Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'

Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'

Uploaded by

bagusrindi2801Copyright:

Available Formats

Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'

Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'

Uploaded by

bagusrindi2801Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'

Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'

Uploaded by

bagusrindi2801Copyright:

Available Formats

Product Data Sheet OK 48.

00

E 'Manual metal-arc welding'

Prepared by Qualified by Approved by Reg no Cancelling Reg date Page

P-O Oskarsson Tero Borg J-P Ernoult EN006953 EN005613 2016-01-11 1 (3)

REASON FOR ISSUE

New AWS classification.

GENERAL

A reliable, general purpose electrode for manual metal arc welding of carbon steels, carbon manganese steels

and fine-grained carbon manganese steels with elevated yield strength. OK 48.00 deposits a tough,

crack-resistant weld metal. The coating is of the low moisture absorption type.

High welding speed in the vertical-up position. OK 48.00 is insensitive to the composition of the base material

within fairly wide limits.

The electrode can be used for welding structures where difficult stress conditions cannot be avoided.

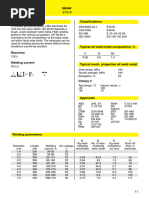

Polarity: DC+(-) Alloy Type: Carbon-Manganese

Coating Type: Lime Basic

Diff Hydrogen: < 4.0 ml/100g

WELDING POSITIONS

1 2 3 4 6

CLASSIFICATIONS Electrode APPROVALS

SFA/AWS A5.1 E7018 H4 R ABS 3Y H5

EN ISO 2560-A E 42 4 B 42 H5 BV 3Y H5

CE EN 13479

DB 10.039.12

DNV 3Y H5

GL 3Y H5

LR 3Ym H5

PRS 3Y H5

RS 3Y H5

VdTÜV 00690

APPROVALS (SPECIFIC)

NAKS/HAKC 2.0-5.0 mm

Seproz UNA 272580

APPROVAL COMMENT

Approvals Specific: Valid for lot numbers starting with SF

Product Data Sheet OK 48.00

E 'Manual metal-arc welding'

Prepared by Qualified by Approved by Reg no Cancelling Reg date Page

P-O Oskarsson Tero Borg J-P Ernoult EN006953 EN005613 2016-01-11 2 (3)

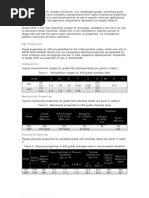

CHEMICAL COMPOSITION

All Weld Metal (%)

Min Max

C 0.02 0.10

Si 0.30 0.70

Mn 0.90 1.40

P 0.020

S 0.015

Cr 0.1

Ni 0.1

Mo 0.06

V 0.04

Nb 0.02

Cu 0.1

Al 0.03

Sn 0.02

Ti 0.03

Pb 0.02

As 0.03

Mn+Ni+Cr+Mo+V 1.75

MECHANICAL PROPERTIES OF WELD METAL

ISO AWS

As welded As welded

Properties Min Max Typ Min Typ

Rp0.2 (MPa) 400

ReL (MPa) 420 475

Rm (MPa) 530 640 565 490

A4 (%) 22

A5 (%) 22 29

Charpy V at -30°C (J) 27 130

Charpy V at -40°C (J) 47 115

Comments: Comments:

EN standard requires Rm min 500 Mpa and

A5 Min 20%.

Product Data Sheet OK 48.00

E 'Manual metal-arc welding'

Prepared by Qualified by Approved by Reg no Cancelling Reg date Page

P-O Oskarsson Tero Borg J-P Ernoult EN006953 EN005613 2016-01-11 3 (3)

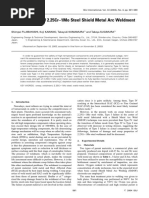

ECONOMICS & CURRENT DATA

Dimension (mm) Current (A)

-

W η N B H T U Welding

-

Ø x Length Min Max Positions

1.6 x 300 30 55 0.9 127 0.59 192 0.38 50 24 1,2,3,4,6

2.0 x 300 55 80 1.4 128 0.65 125 0.63 45 22 1,2,3,4,6

2.5 x 350 70 110 2.5 129 0.67 65 0.96 57 24 1,2,3,4,6

3.2 x 350 90 140 4.7 124 0.70 42 1.24 68 23 1,2,3,4,6

3.2 x 450 90 140 4.7 124 0.73 31 1.33 85 23 1,2,3,4,6

4.0 x 350 120 190 5.5 118 0.70 29 1.63 75 24 1,2,3,4,6

4.0 x 450 120 190 7.0 118 0.71 22 1.76 92 24 1,2,3,4,6

5.0 x 450 190 260 10.6 119 0.75 13 2.61 99 24 1,2,3,4

6.0 x 450 220 340 14.6 120 0.80 9 3.88 97 26 1,2,3

7.0 x 450 280 410 19.6 118 0.79 7.0 4.83 104 27 1,2,3

W = Weight (kg / 100 electrodes)

η = Efficiency (g weld metal x 100 / g core wire)

N = Effective value (kg weld metal / kg electrodes)

B = Changes (number of electrodes / kg weld metal)

H = Deposit rate at 90% of max current (kg weld metal / hour arc time)

T = Fusion time at 90% of max current (s / electrode)

U = Arc voltage (V)

You might also like

- SG Iron GradesDocument2 pagesSG Iron GradesSagarKBL100% (1)

- Iron and Steel Manufacturing ProcessDocument28 pagesIron and Steel Manufacturing ProcessMarnel Roy Mayor78% (32)

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'wangshengfffNo ratings yet

- Product Data Sheet OK 48.60: E 'Manual Metal-Arc Welding' ESAB-MÓR KFT HungaryDocument2 pagesProduct Data Sheet OK 48.60: E 'Manual Metal-Arc Welding' ESAB-MÓR KFT HungaryCristina CoceasuNo ratings yet

- Garde CorpsDocument2 pagesGarde Corpsattiori fabriceNo ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet

- OK-67.50Document3 pagesOK-67.50TadilakshmikiranNo ratings yet

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'abdulazeez88No ratings yet

- OK-74.86Document2 pagesOK-74.86Shaik Nizam UddinNo ratings yet

- Product Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- Weld 71 TDocument1 pageWeld 71 TGanesh HileNo ratings yet

- Product Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'RobertoNo ratings yet

- ETC PH25S DRYDocument1 pageETC PH25S DRYstefavaNo ratings yet

- DATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Document2 pagesDATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Dries VandezandeNo ratings yet

- ThermogunDocument2 pagesThermogunadagmar731No ratings yet

- Ok 347 AutrodDocument2 pagesOk 347 Autrodjoao guilhermeNo ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- Product Data Sheet - OK Tigrod 13.09 PDFDocument2 pagesProduct Data Sheet - OK Tigrod 13.09 PDFarman pangestuNo ratings yet

- Product Data Sheet Ok Aristorod 12.50: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet Ok Aristorod 12.50: G 'Gas-Shielded Metal-Arc Welding'João GuilhermeNo ratings yet

- Smaw Type: Rutile E6013Document1 pageSmaw Type: Rutile E6013Gummadi YugandharNo ratings yet

- Electroldes Enrobees (Ok 48.00)Document2 pagesElectroldes Enrobees (Ok 48.00)Younes DahNo ratings yet

- Product Data Sheet: S 'Submerged Arc Welding'Document1 pageProduct Data Sheet: S 'Submerged Arc Welding'adanmeneses1No ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- L1 34454 en B Boehler Aws E6013 Se en v1Document1 pageL1 34454 en B Boehler Aws E6013 Se en v1brayanNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesdarmawan listyonoNo ratings yet

- B - Boehler DMO-IG - Ss - en - 5 PDFDocument1 pageB - Boehler DMO-IG - Ss - en - 5 PDFDimitris NikouNo ratings yet

- E 6013 Fincord M electrode-oerlikon-en-TN110429Document1 pageE 6013 Fincord M electrode-oerlikon-en-TN110429Khhg AgddsNo ratings yet

- Böhler Fox Ohv: Rutile-Cellulosic Stick Electrode, UnalloyedDocument1 pageBöhler Fox Ohv: Rutile-Cellulosic Stick Electrode, UnalloyedMiroslav MiladinovićNo ratings yet

- Autrod 1264Document2 pagesAutrod 1264Anonymous yL7oldKNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- 055 PDFDocument1 page055 PDFantonio111aNo ratings yet

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- E308l 17Document1 pageE308l 17Gummadi YugandharNo ratings yet

- Conarc 49C: Basic ElectrodeDocument2 pagesConarc 49C: Basic ElectrodeMark Williams100% (1)

- Product Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Filipe CordeiroNo ratings yet

- Bohler EMS 2 Mo - Chapa 16Mo3 - VIROLADocument2 pagesBohler EMS 2 Mo - Chapa 16Mo3 - VIROLAarthurguimaraes10No ratings yet

- Böhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileDocument1 pageBöhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileRaviTeja BhamidiNo ratings yet

- Weld ElectrodesDocument42 pagesWeld ElectrodesNarendraNo ratings yet

- PDS-FILARC PZ6138-rev26Document2 pagesPDS-FILARC PZ6138-rev26umairNo ratings yet

- TOKO 1978 Electric Welding Rod Technical Data SheetDocument8 pagesTOKO 1978 Electric Welding Rod Technical Data SheetYurizki LhzNo ratings yet

- Tenacito 70Document1 pageTenacito 70Luis Angel Unocc FernandezNo ratings yet

- FICHA Técnica Weld 71T-1 PDFDocument2 pagesFICHA Técnica Weld 71T-1 PDFCarlos Padilla67% (3)

- Indura Em12k-H400Document2 pagesIndura Em12k-H400Rodrigo CarizNo ratings yet

- Electrodos-Revestidos KiswellDocument116 pagesElectrodos-Revestidos KiswellJoel FloresNo ratings yet

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocument1 pageB Boehler Aws E316l 17 Se en 5a Mds PDFInaamNo ratings yet

- Filler Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysDocument8 pagesFiller Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysimreNo ratings yet

- L1 8581 en Diamondspark 44 BC CU03100F 3379759 ENDocument1 pageL1 8581 en Diamondspark 44 BC CU03100F 3379759 ENRaviTeja BhamidiNo ratings yet

- Product Data Sheet OK 61.35: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.35: E 'Manual Metal-Arc Welding'C7 TGNo ratings yet

- Smaw Type: Lime-Basic E7018Document1 pageSmaw Type: Lime-Basic E7018Gummadi YugandharNo ratings yet

- 02112015000000B - Boehler FOX DCMS Ti - CeDocument1 page02112015000000B - Boehler FOX DCMS Ti - CeparbinaNo ratings yet

- 03112015000000B - Boehler FOX SUM - CeDocument1 page03112015000000B - Boehler FOX SUM - Cekapster KannourNo ratings yet

- OK 63.30 (Inox 316)Document1 pageOK 63.30 (Inox 316)Tiberiu MunteanuNo ratings yet

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- B - Boehler FOX EV 60 - Se - en - 5Document1 pageB - Boehler FOX EV 60 - Se - en - 5Juan Bedolla FloresNo ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- Fluxofil M 10: FCAW/MCAW Cored Wires C-MN and Low-Alloy SteelsDocument1 pageFluxofil M 10: FCAW/MCAW Cored Wires C-MN and Low-Alloy SteelsbvbarcNo ratings yet

- 03 - Ceramic StructuresDocument17 pages03 - Ceramic StructuresMd. Rafiqul IslamNo ratings yet

- #7 CreepDocument72 pages#7 CreepyolandavmsNo ratings yet

- SB Drill Collar PDFDocument51 pagesSB Drill Collar PDFSiva GanaNo ratings yet

- Corrosion PDFDocument46 pagesCorrosion PDFNixon RamsaranNo ratings yet

- En 10083-2Document39 pagesEn 10083-2Shreenivas ThakurNo ratings yet

- Mohs Scale Data SheetDocument2 pagesMohs Scale Data SheetSheryl Lou AngelesNo ratings yet

- Superfinishing Processes: HoningDocument5 pagesSuperfinishing Processes: HoningAyman HussienNo ratings yet

- Alluminium Section PropertiesDocument4 pagesAlluminium Section PropertiesGihan ChathurangaNo ratings yet

- SS430FDocument3 pagesSS430FbbaskaranNo ratings yet

- Chunky GraphiteDocument16 pagesChunky GraphitesachinguptachdNo ratings yet

- ASTM E140 Hardness Conversion Tables PDFDocument22 pagesASTM E140 Hardness Conversion Tables PDFndt_inspectorNo ratings yet

- Time Date I. Objectives: A. Content StandardsDocument5 pagesTime Date I. Objectives: A. Content StandardsRod ReyesNo ratings yet

- 47-DeVEREAUX - Superfinish & Grinding - ASETS Defense '11Document22 pages47-DeVEREAUX - Superfinish & Grinding - ASETS Defense '11dimitrisNo ratings yet

- Aluminum-Coated (Aluminized) Carbon Steel Wire: Standard Specification ForDocument3 pagesAluminum-Coated (Aluminized) Carbon Steel Wire: Standard Specification ForDoug WilsonNo ratings yet

- Cutting Tool TechnologyDocument5 pagesCutting Tool TechnologyROHAN DESAINo ratings yet

- MAE 343 Intermediate Mechanics of Materials: Xingbo Liu Office: ESB 509 Phone: 293-3339 Email: Xingbo - Liu@mail - Wvu.eduDocument38 pagesMAE 343 Intermediate Mechanics of Materials: Xingbo Liu Office: ESB 509 Phone: 293-3339 Email: Xingbo - Liu@mail - Wvu.edubaig79No ratings yet

- Review 2Document22 pagesReview 2EDENNo ratings yet

- Department of Mines and GeologyDocument15 pagesDepartment of Mines and GeologyStarNo ratings yet

- Inconel Research Paper PDFDocument227 pagesInconel Research Paper PDFAnonymous OEUUoKHYR100% (1)

- Thermal Spray Coating For Steel ProcessingDocument5 pagesThermal Spray Coating For Steel ProcessingRamkiyengar100% (1)

- Data Table For Grades Stainless Steels SUH 660Document2 pagesData Table For Grades Stainless Steels SUH 660Agy RandhikoNo ratings yet

- Astm A563Document9 pagesAstm A563mhmgola100% (1)

- Inbound 834247990563416673Document29 pagesInbound 834247990563416673Lee Anthony CabeguinNo ratings yet

- Creep Behavior of 2.25Cr-1Mo Steel Shield Metal Arc WeldmentDocument10 pagesCreep Behavior of 2.25Cr-1Mo Steel Shield Metal Arc WeldmentTrushar ParmarNo ratings yet

- Commenly Used Materials: Rolta Training Center, Mumbai - IndiaDocument1 pageCommenly Used Materials: Rolta Training Center, Mumbai - IndiaTAMIZHKARTHIKNo ratings yet

- Effect of Deformation On The Continuous Cooling Transformation (CCT) Diagram of Steel 32Crb4Document4 pagesEffect of Deformation On The Continuous Cooling Transformation (CCT) Diagram of Steel 32Crb4Najib RahmanNo ratings yet

- Uddeholm Pocket Book PDFDocument80 pagesUddeholm Pocket Book PDFPeter NomikosNo ratings yet

- Cu ZN 10Document1 pageCu ZN 10Sara RiddleNo ratings yet