I400 Manual

I400 Manual

Uploaded by

Mitchell DanielsCopyright:

Available Formats

I400 Manual

I400 Manual

Uploaded by

Mitchell DanielsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

I400 Manual

I400 Manual

Uploaded by

Mitchell DanielsCopyright:

Available Formats

®

Electrical Specifications

Reference Conditions: 23 ± 5 °C, 20 to 75 % RH; conductor

centered in jaw opening; no dc component; no adjacent

conductor

Instruction Sheet

Measurement Range: 1 A to 400 A ac rms

Output: 1 mA/A

Accuracy: 2 % + 0.06 A, 45 Hz to 400 Hz

Typical Bandwidth: 5 Hz to 20 kHz

i400

Working Voltage: 1000 V ac rms, in compliance with

EN61010

Common Mode Voltage: 1000 V ac rms from earth ground, in

compliance with EN61010

Load Impedance: < 10 Ω

AC Current Clamp Maximum Non-destructive Current: 1000 A

Duty Cycle: 1 A to 400 A continuous

Influence of Adjacent Conductor: < 7.5 mA/A

Introduction Influence of Conductor Position in Jaw Opening: ± 1.0 % of

The Model i400 (hereafter called “the Current Clamp”) is an ac reading + 0.05 A

current clamp that outputs 1 mA/A via safety-shrouded banana

plugs; it is designed to extend the measuring capability of an Safety Specifications

ac current meter to 400 A. Category Rating: CAT III 1000 V and CAT IV 600 V per

EN61010-1, Pollution Degree 2 IEC 61010-02-032

Safety Information

EMC: EN 61326-1, FCC for emission and immunity

XW Read First: Safety Information

To ensure safe operation and service of the Current

): Tested to US and Canadian standards for compliance to

UL61010-1 and CAN/CSA C22.2 No. 101.1:2004

Clamp, follow these instructions:

• Read the operating instructions before use and P: IEC 61010-1 2nd Edition

follow all safety instructions.

• Use the Current Clamp only as specified in the

General Specifications

operating instructions, otherwise the clamp’s safety Output Cable Length: 1.5 m

features may not protect you. Maximum Conductor Size: 32 mm

• Adhere to local and national safety codes. Storage Temperature: -20 °C to 60 °C

Individual protective equipment must be used to Operating Temperature: 0 °C to 50 °C

prevent shock and arc blast injury where hazardous

live conductors are exposed. Relative Humidity: 10 °C to 30 °C: 95 %

• Do not hold the Current Clamp anywhere beyond 30 °C to 40 °C: 75 %

the tactile barrier, see Figure 1. 40 °C to 50 °C: 45 %

• Before each use, inspect the Current Clamp. Look Temperature Coefficient: 0.01 X (specified accuracy)/ °C

for cracks or missing portions of the clamp housing (< 18 °C or > 28 °C)

or output cable insulation. Also look for loose or Altitude: Operating: 2000 m; Non-operating: 12000 m

weakened components. Pay particular attention to

the insulation surrounding the jaws. Dimensions: 150 x 70 x 30 mm

• Never use the clamp on a circuit with voltages Weight: 114 g

higher than 1000 V CAT III or 600 V CAT IV.

• CAT III equipment is designed to protect

Instrument Compatibility

against transients in equipment in fixed- The i400 is compatible with any Fluke Multimeter or any other

current measurement device that has the following features:

equipment installations, such as distribution

panels, feeders and short branch circuits, and • 20 mA ac or greater current range

lighting systems in large buildings. • Banana inputs

• CAT IV equipment is designed to protect • Input accuracy of 2 % or better to take full advantage of

the accuracy of the Current Clamp.

against transients from the primary supply

level, such as an electricity meter or an

• Input impedance of < 10 Ω

overhead or underground utility service. Measurement Considerations

• Use extreme caution when working around bare Observe the following guidelines for positioning the Current

conductors or bus bars. Contact with the conductor Clamp jaws:

could result in electric shock. • Center the conductor inside the Current Clamp jaw.

• Use caution when working with voltages above 60 V • Make sure the clamp is perpendicular to the conductor.

dc or 30 V ac. Such voltages pose a shock hazard.

• For optimal reading, make sure the conductor is positioned

Symbols between the alignment marks on the jaw of the Current

Clamp.

Application around and removal from hazardous live Observe the following guidelines when making measurements:

, conductors is permitted. • Avoid taking measurements close to other current-carrying

T Product is protected by double insulation. conductors.

• The Current Clamp displays current readings at 1/1000 of

W Risk of Danger. Important information. See Instruction Sheet. the actual current on the conductor. For example, a

X Hazardous voltage. 5 A input current will be transformed into a 5 mA output

current.

Conforms to relevant Canadian Standards Association

) directives. Low-Level Current Measurements

P Conforms to relevant European Union directives. The Current Clamp is specified to measure currents of 1 A or

greater. Measurement accuracy of currents less than 1 A is

unspecified.

PN 2282667

December 2004

Operation

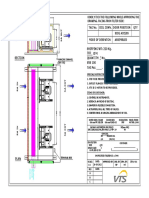

© 2004 Fluke Corporation, All rights reserved. Printed in U.S.A. To use the i400, (refer to Figure 1):

All product names are trademarks of their respective companies.

sales@GlobalTestSupply.com Fluke-Direct .com 1.888.610.7664

1. Insert the banana plug into the common and current LIMITED WARRANTY AND LIMITATION OF LIABILITY

inputs of a Multimeter and switch the Meter on. Each Fluke product is warranted to be free from defects in material and

2. Select a 20 mA ac or greater current range. workmanship under normal use and service. The warranty period is

one year and begins on the date of shipment. Parts, product repairs,

3. Clamp the i400 around the current-carrying conductor and services are warranted for 90 days. This warranty extends only to

to be measured. Make sure the jaws are tightly closed the original buyer or end-user customer of a Fluke authorized reseller,

around the conductor. The Current Clamp is designed and does not apply to fuses, disposable batteries, or to any product

for highest accuracy when the conductor is centered on which, in Fluke's opinion, has been misused, altered, neglected,

the jaw’s alignment marks, see Figure 1. contaminated, or damaged by accident or abnormal conditions of

XW Warning operation or handling. Fluke warrants that software will operate

substantially in accordance with its functional specifications for 90 days

To avoid shock or personal injury, keep fingers and that it has been properly recorded on non-defective media. Fluke

behind the tactile barrier, see Figure 1. does not warrant that software will be error free or operate without

4. Multimeter readings displayed in milliamps (mA) can be interruption.

read directly as amperes of input current. Readings Fluke authorized resellers shall extend this warranty on new and

displayed in amperes (A) must be multiplied times unused products to end-user customers only but have no authority to

1000 to obtain the amperes of input current. extend a greater or different warranty on behalf of Fluke. Warranty

support is available only if product is purchased through a Fluke

Maintenance authorized sales outlet or Buyer has paid the applicable international

XW Warning price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is

To avoid possible electric shock or personal submitted for repair in another country.

injury: Fluke's warranty obligation is limited, at Fluke's option, to refund of the

• Before each use, inspect the Current Clamp. purchase price, free of charge repair, or replacement of a defective

Look for cracks or missing portions of the product which is returned to a Fluke authorized service center within

clamp housing and output cable insulating the warranty period.

cover and for loose or weakened To obtain warranty service, contact your nearest Fluke authorized

components. Pay particular attention to the service center to obtain return authorization information, then send the

insulation surrounding the clamp jaws. product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no

• Do not use a damaged Current Clamp. If a risk for damage in transit. Following warranty repair, the product will be

clamp is damaged, tape it shut to prevent returned to Buyer, transportation prepaid (FOB Destination). If Fluke

unintended operation. A damaged clamp determines that failure was caused by neglect, misuse, contamination,

under warranty will be promptly repaired or alteration, accident, or abnormal condition of operation or handling,

replaced (at Fluke’s discretion) and returned including overvoltage failures caused by use outside the product’s

at no extra charge. specified rating, or normal wear and tear of mechanical components,

Fluke will provide an estimate of repair costs and obtain authorization

If the Current Clamp does not work or perform properly, use before commencing the work. Following repair, the product will be

the following steps to help isolate the problem: returned to the Buyer transportation prepaid and the Buyer will be

1. Inspect the jaw mating surface for cleanliness. If any billed for the repair and return transportation charges (FOB Shipping

foreign material is present, the jaw will not close properly Point).

and measurement errors will result. THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY

2. Verify that the function selection and range on the AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

Multimeter are correct and adjusted to the sensitivity of the IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

Current Clamp. PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY

3. Verify the DMM current fuse. If the current fuse is open, SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

the clamp may not function properly. DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, ARISING

FROM ANY CAUSE OR THEORY.

Cleaning

Since some countries or states do not allow limitation of the term of an

Periodically wipe the case with a damp cloth and mild implied warranty, or exclusion or limitation of incidental or

detergent. consequential damages, the limitations and exclusions of this warranty

W Caution may not apply to every buyer. If any provision of this Warranty is held

invalid or unenforceable by a court or other decision-maker of

To avoid damaging the Current Clamp, do not use competent jurisdiction, such holding will not affect the validity or

abrasives or solvents to clean the clamp. enforceability of any other provision.

Open the jaws and wipe the magnetic pole pieces with a lightly

oiled cloth. Do not allow rust or corrosion to form on the

magnetic core ends.

320 mA 87 V TRUE RMS MULTIMETER

320 A

°C/°F

MIN MAX RANGE AutoHOLD

Peak MIN MAX

REL Hz %

4½ DIGITS

AC Current

1 Second

mV

Function V

mA

A

A

Single Current V

LO

Carrying Conductor OFF

A mA A COM V

400mA

10A MAX FUSED

FUSED

Alignment

Marks

Tactile

Barrier

aym02f.eps

Figure 1. i400 Setup

sales@GlobalTestSupply.com Fluke-Direct .com 1.888.610.7664

You might also like

- IFR 1500 Maintenance Manual PDFDocument670 pagesIFR 1500 Maintenance Manual PDFMitchell DanielsNo ratings yet

- MS1000 SGDocument97 pagesMS1000 SGMitchell Daniels0% (1)

- Renewable EnergyDocument18 pagesRenewable EnergyEngSafwanQadousNo ratings yet

- CL120 1390362art WebDocument36 pagesCL120 1390362art WebCristann MartinezNo ratings yet

- Relé de SegurançaDocument5 pagesRelé de SegurançaTÁ CURRUTNo ratings yet

- CPX400DP Instruction Manual-Iss1Document34 pagesCPX400DP Instruction Manual-Iss1Jonathan ArreolaNo ratings yet

- Rish CON SI-102 V-MDocument3 pagesRish CON SI-102 V-MManoj MakholiyaNo ratings yet

- 5A IntegratorDocument5 pages5A IntegratorWilsonNo ratings yet

- Rish Con Si-101: Data SheetDocument3 pagesRish Con Si-101: Data SheetSagar PatelNo ratings yet

- Fiche Technique 505610 Inter Val Seuils 0 10 VDC Ovl1 24 Vacdc Tele 170015Document2 pagesFiche Technique 505610 Inter Val Seuils 0 10 VDC Ovl1 24 Vacdc Tele 170015CAlou PsoNo ratings yet

- Numerical Relay S Series Feeder Protection RelayDocument8 pagesNumerical Relay S Series Feeder Protection RelayQatada1No ratings yet

- Inteligen 1000 Marine 1.2.0 DatasheetDocument5 pagesInteligen 1000 Marine 1.2.0 DatasheetFranciscon VelaNo ratings yet

- AMB-25 Insulation-Tester Manual PDFDocument9 pagesAMB-25 Insulation-Tester Manual PDFAnderson William Huamani HuaytaNo ratings yet

- Multi MeterDocument10 pagesMulti MeterMoolaramNo ratings yet

- 3UG46321AW30 Datasheet enDocument5 pages3UG46321AW30 Datasheet enSreegith ChelattNo ratings yet

- CYFGCS50LRSHDocument2 pagesCYFGCS50LRSHMelvis VillegasNo ratings yet

- Sunelt Dpu6000 enDocument6 pagesSunelt Dpu6000 enmeNo ratings yet

- Spesifikasi Loop Calibrator VC05sDocument4 pagesSpesifikasi Loop Calibrator VC05sDaniel SilitongaNo ratings yet

- 3RQ20001BW00 Datasheet enDocument6 pages3RQ20001BW00 Datasheet enthyago.rNo ratings yet

- 3TK28251BB40 DatashnDocument4 pages3TK28251BB40 DatashnVinicius MateusNo ratings yet

- 2012 RCS FlyerDocument4 pages2012 RCS FlyerKarthik RajaNo ratings yet

- Sup 602s Signal Isolator User ManualDocument2 pagesSup 602s Signal Isolator User ManualMd. Mamon RanaNo ratings yet

- jf5018-00 Rev4c (14317)Document12 pagesjf5018-00 Rev4c (14317)larryNo ratings yet

- Agilent U1210 Series Handheld Clamp Meters: Handle Big Currents - More SafelyDocument16 pagesAgilent U1210 Series Handheld Clamp Meters: Handle Big Currents - More SafelySrf SaharinNo ratings yet

- Type RXP8n, RXPQ8n: Auxiliary RelayDocument5 pagesType RXP8n, RXPQ8n: Auxiliary RelayMathew LijuNo ratings yet

- Arteche DS RXR4 enDocument4 pagesArteche DS RXR4 enwillvinNo ratings yet

- 3TK28301CB30 Datasheet enDocument4 pages3TK28301CB30 Datasheet enluc.ayresNo ratings yet

- TS Series Instruction Manual - Iss 8Document26 pagesTS Series Instruction Manual - Iss 8qazNo ratings yet

- D00sal12 13Document8 pagesD00sal12 13amir.bptpkaNo ratings yet

- Sunelt Dpu2000 enDocument6 pagesSunelt Dpu2000 enmeNo ratings yet

- K109LV ManualDocument8 pagesK109LV Manualdat nguyenNo ratings yet

- Catalog Capacitor 2Document8 pagesCatalog Capacitor 2Marcos YanezNo ratings yet

- CS Ar-08Document2 pagesCS Ar-08Marlon BeckertNo ratings yet

- 120kv 5ma DC Hipot TesterDocument12 pages120kv 5ma DC Hipot TesterRichard bangcayaNo ratings yet

- 3UG46311AA30 Datasheet enDocument4 pages3UG46311AA30 Datasheet enMaya SimeonovaNo ratings yet

- MONITORING RELAYS. W VOLTAGE MONITORING RELAY UR5U1011. W SCHRACK-INFO. W TECHNICAL DATA PDFDocument34 pagesMONITORING RELAYS. W VOLTAGE MONITORING RELAY UR5U1011. W SCHRACK-INFO. W TECHNICAL DATA PDFovidiuNo ratings yet

- 520PSD01 DS enDocument3 pages520PSD01 DS enDJ ThangNo ratings yet

- G2ba400v12a-4-20ma enDocument2 pagesG2ba400v12a-4-20ma enStipe CorakNo ratings yet

- H Ur6u1052 enDocument4 pagesH Ur6u1052 enmartoNo ratings yet

- 1md8a 3upDocument3 pages1md8a 3upDirson Volmir WilligNo ratings yet

- rmcl55bd DocumentDocument3 pagesrmcl55bd DocumentYorkyNo ratings yet

- InteliDrive Lite FPC Datasheet - 4Document4 pagesInteliDrive Lite FPC Datasheet - 4widiNo ratings yet

- JF5006 Generic At10 R1Document12 pagesJF5006 Generic At10 R1Nguyễn Anh DanhNo ratings yet

- Type CV2: Auxiliary RelayDocument7 pagesType CV2: Auxiliary RelayNikki AgarwalNo ratings yet

- Technical Data: Industrial+Commercial ZMD402CT, ZFD402CTDocument6 pagesTechnical Data: Industrial+Commercial ZMD402CT, ZFD402CTShuhan Mohammad Ariful HoqueNo ratings yet

- H zr5mf025 - en PDFDocument2 pagesH zr5mf025 - en PDFsetotri 5370No ratings yet

- Enya SeriesDocument3 pagesEnya SeriesDavid HerediaNo ratings yet

- En G2bm400v12al10Document3 pagesEn G2bm400v12al10Stipe CorakNo ratings yet

- Varitrans® P 27000-S007 Universal Isolators: Ta-251.103-Kne01 20120802 84762Document12 pagesVaritrans® P 27000-S007 Universal Isolators: Ta-251.103-Kne01 20120802 84762Alan Barros SallesNo ratings yet

- 1 - A1800 CT Meter Main CatalogueDocument2 pages1 - A1800 CT Meter Main Cataloguemelisza.schwarzNo ratings yet

- Manual Tranduser Weigel A1U 2.3Document4 pagesManual Tranduser Weigel A1U 2.3Arief RahmanNo ratings yet

- G2ba480v12a-010v enDocument2 pagesG2ba480v12a-010v enStipe CorakNo ratings yet

- Coet CVTDocument2 pagesCoet CVTizzat ismailNo ratings yet

- AC Current Transducer AP-B10 I 10 .. 400 A: Electrical Data FeaturesDocument2 pagesAC Current Transducer AP-B10 I 10 .. 400 A: Electrical Data FeaturesCESAR BARROSO NO HAY QUE SER UN EXPERTO.No ratings yet

- 86CBF Bi 16RPDocument6 pages86CBF Bi 16RPCEPCO karthikNo ratings yet

- Smart Energy Meters CatalogDocument13 pagesSmart Energy Meters Catalognader manoNo ratings yet

- 3UG46221AW30 Datasheet enDocument4 pages3UG46221AW30 Datasheet encynthia velasquezNo ratings yet

- Dt-9205 MultimeterDocument5 pagesDt-9205 MultimeterBen ThiartNo ratings yet

- Intelimains 1010 3.1.0 DatasheetDocument5 pagesIntelimains 1010 3.1.0 Datasheetvishnu jayakumarNo ratings yet

- 3TK28241BB40 Datasheet enDocument4 pages3TK28241BB40 Datasheet enDads DragNo ratings yet

- K8ab-Ph Ca csm1996 PDFDocument8 pagesK8ab-Ph Ca csm1996 PDFnl vinay kumarNo ratings yet

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- NSC单级双吸中开式离心泵Document116 pagesNSC单级双吸中开式离心泵Mitchell DanielsNo ratings yet

- Exploded ViewDocument18 pagesExploded ViewMitchell DanielsNo ratings yet

- MM30 Manual - en 00154Document30 pagesMM30 Manual - en 00154Mitchell DanielsNo ratings yet

- RCX TG Example 1 To 11Document47 pagesRCX TG Example 1 To 11Mitchell DanielsNo ratings yet

- Battery Management SystemDocument2 pagesBattery Management SystemMitchell DanielsNo ratings yet

- Hilti SFD 2-ADocument25 pagesHilti SFD 2-AMitchell DanielsNo ratings yet

- Datasheet Solis 10K LV 3phaseDocument1 pageDatasheet Solis 10K LV 3phaseMitchell DanielsNo ratings yet

- Panasonic 120 150 PDFDocument5 pagesPanasonic 120 150 PDFMitchell DanielsNo ratings yet

- 3M 8300 Series Particulate Respirator: Technical Data SheetDocument3 pages3M 8300 Series Particulate Respirator: Technical Data SheetMitchell DanielsNo ratings yet

- LCM S24064GSF 1134121Document5 pagesLCM S24064GSF 1134121Mitchell DanielsNo ratings yet

- HDM 128GS24: Dimensional DrawingDocument2 pagesHDM 128GS24: Dimensional DrawingMitchell DanielsNo ratings yet

- GLK24064-25/GLT24064: Technical ManualDocument69 pagesGLK24064-25/GLT24064: Technical ManualMitchell DanielsNo ratings yet

- Wye-Delta and Solid-State StartersDocument22 pagesWye-Delta and Solid-State StartersMitchell DanielsNo ratings yet

- Panasonic Autodoor 228 248 Eng PDFDocument49 pagesPanasonic Autodoor 228 248 Eng PDFWerner Wolff Neuert100% (1)

- Manual Vector Reflectometer Arinst VR 23-6200 ENGDocument56 pagesManual Vector Reflectometer Arinst VR 23-6200 ENGMitchell DanielsNo ratings yet

- NHD-24064CZ-NSW-BBW: Graphic Liquid Crystal Display ModuleDocument11 pagesNHD-24064CZ-NSW-BBW: Graphic Liquid Crystal Display ModuleMitchell DanielsNo ratings yet

- Manual Changeover Switches & Automatic Transfer SwitchesDocument16 pagesManual Changeover Switches & Automatic Transfer SwitchesMitchell DanielsNo ratings yet

- Ifr 1000s Operation ManualDocument351 pagesIfr 1000s Operation ManualMitchell DanielsNo ratings yet

- THERMAL INSULATION OF SINGLE LEAF FIRE DOORS TestDocument7 pagesTHERMAL INSULATION OF SINGLE LEAF FIRE DOORS TestMitchell DanielsNo ratings yet

- User Guide: 300Mbps Wireless N Router TL-WR841NDocument184 pagesUser Guide: 300Mbps Wireless N Router TL-WR841NMitchell DanielsNo ratings yet

- User Manual PowerRayDocument36 pagesUser Manual PowerRayMitchell DanielsNo ratings yet

- Features: Medium Size Graphic Type LCD ModuleDocument1 pageFeatures: Medium Size Graphic Type LCD ModuleMitchell DanielsNo ratings yet

- SGM Series RF Modules: Fast Time To Market For Your Product - With Proven RF Performance !Document4 pagesSGM Series RF Modules: Fast Time To Market For Your Product - With Proven RF Performance !Mitchell DanielsNo ratings yet

- Gas Control & Regulation Products: Solenoid, Motorised & Pneumatic Control ValvesDocument2 pagesGas Control & Regulation Products: Solenoid, Motorised & Pneumatic Control ValvesPune Gas Service TeamNo ratings yet

- Farahani Et Al. (2019)Document11 pagesFarahani Et Al. (2019)Aline Caiado MachadoNo ratings yet

- PESTLE AnalysisDocument30 pagesPESTLE Analysispriti_chitiNo ratings yet

- Inverter Temperature MonitoringDocument3 pagesInverter Temperature Monitoringnemarc08No ratings yet

- 5600 CFMDocument1 page5600 CFMmohammed rameesNo ratings yet

- Mod 941Document2 pagesMod 941J. M.No ratings yet

- SACE PR010/T Test Unit Annex: RH0029002.book Page 1 Thursday, May 5, 2011 12:14 PMDocument30 pagesSACE PR010/T Test Unit Annex: RH0029002.book Page 1 Thursday, May 5, 2011 12:14 PMJatupol PongsirisartNo ratings yet

- MTU - S60 Marine ContinuousDocument2 pagesMTU - S60 Marine ContinuousRomie HarieNo ratings yet

- Denyo CatalogueDocument9 pagesDenyo CatalogueEslam MahfouzNo ratings yet

- Ruby Conference PaperDocument6 pagesRuby Conference Paperwilliamcutler2001No ratings yet

- C 05 Transmission of PowerDocument25 pagesC 05 Transmission of PowerMinh SpamNo ratings yet

- Glass Ceiling Effect On Women's Career Development in Public and Private Companies: A Comparative Study in Oman Oil and Gas SectorDocument7 pagesGlass Ceiling Effect On Women's Career Development in Public and Private Companies: A Comparative Study in Oman Oil and Gas SectorajmrdNo ratings yet

- Heat TransferDocument21 pagesHeat TransferRahel Yemane Embaye TeweldeNo ratings yet

- Lesson Plan in Earth and Life Science 12Document2 pagesLesson Plan in Earth and Life Science 12Ryl MitchNo ratings yet

- A 48 CP, Ap, FPDocument1 pageA 48 CP, Ap, FPMuhammad HannanNo ratings yet

- Nufft ManualDocument13 pagesNufft ManualPablo MartinezNo ratings yet

- A Year of Process Safety Incident Case Studies 1711203178Document27 pagesA Year of Process Safety Incident Case Studies 1711203178nyccmpkv2yNo ratings yet

- Lecture 23: Outline: Yell If You Have Any QuestionsDocument43 pagesLecture 23: Outline: Yell If You Have Any Questionsakirank1No ratings yet

- Project Variation To Shell DEP 31.29.02.30 Centrifugal Pumps (Amendments / Supplements To ISO 13709)Document24 pagesProject Variation To Shell DEP 31.29.02.30 Centrifugal Pumps (Amendments / Supplements To ISO 13709)tonful143No ratings yet

- FLEXIM GMBH 2012 NFOGM - 01Document21 pagesFLEXIM GMBH 2012 NFOGM - 01Chanchalraj BhatiNo ratings yet

- RATHDocument12 pagesRATHYoo KyungsikNo ratings yet

- Case Study IDocument1 pageCase Study IAldrin B. Lopez33% (3)

- A Seminar Report On: Robot Welding Technology ' BYDocument24 pagesA Seminar Report On: Robot Welding Technology ' BYShadabNo ratings yet

- PDACCINDocument1 pagePDACCINgadjezNo ratings yet

- Bvi Man Marc2-C10 Used Machine For Sale No. 138468526Document5 pagesBvi Man Marc2-C10 Used Machine For Sale No. 138468526Aaron GamezNo ratings yet

- Application of Molded and Field Sucker Rod GuidesDocument28 pagesApplication of Molded and Field Sucker Rod GuidesRuben Chirinos OlivaresNo ratings yet

- 07 20mm LT Neutrex Titanium Brochure Rev 7 Aug 2 2017Document1 page07 20mm LT Neutrex Titanium Brochure Rev 7 Aug 2 2017Saif MoumeNo ratings yet

- 19338-Technical Specification - R1 (001-250)Document250 pages19338-Technical Specification - R1 (001-250)Jesus SevillaNo ratings yet

- Black Box Tech Lab: simple Adams motor concept 亚当斯电机原理11Document10 pagesBlack Box Tech Lab: simple Adams motor concept 亚当斯电机原理11Janet WaldeNo ratings yet