DK013,00

DK013,00

Uploaded by

marceloCopyright:

Available Formats

DK013,00

DK013,00

Uploaded by

marceloCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

DK013,00

DK013,00

Uploaded by

marceloCopyright:

Available Formats

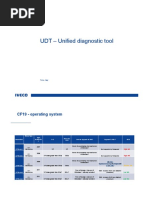

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

Check PCV for opening (PWM=0% --> no pressure)

Pressure Control Valve (PCV) stuck in close position,

Check wiring harness for electric power (short circuit) or Check wiring for metering unit for partial short

additional current through PCV due to electric problem in wiring,

Fuel pressure control Pressure control valve: Maximum rail pressure in limp circuit (current by-passes MeUn)

18 14 12000E Fuel pressure (Rail) control return flow tube from PCV clogged

home mode exceeded Check return tube from PCV to tank for clogging and Check 0-delivery valve of CP

Metering Unit (MeUn) stuck in full feeding position

Check metering Unit for 0-delivery (PWM=100% --> no delivery)

No electrical power to metering unit

Check return flow tube from zero delivery valve to tank for clogging

Fuel pressure control: Insufficient rail pressure, fuel injection release

18 31 12001F Fuel pressure Rail pressure insufficient to start the engine Check reason for insufficient rail pressure, tank empty,fuel filter clogged, pump problem or leakage

inhibited

Clean fuel filter

97 31 61001F Water in Fuel Determination: Water in Fuel Water in Fuel determination Water in fuel filter

Check Sensor measured value

Oil Pump control: Duty cycle above maximum limit expected for the

100 0 640000 Oil Lubricant Oil level low, oil leakages, oil pump wear or oil pressure sensor measurement incorrect Check oil level, check oil pressure measure, check system for leakage, check oil pump.

considered operating point

Oil pressure sensing: Diagnostic fault check for oil pressure below minimum

100 1 640001 Oil pressure sensing Low oil pressure or digital oil pressure switch blocked Check oil level and pressure, check oil pressure switch

limit

Sensor defective or wiring short circuit to external source

100 3 640003 Oil pressure sensing: SRC high for oil pressure sensor Oil pressure sensing Check wiring and connector continuity or replace sensor

Remark: Most ECU analog input pins are provided with a pullup resistor. In this case an open circuit

error will also be identified as an SRC Max error.

100 4 640004 Oil pressure sensing: SRC low for Oil pressure sensor Oil pressure sensing Sensor defective or short circuit to ground in the wiring Check wiring or replace sensor

Check oil level, check oil leakage, check wiring and the accuracy of Oil Pressure sensor and replace it if

100 18 640012 Oil Pressure Sensor: Physical signal below minimum limit Oil pressure sensing Oil pressure too low, or inaccurate or defective Oil Pressure sensor, or defect in its wiring

necessary

Short circuit of sensor to external source or defective sensor

102 3 660003 Boost pressure sensor: SRC High Air Intake pressure value Boost pressure Check wiring and connector continuity or replace sensor

Remark: Most ECU analog input pins are provided with a pullup resistor. In this case an open circuit

error will also be identified as an SRC Max error.

102 4 660004 Boost pressure sensor: SRC Low Air Intake pressure value Boost pressure Short circuit at wiring harness or inside the boost pressure sensor to ground or open circuit Check of wiring or replace boost pressure sensor

102 15 66000F Boost Pressure: Diagnostic Fault Check for High Plausibility error Boost pressure Inaccurate or defective boost pressure sensor, defect in the wiring Check wiring and the accuracy of the boost pressure sensor and replace it if necessary

102 17 660011 Boost Pressure: Diagnostic Fault Check for Low Plausibility error Boost pressure Inaccurate or defective boost pressure sensor, defect in the wiring Check wiring and the accuracy of the boost pressure sensor and replace it if necessary

Rev.00 Page 1 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

Implausible turbine speed variation, defective sensor

103 2 670002 Turbine speed sensor: Implausible speed variations Turbocharger speed sensor check wiring or replace sensor

Sticking turbine?

103 3 670003 Turbine speed sensor: SRC High fault path Turbocharger speed sensor Damaged Turbocharger or Turbine Speed sensor defective Check turbocharger, check wiring or replace sensor

103 4 670004 Turbine speed sensor: SRC low fault path Turbocharger speed sensor Damaged Turbocharger or Turbine Speed sensor defective Check turbocharger, check wiring or replace sensor

Signal connection from sensor to ECU is interrupted

103 8 670008 Turbine speed sensor: signal long period fault path Turbocharger control Check wiring, check sensor

Signal line has a short circuit to supply or ground.

Clogged air filter leading to low intake pressure and turbine overspeed, inadequate application of Check, clean or replace air filter, check application of speed evaluation, check for plausiblity of raw turbine

103 31 67001F Turbocharger Irreversible overspeed detection Turbocharger control

speed evaluation from raw signal, defective turbine speed sensor, sticking VGT speed signals (pulses), replace sensor, check VGT

Short circuit of sensor to external source or defective sensor

105 3 690003 Boost temperature: SRC high for air intake temperature Boost temperature Check wiring and connector continuity or replace sensor

Remark: Most ECU analog input pins are provided with a pullup resistor. In this case an open circuit

error will also be identified as an SRC Max error.

105 4 690004 Boost temperature: SRC low for air intake temperature Boost temperature Short circuit of sensor to ground or defective sensor Check wiring or replace sensor

Check cause for exceeding maximum allowed threshold (like environmental factors, system problem or

engine misuse).

105 16 690010 Boost temperature: Physical Signal above maximum limit Boost temperature Excessive boost temperature is measured

If threshold exceeding is implausible check wiring and the accuracy of the sensor and replace it if

necessary.

Check cause for value to fall below minimum allowed threshold (like environmental factors, system problem

or engine misuse).

105 18 690012 Boost temperature: Physical Signal below minimum limit Boost temperature Excessively low boost temperature is measured

If threshold exceeding is implausible check wiring and the accuracy of the sensor and replace it if

necessary.

107 15 6B000F Air FIlter Clogging first level warning Air FIlter Air filter is clogged Clean or replace air filter

107 16 6B0010 Air FIlter Clogging second level warning Air FIlter Air filter is clogged Clean or replace air filter

108 3 6C0003 Environmental pressure: Signal Range Check High Ambient pressure sensor Sensor defective or short circuit to external source If sensor is defective ECU must be replaced.

Rev.00 Page 2 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

108 4 6C0004 Environmental pressure: Signal Range Check Low Ambient pressure sensor Sensor defective or short circuit to ground If sensor is defective ECU must be replaced.

If the vehicle is not located at extremely low altitude (below sea level), check pressure sensor for

plausibility.

108 20 6C0014 Environmental pressure: Physical value implausibly high Ambient pressure sensor Enviornemantal pressure implausibly high

If sensor is defective ECU must be replaced.

If the vehicle is not located at extremely high altitude, check pressure sensor for plausibility

108 21 6C0015 Environmental pressure: Physical value implausibly low Ambient pressure sensor Enviornemantal pressure implausibly low

If sensor is defective ECU must be replaced.

110 0 6E0000 Info: Engine temperature exceeded warn level Info: Torque Limitation active Too high engine temperature Cooling system problem or simply overheated engine due to heavy use or high environmental temperature

Very cold ambient conditions and cabin heater(s) on full power (specially if additional heaters using

Ensure that engine was not running in extreme ambient conditions.

coolant temperature installed in the vehicle)

Check wiring and connectors (corrosion)

110 2 6E0002 Coolant temp sensor: defect fault check for Absolute plausibility test Coolant temp sensor Additional electrical resistance in the wiring (corroded connector)

Check accuracy of sensor, replacement of sensor

Inaccurate sensor (although sensor does not exceed its signal range)

Check Thermostat functionality

Engine thermostat blocked in open position

Check sensor

Engine Coolant Temperature: value not plausible compared to reference

110 7 6E0007 Coolant temp sensor Coolant temperature sensor drifted

temp sensor after long stand still time Remark: If the vehicle is provided of a blockheater (WEBASTO or similar) ghost failures may be detected.

The heater is not managed or recognised by Engine control unit

Plausibility check: One or more temperature sensors deviating from

110 11 6E000B Temperature Sensor One or more temperature sensors deviating from expected value (measured temperature too low) Check wiring, check sensors

expected value at cold start (measured temp.too low)

110 15 6E000F Info: Engine coolant temperature exceedingly high (1st detection) None Event detection, engine coolant temperature too high No intervention necessary

110 16 6E0010 Info: Engine temperature exceeded pre-warn level Info: Torque Limitation active Too high engine temperature Cooling system problem or simply overheated engine due to heavy use or high environmental temperature

Check cause for value to fall below minimum allowed threshold (like environmental factors, system problem

Engine Cooling Water Temperature Sensor: Physical Signal below or engine misuse).

110 18 6E0012 Coolant temp sensor Excessively low Coolant temperature is measured

minimum limit If threshold exceeding is implausible check wiring and the accuracy of the sensor and replace it if

necessary.

152 11 98000B External device triggered an ECU reset during normal ECU initialisation ECU Internal At least one external device using IO external library, required ECU reset due to internal errors Check connected external devices

152 31 98001F External device triggered an ECU reset during normal ECU driving ECU Internal At least one external device using IO external library, required ECU reset due to internal errors Check connected external devices

Rev.00 Page 3 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

Ensure correct wiring and proper functioning of rail pressure sensor,

Fuel pressure (Rail) sensor: offset rail pressure correction is below

157 1 9D0001 Fuel pressure (Rail) sensor Rail pressure sensor signal inaccurate

minimum value

Replace sensor if necessary and reset learning values in EEPROM / start New learning

Check wiring and connectors of Rail pressure sensor for good contacts.

157 2 9D0002 Fuel pressure (Rail) sensor: Rail pressure raw value is intermittent Fuel pressure (Rail) sensor Periodical loose of contact in the weiring, the connectors or sensor itself

Check sensor, replace sensor if necessary and reset learning values in EEPROM / start New learning

Check wiring and proper functioning of rail pressure sensor

157 4 9D0004 Fuel pressure (Rail) sensor: Sensor voltage below lower limit Fuel pressure (Rail) sensor Short circuit of wiring to ground or defective pressure sensor

Replace sensor if necessary and reset learning values in EEPROM / start New learning

Short circuit of wiring to external source or defective pressure sensor

Check wiring and connector continuity or replace sensor

157 11 9D000B Fuel pressure (Rail) sensor: Sensor voltage above upper limit Fuel pressure (Rail) sensor

Remark: Most ECU analog input pins are provided with a pullup resistor. In this case an open circuit

Replace sensor if necessary and reset learning values in EEPROM / start New learning

error will also be identified as an SRC Max error.

Fuel pressure (Rail) sensor: offset rail pressure check aborted due to CHeck reason for irregular ECU switch off (ECU supply cut, interrupted afterrun by operator or ECU supply

157 14 9D000E None Irregular ECU switch off was detected

irregular ECU switch OFF management)

157 16 9D0010 Rail Collective fault1 Positive detected Fuel pressure (Rail) control At least one error causing rail pressurepositive deviation was detected Check and repair source failure

Ensure correct wiring and proper functioning of rail pressure sensor,

Fuel pressure (Rail) sensor: rail pressure raw value is above maximum

157 20 9D0014 Fuel pressure (Rail) sensor Rail pressure sensor signal inaccurate

offset

Replace sensor if necessary and reset learning values in EEPROM / start New learning

Ensure correct wiring and proper functioning of rail pressure sensor, replace sensor

157 21 9D0015 Fuel pressure (Rail) sensor: rail pressure raw value is below minimum offset Fuel pressure (Rail) sensor Rail pressure sensor signal inaccurate

Replace sensor if necessary and reset learning values in EEPROM / start New learning

Battery voltage: Power stage diagnosis could be disabled due to high Power supply is to high --> possibly external power supply connected (battery charger??) or internal Check battery status and voltage level,Disconnect external device if connected or replace ECU if no supply

158 16 9E0010 Battery voltage

Battery voltage failure of ECU (wrong measurement of supply voltage) problem is found.

Battery voltage: Power stage diagnosis could be disabled due to low Battery Too low battery voltage, possible also during engine cranking (possibly in cold conditrion), too low Chech battery state (charge state). Check connectors and wiring harness to corrosion and/or too high

158 18 9E0012 Battery voltage

voltage measurement of battery voltage possibly due to corroded contacts or wiring harness electrical resistance

168 3 A80003 Battery voltage: SRC high for battery voltage sensor Battery voltage Alternator voltage governor defect Replace alternator governor device or alternator

Battery defect, alternator defect, wiring problems (too high resistance) or ECU defect. Occurrence

168 4 A80004 Battery voltage: SRC low for battery voltage sensor Battery voltage Replace battery or alternator. Check ECU and wiring.

possible during cold start.

Rev.00 Page 4 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

168 16 A80010 Battery voltage: SRC high for battery voltage sensor Battery voltage Alternator voltage governor defect, Battery defect, wiring defect or ECU defect. Check and replace if necessary battery, alternator, wiring or ECU.

Battery defect, alternator defect, wiring problems (too high resistance) or ECU defect. Occurence

168 18 A80012 Battery voltage: SRC low for battery voltage sensor Battery voltage Replace battery or alternator. Check ECU and wiring.

possible during cold start.

Selected Temperature sensor 3 delivering implausible value (check

171 2 AB0002 Temperature Sensor The temperature sensor is drifted Check temperature sensor

description for detail)

Sensor defective or short circuit in wiring to external source

Environmental Temperature sensor (in humidity sensor): SRC High for

171 3 AB0003 Ambient temperature sensor Check wiring and connector continuity or replace sensor

Environment Temperature Remark: Most ECU analog input pins are provided with a pullup resistor. In this case an open circuit

error will also be identified as an SRC Max error.

Environmental Temperature sensor (in humidity sensor): SRC low for

171 4 AB0004 Ambient temperature sensor Sensor defective or short circuit wiring to ground Check wiring or replace sensor

Environment Temperature

Selected Temperature sensor 1 delivering implausible value (check

172 2 AC0002 Temperature Sensor The temperature sensor is drifted Check temperature sensor

description for detail)

Sensor defective or short circuit to external source

Intake Manifold Air Temperature: Signal Range Check High for Temperature

172 3 AC0003 Intake Air Manifold Temperature Sensor Check wiring and connector continuity or replace sensor

sensor (Voltage High) Remark: Most ECU analog input pins are provided with a pullup resistor. In this case an open circuit

error will also be identified as an SRC Max error.

Sensor defective or short circuit to ground

Intake Manifold Air Temperature: Signal Range Check Low for Temperature

172 4 AC0004 Intake Air Manifold Temperature Sensor Check wiring or replace sensor

sensor (Voltage Low) Note: This failure can also be detected, if a very high boost temperature occured (> 350°C) e.g. due to

full flow of non cooled EGR or fire ....

Selected Temperature sensor 2 delivering implausible value (check

172 14 AC000E Temperature Sensor The temperature sensor is drifted Check temperature sensor

description for detail)

174 3 AE0003 Fuel Temp Sensor: SRC high for fuel temperature sensor Fuel Temp Sensor Sensor defective or short circuit to external source Check wiring or replace sensor

174 4 AE0004 Fuel Temp Sensor: SRC low for fuel temperature sensor Fuel Temp Sensor Sensor defective or short circuit to ground Check wiring or replace sensor

Check cause for exceeding maximum allowed threshold (like environmental factors, system problem or

engine misuse).

174 16 AE0010 Fuel Temperature Sensor: Physical Signal above maximum limit Fuel Temp Sensor Excessive Fuel temperature measured

If threshold exceeding is implausible check wiring and the accuracy of the sensor and replace it if

necessary.

Rev.00 Page 5 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

Sensor defective or wiring short circuit to external source

175 3 AF0003 Oil Temperature sensing: SRC High for Oil Temperature Oil Temperature sensing Check wiring and connector continuity or replace sensor

Remark: Most ECU analog input pins are provided with a pullup resistor. In this case an open circuit

error will also be identified as an SRC Max error.

175 4 AF0004 Oil Temperature sensing: SRC low for Oil Temperature Oil Temperature sensing Sensor defective or wiring short circuit to ground Check wiring or replace sensor

Check cause for exceeding maximum allowed threshold (like environmental factors, system problem or

engine misuse).

175 15 AF000F Oil Temperature sensing: Physical Signal above maximum limit Oil Temperature sensing Excessive measured Oil temperature

If threshold exceeding is implausible check wiring and the accuracy of the sensor and replace it if

necessary.

Check cause for exceeding maximum allowed threshold (like environmental factors, system problem or

engine misuse).

175 16 AF0010 Oil Temperature sensing: Oil temperature too high Oil Temperature sensing Measured oil temperature too high

If threshold exceeding is implausible check wiring and the accuracy of the sensor and replace it if

necessary.

Check cause for value to fall below minimum allowed threshold (like environmental factors, system problem

or engine misuse).

175 18 AF0012 Oil Temperature sensing: Physical Signal below minimum limit Oil Temperature sensing Excessively low measured Oil temperature

If threshold exceeding is implausible check wiring and the accuracy of the sensor and replace it if

necessary.

No reactions necessary only if this fault/information status reoccurs frequently. In this case check driving

190 0 BE0000 Engine Overspeed: Overspeed detection in component engine protection Engine Overspeed Engine overspeed has occurred conditions of vehicle, engine speed acquisition and injection system for quantity set point and actual value

during fault recognition, check also for ECM errors.

190 15 BE000F Info: Engine speed too high (3rdt detection) Engine Overspeed Event detection, engine speed too high No intervention necessary

354 4 620104 Intake Air humidity Sensor: SRC low for Induction Air Humidity Intake Air humidity Sensor Short circuit of wiring to ground or defective sensor Check wiring and sensor

354 16 620110 Induction Air Humidity Sensor: Physical signal above maximum limit Intake Air humidity Sensor Inaccurate or defective Induction Air Humidity sensor, or defect in its wiring Check wiring and the accuracy of Induction Air Humidity sensor and replace it if necessary

354 18 620112 Induction Air Humidity Sensor: Physical signal below minimum limit Intake Air humidity Sensor Inaccurate or defective Induction Air Humidity sensor, or defect in its wiring Check wiring and the accuracy of Induction Air Humidity sensor and replace it if necessary

NO action needed as long as the failure IndAHSRCMaxDly is not active.

354 31 62011F Info: Intake Air humidity Sensor: SRC high for Induction Air Humidity Intake Air humidity Sensor Sensor defective or short circuit to external source

If failure IndAHSRCMaxDly is not active, check duration of failure active: If a single duration lasts longer

than ~10 min --> there is probably an electrical failure. --> Check wiring or replace sensor

ECU internal: write access to non volatile memory failed for at least one

628 14 74020E ECU Internal ECU internal error If the error appears sporadically no intervention is needed, if persistent, ECU must be replaced

block

Rev.00 Page 6 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

ECU internal: read access to non volatile memory failed for at least one

628 31 74021F ECU Internal ECU internal error If the error appears sporadically no intervention is needed, if persistent, ECU must be replaced

block

Cam Shaft speed signal not stable:

Check wiring, sensor installation and proper functioning of camshaft phase sensor (evaluate raw signals)

- electrical intermittent open circuit

Check if sensor fixed correctly (should not be moveable),check wiring harness and contacts, check if

636 2 7C0202 Engine speed sensing: DFC for camshaft signal diagnosis - disturbed signal Engine speed sensing - sensor not fixed correctly

electrical lines with high electric performance are additionally installed (components not validated by the

- electrical disturbances due to damaged isolation of wiring harness

vehicle manufacturer).

- electrical disturbances due to special electrical features

Camshaft speed sensor defective Check if sensor mounted correctly

636 9 7C0209 Engine speed sensing: DFC for camshaft signal diagnosis - no signal Engine speed sensing Wiring harness "open circuit" Check wiring harness

Camshaft sensor not mounted Check sensor functionality and replace it if necessary

Camshaft sensor position deviates form crankshaft position:

- camshaft mal positioned (e.g. tooth belt: 1 tooth skipped)

636 31 7C021F Engine speed sensing: DFC for camshaft offset angle exceeded Engine speed sensing - camshaft position wheel mal positioned (if adjustable) Check correct positions of camshaft signal wheel and crankshaft signal wheel to piston position

- camshaft sensor position mal positioned (if adjustable)

- crankshaft signal mal positioned (same as camshaft)

Check if sensor fixed correctly (should not be moveable)

- High vibration of crank shaft signal sensor

Check wiring harness and contacts

- Intermittent open circuit of sensor

637 2 7D0202 Engine speed sensing: Crankshaft signal disturbance Engine speed sensing

- Electrical disturbances due to damaged isolation of wiring harness

Check if electrical lines with high electric performance are additionally installed (components not validated

- Electrical disturbances due external electromagnetic disturbances

by the vehicle manufacturer)

Crank shaft speed sensor defect Check if crank shaft speed sensor mounted correctly

637 9 7D0209 Engine speed sensing: Crankshaft signal loss Engine speed sensing Crank shaft speed sensor not mounted correctly Check wiring harness to open/short circuit

Crank shaft speed sensor not connected electrically, open circuit or short circuit. Check crank shaft speed sensor for correct function and replace it if necessary

641 14 81020E eVGT Actuator: Electrical failure detected Turbocharger control Defective eVGT actuator, electrical problem Check eVGT supply, wiring, replace actuator

641 16 810210 Turbine ovespeed defect recognition Turbocharger control It's possible a clogging of the air filter. Check the air filter, clean or replace it.

641 31 81021F eVGT Actuator: General error reported by actuator via CAN message Turbocharger control Defective eVGT Actuator, general error Check eVGT supply, wiring, replace actuator

651 3 8B0203 Injector: Short Circuit between High Side and Low Side for injector 1 Injector Short circuit between High-Side and Low−Side for injector 1 detected Check wiring and injector 1 for electrical problems

651 4 8B0204 Injector: Short Circuit at Low Side for injector 1 Injector Short circuit at Low−Side for injector 1 detected Check wiring and injector 1] for electrical problems

651 5 8B0205 Injector: Open load for injector 1 None Open load between Low−Side and High−Side for injector 1 detected Check wiring and injector 1 for electrical problems

Rev.00 Page 7 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

652 3 8C0203 Injector: Short Circuit between High Side and Low Side for injector 2 Injector Short circuit between High-Side and Low−Side for injector 2 detected Check wiring and injector 2 for electrical problems

652 4 8C0204 Injector: Short Circuit at Low Side for injector 2 Injector Short circuit at Low−Side for injector 2 detected Check wiring and injector 2] for electrical problems

652 5 8C0205 Injector: Open load for injector 2 None Open load between Low−Side and High−Side for injector 2 detected Check wiring and injector 2 for electrical problems

653 3 8D0203 Injector: Short Circuit between High Side and Low Side for injector 3 Injector Short circuit between High-Side and Low−Side for injector 3 detected Check wiring and injector 3 for electrical problems

653 4 8D0204 Injector: Short Circuit at Low Side for injector 3 Injector Short circuit at Low−Side for injector 3 detected Check wiring and injector 3] for electrical problems

653 5 8D0205 Injector: Open load for injector 3 None Open load between Low−Side and High−Side for injector 3 detected Check wiring and injector 3 for electrical problems

654 3 8E0203 Injector: Short Circuit between High Side and Low Side for injector 4 Injector Short circuit between High-Side and Low−Side for injector 4 detected Check wiring and injector 4 for electrical problems

654 4 8E0204 Injector: Short Circuit at Low Side for injector 4 Injector Short circuit at Low−Side for injector 4 detected Check wiring and injector 4] for electrical problems

654 5 8E0205 Injector: Open load for injector 4 None Open load between Low−Side and High−Side for injector 4 detected Check wiring and injector 4 for electrical problems

655 3 8F0203 Injector: Short Circuit between High Side and Low Side for injector 5 Injector Short circuit between High-Side and Low−Side for injector 5 detected Check wiring and injector 5 for electrical problems

655 4 8F0204 Injector: Short Circuit at Low Side for injector 5 Injector Short circuit at Low−Side for injector 5 detected Check wiring and injector 5] for electrical problems

655 5 8F0205 Injector: Open load for injector 5 None Open load between Low−Side and High−Side for injector 5 detected Check wiring and injector 5 for electrical problems

Rev.00 Page 8 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

656 3 900203 Injector: Short Circuit between High Side and Low Side for injector 6 Injector Short circuit between High-Side and Low−Side for injector 6 detected Check wiring and injector 6 for electrical problems

656 4 900204 Injector: Short Circuit at Low Side for injector 6 Injector Short circuit at Low−Side for injector 6 detected Check wiring and injector 6] for electrical problems

656 5 900205 Injector: Open load for injector 6 None Open load between Low−Side and High−Side for injector 6 detected Check wiring and injector 6 for electrical problems

677 3 A50203 Starter Relay HS: power stage output short circuit to battery Starter control Short circuit of wiring to external source or defective HS starter relay Check of wiring or replacement of HS relay

677 4 A50204 Starter Relay HS: power stage output short circuit to ground Starter control Short circuit of wiring to ground or defective HS starter relay Check of wiring or replacement of HS starter relay

729 3 D90203 Air heater: Short circuit to battery on power stage 0 Air heater Short circuit of wiring to external source or inside air heater Check of wiring, replace air heater

729 4 D90204 Air heater: Short circuit to ground error on power stage 0 Air heater Short circuit of wiring to ground or inside air heater Check of wiring, replace air heater

729 5 D90205 Air heater: Open load on Power stage 0 Air heater Broken or disconnected wiring or defective air heater Check of wiring or replace air heater

729 6 D90206 Air heater: Over temperature on Power stage 0 Air heater High battery voltage, high temperature inside ECU, high load or wiring problem Check load and output, check wiring, replace ECU

Check wiring for correct voltage supply of the connected sensor.Check connected sensors electrical

1043 15 13040F Monitoring of internal 12V supply SRC_HIGH Error ECU Voltage Supply Defect in wiring harness, electrical failure in connected sensors or in the ECM integrity.

Replace ECM.

Check wiring for correct voltage supply of the connected sensor.Check connected sensors electrical

1043 17 130411 Monitoring of internal 12V supply SRC_LOW Error ECU Voltage Supply Defect in wiring harness, electrical failure in connected sensors or in the ECM integrity.

Replace ECM.

Check wiring for correct voltage supply of the connected sensor.Check connected sensors electrical

1043 20 130414 Monitoring of 12V sensor supply 1 SRC_HIGH Error ECU Voltage Supply Defect in wiring harness, electrical failure in connected sensors or in the ECM integrity.

Replace ECM.

Rev.00 Page 9 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

Check wiring for correct voltage supply of the connected sensor.Check connected sensors electrical

1043 21 130415 Monitoring of 12V sensor supply 1 SRC_LOW Error ECU Voltage Supply Defect in wiring harness, electrical failure in connected sensors or in the ECM integrity.

Replace ECM.

ECU Internal: Diagnostic fault check to report the ECR (engine

1072 31 30041F ECU Internal ECM internal failure or calibration error. 0

decompression brake) release error

1073 31 31041F ECU Internal: Diagnostic fault check to report the engine brake release error ECU Internal ECM internal failure or calibration error. 0

ECU Internal: Diagnostic fault check to report the exhaust flap brake release

1074 31 32041F None ECM internal failure or calibration error. Replace ECU

error

ECU Internal: Diagnostic fault check to report the error due to injection

1116 31 5C041F ECU Internal ECU internal failure or calibration error. Contact Helpdesk

quantity correction

VGT actuator sticking, PCR control signal deviating (turbo speed? boost pressure? exhaust

1127 0 670400 Turbocharger control: Boost pressure value above highest threshold value Turbocharger control Check PCR control sensors, check VGT actuator

pressure?)

Check wiring and the accuracy of the temperature sensor and replace it if necessary (Sensor is ECU

1136 3 700403 ECU Temperature Sensor: Signal above maximum limit ECU Temperature sensing Inaccurate or defective temperature sensor, defect in the wiring

internal, only ECU replacement possible)

Check wiring and the accuracy of the temperature sensor and replace it if necessary (Sensor is ECU

1136 4 700404 Diagnostic Fault Check for Signal below minimum limit ECU Temperature sensing Inaccurate or defective temperature sensor, defect in the wiring

internal, only ECU replacement possible)

1136 6 700406 ECU Temperature Sensor: Short circuit to battery (ECU internal error) ECU Temperature sensing ECU internal error ECU should be replaced

Check cause for exceeding maximum allowed threshold (like environmental factors)

ECU Temperature Sensor: Physical Signal ECU Temperature first sensor

1136 16 700410 ECU Temperature sensing Excessive ECU temperature measured Check wiring and the accuracy of the temperature sensor and replace it if necessary (Sensor is ECU

above maximum limit

internal, only ECU replacement possible)

Check cause for value to fall below minimum allowed threshold (like environmental factors)

ECU Temperature Sensor: Physical Signal ECU Temperature first sensor

1136 18 700412 ECU Temperature sensing Excessively low ECU temperature measured Check wiring and the accuracy of the temperature sensor and replace it if necessary (Sensor is ECU

below minimum limit

internal, only ECU replacement possible)

Wrong configuration of CAN timing (Prescaler, synchronization jump width, sampling, propagation Check timing configuration with hardware compatibility, check termination resistors and network connection

1231 11 CF040B CAN Bus: Error CAN Bus Node 1 CAN Bus and phase segments), bad termination resistors, defective network connection and contacts or and contacts. Short circuits to external source, ground or CAN High to Low.Monitor CAN communication for

defective CAN controller with erroneous messages. erroneous behaviour of a participant.

Rev.00 Page 10 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

Wrong configuration of CAN timing (Prescaler, synchronization jump width, sampling, propagation

Check timing configuration with hardware compatibility, check termination resistors and network connection

and phase segments), bad termination resistors, defective network connection and contacts or

and contacts. Short circuits to external source, ground or CAN High to Low.Monitor CAN communication for

1235 11 D3040B CAN Bus: Error CAN Bus Node 2 CAN Bus defective CAN controller with erroneous messages.

erroneous behaviour of a participant.

Power/ground fault originating from the ATS relay. CAN network not able to send messages due to a

Check for power, continutiy, and short circuit conditions at ATS relay and associated wiring.

no power condition.

Wrong configuration of CAN timing (Prescaler, synchronization jump width, sampling, propagation

Check timing configuration with hardware compatibility, check termination resistors and network connection

and phase segments), bad termination resistors, defective network connection and contacts or

and contacts. Short circuits to external source, ground or CAN High to Low.Monitor CAN communication for

1235 31 D3041F CAN Bus: Error passive CAN Bus Node 2 CAN Bus defective CAN controller with erroneous messages.

erroneous behaviour of a participant.

Power/ground fault originating from the ATS relay. CAN network not able to send messages due to a

Check for power, continutiy, and short circuit conditions at ATS relay and associated wiring.

no power condition.

Check low pressure system for clogging (specially fuel filter)

Leakage in the high pressure system:

Che tubing between presupply and gear pump

low efficiency of high pressure pump, internal leakage of injector, leaking pressure control valve

1240 11 D8040B Fuel pressure control Metering unit: Leakage in overrun Fuel pressure control Metering unit Check feeding of presupply pump (possibly low due to clogged tubes at tank outlet)

Too low pressure at High pressure pump inlet due clogged filter, leaking low pressure tubes, electric

Check hgih pressure part for leakages (internal / external)

presupply pump defective or gear pump defective

Check High pressur pump for efficiency

Check low pressure system for clogging (specially fuel filter)

Leakage in the high pressure system:

Che tubing between presupply and gear pump

injection nozzle stuck in open position, low efficiency of high pressure pump, internal leakage of

Fuel pressure control Metering unit: Leakage in high pressure system Check feeding of presupply pump (possibly low due to clogged tubes at tank outlet)

1240 14 D8040E Fuel pressure control Metering unit injector, leaking pressure control valve

detected at idle Check hgih pressure part for leakages (internal / external)

Too low pressure at High pressure pump inlet due clogged filter, leaking low pressure tubes, electric

Check High pressur pump for efficiency

presupply pump defective or gear pump defective

Check injectors for tightness

External leakage in the high pressure or low pressure system. Check if system has no external leakage

Fuel pressure sensor signal shows wrong (mainly too low) values. Check if fuel pressure sensor signal is correct

1240 31 D8041F Fuel pressure (Rail) control: Leakage in high pressure system Fuel pressure (Rail) control Injectors leak internally (do not close) Check if injectors close well

High pressure pump has too low feeding efficiency Check High pressure pump delivery

Restriction in fuel supply Check fuel supply line and check for clogged filter

1321 3 290503 Starter Relay LS: power stage output short circuit to battery. Starter control Short circuit of wiring to external source or defective LS starter relay Check of wiring or replacement of LS starter relay

1321 4 290504 Starter Relay LS: Power stage output short circuit to ground Starter control Short circuit of wiring to ground or defective LS starter relay Check of wiring or replacement of LS starter relay

1321 5 290505 Starter Relay LS: power stage output No Load error Starter control Broken or disconnected wiring or defective LS starter relay Check of wiring or replacement of LS starter relay

1321 6 290506 Starter Relay LS: power stage output over temperature error Starter control High battery voltage, high temperature inside ECU, high load or wiring problem Check battery voltage, wiring, power stage and LS starter relay

Check metering Unit (MeUn), if closing (PWM = 100%)

Metering unit stuck in open position, zero-delivery throttle clogged, metering unit without power due to

Fuel pressure control Metering unit: Fuel Rail pressure above maximum Check electric wiring to MeUn

1442 0 A20500 Fuel pressure control Metering unit electrical error.

limit with MeUn Control Check low pressure fuel tubes (return from CP to tank free?)

Low pressure side: pressure after zero-delivery throttle too high (Pump backflow pressure too high)

Check zero delivery valve for correct working

Bad Contacts on Connector Check Connector

Fuel metering unit: Error check for loose contact between metering unit

1442 2 A20502 Fuel metering unit "Broken" wiring harness or Insulation (--> short circuits) Check Wiring Harness

(MeUn) and ECU

Defective Metering Unit (MeUn) Check Metering unit (MeUn)

1. Replace main relay (sticky contacts)

1485 7 CD0507 Main Relay sticking None Sticky Main Relay

2. Delete stored faults in failure memory

Rev.00 Page 11 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

1624 19 58061F Vehicle speed sensor: Vehicle speed signal via CAN defective Vehicle speed sensor Defective or incorrect functioning of vehicle speed measuring device Check speed measuring device for proper functioning

1. Erase Level 2/3 error from fault code memory.

2. Operate vehicle for a short distance - e.g. few kilometers; if diagnosable checking the operation point in

ECU Internal: Diagnostic fault check to report "WDA active" due to errors in The procedure is independent from Level 1 errors which may have been entered in parallel, e.g. by which the error entry was set.

1648 12 70060C ECU Internal

query-/response communication Level 1 functions similar to the one causing the Level 2/3 entry due to functional dependencies. 3. a) If Level 2/3 error does not reappear: do not replace ECU, but erasure of fault code memory is

sufficient.

3. b) If Level 2/3 error does reappear: replace ECU.

1675 31 8B061F ECU Key 16: Defective T50 switch ECU Key 16 Too long cranking request, short circuit in ignition key module or in wiring Check ignition key module and wiring

1761 1 E10601 SCR Reagent Tank Level: Empty Urea Tank SCR Reagent Tank Level Tank is empty Refill Urea tank

1761 3 E10603 SCR Reagent Tank Level Sensor: Signal above maximum limit. SCR Reagent Tank Level Reduction agent level in the tank sensor defective or short circuit to battery Check wiring or replace sensor

1761 4 E10604 SCR Reagent Tank Level Sensor: Signal below minimum limit. SCR Reagent Tank Level Reduction agent level in the tank sensor defective or short circuit to ground Check wiring or replace sensor

1761 14 E1060E Urea Tank Level: system error SCR Reagent Tank Level Urea tank level sensor reports a system error Replace sensor

Info: SCR reagent tank level below first warning level, DFC for triggering

1761 17 E10611 SCR Reagent Tank Level Reducing agent tank level below first warning level Refill reducing agent tank

warning action dependent on filling level of reducing agent

Info: SCR reagent tank level below second warning level, DFC for triggering

1761 18 E10612 SCR Reagent Tank Level Reducing agent tank level below low second warning level Refill reducing agent tank

warning action dependent on filling level of reducing agent

1761 19 E10613 Diagnostic fault check for signal error from CAN SCR Reagent Level Sensing Urea tank level sensor sending an error message Urea tank level sensor defective, replace it.

Selected Temperature sensor 4 delivering implausible value (check

2630 2 460A02 Temperature Sensor The temperature sensor is drifted Check temperature sensor

description for detail)

2797 1 ED0A01 Injector: Booster voltage too low Injector Diagnosis threshold of the booster voltage is not reached. Replace ECU

Rev.00 Page 12 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

2797 4 ED0A04 Injector: Short circuit of the HDEV power stage high−side (first bank error) Injector Short circuit at High−Side on one or more injectors of First Bank Check wiring and injectos of First Bank

Injector: Number of injections is limited by electrical load balance of the

2797 31 ED0A1F Injector Application of number of requested injections not compatible with system capability 0

booster capacitor

Injector: Short circuit of the HDEV power stage high−side (second bank

2798 4 EE0A04 Injector Short circuit at High−Side on one or more injectors of Second Bank Check wiring and injectos of Second Bank

error)

SCR Reagent Tank Temperature sensing: SRC high for Urea temperature SCR Reagent Tank Temperature

3031 3 D70B03 Sensor defective or short circuit in wiring to external source Check wiring or replace sensor

sensor sensing

SCR Reagent Tank Temperature sensing: SRC low for Urea temperature SCR Reagent Tank Temperature

3031 4 D70B04 Short circuit of sensor to battery or defective sensor Check wiring or replace sensor

sensor sensing

Check tank temperature sensor, check tank heater valve

Tank overheated: tank temperature sensor measures implausible values or tank heater valve

3031 6 D70B06 Urea Tank temperature: overheating of the AdBlue tank SCR Tank heater

permanently open

Check coolant lines assignment on tank heater valve for correct assembly (lines not mixed up)

3031 11 D70B0B Urea Tank Temperature: system error SCR Temp Sensing Urea tank temperature sensor reports a system error Replace sensor

SCR Reagent Tank Temperature

3031 19 D70B13 SCR Reagent Tank Temperature sensing: Signal error for CAN message Urea tank temperature sensor defective Check sensor and replace it if necessary

sensing

UREA Tank Temperature: Tank temperature sensor plausibility check failed

3031 20 D70B14 SCR Temp Sensing Urea Tank temperature sensor drifted Check sensor connector, wiring and sensor measured value

(> max drift)

UREA Tank Temperature: Tank temperature sensor plausibility check failed

3031 21 D70B15 SCR Temp Sensing Urea Tank temperature sensor drifted Check sensor connector, wiring and sensor measured value

(< min drift)

3064 7 F80B07 DPF model plausibility: Diagnostic fault check for damaged particulate filter DPF model plausibility Cracked or dismounted particulate filter Check if black smoke is visible at exhaust pipe.

Short Circuit or Open wire in Sensor internal wiring harness

3216 2 900C02 NOx Upstream Sensor (CAN): Nox Concentration invalid NOx Sensor (CAN) Replace NOx Upstream Sensor

Defective NOx Upstream Sensor

Rev.00 Page 13 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

3216 14 900C0E NOx Upstream Sensor: Sensor Implausible Upstream NOx Sensing NOx upstream sensor measurement deviation Check and replace NOx upstream sensor

3216 31 900C1F NOx Upstream Sensor (CAN): NOx Sensor detects incorrect supply NOx Sensor (CAN) Defective NOx upstream sensor supply Check wiring harness, vehicle supply voltage. If failure is still peresent replace the NOx upstream sensor

3222 12 960C06 NOx Upstream Sensor (CAN): Sensor Heater performance insufficient NOx Sensor (CAN) NOx upstream sensor heater efficiency decreased Check wiring/supply, replace NOx upstream sensor.

Wiring defect

3223 5 970C05 CAN NOx Upstream Sensor: Open Circuit Error for NOx Upstream Sensor CAN NOx Sensor Internal NOx upstream sensor wiring defect, replace sensor.

NOx upstream sensor defect

Wiring defect

3223 6 970C06 CAN NOx Upstream Sensor: Short Circuit Error for NOx Upstream Sensor CAN NOx Sensor Internal NOx upstream sensor wiring defect, replace sensor.

NOx upstream sensor defect

NOx upstream Sensor: Lambda value measurement from NOx upstream NOx sensors upstream is measuring lambda value different from modelled expected value or air/fuel Check correct mounting of NOx upstream sensor, check system for presence other faults involving fuelling

3224 2 980C02 NOx Sensing

sensor incorrect quantity estimation is incorrect. or air quantity determination, replace Nox upstream sensor

Wiring defect

3224 5 980C05 NOx Upstream Sensor (CAN): Open Wire error detected by sensor NOx Sensor (CAN) Internal NOx Upstream Sensor wiring defect, replace sensor.

NOx Upstream Sensor defect

Wiring defect

3224 6 980C06 NOx Upstream Sensor (CAN): Short circuit error detected by sensor NOx Sensor (CAN) Internal NOx Upstream Sensor wiring defect, replace sensor.

NOx Upstream Sensor defect

3226 10 9A0C0A NOx Downstream Sensor: measured value stuck NOx Sensing NOx Downstream Sensor defective or incorrectly mounted Check sensor mounting, replace NOx Downstream Sensor

3226 31 9A0C1F NOx Downstream Sensor (CAN): NOx Sensor detects incorrect supply NOx Sensor (CAN) Defective NOx Downstream Sensor supply Check wiring harness, vehicle supply voltage. If failure is still present replace the NOx Downstream Sensor

Wiring defect

3232 5 A00C05 CAN NOx Downstream Sensor: Open Circuit Error for Nox Sensor CAN NOx Sensor Internal NOx downstream Sensor wiring defect, replace sensor.

NOx downstream Sensor defect

Wiring harness has short circuit

3232 6 A00C06 CAN NOx Downstream Sensor: Short Circuit Error for Nox Sensor CAN NOx Sensor Internal NOx downstream Sensor wiring defect, replace sensor.

NOx downstream Sensor defect

Rev.00 Page 14 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

3232 12 A00C0C NOx Downstream Sensor (CAN): Sensor Heater performance insufficient NOx Sensor (CAN) NOx downstream sensor heater efficiency decreased Check wiring/supply, replace NOx downstream sensor

3234 2 A20C02 NOx Sensor: Lambda value measurement from NOx sensor incorrect NOx Sensing NOx sensors downstream is measuring lambda value different from Lambda modelled value Check NOx sensor, check system for presence other faults involving fuelling or air quantity determination.

Wiring defect

3234 5 A20C05 NOx Downstream Sensor (CAN): Open circuit error detected by sensor NOx Sensor (CAN) Internal NOx downstream Sensor wiring defect, replace sensor.

NOx downstream Sensor defect

Wiring defect

3234 6 A20C06 NOx Downstream Sensor (CAN): Short circuit error detected by sensor NOx Sensor (CAN) Internal NOx Downstream Sensor wiring defect, replace sensor.

NOx Downstream Sensor defect

Note: Fast ambient temperature change, e.g. vehicle exposed to sun shine after very cold night, or if the

sensor is in a "warm air stream" (e.g. by additional engines like a cooling compressor for a cold

Exhaust Temperature monitoring 3: deviation from other sensors at cold

3242 14 AA0C0E Exhaust Temp monitoring Exhaust Temperature before SCR Catalyst measures wrong values compartment which runs also during vehicle stand still, or an external source like a "exhaust stream" of a

start (check description for details)

builidng climatisation) can cause this failure, if the ambient of this sensor is not equal to the "normal"

ambient! --> in this case no action needed!. Check wiring and connectors and replace sensor if necessary

Check wiring and connectors for correct isolation / contact

Check sensor and replace it, if necessary

Exhaust Temperature monitoring 2: Measured value deviating from Bad electrical wiring (e.g. corroded connector or damaged isolation of wire) or gain offset of sensor for

3242 31 AA0C1F Exhaust Temp monitoring Note: failure can also be caused, if the real exhaust temperature differes from the calculated one due to a

modelled temperature (check description for details) Exhaust Temperature after Oxidation Catalyst measures wrong values

failure in the engine like wrong injection pressure, wrong injection begin, wrong EGR rate. Therefore check

also the engine system, if the failure can not be repaired easily.

3251 2 B30C02 DPF pressure monitoring: Fault check for the pressure sensor plausibility DPF pressure monitoring Differential pressure sensor is inaccurate. Check accuracy of differential pressure sensor.

Short circuit of wiring to external source or defective sensor

3251 3 B30C03 DPF differential pressure sensor: SRC value above maximum limit DPF pressure sensing Check wiring and connector continuity or replace sensor

Remark: Most ECU analog input pins are provided with a pullup resistor. In this case an open circuit

error will also be identified as an SRC Max error.

3251 4 B30C04 DPF differential pressure sensor: SRC value below minimum limit DPF pressure sensing Short circuit of wiring to ground or defective sensor Check wiring or replace sensor

3251 11 B30C0B DPF filter differential pressure sensor: Digital Signal Processor DSP fault DPF pressure monitoring Sensor internal error Replace sensor

3251 12 B30C0C DPF filter differential pressure sensor: sensor reports an internal fault DPF pressure sensing Sesnor defective Replace sensor

DPF filter differential pressure sensor: measured data invalid (secure check

3251 14 B30C0E DPF pressure sensing Sensor internal fault Replace sensor

failed)

Rev.00 Page 15 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

Check filter for proper installation and function.

DPF pressure monitoring: Differential pressure over DPF higher then

3251 15 B30C0F DPF pressure monitoring Filter is clogged or not installed correctly (exhaust flow restricted) If foreseen perform service regeneration or parking regeneration (if functionality available) or replace filter

expected

(depending on troubleshooting instructions project specific)

Check filter for proper installation and function.

Perform service regeneration and reset soot oveload error using UDS Routine control $0300

3251 16 B30C10 Differential pressure over particulate filter value above maximum threshold DPF pressure monitoring Filter is clogged or not installed correctly (exhaust flow restricted) Remark: Parking regeneration cannot be started.

For Muffler versions where dP sensor is measuring difference over OxiCat + DPF+AdBlue mixer, clogging

should be considered also for all the parts involved (i.e. urea cristallization)

DPF filter differential pressure sensor: counter for frame receive error above

3251 19 B30C13 DPF pressure sensing Sensor internal error Replace sensor

maximum limit

3251 31 B30C1F DPF filter differential pressure sensor: sensor reports internal failure DPF pressure sensing Sensor internal fault Replace sensor

DPF filter differential pressure sensor: sensor reporting SRC high

3285 3 D50C03 DPF pressure monitoring Measured pressure too high, sensor piping interchanged? Check correct piping install, check compatibility of sensor with measured pressure range

information

3285 4 D50C04 DPF filter differential pressure sensor: sensor reporting SRC low information DPF pressure monitoring Measured pressure too low Check correct piping install, check compatibility of sensor with measured pressure range

3285 5 D50C05 DPF filter differential pressure sensor: sensor reporting underr voltage error DPF pressure sensing Sensor supply too low Check wiring (integrity, resistance)

3285 6 D50C06 DPF filter differential pressure sensor: sensor reporting over voltage error DPF pressure sensing Sensor supply to high Check wiring (integrity, resistance)

3361 7 210D07 SCR monitoring: Clogged filter detected SCR Reagent Feeding Urea filter clogged Replace filter

Communication problem between ECU and Supply Module Check wiring harness and electrical connections

Supply Module Temperature signal not correct: Time period outside

3361 8 210D08 SCR Supply Module

specified range

Wiring harness defective If no problem found on wiring harness or connectors, replace Supply Module

Communication problem between ECU and Supply Module Check wiring harness and electrical connections

Supply Module Temperature signal: Synchronisation (Sync) signal not

3361 14 210D0E SCR Supply Module

correct

Wiring harness defective If no problem found on wiring harness or connectors, replace Supply Module

Verify that the dataset is matching to the Supply Module type used on the machine

Communication problem between ECU and Supply Module

3361 31 210D1F Supply Module Temperature not available SCR Supply Module Check wiring harness and electrical connections

Wiring harness defective

If no problem found on wiring harness or connectors, replace Supply Module

Rev.00 Page 16 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

Check system for leakages.

3362 7 220D07 SCR monitoring: Leakage detection during phase without dosing SCR Control SCR System leakage or dosing valve untight

Execute an Urea-Dosing-System-Test (UDST) and follow the UDST-Trouble-Shooting Guideline to repair

the failure

Wiring harness defective Check wiring harness and electrical connections

SCR Reagent Heating: Short circuit to battery error of Urea Tank Heater

3363 3 230D03 SCR Tank heater

Valve

Defective Urea Tank Heater Valve If no problem found on wiring harness or connectors, replace Urea Tank Heater Valve

Wiring harness defective Check wiring harness and electrical connections

SCR Reagent Heating: Short circuit to ground error of Urea Tank Heater

3363 4 230D04 SCR Tank heater

Valve

Defective Urea Tank Heater Valve If no problem found on wiring harness or connectors, replace Urea Tank Heater Valve

Urea Tank Heater Valve not connected at K15-ON

Check wiring harness and electrical connections

3363 5 230D05 SCR Reagent Heating: Open Load error of Urea Tank Heater Valve SCR Tank heater Wiring harness defective

If no problem found on wiring harness or connectors, replace Urea Tank Heater Valve

Defective Urea Tank Heater Valve

Check wiring harness and electrical connections

High temperature inside ECU, caused by

3363 6 230D06 SCR Reagent Heating: Over Temperature error of Urea Tank Heater Valve SCR Tank heater

high battery voltage, high load or problem on wiring harness or connectors

If no problem found on wiring harness or connectors, replace Urea Tank Heater Valve

Tank Heater Valve defective

Check Tank Heater Valve function

3363 12 230D0C SCR Tank heater: Urea tank heating insufficient SCR Tank heater Wiring harness defective

Check coolant lines assignment on Tank Heater Valve for correct assembly (lines not mixed up)

Coolant lines on Tank Heater Valve mixed up

3364 5 240D05 UREA Quality Sensor: Short Circuit to Ground Error (quality signal) SCR Reagent Quality Short Circuit to Ground error of quality sensor (property signal) If the error is frequent or permanent replace sensor

3364 6 240D06 UREA Quality Sensor: Short Circuit to Battery Error (quality signal) SCR Reagent Quality Short Circuit to Battery error of quality sensor (property signal) If the error is frequent or permanent replace sensor

3364 18 240D12 Urea quality: concentration low (time based evaluation) SCR Reagent Quality DEF with too low concentration detected Check DEF in the tank, replace it if non conform fluid is present

3507 3 B30D03 Short circuit to battery error at high side actuator relay with index x = 2 Actuator Relay (ECU Internal) Short circuit of wiring to external source or inside connected actuator Check of wiring or replacement of connected actuator

3507 4 B30D04 Short circuit to ground error at high side actuator relay with index x = 0 Actuator Relay (ECU Internal) Short circuit of wiring to ground or inside connected actuator Check of wiring or replacement of connected actuator

3507 6 B30D06 Short circuit to ground error at high side actuator relay with index x = 2 Actuator Relay (ECU Internal) Short circuit of wiring to ground or inside connected actuator Check of wiring or replacement of connected actuator

Rev.00 Page 17 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

3507 14 B30D0E Short circuit to ground error at high side actuator relay with index x = 1 Actuator Relay (ECU Internal) Short circuit of wiring to ground or inside connected actuator Check of wiring or replacement of connected actuator

3507 31 B30D1F Short circuit to battery error at high side actuator relay with index x = 3 Actuator Relay (ECU Internal) Short circuit of wiring to external source or inside connected actuator Check of wiring or replacement of connected actuator

3508 14 B40D0E Short circuit to battery error at high side actuator relay with index x = 0 Actuator Relay (ECU Internal) Short circuit of wiring to external source or inside connected actuator Check of wiring or replacement of connected actuator

3508 31 B40D1F Short circuit to battery error at high side actuator relay with index x = 1 Actuator Relay (ECU Internal) Short circuit of wiring to external source or inside connected actuator Check of wiring or replacement of connected actuator

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3509 3 B50D03 ECU Power Stage 1: Overvoltage failure at sensor supply 1 ECU Power Stage 1

ECM Replace ECM

Check wiring of the connected sensor and the ECM.

3509 4 B50DB4 ECU Power Stage 1: Short Circuit to Ground failure at sensor supply 1 ECU Power Stage 1 Defect in wiring harness, electrical failure in connected sensors or in the ECM

Replace ECM

Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3509 5 B50D05 ECU Power Stage 1: Undervoltage failure at sensor supply 1 ECU Power Stage 1 Low battery voltage, defect in wiring harness, electrical failure in connected sensors or in the ECM

Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3509 6 B50D06 ECU Power Stage 1: Overtemperature failure at sensor supply 1 ECU Power Stage 1

ECM Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3509 12 B50D0C ECU Power Stage 1: Error Sensor supply for sensors ECU Power Stage 1

ECM Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3510 3 B60D03 ECU Power Stage 2: Overvoltage failure at sensor supply 2 ECU Power Stage 2

ECM Replace ECM

Check wiring of the connected sensor and the ECM.

3510 4 B60D04 ECU Power Stage 2: Short Circuit to Ground failure at sensor supply 2 ECU Power Stage 2 Defect in wiring harness, electrical failure in connected sensors or in the ECM

Replace ECM

Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3510 5 B60D05 ECU Power Stage 2: Undervoltage failure at sensor supply 2 ECU Power Stage 2 Low battery voltage, defect in wiring harness, electrical failure in connected sensors or in the ECM

Replace ECM

Rev.00 Page 18 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3510 6 B60D06 ECU Power Stage 2: Overtemperature failure at sensor supply 2 ECU Power Stage 2

ECM Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3510 12 B60D0C ECU Power Stage 2: Error Sensor supply for sensors ECU Power Stage 2

ECM Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3511 3 B70D03 ECU Power Stage 3: Overvoltage failure at sensor supply 3 ECU Power Stage 3

ECM Replace ECM

Check wiring of the connected sensor and the ECM.

3511 4 B70D04 ECU Power Stage 3: Short Circuit to Ground failure at sensor supply 3 ECU Power Stage 3 Defect in wiring harness, electrical failure in connected sensors or in the ECM

Replace ECM

Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3511 5 B70D05 ECU Power Stage 3: Undervoltage failure at sensor supply 3 ECU Power Stage 3 Low battery voltage, defect in wiring harness, electrical failure in connected sensors or in the ECM

Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3511 6 B70D06 ECU Power Stage 3: Overtemperature failure at sensor supply 3 ECU Power Stage 3

ECM Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3511 12 B70D0C ECU Power Stage 3: Error Sensor supply for sensors ECU Power Stage 3

ECM Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3512 3 B80D03 ECU Power Stage 4: Overvoltage failure at sensor supply 4 ECU Power Stage 4

ECM Replace ECM

Check wiring of the connected sensor and the ECM.

3512 4 B80D04 ECU Power Stage 4: Short Circuit to Ground failure at sensor supply 4 ECU Power Stage 4 Defect in wiring harness, electrical failure in connected sensors or in the ECM

Replace ECM

Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3512 5 B80D05 ECU Power Stage 4: Undervoltage failure at sensor supply 4 ECU Power Stage 4 Low battery voltage, defect in wiring harness, electrical failure in connected sensors or in the ECM

Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3512 6 B80D06 ECU Power Stage 4: Overtemperature failure at sensor supply 4 ECU Power Stage 4

ECM Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3512 12 B80D0C ECU Power Stage 4: Error Sensor supply for sensors ECU Power Stage 4

ECM Replace ECM

Rev.00 Page 19 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3513 3 B90D03 ECU Power Stage 5: Overvoltage failure at sensor supply 5 ECU Power Stage 5

ECM Replace ECM

Check wiring of the connected sensor and the ECM.

3513 4 B90D04 ECU Power Stage 5: Short Circuit to Ground failure at sensor supply 5 ECU Power Stage 5 Defect in wiring harness, electrical failure in connected sensors or in the ECM

Replace ECM

Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3513 5 B90D05 ECU Power Stage 5: Undervoltage failure at sensor supply 5 ECU Power Stage 5 Low battery voltage, defect in wiring harness, electrical failure in connected sensors or in the ECM

Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3513 6 B90D06 ECU Power Stage 5: Overtemperature failure at sensor supply 5 ECU Power Stage 5

ECM Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3513 12 B90D0C ECU Power Stage 5: Error Sensor supply for sensors ECU Power Stage 5

ECM Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3514 3 BA0D03 ECU Power Stage 6: Overvoltage failure at sensor supply 6 ECU Power Stage 6

ECM Replace ECM

Check wiring of the connected sensor and the ECM.

3514 4 BA0D04 ECU Power Stage 6: Short Circuit to Ground failure at sensor supply 6 ECU Power Stage 6 Defect in wiring harness, electrical failure in connected sensors or in the ECM

Replace ECM

Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3514 5 BA0D05 ECU Power Stage 6: Undervoltage failure at sensor supply 6 ECU Power Stage 6 Low battery voltage, defect in wiring harness, electrical failure in connected sensors or in the ECM

Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3514 6 BA0D06 ECU Power Stage 6: Overtemperature failure at sensor supply 6 ECU Power Stage 6

ECM Replace ECM

Excessive battery voltage, defect in wiring harness, electrical failure in connected sensors or in the Check battery voltage, check wiring for correct voltage supply of the connected sensor and the ECM.

3514 12 BA0D0C ECU Power Stage 6: Error Sensor supply for sensors ECU Power Stage 6

ECM Replace ECM

3515 31 BB0D1F DEF qualty sensor: Temperature not plausible, sensor possibly dismounted SCR Reagent Quality Quality Sensor not mounted in the DEV circuit, possible tampering Check sensor mounting, check temperature measured value both on tank and sensor.

3516 1 BC0D01 Urea quality: concentration low SCR Reagent Quality DEF with too low concentration detected Check DEF in the tank, replace it if non conform fluid is present

Rev.00 Page 20 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

DEF quality sensor is not able to deliver a valid measured value, there could be a problem with air

3516 12 BC0D0C Urea quality: sensor defective SCR Reagent Quality Check urea in the tank, check correct sensor installation or possible tampering.

bubbles or debris in the tank interfering with the sensor normal function

3521 31 C10D1F DEF qualty sensor: critical fluid identified SCR Reagent Quality Critical substance instead of reagent was detected (diesel or other fluid potentially destructive) Replace reagent

Special ambient conditions or vehicle use (city cycle) which lead to too low DPF temperature for real

Check temperature sensor before Oxicat and before DPF for correct measuring

regeneration.

DPF model plausibility: Fault path for maximum number of locked Temperature sensor before Oxicat or before DPF show too low temperature, so system dose not

3525 0 C50D00 DPF model plausibility Check Oxicat

regenerations detect real regeneration.

Oxicat does not work correctly, i.e. the temperature increase is too low (should be shown by a

Check DPF

additionally stored dedicated failure)

3555 2 E30D02 Environmental pressure: Value implausible Ambient pressure sensor ECU internal sensor defective Replace ECU

Another failure requested engine speed limitation.

3607 14 170E0E ECU internal Check: Injection cut off demand (ICO) for shut off coordinator ECU internal Check This failure path should always appear in failure memory with another lead failure from ECM No action, this is only an information path

monitoring level (level 2)

3695 2 6F0E02 DPF emergency regeneration switch: Not plausible switch value DPF emergency regen.switch Emergency regeneration switch pressed at high vehicle speed or switch defective Check emergency regeneration switch

Particulate filter service regeneration: number of regeneration requested via Service regeneration started via service tester should be carried out or counter resetted via service tool

3696 0 8F0E1F DPF emergency regen.switch Particulate filter service regeneration was requested too many times

vehicle button exceeded limit (Routine control $0302)

3696 7 700E07 Particulate filter emergency regeneration switch stuck closed DPF emergency regen.switch Emergency regeneration switch stuck Check and repair Emergency regeneration switch

3697 3 710E03 DPF Control Lamp: Short circuit to battery error DPF Control Lamp Short circuit of wiring to battery Check of wiring

3697 4 710E04 DPF Control Lamp: Short circuit to ground error DPF Control Lamp Short circuit of wiring to ground Check of wiring

3697 5 710E05 DPF Control Lamp: No load error DPF Control Lamp Broken or disconnected wiring or defective lamp Check of wiring or replace lamp

No reaction needed if failure isn't present after short time, check load and output, check wiring, replace

3697 6 710E06 DPF Control Lamp: Over temperature error DPF Control Lamp High battery voltage, high temperature inside ECU, high load or wiring problem

ECU

Rev.00 Page 21 of 47 08/22/2023

V454/V458 Unified Fault Code Chart

SPN FMI DTC Description Component Failure Cause Failure Repair

3703 7 770E07 Particulate FIlter Inhibition Switch stuck None Switch for filter regeneraration inhibition stuck in pressed postion Check regeneration filter inhibition switch

Special ambient conditions and vehicle use which does not allow correct DPF regeneration due to too

low exhaust temperatures Service regeneration should be performed to reduce soot mass in the filter

3719 16 870E10 DPF model plausibility: Calculated soot mass above threshold DPF model plausibility Temperature sensor before Oxicat and/or before DPF shows too low temperature

Oxicat does not work correctly (bad HC burning) - in this case also a further dedicated failure should If Service regeneration fails: see troubleshooting there.

be stored and the vehicle shows blue smoke and strong odour.

Particulate filter service regeneration: regeneration requested via vehicle Service regeneration started via service tester should be carried out or counter resetted via service tool

3727 31 8F0E1F DPF emergency regen.switch Service regeneration started via vehicle button was interrupted too many times

button interrupted too many times (Routine control $0302)

Fuel filter heater: Short circuit to battery error in power stage of fuel filter

4009 3 A90F03 Fuel filter heater Short circuit of wiring to external source or inside fuel filter heater Check of wiring, replace fuel filter heater

heating

Fuel filter heater: Short circuit to ground error in power stage of fuel filter

4009 4 A90F04 Fuel filter heater Short circuit of wiring to ground or inside fuel filter heater Check of wiring, replace fuel filter heater

heating

4009 5 A90F05 Fuel filter heater: No load error in power stage of fuel filter heating Fuel filter heater Broken or disconnected wiring or defective fuel filter heater. Check of wiring or replace fuel filter heater

4009 6 A90F06 Fuel filter heater: Over Temperature error at ECM power stage Fuel filter heater High battery voltage, high temperature inside ECU, high load or wiring problem Check load and output, check wiring, replace ECU

Sensor defective or short circuit to external source

Coolant temp sensor: SRC High for Engine coolant temperature(down

4076 3 EC0F03 Coolant temp sensor Check wiring and connector continuity or replace sensor

stream) Remark: Most ECU analog input pins are provided with a pullup resistor. In this case an open circuit

error will also be identified as an SRC Max error.

Coolant temp sensor: SRC low for Engine coolant temperature(down

4076 4 EC0F04 Coolant temp sensor Sensor defective or short circuit to ground Check wiring or replace sensor

stream)

Reagent with too low UREA concentration (<<32%) Check Reagent, if correct concentration, Check Dosing quantity of SCR system, Check if the catalyst has

Too low or no Reagent injection been tampered. Check if engine raw emissions are OK (e.g. drive vehicle at constant speed without

Too High NOx Emissions: Catalyst efficiency lower than first NOx

4090 0 FA0F00 Too High NOx Emissions Wrong NOx measurement (NOx Sensor measures too high values) Reagent injection and compare measured with estimated NOx with tester), if not check NOx Sensor,

production threshold level

Engine NOx raw emissions higher than expected (humidity sensor measures too humid air, injection Humidity Sensor, Fuel pressure sensor,Injection timing. If OK, repeat test WITH Reagent dosing and check

timing anticipated, fuel pressure sensor measures too low fuel pressure Closed Loop Control parameter: if continuously < 0.7 or > 1.3 --> risk of NH3 slip due to system problem.