100%(3)100% found this document useful (3 votes)

2K viewsAmmonia Material 2520 Balance

Ammonia Material 2520 Balance

Uploaded by

api-3714811The document describes the material balance of a naphtha desulphurization and ammonia synthesis process. It details the inputs and outputs at each stage of processing, which includes desulphurization, reforming, shifting, absorption, methanation and ammonia synthesis. The goal is to produce ammonia (NH3) from naphtha through these conversion and purification steps.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Ammonia Material 2520 Balance

Ammonia Material 2520 Balance

Uploaded by

api-3714811100%(3)100% found this document useful (3 votes)

2K views7 pagesThe document describes the material balance of a naphtha desulphurization and ammonia synthesis process. It details the inputs and outputs at each stage of processing, which includes desulphurization, reforming, shifting, absorption, methanation and ammonia synthesis. The goal is to produce ammonia (NH3) from naphtha through these conversion and purification steps.

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

The document describes the material balance of a naphtha desulphurization and ammonia synthesis process. It details the inputs and outputs at each stage of processing, which includes desulphurization, reforming, shifting, absorption, methanation and ammonia synthesis. The goal is to produce ammonia (NH3) from naphtha through these conversion and purification steps.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(3)100% found this document useful (3 votes)

2K views7 pagesAmmonia Material 2520 Balance

Ammonia Material 2520 Balance

Uploaded by

api-3714811The document describes the material balance of a naphtha desulphurization and ammonia synthesis process. It details the inputs and outputs at each stage of processing, which includes desulphurization, reforming, shifting, absorption, methanation and ammonia synthesis. The goal is to produce ammonia (NH3) from naphtha through these conversion and purification steps.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 7

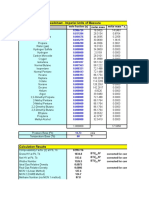

MATERIAL BALANCE

The naphtha has the following composition by weight

Hydrogen 16.2%

Carbon 83.0%

Sulphur 0.8%

Composition of the same naphtha by mole is

Hydrogen (H2) 53.85%

Carbon (C) 45.98%

Sulphur (S) 0.17%

Desulphurizer

Sulphur present is removed as Hydrogen Sulphide in the desulphurizer

Input

Naptha :

Hydrogen (H2) 2454.7 kmol/hr

Carbon (C) 1929.7 kmol/hr

Sulphur (S) 11.1 kmol/hr

Hydrogen gas stream(H2) 209.8 kmol/hr

Output

Desulphurized Naptha :

Hydrogen (H2) 2454.7 kmol/hr

Carbon (C) 1929.7 kmol/hr

Hydrogen gas (H2) 198.1 kmol/hr

Hydrogen Sulphide (H2S) 11.1 kmol/hr

Primary Reformer

In the primary reformer the desulphurized naphtha is made to react with Steam

to yield Hydrogen, Carbon monoxide, Carbon dioxide, Methane.

To prevent the formation of carbon the steam to carbon ratio is maintained at 3.9

Input

Desulphurized Naptha:

Hydrogen (H2) 2454,7 kmol/hr

Carbon (C) 1929.7 kmol/hr

Hydrogen gas 198.1 kmol/hr

Steam (H2O) 7525.8 kmol/hr

Output

Hydrogen (H2) 3745.8 kmol/hr

Carbon monoxide (CO) 964.8 kmol/hr

Carbon dioxide (CO2) 567.6 kmol/hr

Methane (CH4) 397.4 kmol/hr

Steam (H2O) 5440.0 kmol/hr

Secondary Reformer

Input

Hydrogen (H2) 3745.8 kmol/hr

Carbon monoxide (CO) 964.8 kmol/hr

Carbon dioxide (CO2) 567.6 kmol/hr

Methane (CH4) 397.4 kmol/hr

Air:

Nitrogen (N2) 2148,4 kmol/hr

Oxygen (O2) 596.4 kmol/hr

Inerts (Ar +others) 9.5 kmol/hr

Water vapour (H2O) 428.4 kmol/hr

Steam (H2O) 5440 kmol/hr

Output

Hydrogen (H2) 5418.4 kmol/hr

Carbon monoxide (CO) 1093.2 kmol/hr

Carbon dioxide (CO2) 817.5 kmol/hr

Methane (CH4) 19.0 kmol/hr

Nitrogen (N2) 2148,4 kmol/hr

Inerts (Ar +others) 9.5 kmol/hr

Steam (H2O) 5350.5 kmol/hr

High Temperature Shift Converter

Input

Hydrogen (H2) 5418.4 kmol/hr

Carbon monoxide (CO) 1093.2 kmol/hr

Carbon dioxide (CO2) 817.5 kmol/hr

Methane (CH4) 19.0 kmol/hr

Nitrogen (N2) 2148,4 kmol/hr

Inerts (Ar +others) 9.5 kmol/hr

Steam (H2O) 5350.5 kmol/hr

Output

Hydrogen (H2) 6202.9 kmol/hr

Carbon monoxide (CO) 308.9 kmol/hr

Carbon dioxide (CO2) 1602.0 kmol/hr

Methane (CH4) 19.0 kmol/hr

Nitrogen (N2) 2148,4 kmol/hr

Inerts (Ar +others) 9.5 kmol/hr

Steam (H2O) 4566.5 kmol/hr

Low Temperature Shift Converter

Input

Hydrogen (H2) 6202.9 kmol/hr

Carbon monoxide (CO) 308.9 kmol/hr

Carbon dioxide (CO2) 1602.0 kmol/hr

Methane (CH4) 19.0 kmol/hr

Nitrogen (N2) 2148,4 kmol/hr

Inerts (Ar +others) 9.5 kmol/hr

Steam (H2O) 4566.5 kmol/hr

Output

Hydrogen (H2) 6474.9 kmol/hr

Carbon monoxide (CO) 31.7 kmol/hr

Carbon dioxide (CO2) 1879.0 kmol/hr

Methane (CH4) 19.0 kmol/hr

Nitrogen (N2) 2148,4 kmol/hr

Inerts (Ar +others) 9.5 kmol/hr

Steam (H2O) 4289.5 kmol/hr

Condenser

The exit stream from the Low temperature Converter is sent into a condenser to

remove the steam present which would be an additional excess load on the

Absorber

Within the condenser all the water is removed as condensate. Only water is

removed and the exit stream from this goes to the Absorber

Input

Hydrogen (H2) 6474.9 kmol/hr

Carbon monoxide (CO) 31.7 kmol/hr

Carbon dioxide (CO2) 1879.0 kmol/hr

Methane (CH4) 19.0 kmol/hr

Nitrogen (N2) 2148,4 kmol/hr

Inerts (Ar +others) 9.5 kmol/hr

Steam (H2O) 4289.5 kmol/hr

Output

Hydrogen (H2) 6474.9 kmol/hr

Carbon monoxide (CO) 31.7 kmol/hr

Carbon dioxide (CO2) 1879.0 kmol/hr

Methane (CH4) 19.0 kmol/hr

Nitrogen (N2) 2148,4 kmol/hr

Inerts (Ar +others) 9.5 kmol/hr

Absorber

Within the absorber Carbon dioxide is absorbed using Monoethanolamine. It is

assumed that only Carbon dioxide is soluble in MEA solution. Solubility of other

gases in MEA is assumed to be negligible. It is further obtained from literature

that the CO2 content in the exit stream is 0.5% of the total gas stream.

Input

Hydrogen (H2) 6474.9 kmol/hr

Carbon monoxide (CO) 31.7 kmol/hr

Carbon dioxide (CO2) 1879.0 kmol/hr

Methane (CH4) 19.0 kmol/hr

Nitrogen (N2) 2148,4 kmol/hr

Inerts (Ar +others) 9.5 kmol/hr

Output

Hydrogen (H2) 6474.9 kmol/hr

Carbon monoxide (CO) 31.7 kmol/hr

Carbon dioxide (CO2) 1879.0 kmol/hr

Methane (CH4) 19.0 kmol/hr

Nitrogen (N2) 2148,4 kmol/hr

Inerts (Ar +others) 9.5 kmol/hr

Methanator

Within the Methanator Oxides of Carbon are made to react with Hydrogen in the

presence of catalysts because oxides of carbon act as poisons for the catalysts in

the Ammonia synthesis loop. CO and CO2 react with Hydrogen to form Methane

and steam. Steam is removed by condensation and separated from the gaseous

mixture going into the synthesis loop. Methane is an inert material in the

synthesis loop.

Input

Hydrogen (H2) 6474.9 kmol/hr

Carbon monoxide (CO) 31.7 kmol/hr

Carbon dioxide (CO2) 1879.0 kmol/hr

Methane (CH4) 19.0 kmol/hr

Nitrogen (N2) 2148,4 kmol/hr

Inerts (Ar +others) 9.5 kmol/hr

Output

Hydrogen (H2) 6367.9 kmol/hr

Methane (CH4) 60.1 kmol/hr

Nitrogen (N2) 2148,4 kmol/hr

Inerts (Ar +others) 34.5 kmol/hr

Steam (H2O) 25.3 kmol/hr

Ammonia Synthesis Loop

Make up Gas

Hydrogen (H2) 6367.4 kmol/hr

Methane (CH4) 60.1 kmol/hr

Nitrogen (N2) 2148,4 kmol/hr

Inerts (Ar +others) 34.5 kmol/hr

Recycle Stream

Hydrogen (H2) 18624.3 kmol/hr

Nitrogen (N2) 6182.2 kmol/hr

Ammonia (NH3) 774.9 kmol/hr

Inerts (Ar + CH4) 4555.0 kmol/hr

Gas into Converter

Hydrogen (H2) 24991.7 kmol/hr

Nitrogen (N2) 8330.6 kmol/hr

Ammonia (NH3) 774,9 kmol/hr

Inerts (Ar + CH4) 4649.6 kmol/hr

Purge

Hydrogen (H2) 560.5 kmol/hr

Nitrogen (N2) 69.8 kmol/hr

Ammonia (NH3) 74.2 kmol/hr

Inerts (Ar + CH4) 72.4 kmol/hr

Storage

Ammonia (NH3) 3676.4 kmol/hr

Nitrogen (N2) 204.2 kmol/hr

Hydrogen (H2) 183.8 kmol/hr

Inerts (Ar + CH4) 20.4 kmol/hr

You might also like

- H - H O O: 2019 Raci Australian National Chemistry Quiz Years 7 & 8 DataDocument11 pagesH - H O O: 2019 Raci Australian National Chemistry Quiz Years 7 & 8 Dataxyz100% (5)

- Lurgi MegamethanolDocument8 pagesLurgi MegamethanolAngeloNo ratings yet

- Soda Ash Material BalanceDocument5 pagesSoda Ash Material BalanceVinh Do Thanh100% (4)

- Advanced Gas-Heated Reformer: P. W. FarneilDocument9 pagesAdvanced Gas-Heated Reformer: P. W. FarneilAlfonso BlancoNo ratings yet

- Ammonia Synthesis Loops Variables Investigated by Steady-State SimulationDocument14 pagesAmmonia Synthesis Loops Variables Investigated by Steady-State Simulationpolonium2310No ratings yet

- ATR Haldor TopsoeDocument12 pagesATR Haldor Topsoepraveenk_13100% (1)

- 2012 5 Toc r1Document11 pages2012 5 Toc r1adame_uds100% (1)

- Proposal For UreaDocument24 pagesProposal For UreaUmar ZamanNo ratings yet

- Confined Space Entry: Approval and Authority To CommenceDocument2 pagesConfined Space Entry: Approval and Authority To CommenceAndiWSutomo100% (1)

- Haber Process For The Production of Ammonia 1Document4 pagesHaber Process For The Production of Ammonia 1Nisha SundarNo ratings yet

- (A) Ammonia Energy CalculationDocument3 pages(A) Ammonia Energy Calculationlightsons100% (1)

- Ammonia Mass BalanceDocument34 pagesAmmonia Mass Balanceaskaridumbo82% (17)

- Ammonia - Heat & Mat. BalanceDocument30 pagesAmmonia - Heat & Mat. BalanceRajeshkumar ElangoNo ratings yet

- New KBR Process For Coal To Ammonia: Kamal Gursahani, Siva Ariyapadi, Meghji Shah and Richard StraitDocument12 pagesNew KBR Process For Coal To Ammonia: Kamal Gursahani, Siva Ariyapadi, Meghji Shah and Richard Straitvaratharajan g rNo ratings yet

- KSFL ReportDocument56 pagesKSFL ReportAbhishek KumarNo ratings yet

- Feasibilty For The ProjectDocument18 pagesFeasibilty For The ProjectRana UzairNo ratings yet

- Ammonia Energy 2520 BalanceDocument7 pagesAmmonia Energy 2520 Balanceapi-3714811No ratings yet

- Plant Layout PDFDocument19 pagesPlant Layout PDFazzatul amiraNo ratings yet

- Natural Gas To MethanolDocument2 pagesNatural Gas To MethanolHafiz Aziz67% (3)

- Ammonia and Urea ProductionDocument10 pagesAmmonia and Urea Productionwaheed_bhattiNo ratings yet

- Ammonia ProductionDocument28 pagesAmmonia ProductionMuhammad Ali HashmiNo ratings yet

- Workshop On Energy Efficiency and CO2 ReductionDocument124 pagesWorkshop On Energy Efficiency and CO2 ReductionvirginiaucvNo ratings yet

- Hysys Methanol ProductionDocument1 pageHysys Methanol ProductionNguyễn Tiến Dũng100% (1)

- Coal GasificationDocument16 pagesCoal GasificationSheheryar MirzaNo ratings yet

- Equipment History SheetDocument4 pagesEquipment History Sheetasnandy100% (1)

- AS.B1EN 1113 - &AA - History - .Layout19 - 4353 PDFDocument20 pagesAS.B1EN 1113 - &AA - History - .Layout19 - 4353 PDFAbednego ZanoNo ratings yet

- The Uhde Ammonia ProcessesDocument2 pagesThe Uhde Ammonia ProcessesMohamed R BeialyNo ratings yet

- Hydrogen Production by Steam Reforming of HC by TopsoeDocument2 pagesHydrogen Production by Steam Reforming of HC by TopsoeMainak Sarkar100% (1)

- Topsoe Ammonia 4 Start Up Worlds Largest Ammonia PlantDocument13 pagesTopsoe Ammonia 4 Start Up Worlds Largest Ammonia PlantSyariful Maliki NejstaršíNo ratings yet

- Green Ammonia ShipmentDocument9 pagesGreen Ammonia ShipmentVedant ParabNo ratings yet

- JM Methanol BrochureDocument24 pagesJM Methanol BrochureM Alim Ur Rahman100% (1)

- Methanol Catalyst Poisons - A Literature Study (CCS)Document19 pagesMethanol Catalyst Poisons - A Literature Study (CCS)ahsan888No ratings yet

- Ammonia The Next StepDocument11 pagesAmmonia The Next StepmuralleroNo ratings yet

- Rectisol Wash Units: Acid Gas Removal For Polygeneration Concepts Downstream GasificationDocument34 pagesRectisol Wash Units: Acid Gas Removal For Polygeneration Concepts Downstream Gasificationpippo2378793No ratings yet

- Simulation of Ammonia Production From Synthesis GaDocument12 pagesSimulation of Ammonia Production From Synthesis Gasagar dasguptaNo ratings yet

- Ammonia TechnologyDocument7 pagesAmmonia TechnologyAbhiyan Anala ArvindNo ratings yet

- Two Main Types of Production Process For Ammonia Synthesis Gas Are Currently in Operation in EuropeDocument9 pagesTwo Main Types of Production Process For Ammonia Synthesis Gas Are Currently in Operation in EuropetauseefaroseNo ratings yet

- Acetic AcidDocument8 pagesAcetic AcidMohammedRahimNo ratings yet

- Published January 16, 2012 at In: 813 × 699 Block Diagram of Urea Production From NH3 and CO2Document9 pagesPublished January 16, 2012 at In: 813 × 699 Block Diagram of Urea Production From NH3 and CO2himanshuchawla654No ratings yet

- GV Absorber Shell Leak in Ammonia Plant-II at IFFCO, Aonla Unit, IndiaDocument12 pagesGV Absorber Shell Leak in Ammonia Plant-II at IFFCO, Aonla Unit, Indiavaratharajan g rNo ratings yet

- 2009 Margarita Seminar - 10 Successful Applications of Casale Technology To Grass-Roots PlantsDocument32 pages2009 Margarita Seminar - 10 Successful Applications of Casale Technology To Grass-Roots PlantsIvonneNo ratings yet

- Ammonia Energy - EfficiencyDocument4 pagesAmmonia Energy - Efficiencyanupam01013787No ratings yet

- PROCESS Description 2Document9 pagesPROCESS Description 2Nabeel SiddiqueNo ratings yet

- Economics of Ammonia Production From OffgasesDocument6 pagesEconomics of Ammonia Production From Offgasesvkarora58No ratings yet

- Ammonia Cracker PDFDocument8 pagesAmmonia Cracker PDFpinky_y2kNo ratings yet

- New SynCOR Ammonia™ ProcessDocument12 pagesNew SynCOR Ammonia™ Processrukam18No ratings yet

- Uhde Brochures PDF en 5 (Ammonia)Document0 pagesUhde Brochures PDF en 5 (Ammonia)golovanNo ratings yet

- 3327hd - Ludman Compaction PDFDocument116 pages3327hd - Ludman Compaction PDFsharemwNo ratings yet

- Four Challenges For Nickel Steam-Reforming CatalystsDocument8 pagesFour Challenges For Nickel Steam-Reforming CatalystsReza Rhi100% (2)

- Commissioning of The First Ammonia-Urea Complex: A Challenging Venture For The Vietnamese EconomyDocument13 pagesCommissioning of The First Ammonia-Urea Complex: A Challenging Venture For The Vietnamese Economyvaratharajan g rNo ratings yet

- Aiche-36-021Equipment Performance of AmmoniaDocument9 pagesAiche-36-021Equipment Performance of AmmoniaHsein Wang100% (1)

- Ammonia Material BalanceDocument7 pagesAmmonia Material BalanceSiva KumarNo ratings yet

- Desulfurizer: G CM KG C ComoDocument2 pagesDesulfurizer: G CM KG C ComogimanNo ratings yet

- In Steady State Flow, The Total Mass of Material Entering A Reactor Must Equal To Total Mass Leaving The ReactorDocument8 pagesIn Steady State Flow, The Total Mass of Material Entering A Reactor Must Equal To Total Mass Leaving The Reactoriko856No ratings yet

- The Ammonia Manufacturing ProcessDocument85 pagesThe Ammonia Manufacturing Processdabit imageNo ratings yet

- Boiler Efficiency by Indirect Method Coal Fired BoilerDocument4 pagesBoiler Efficiency by Indirect Method Coal Fired BoilerM Ziaul ArifNo ratings yet

- Flue GasDocument5 pagesFlue GasMortalNo ratings yet

- Cálculo de Eficiencia de Un HornoDocument29 pagesCálculo de Eficiencia de Un HornoFranklin Santiago Suclla PodestaNo ratings yet

- Material BalanceDocument6 pagesMaterial BalanceMehran Rasheed GorayaNo ratings yet

- Mass Balance ReportDocument43 pagesMass Balance ReportSzelee Kuek50% (2)

- Goga Sent FileDocument19 pagesGoga Sent FileShah Ali NaqviNo ratings yet

- Practical Synthetic Organic Chemistry: Reactions, Principles, and TechniquesFrom EverandPractical Synthetic Organic Chemistry: Reactions, Principles, and TechniquesNo ratings yet

- Acetaldehyde Pollution 2520control&safetyDocument2 pagesAcetaldehyde Pollution 2520control&safetyapi-3714811No ratings yet

- Acetaldehyde Plant 2520Location&LayoutDocument6 pagesAcetaldehyde Plant 2520Location&Layoutapi-3714811No ratings yet

- Acetaldehyde Energy 2520 BalanceDocument10 pagesAcetaldehyde Energy 2520 Balanceapi-3714811100% (1)

- Acetaldehyde Energy 2520 BalanceDocument10 pagesAcetaldehyde Energy 2520 Balanceapi-3714811100% (1)

- Acetaldehyde Cost 2520Estimation&EconomicsDocument8 pagesAcetaldehyde Cost 2520Estimation&Economicsapi-3714811100% (1)

- Distillation Column Complete DesignDocument59 pagesDistillation Column Complete DesignViswanath KapavarapuNo ratings yet

- Acetaldehyde Methods 2520of 2520 ProductionDocument6 pagesAcetaldehyde Methods 2520of 2520 Productionapi-3714811100% (3)

- AAS Energy 2520 BalanceDocument3 pagesAAS Energy 2520 Balanceapi-3714811No ratings yet

- AAS Pollution 2520control&safetyDocument1 pageAAS Pollution 2520control&safetyapi-3714811No ratings yet

- Acetaldehyde Bibliography PDFDocument1 pageAcetaldehyde Bibliography PDFRajat MittalNo ratings yet

- AAS Properties&UsesDocument3 pagesAAS Properties&Usesapi-3714811No ratings yet

- Ammonia Properties&UsesDocument3 pagesAmmonia Properties&UsessogieriakhiNo ratings yet

- Bracket Design For ReactorDocument32 pagesBracket Design For ReactorbrencejunNo ratings yet

- AAS Material 2520 BalanceDocument4 pagesAAS Material 2520 Balanceapi-3714811No ratings yet

- Ammonia Plant 2520Location&LayoutDocument4 pagesAmmonia Plant 2520Location&Layoutapi-3714811100% (1)

- Ammonia Design 2520of 2520equipmentsDocument32 pagesAmmonia Design 2520of 2520equipmentsapi-3714811100% (1)

- Acrylic 2520acid Pollution 2520control&safetyDocument6 pagesAcrylic 2520acid Pollution 2520control&safetyMarnel Roy MayorNo ratings yet

- Ammonia - Methods 2520of 2520production PDFDocument4 pagesAmmonia - Methods 2520of 2520production PDFchetanmaleNo ratings yet

- Ammonia Energy 2520 BalanceDocument7 pagesAmmonia Energy 2520 Balanceapi-3714811No ratings yet

- Acrylic 2520acid 2520Properties&UsesDocument6 pagesAcrylic 2520acid 2520Properties&UsesDhaval PatelNo ratings yet

- Acrylic 2520acid Methods 2520of 2520 ProductionDocument8 pagesAcrylic 2520acid Methods 2520of 2520 Productionapi-3714811No ratings yet

- Udex PlantDocument4 pagesUdex PlantMiko Yee Teng100% (1)

- Toluene Properties&UsesDocument7 pagesToluene Properties&Usesapi-3714811100% (1)

- Toluene Pollution 2520control&safetyDocument8 pagesToluene Pollution 2520control&safetyapi-3714811No ratings yet

- Acrylic 2520acid 2520 Material 2520 BalanceDocument6 pagesAcrylic 2520acid 2520 Material 2520 Balanceapi-3714811No ratings yet

- Toluene Plant 2520Location&LayoutDocument7 pagesToluene Plant 2520Location&Layoutapi-3714811No ratings yet

- Toluene Energy 2520 BalanceDocument3 pagesToluene Energy 2520 Balanceapi-3714811No ratings yet

- Toluene Material 2520 BalanceDocument5 pagesToluene Material 2520 Balanceapi-3714811No ratings yet

- Toluene IntroductionDocument4 pagesToluene IntroductionVinay BabuNo ratings yet

- 4A. IntroductionDocument20 pages4A. IntroductionZoonieFRNo ratings yet

- ACSI 2021 PrelimsDocument23 pagesACSI 2021 PrelimsTrần KiênNo ratings yet

- HEV Application GuideDocument56 pagesHEV Application GuidejonbirdunccNo ratings yet

- Champion 100624 Log SPlitter ENDocument31 pagesChampion 100624 Log SPlitter ENTenny SupNo ratings yet

- MCT MC (T + 273) : IB Chemistry SL Topic 5 Questions 1. 5. 9Document16 pagesMCT MC (T + 273) : IB Chemistry SL Topic 5 Questions 1. 5. 9MiriamNo ratings yet

- 2014 Industrial Product Guide PG66691 NCLDocument130 pages2014 Industrial Product Guide PG66691 NCLNaser JahangiriNo ratings yet

- Carbon FamilyDocument33 pagesCarbon Familyk narayanaraoNo ratings yet

- CUET 2022 PYQ English (3 Sets)Document35 pagesCUET 2022 PYQ English (3 Sets)Sarvesh SreedharNo ratings yet

- No. of Patents US4013428 - Lurgi Gasification ProcessDocument8 pagesNo. of Patents US4013428 - Lurgi Gasification ProcessChristian ImanuelNo ratings yet

- Engineering ChemistryDocument60 pagesEngineering ChemistryAditya ShindeNo ratings yet

- Final ProjectDocument80 pagesFinal ProjectLASSANANo ratings yet

- AGA5 Calculation-Imperial UnitDocument24 pagesAGA5 Calculation-Imperial UnitlubangjarumNo ratings yet

- Manufacturing Methods: 1. Methanol Carbonylation 2. Acetaldehyde Oxidation 3. Ethylene Oxidation 4. Anerobic FermentationDocument39 pagesManufacturing Methods: 1. Methanol Carbonylation 2. Acetaldehyde Oxidation 3. Ethylene Oxidation 4. Anerobic Fermentationkumari svgNo ratings yet

- Occupational Toxicology: Threshold Limit Values (TLVS) Environmental ToxicologyDocument7 pagesOccupational Toxicology: Threshold Limit Values (TLVS) Environmental ToxicologyJustin Victor AngNo ratings yet

- Preparation of A New Precipitated Iron Catalyst F-T - FujimotoDocument5 pagesPreparation of A New Precipitated Iron Catalyst F-T - FujimotoAngélica ForgionnyNo ratings yet

- Chemical Reactions PDFDocument100 pagesChemical Reactions PDFbabyu1100% (1)

- Gas Service HandbookDocument36 pagesGas Service HandbookImah MahdiNo ratings yet

- 05-Equilibrium Composition of FlamesDocument47 pages05-Equilibrium Composition of FlamesAreti MalkogianniNo ratings yet

- Army Aviation Digest - Mar 1986Document48 pagesArmy Aviation Digest - Mar 1986Aviation/Space History LibraryNo ratings yet

- Air PowerpointDocument12 pagesAir Powerpointrengar gamerNo ratings yet

- Life Cycle Associates - E15 ReportDocument62 pagesLife Cycle Associates - E15 ReportAirChicago100% (1)

- 2-Air Pollution ControlDocument85 pages2-Air Pollution ControlRameish SubarmaniyanNo ratings yet

- EMS Burn Management PDFDocument30 pagesEMS Burn Management PDFRaymond Sitanaja0% (1)

- ASTM D6522-00 Determination of NOx, CO, and O2 Concentrations in Emissions Using Portable AnalyzersDocument9 pagesASTM D6522-00 Determination of NOx, CO, and O2 Concentrations in Emissions Using Portable AnalyzersFredi Cari Carrera100% (1)

- Henares, Jr. vs. Land Transportation Franchising and Regulatory BoardDocument23 pagesHenares, Jr. vs. Land Transportation Franchising and Regulatory BoardtynapayNo ratings yet

- Air Quality:: Definitions, Characteristics, and PerspectivesDocument37 pagesAir Quality:: Definitions, Characteristics, and Perspectives^nana^No ratings yet

- Aqi LabDocument3 pagesAqi Labapi-332813379No ratings yet

- Catalyst Development For Water-Gas Shift: Volume 3, Part 2, PP 190-201 inDocument13 pagesCatalyst Development For Water-Gas Shift: Volume 3, Part 2, PP 190-201 inleonardoNo ratings yet