210.0105.

Para. 2: threaded hexagonal rivets added. (GF)

CONFIDENTIAL

--- --- 07/13/01 Edition 6 --- Fully revised. (DA)

A 02/23/04 Edition 6 --- Production method to R80 SD added . (FD)

ANY PRINTED COPY IS TO BE DEEMED AS UNCHECKED; THEREFORE THE UPDATED COPY MUST BE CHECKED IN THE APPROPRIATE WEB SITE

PUBLISHED BY SATIZ --- NORMAZIONE

Page 2

52605/02 Change

| § ‘‘A’’ : NECESSARY TESTING EQUIPMENT

The necessary testing equipment is the one specified in the Standards listed in § “B”.

| § ”B” : REFERENCES

|01307 | Pictorial representation, designation, and marking of threads, bolts, screws,

and nuts TFO

|01506 | ISO Metric V threads --- Coarse pitch series --- Nominal dimensions. TFO

|01507 | ISO Metric V threads --- Fine pitch series --- Nominal dimensions. TFO

|10143/02 | Hexagon high nuts for projection welding severe applications. TPM

|50140 | Ferrous material surface heat treatments case depth selection criteria and sur-

face characteristics. TMD

|52403 | Case hardening steels --- Carbon steel C 15. TMD

|52405 | Case hardening steels --- Carbon steel C 10. TMD

|52409 | Case hardening steels --- Nickel --- chrome steel 12 NC 3. TMD

|52419 | Case hardening steels --- Chrome --- nickel --- molybdenum 15 CND 3. TMD

|52431 | Case hardening steels --- Chrome steel 15 Cr 3. TMD

|52505 | Hardening and tempering steel --- Carbon steels C 30 --- C 40. TMD

|52518 | Hardening and tempering steel --- Chrome --- molybdenum 30 CD 4. TMD

|52542 | Hardening and tempering steel --- Chrome steel 32 Cr 4. TMD

|52605/01 | Standard application threaded fastener property classes. TMD

|52605/03 | Critical application fastener property classes. TMD

|52605/07 | Grade A2 and A3 stainless steel corrosion resistant fasteners. TMD

|52606 | Machining and free cutting steels. TMD

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES

WITHOUT PRIOR WRITTEN CONSENT BY FIAT AUTO S.P.A. IN CASE OF DISPUTE

|52610 | Non --- heat --- treatable heading and extrusion steels. TMD

|52611 | Cold heading and cold extrusion quality boron steels. Characteristics, require-

THE ONLY VALID REFERENCE IS THE ORIGINAL ITALIAN EDITION

ments and tests. TMD

|52891 | Hot rolled or drawn steels. General --- purpose constructional sheet, strip, wire,

bar, shapes and sections. TMD

|9.52605/01 | Threaded fasteners for standard or special applications. TMD

CONFIDENTIAL

|9.52605/03 | Threaded fasteners for severe applications. TMD

PUBLISHED BY SATIZ --- NORMAZIONE

Page 3

Change

52605/02

1

GENERAL

Fastener property classes covered in this standard are applicable to carbon or alloy screws and

nuts with diameter ≤ 39 mm when special properties such as weldability or surface hardness

higher than core hardness are required.

High strength screws and nuts for heavy --- duty application are excluded.

Mechanical properties are applicable at ambient temperature, while for a correct use of screws

or nuts of the various strength classes at temperatures different from ambient temperature,

between +300ûC and --- 50ûC, changes occurring in mechanical properties in relation to

temperature for each property class shall be taken into account, especially as regards

toughness at --- 20ûC to --- 50ûC.

--- For property classes of fasteners for Standard applications see Std. 52605/04.

--- For property classes of fasteners for severe applications, see Std. 52605/03.

--- For corrosion resistant fasteners see Std. 52605/07.

--- For low temperature, corrosion or heat resistant and/or thread diameter > 39 mm screws

and nuts, material and characteristics shall be specified on drawing.

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES

WITHOUT PRIOR WRITTEN CONSENT BY FIAT AUTO S.P.A. IN CASE OF DISPUTE

THE ONLY VALID REFERENCE IS THE ORIGINAL ITALIAN EDITION

CONFIDENTIAL

PUBLISHED BY SATIZ --- NORMAZIONE

Page 4

52605/02 Change

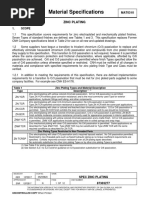

PROPERTY CLASSES

Mechanical properties in the as

supplied conditions ©

Property Property

class R Rs min. Hardness classes of

Application A screws to be

¡ on entire screws min. mated

core Surface

N/mm2 N/mm2 %

Parts to be cold---

R40 RCT 330 to 410 195 30 HRB 61 to 67 ---

riveted. ¢

E g : Rivets,

E.g.: Rivets

R50 RCT threaded hexag. 410 to 590 245 25 HRB 67 to 85 ---

rivets

Not very important

parts requiring

surface with

hardness greater HV 0.3

R40 IND HV ≥ 450

than core. ≥ 490 (295) --- ---

£ 150 to 390

E.g.: tapping ¤

screws and

serrated flange

hexagon nuts.

Medium---stressed

parts requiring

surface with

hardness greater HV HV 0.3

R50 IND ≥ 690 (490) --- ---

than core. E.g.: Set 215 to 420 ≥ 560

screws, link joints

and self---drilling

tapping screws.

Hv HV 0.3

Hexagon screws

260 to 336

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES

R80 IND with serrated ≥ 790 --- --- ≥ 450 ---

WITHOUT PRIOR WRITTEN CONSENT BY FIAT AUTO S.P.A. IN CASE OF DISPUTE

HRC

flange. ¤

24 to 34

THE ONLY VALID REFERENCE IS THE ORIGINAL ITALIAN EDITION

Projection welded

R40 SD ≥ 390 (295) --- HRB ≥ 65 5.8

nuts

HRB ≥ 89

R50 SD Arc welded nuts ≥ 650 (450) --- 8.8

HRC ≤ 20

CONFIDENTIAL

8.8

HV 190 to 320 R8

Projection welded

8 SD ¥ ≥ 650 (450) --- HRB ≥ 89 8R

nuts

HRC ≤ 32

¦

R50 SD Screws to be

welded, projection ≥ 390 (245) --- HRB ≥ 68 ---

STAB §

welded

Screws to be pro-

640 12 --- ---

jection welded

R80 SD 800 to HV 255 to 320

¨ 1000 HRC 23 to 32 10.9

Nuts to be projec-

(640) --- --- R10

tion welded

10R

For notes see Page 6

PUBLISHED BY SATIZ --- NORMAZIONE

Page 5

Change

52605/02

3

CORRELATIONS BETWEEN PROPERTY CLASSES AND APPROVED MATERIALS

Property Production Approved materials

Notes

classes method Code (F) Std.

FE 360 C

52891

Machining FE 360 D

R40 RCT C 10 52405

Stress relieving to be carried out

CB4FU KD after part forming at temperature

Cold heading 52610

CB4FF KD suitable to prevent grain growth.

FE 430 C For production by machining,

52891

Machining FE 430 D materials for cold and hot heading,g,

C 10 52405 of the same class, can also be

R50 RCT used

used.

Hot heading FE44C KB 52610

CB15FF KD

Cold heading 52610

CQ15FF KD

C 10 52405

Machining 9 SMNPB 28

52606 Hardening shall preferably be

R40 IND (:) 10 SPB 20

obtained by carbonitriding.

carbonitriding

CB4FF KD

Cold heading 52610

CB10FF KD

C 15 52403

Machining

g 12 NC 3 52409 ---

15 Cr 3 52431

R50 IND

CQ15FF KD Hardening shall preferably be

52610

Cold heading CB20FF KD obtained by carbonitriding.

12 NC 3 52409 ---

CB20FF KD 52610 Hardeningg of hexagon

g serrated

fl

flange screws shall

h ll b

be obtained

bt i d

15 Cr 3 52431

through carbonitriding with effective

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES

R80 IND Cold heading 15 CND 3 52419 thickness of

WITHOUT PRIOR WRITTEN CONSENT BY FIAT AUTO S.P.A. IN CASE OF DISPUTE

C16B KD 52611

0 10 + 0.05 mm

0.10 mm.

THE ONLY VALID REFERENCE IS THE ORIGINAL ITALIAN EDITION

C188 KD (J) --- 0

12 NC 3 52409

Machining

FE 510 D 52891

R40 SD ---

CB4FF KD

Cold heading 52610

CB10FF KD

CONFIDENTIAL

C30 52505

C33 52503

R50 SD Machining ---

32 Cr 4 52542

30 CD 4 52518

CB20FF KD 52610

8 SD Cold heading ---

12 NC 3 52409

Machining 12 NC 3 52409

R50 SD STAB CB4FF KD ---

Cold heading CB10FF KD 52610

CB20FF KD

C22B KD

Cold heading 52611 ---

R80 SD 22MN4B KD

Machining 28 Mn 6/8.8 53612

For notes see Page 6

PUBLISHED BY SATIZ --- NORMAZIONE

Page 6

52605/02 Change

NOTES

¡ For designations of classes see Std. 01307 --- ( ) Indicative values.

© Requirements for screws and nuts to be welded are mandatory also after welding.

¢ The threaded hexagonal rivets shall comply with the provisions of class 8 relating to test

load resistance as per Procurement Spec. 9.52605/01.

£ Serrated flange hexagon nuts shall meet the requirements of P.S. 9.52605/03 relating to

test load resistance with yield strength Rcp of 820 N/mm2 . For these nuts, a minimum core

hardness = HV 114 is allowed.

¤ Standard inspection is carried out by checking that parts are file hard (see Std. 50140).

¥ Nuts shall meet the requirements of P.S. 9.52605/03 relating to test load resistance with

yield strength Rcp of 780 N/mm2 for regular height nuts and 1000 N/mm2 for high nuts (Std.

10143/02).

¦ High nuts (Std. Sh. 10143/02) can be mated with screws with property class 10.9, R10 and

10R.

§ Any stabilizing treatment shall eliminate work --- hardening due to upsetting or drawing,

which might cause embrittlement during welding or brazing, but without reducing strength

to < 390 N/mm2 . To check for work hardening, screws shall be subjected to head bend test,

as per P.S. 9.52605/01 after heating to 600ûC approx.

¨ Screws shall be quenched and tempered. Total plus partial decarburization shall be ≤ 1/13

h3 on thread crest and ≤ 1/13 h3 on thread root.

(h3 = normal total thread height as per Stds. 01506 and 01507).

(F) For production method with machining, the corresponding lead --- content steels quoted in

the applicable Standards are allowed.

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES

WITHOUT PRIOR WRITTEN CONSENT BY FIAT AUTO S.P.A. IN CASE OF DISPUTE

(:) Serrated flange hexagon nuts shall be made of CB4FF KD and hardening obtained through

carbonitriding shall have an effective thickness of

THE ONLY VALID REFERENCE IS THE ORIGINAL ITALIAN EDITION

+ 0.05

0.10 mm

--- 0

(J) Steel C18B KD has a chemical composition equal to that of C16B KD except for carbon

whose limits are: 0.15 to 0.21%.

CONFIDENTIAL

PUBLISHED BY SATIZ --- NORMAZIONE

You might also like

- 18-1600 enDocument13 pages18-1600 enCaique de Oliveira100% (1)

- WSS M1a368 A14Document14 pagesWSS M1a368 A14nguyễn mạnhNo ratings yet

- WSS M1P87 BXDocument6 pagesWSS M1P87 BXShu Fu50% (2)

- TL 212 en 2021 06Document9 pagesTL 212 en 2021 06David DomokosNo ratings yet

- WSD M1a283 B37 B38 PDFDocument9 pagesWSD M1a283 B37 B38 PDF'Lampa'No ratings yet

- 52605-01 - 04-2011 - EngDocument12 pages52605-01 - 04-2011 - Enghkatzer100% (2)

- TSH7702GDocument8 pagesTSH7702GEmir AkçayNo ratings yet

- GMW 8-2008Document9 pagesGMW 8-2008Clauco Tiago Seno RoqueNo ratings yet

- General Dimensional Tolerance For Parts Formed by Press Working From Sheet MetalDocument2 pagesGeneral Dimensional Tolerance For Parts Formed by Press Working From Sheet MetalRicardo F.A.100% (3)

- Finish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019Document5 pagesFinish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019Josh100% (1)

- Nominal Sheet Steel Thicknesses and Thickness Tolerances: Worldwide Engineering StandardsDocument5 pagesNominal Sheet Steel Thicknesses and Thickness Tolerances: Worldwide Engineering StandardsMarcos FerreiraNo ratings yet

- JDM F20Document8 pagesJDM F20X800XL100% (1)

- NES M 2020 2009-N Cold Rolled C & Steel & StripsDocument13 pagesNES M 2020 2009-N Cold Rolled C & Steel & Stripssalvador hernandezNo ratings yet

- VW605 60Document6 pagesVW605 60Rudiney TrombettaNo ratings yet

- N67F CM-ZN-2 - 5001.110.016 - NormDocument22 pagesN67F CM-ZN-2 - 5001.110.016 - Normgokul100% (1)

- Product Industry Consumer Analysis - Steel: Suman Sourabh, Sudipto Sen Gupta, Goutham KrishnamurthyDocument28 pagesProduct Industry Consumer Analysis - Steel: Suman Sourabh, Sudipto Sen Gupta, Goutham KrishnamurthyGouthamKrishnamurthy100% (1)

- FCA - PS.50009 (2014) - Ex PS.5570Document7 pagesFCA - PS.50009 (2014) - Ex PS.5570FeliceNo ratings yet

- DBL 4023 2012-08Document7 pagesDBL 4023 2012-08Fernando MartínNo ratings yet

- CNH 87303277 N MP 12 eDocument12 pagesCNH 87303277 N MP 12 eYogesh100% (2)

- FORD WX200 Rev2014Document4 pagesFORD WX200 Rev2014Amandeep SinghNo ratings yet

- Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument2 pagesWorldwide Fastener Standard: Printed Copies Are UncontrolledRasatja Yongskulrote100% (1)

- Harmonized "Cluster" Document: For Electrical Connectors Conductive Plated CoatingsDocument22 pagesHarmonized "Cluster" Document: For Electrical Connectors Conductive Plated CoatingsFrederico CésarNo ratings yet

- Norma Fiat - 54316 Dimensões e ToleranciasDocument6 pagesNorma Fiat - 54316 Dimensões e ToleranciasRoberto Alves MoreiraNo ratings yet

- WX 100Document17 pagesWX 100anon_967426204100% (1)

- Hes A1301 14 Material Selection Reference of Steel NutsDocument6 pagesHes A1301 14 Material Selection Reference of Steel Nutshkatzer100% (1)

- No.29 MMC Standard-Zinc Electroplating Standard. MS82-3701Document7 pagesNo.29 MMC Standard-Zinc Electroplating Standard. MS82-3701Alejandro Tique100% (1)

- Ford Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument17 pagesFord Worldwide Fastener Standard: Printed Copies Are UncontrolledRico Malibiran100% (1)

- WV - TL245Document9 pagesWV - TL245Juan José Viñas MéndezNo ratings yet

- TSB1503G 9 P 1 PDFDocument18 pagesTSB1503G 9 P 1 PDFHatada Felipe100% (2)

- Jdma17 2Document8 pagesJdma17 2qualidadesider0% (1)

- 9.57405-Eng - Plating Std.Document20 pages9.57405-Eng - Plating Std.Baravkar Auto Parts100% (2)

- NES-M2032 - 2021 - (ColdRoll-High Tensile)Document13 pagesNES-M2032 - 2021 - (ColdRoll-High Tensile)dpfloresNo ratings yet

- Mpaps G-20Document6 pagesMpaps G-20PANKAJ CHAUHANNo ratings yet

- Ford Wa 960-2004Document1 pageFord Wa 960-2004DanielMa0% (1)

- Hes D3211-99a Mechnical Properties of Steel Bolts and ScreDocument12 pagesHes D3211-99a Mechnical Properties of Steel Bolts and ScrePreetam KumarNo ratings yet

- DBL 9440 2012-10 EnglishDocument12 pagesDBL 9440 2012-10 EnglishJoao Pedro SousaNo ratings yet

- VW 011 03Document22 pagesVW 011 03Alexandre UrquizaNo ratings yet

- VW01155 en 2005-02-01Document8 pagesVW01155 en 2005-02-01koalaboi0% (1)

- Technical Drawings: Commercial Vehicle EngineeringDocument14 pagesTechnical Drawings: Commercial Vehicle EngineeringAleks SenaNo ratings yet

- Material Specifications: Zinc PlatingDocument10 pagesMaterial Specifications: Zinc PlatingAntônio Rafael BatistaNo ratings yet

- Engineering Material Specification: Printed Copies Are UncontrolledDocument6 pagesEngineering Material Specification: Printed Copies Are UncontrolledRicardo VitorianoNo ratings yet

- DBL 9440 - 201912 - Englisch - Fasteners With Metric Thread Surface ProtectionDocument18 pagesDBL 9440 - 201912 - Englisch - Fasteners With Metric Thread Surface ProtectionEmir AkçayNo ratings yet

- JDM F17X3: Relationships Between Various John Deere Paint Performance Standards and QualificationsDocument8 pagesJDM F17X3: Relationships Between Various John Deere Paint Performance Standards and QualificationsX800XLNo ratings yet

- JDM F17 Pintura IJDDocument14 pagesJDM F17 Pintura IJDcharssx100% (3)

- VW - TL 217 - en - 01Document8 pagesVW - TL 217 - en - 01Gabriel MesquitaNo ratings yet

- JDM F11Document5 pagesJDM F11X800XLNo ratings yet

- JDM F0023 2014-04-08Document12 pagesJDM F0023 2014-04-08Emir AkçayNo ratings yet

- FCA - PS.50023 (2017) - Hidrogen EmbrittlementDocument10 pagesFCA - PS.50023 (2017) - Hidrogen EmbrittlementFeliceNo ratings yet

- Standard STD 121-0003Document9 pagesStandard STD 121-0003RobertoNo ratings yet

- GM Approved Finishers - ApplicatorsDocument3 pagesGM Approved Finishers - ApplicatorsScott Kramer0% (1)

- Standard: Normalisation Renault Automobiles Service 60201 Section Normes Et Cahiers Des ChargesDocument16 pagesStandard: Normalisation Renault Automobiles Service 60201 Section Normes Et Cahiers Des ChargesRicardo VitorianoNo ratings yet

- Wss-M1a367-A33, 37,38,44Document11 pagesWss-M1a367-A33, 37,38,44nguyễn mạnhNo ratings yet

- DBL 8451 2015-06enDocument16 pagesDBL 8451 2015-06enEmir AkçayNo ratings yet

- JDM A28: Specification For Fluid Line Tubing of Carbon and Low Alloy SteelsDocument4 pagesJDM A28: Specification For Fluid Line Tubing of Carbon and Low Alloy SteelsGANESH GNo ratings yet

- DWGB106Document6 pagesDWGB106LucaNo ratings yet

- Astm B850-98Document3 pagesAstm B850-98luiz.superv.valbracNo ratings yet

- Embrittlement Avoidance WSS-M99A3-A 1. Scope: Engineering Material SpecificationDocument5 pagesEmbrittlement Avoidance WSS-M99A3-A 1. Scope: Engineering Material SpecificationGustavo FelipeNo ratings yet

- E M5083 2016-NDocument7 pagesE M5083 2016-NPongsan57% (7)

- Fastener MaterialsDocument6 pagesFastener MaterialsJohn “JOHN” DonNo ratings yet

- RG-S-00-13A0-004 Spec for painting onshoreDocument33 pagesRG-S-00-13A0-004 Spec for painting onshoreManickam GanapathyNo ratings yet

- 699 50SP 0001 - 15Document145 pages699 50SP 0001 - 15b_m_leeNo ratings yet

- 54406-Dic-93 Dimensioni e Tolleranze Laminati A CaldoDocument6 pages54406-Dic-93 Dimensioni e Tolleranze Laminati A CaldoLucaNo ratings yet

- DWGB065Document3 pagesDWGB065LucaNo ratings yet

- CNH - 87354249 - National & International Standard PartsDocument156 pagesCNH - 87354249 - National & International Standard PartsLucaNo ratings yet

- MAT1001 MaterialiDocument37 pagesMAT1001 MaterialiLucaNo ratings yet

- STPF650 - (87307111) - SpacersDocument8 pagesSTPF650 - (87307111) - SpacersLucaNo ratings yet

- Norma 86620212 ENS0301Document10 pagesNorma 86620212 ENS0301LucaNo ratings yet

- Mat0310 (Zincatura)Document10 pagesMat0310 (Zincatura)LucaNo ratings yet

- Opss-Prov 906 - 2004 - Construction Specification For Structural Steel For BridgesDocument29 pagesOpss-Prov 906 - 2004 - Construction Specification For Structural Steel For BridgesPubcrawlNo ratings yet

- Principal Application Fields Case Hardening Steel:: Technical Card 16Mncr5Document1 pagePrincipal Application Fields Case Hardening Steel:: Technical Card 16Mncr5Bhuvnesh VermaNo ratings yet

- Detail Wall Thickness Calc. CorrosionDocument69 pagesDetail Wall Thickness Calc. Corrosionbagus handokoNo ratings yet

- Keckley Y StrainersDocument261 pagesKeckley Y StrainersthomasnafNo ratings yet

- Material Conversation TableDocument1 pageMaterial Conversation TableSerdar BıyıktaşNo ratings yet

- Articulo Junker PDFDocument11 pagesArticulo Junker PDFPrateek JoshiNo ratings yet

- Organization Study of Adishakthi Iron Castings PVT - LTD Inplant Training 2015Document56 pagesOrganization Study of Adishakthi Iron Castings PVT - LTD Inplant Training 2015shivakumar52No ratings yet

- FG52806 - 12-04-2010Document13 pagesFG52806 - 12-04-2010Roberto Carlos100% (1)

- Mechanical Properties For Stainless Steel FastenersDocument3 pagesMechanical Properties For Stainless Steel FastenersGonzalo MazaNo ratings yet

- Joy Reap Brochure-1Document4 pagesJoy Reap Brochure-1Alex TranNo ratings yet

- kippap-handout-sec-32-steel-design-weldsDocument9 pageskippap-handout-sec-32-steel-design-weldscee1123581321No ratings yet

- Growth Kinetics of Intermediate Phase Layers in An Early Stage of Hot Dip Galvanizing at 450C 2008 Journal of Materials ScienceDocument3 pagesGrowth Kinetics of Intermediate Phase Layers in An Early Stage of Hot Dip Galvanizing at 450C 2008 Journal of Materials SciencehvermesanNo ratings yet

- Repair Welding of A Rotating Electrical Machine's Broken ShaftDocument7 pagesRepair Welding of A Rotating Electrical Machine's Broken ShaftkanosriNo ratings yet

- Welding Summary Control Sheet - MASTER UP To 30-Aug-2019Document1,774 pagesWelding Summary Control Sheet - MASTER UP To 30-Aug-2019Anas PratamaNo ratings yet

- 127 Marsoflex Schlauchtechnik Ed PDFDocument1 page127 Marsoflex Schlauchtechnik Ed PDFMohamed ElmakkyNo ratings yet

- Roofing and Cladding Catalogue 2020Document163 pagesRoofing and Cladding Catalogue 2020q1w2e3r4t5y6u7i8oNo ratings yet

- (D-301) General Requirement in Equipment Installation - Rev.4 PDFDocument11 pages(D-301) General Requirement in Equipment Installation - Rev.4 PDFmihir_jha2No ratings yet

- Previous Standard Previous Steel Grade Current Steel Grade Current StandardDocument1 pagePrevious Standard Previous Steel Grade Current Steel Grade Current StandardakmlogaNo ratings yet

- Heat Treatment and Related Processes: AnnealingDocument24 pagesHeat Treatment and Related Processes: AnnealingmiteshNo ratings yet

- Visual Inspection Report-BaiturDocument5 pagesVisual Inspection Report-BaiturBlusukan negeri100% (1)

- 3 Way Electrical Control Valve: TYPE 7562EDocument13 pages3 Way Electrical Control Valve: TYPE 7562EAhmed EmamNo ratings yet

- AWS D1.1 (2020) - Essential Variable For WPS & WeldersDocument7 pagesAWS D1.1 (2020) - Essential Variable For WPS & WeldersFouad OudinaNo ratings yet

- Act 87-88 Esp - Data PDFDocument12 pagesAct 87-88 Esp - Data PDFnaraNJORNo ratings yet

- Manufacturing Industries next toppersDocument22 pagesManufacturing Industries next toppersdilipmahnarNo ratings yet

- DNV Bolts Failure Analisys Marine ApplicationDocument34 pagesDNV Bolts Failure Analisys Marine ApplicationBrian Chmeisse100% (2)

- Is.15369.2003 Vault RoomDocument14 pagesIs.15369.2003 Vault RoomTaraknath Pal100% (1)

- ASTM A29-16 Standard Specification For General Requirements For Steel Bars, Carbon and Alloy, Hot-WroughtDocument17 pagesASTM A29-16 Standard Specification For General Requirements For Steel Bars, Carbon and Alloy, Hot-WroughtMalaz Abdul JalilNo ratings yet

- Bekafix PostDocument5 pagesBekafix PostDoss MartinNo ratings yet

- Washerman in Madurai CityDocument20 pagesWasherman in Madurai CityS.Rengasamy100% (1)