Crgo MTC

Crgo MTC

Uploaded by

Gupta GuptaCopyright:

Available Formats

Crgo MTC

Crgo MTC

Uploaded by

Gupta GuptaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Crgo MTC

Crgo MTC

Uploaded by

Gupta GuptaCopyright:

Available Formats

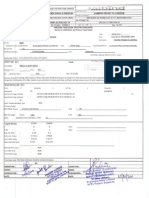

Mill Test Certificate/

Order No./ Supplier/ Customer/ :0004944308 :POSCO Asia Co., Ltd. :POS-IDPC

Weight Product No. Quantity (kg) Heat No.

P O S I T I O N

Certificate No./ Date of Issue/ Insulation Coating/ PO No./ Commodity/ Spec & Type/

Core Loss Core Loss

60Hz/1.7T

:111014-PESC-022-001 :Dec., 08, 2011 :C-10A Coating SRA Permitted

:4944308 :CGO COIL :POSCO 27PG 130

D I V I S I O N

Size/

50Hz/1.7T

MagneticFlux Density

800A/m

Chemical Composition/ C -4 Si -3 Mn -3 P -4 S -4

(%)

(W/kg) 0.98

(W/kg) 1.29

(Tesla) 1.89

0.27x1000xC *** Sub Total *** Grade Total *** *** Grand Total ***

EAV1404B ( 030 ) ***

1 1 1 1

4,020

SB13707

4,020 (kg) 4,020 (kg) 4,020 (kg) === Last Item ===

* * * * * * * * *

Position - T : Top, M : Middle, B : Bottom Bend test: min 3 bends waviness: max 1.5% (Height/Pitch) Stacking factor: 0.23mm-min 94.5%/0.27mm-95%/0.30mm-95.5%/0.35mm-96% Ageing: max 3% deterioration after 150C x 216hr Guarantee : core loss(1.7T/50Hz), Induction(B8), Stacking factor Division - L:Ladle Analysis Chemical Composition Unit: -2:x1/100, -3:x1/1000, -4:x1/10000, -5:x1/100000 Tr : It is within the standard range and include trace element.

We hereby certify that the material herein has been made in accordance with the order and above specification. 1) Measurements have been made in accordance with the procedure of the test method(JIS C2550 or ASTM A343) for electrical steel sheets. 2) Measurements have been made after stress relief annealing under the condition of 84010? for 1hr at 100% N2 atmosphere

This material is fine grained steel. * This Mill Test Certificate cannot be copied for any purpose.

Surveyor To:

POSCO Pohang Works, 5 Dongchon-dong, Nam-gu, Pohang-si, Gyeongsangbuk-do, 790-785, Korea

Chief of material testing section

Man Soo, Jang

Mill Test Certificate/

Order No./ Supplier/ Customer/ :0004950487 :POSCO Asia Co., Ltd. :POS-IDPC

Weight Product No. Quantity (kg) Heat No.

P O S I T I O N

Certificate No./ Date of Issue/ Insulation Coating/ PO No./ Commodity/ Spec & Type/ :4950487 :HGO COIL :POSCO 23PHD085

D I V I S I O N

:111014-PESC-004-001 :Dec., 08, 2011 :C-10A Coating SRA Permitted

Size/

SST. MagneticFlux Density

800A/m

SST. Core Loss

50Hz/1.7T

SST. Core Loss

60Hz/1.7T

Chemical Composition/ C -4 Si -3 Mn -3 P -4 S -4

(%)

(Tesla) 1.92 0.76 0.99

0.23x1000xC *** Sub Total *** Grade Total *** *** Grand Total ***

EAW1376C ( 010 ) ***

1 1 1 1

4,120

SB17893

4,120 (kg) 4,120 (kg) 4,120 (kg) === Last Item ===

* * * * * * * * *

Position - T : Top, M : Middle, B : Bottom Bend test: min 3 bends waviness: max 1.5% (Height/Pitch) Stacking factor: 0.23mm-min 94.5%/0.27mm-95%/0.30mm-95.5%/0.35mm-96% Ageing: max 3% deterioration after 150C x 216hr Guarantee : core loss(1.7T/50Hz), Induction(B8), Stacking factor Division - L:Ladle Analysis Chemical Composition Unit: -2:x1/100, -3:x1/1000, -4:x1/10000, -5:x1/100000 Tr : It is within the standard range and include trace element.

We hereby certify that the material herein has been made in accordance with the order and above specification. 1) Measurements for core loss and magnetic flux density have been made in accordance with JIS C2556(1996) by SST(Single Sheet Tester) on the specimens as sheared. 2) Stress-relief annealing will nullify the beneficial effects of domain refinement by laser irradiation.

This material is fine grained steel. * This Mill Test Certificate cannot be copied for any purpose.

Surveyor To:

POSCO Pohang Works, 5 Dongchon-dong, Nam-gu, Pohang-si, Gyeongsangbuk-do, 790-785, Korea

Chief of material testing section

Man Soo, Jang

Mill Test Certificate/

Order No./ Supplier/ Customer/ :0004950497 :POSCO Asia Co., Ltd. :POS-IDPC

Weight Product No. Quantity (kg) Heat No.

P O S I T I O N

Certificate No./ Date of Issue/ Insulation Coating/ PO No./ Commodity/ Spec & Type/

Core Loss Core Loss

60Hz/1.5T

:111014-PESC-006-001 :Dec., 08, 2011 :C-10A Coating SRA Permitted

:4950497 :HGO COIL :POSCO 23PH 095

MagneticFlux Density

800A/m D I V I S I O N

Size/

Core Loss

60Hz/1.7T

Chemical Composition/ C -4 Si -3 Mn -3 P -4 S -4

(%)

50Hz/1.7T

(W/kg) 0.90

(W/kg)

(W/kg) 1.18

(Tesla) 1.90

0.23x1000xC *** Sub Total *** Grade Total *** *** Grand Total ***

EAV1189B ( 010 ) ***

1 1 1 1

2,500

SB14461

2,500 (kg) 2,500 (kg) 2,500 (kg) === Last Item ===

* * * * * * * * *

Position - T : Top, M : Middle, B : Bottom Bend test: min 3 bends waviness: max 1.5% (Height/Pitch) Stacking factor: 0.23mm-min 94.5%/0.27mm-95%/0.30mm-95.5%/0.35mm-96% Ageing: max 3% deterioration after 150C x 216hr Guarantee : core loss(1.7T/50Hz), Induction(B8), Stacking factor Division - L:Ladle Analysis Chemical Composition Unit: -2:x1/100, -3:x1/1000, -4:x1/10000, -5:x1/100000 Tr : It is within the standard range and include trace element.

We hereby certify that the material herein has been made in accordance with the order and above specification. 1) Measurements have been made in accordance with the procedure of the test method(JIS C2550 or ASTM A343) for electrical steel sheets. 2) Measurements have been made after stress relief annealing under the condition of 84010? for 1hr at 100% N2 atmosphere

This material is fine grained steel. * This Mill Test Certificate cannot be copied for any purpose.

Surveyor To:

POSCO Pohang Works, 5 Dongchon-dong, Nam-gu, Pohang-si, Gyeongsangbuk-do, 790-785, Korea

Chief of material testing section

Man Soo, Jang

Mill Test Certificate/

Order No./ Supplier/ Customer/ :0004956149 :POSCO Asia Co., Ltd. :POS-IDPC

Weight Product No. Quantity (kg) Heat No.

P O S I T I O N

Certificate No./ Date of Issue/ Insulation Coating/ PO No./ Commodity/ Spec & Type/

Core Loss Core Loss

60Hz/1.7T

:111014-PESC-014-001 :Dec., 08, 2011 :C-10A Coating SRA Permitted

:4956149 :HGO ELECTRICAL STEEL :POSCO 27PH 100

D I V I S I O N

Size/

50Hz/1.7T

MagneticFlux Density

800A/m

Chemical Composition/ C -4 Si -3 Mn -3 P -4 S -4

(%)

(W/kg) 0.94

(W/kg) 1.24

(Tesla) 1.92

0.27x1000xC *** Sub Total *** Grade Total *** *** Grand Total ***

EAV0196A ( 010 ) ***

1 1 1 1

3,520

SB12896

3,520 (kg) 3,520 (kg) 3,520 (kg) === Last Item ===

* * * * * * * * *

Position - T : Top, M : Middle, B : Bottom Bend test: min 3 bends waviness: max 1.5% (Height/Pitch) Stacking factor: 0.23mm-min 94.5%/0.27mm-95%/0.30mm-95.5%/0.35mm-96% Ageing: max 3% deterioration after 150C x 216hr Guarantee : core loss(1.7T/50Hz), Induction(B8), Stacking factor Division - L:Ladle Analysis Chemical Composition Unit: -2:x1/100, -3:x1/1000, -4:x1/10000, -5:x1/100000 Tr : It is within the standard range and include trace element.

We hereby certify that the material herein has been made in accordance with the order and above specification. 1) Measurements have been made in accordance with the procedure of the test method(JIS C2550 or ASTM A343) for electrical steel sheets. 2) Measurements have been made after stress relief annealing under the condition of 84010? for 1hr at 100% N2 atmosphere

This material is fine grained steel. * This Mill Test Certificate cannot be copied for any purpose.

Surveyor To:

POSCO Pohang Works, 5 Dongchon-dong, Nam-gu, Pohang-si, Gyeongsangbuk-do, 790-785, Korea

Chief of material testing section

Man Soo, Jang

You might also like

- Stitch Fix Answer - Sumit K GuptaDocument3 pagesStitch Fix Answer - Sumit K GuptaGupta Gupta100% (3)

- QM-System: Certification As Per ISO 9001: (WWW - Dillinger.de/certificate)Document20 pagesQM-System: Certification As Per ISO 9001: (WWW - Dillinger.de/certificate)hemantmech099200No ratings yet

- Sample FET To ISO 15848-1 PDFDocument4 pagesSample FET To ISO 15848-1 PDFVivi Oktavianti100% (1)

- Flange Type Pig SignallerDocument1 pageFlange Type Pig SignallerPrajwal ShettyNo ratings yet

- Mill Test Certificate: Yong Metal Co.,LimitedDocument2 pagesMill Test Certificate: Yong Metal Co.,LimitedMisael100% (2)

- MTC of Pipe - SSP MakeDocument4 pagesMTC of Pipe - SSP Makemubeennavaz100% (1)

- Mag General Business: Mill Test CertificateDocument1 pageMag General Business: Mill Test CertificateRaul Sebastiam100% (1)

- Posco Korea MTC SampleDocument2 pagesPosco Korea MTC SampleAram Hovsepian0% (1)

- Inc 800 MTC - FlangeDocument1 pageInc 800 MTC - Flangeranjith_007100% (1)

- Commented - 8' PIPE TCDocument1 pageCommented - 8' PIPE TCAqib Khan VCSPNo ratings yet

- MTC FormatDocument1 pageMTC FormatNirmit GandhiNo ratings yet

- Ball Valve MTCDocument1 pageBall Valve MTCAdnanAtifNo ratings yet

- Offshore A312A358 R2Document1 pageOffshore A312A358 R2Prathamesh OmtechNo ratings yet

- Mill Test Certificate: Apco Pipe Fittings Co., LTDDocument1 pageMill Test Certificate: Apco Pipe Fittings Co., LTD120491gokulNo ratings yet

- Hebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEDocument1 pageHebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEAnonymous TPoO5u8MeNo ratings yet

- 4140 Material For TubeDocument2 pages4140 Material For Tubesharafudheen_sNo ratings yet

- Issued: Posco Ot Rolled Steel Sheet in Coils: Tensile/ R'! T%Document13 pagesIssued: Posco Ot Rolled Steel Sheet in Coils: Tensile/ R'! T%Data Control POS-QCNo ratings yet

- MTC (JSL & MSL)Document2 pagesMTC (JSL & MSL)manu_giteNo ratings yet

- LF' JLRDocument1 pageLF' JLRIslam SahafayatNo ratings yet

- DVC6200Document2 pagesDVC6200Abid Hossain Rupam100% (1)

- MTCDocument6 pagesMTCNauman Zia100% (1)

- TC No-1451Document1 pageTC No-1451Structures ProductionNo ratings yet

- PSV 430066 PDFDocument41 pagesPSV 430066 PDFErikikoNo ratings yet

- Flange 8 Inch RTJDocument3 pagesFlange 8 Inch RTJreniNo ratings yet

- MTC - Pipe Erw 10x10mm - s355j2h - THL, UaeDocument1 pageMTC - Pipe Erw 10x10mm - s355j2h - THL, UaetariqananNo ratings yet

- Test Certificate-En 10204 3.1Document1 pageTest Certificate-En 10204 3.1Renjith GopinathNo ratings yet

- Maharashtra Seamless LimitedDocument1 pageMaharashtra Seamless LimitedTushar KasabeNo ratings yet

- Red DN80 50 50936Document1 pageRed DN80 50 50936slimane AIT-IDIRNo ratings yet

- Anchor Bolt MTCDocument6 pagesAnchor Bolt MTCshamshadkadavath1998No ratings yet

- Mag General Business: Mill Test CertificateDocument1 pageMag General Business: Mill Test CertificateRaul SebastiamNo ratings yet

- Ball Valve Passport 10x8 2500#Document43 pagesBall Valve Passport 10x8 2500#Alejandro RojasNo ratings yet

- 6 MM TCDocument1 page6 MM TCpranesh kadamNo ratings yet

- MTC Item # 01Document18 pagesMTC Item # 01ClarkFedele27No ratings yet

- 19013 MTC【CY】 PDFDocument1 page19013 MTC【CY】 PDFConstruction ProjectsNo ratings yet

- Test Report: H.D.G. Bolts, Nuts & Plain WasherDocument1 pageTest Report: H.D.G. Bolts, Nuts & Plain WasherSumanta AdhikariNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- Certificado EsparragosDocument8 pagesCertificado EsparragosJesus CondoriNo ratings yet

- FRA20-034-3 - Filttro YDocument1 pageFRA20-034-3 - Filttro YHuber Pucuhuayla RojasNo ratings yet

- Ga Drawing of Gate, Ball, Check, Butterfly Valve & T Type Stainer P.O. No. - Pl17100130 W.O. No. - 100181 r1Document7 pagesGa Drawing of Gate, Ball, Check, Butterfly Valve & T Type Stainer P.O. No. - Pl17100130 W.O. No. - 100181 r1siva8000100% (1)

- Mittal Corp Limited Test Certificate FinalDocument1 pageMittal Corp Limited Test Certificate FinalMehmet SoysalNo ratings yet

- TRILAD Flanges and Fittings, Inc.: 1652 Q"'4HRSDocument111 pagesTRILAD Flanges and Fittings, Inc.: 1652 Q"'4HRSMohamed RaafatNo ratings yet

- MTC For E-7018Document2 pagesMTC For E-7018Babar Manzoor Ghauri100% (2)

- Eil FormatDocument1 pageEil Formatsales.aquavalvesNo ratings yet

- 01 Raw Material RSP1 5.0X1400 OKDocument21 pages01 Raw Material RSP1 5.0X1400 OKTARUNKUMARNo ratings yet

- MTC 410-317-304 - FastenerDocument2 pagesMTC 410-317-304 - Fastenermiguel contrerasNo ratings yet

- SS SAW Welding Flux Sample MTCDocument1 pageSS SAW Welding Flux Sample MTCKunal AjgaonkarNo ratings yet

- T Type Strainer Butt Weld 1 PDFDocument1 pageT Type Strainer Butt Weld 1 PDFprashant mishraNo ratings yet

- Material A105+nace A A105Document4 pagesMaterial A105+nace A A105Elicerio FlorezNo ratings yet

- En19 Steel - 4140 - 1.7225 - Scm440 - 42crmo4: Related Specifications Astm A29/A29M Din en 10083/3 Jis G4053 GB GB/TDocument7 pagesEn19 Steel - 4140 - 1.7225 - Scm440 - 42crmo4: Related Specifications Astm A29/A29M Din en 10083/3 Jis G4053 GB GB/THugh O'Brien GwazeNo ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- N.R. Engineering: Chemical AnalysisDocument4 pagesN.R. Engineering: Chemical Analysisrajesh reddyNo ratings yet

- TUBE, UNS S31600/S31609, SMLS, AnnealedDocument2 pagesTUBE, UNS S31600/S31609, SMLS, AnnealedTuấn Dương QuốcNo ratings yet

- MTC, Annexure & Tally Sheet PDFDocument23 pagesMTC, Annexure & Tally Sheet PDFashish.mathur1No ratings yet

- DB-En 19 R-2-829 PDFDocument4 pagesDB-En 19 R-2-829 PDFashokNo ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- Bhushan Power & Steel Limited: Mill Test CertificateDocument1 pageBhushan Power & Steel Limited: Mill Test CertificateKamal PriyanNo ratings yet

- Certificado 3.1 y Calibracion Termopares - TecamDocument11 pagesCertificado 3.1 y Calibracion Termopares - TecamigorNo ratings yet

- MTC 2257 SPECTRA 304 HR COIL 8mm X 1250Document1 pageMTC 2257 SPECTRA 304 HR COIL 8mm X 1250Amit Kumar OjhaNo ratings yet

- TDC Tech Spec For PlateDocument3 pagesTDC Tech Spec For PlateBantoo RajamandiNo ratings yet

- PV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Document8 pagesPV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Mayank MittalNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- S Auction DTDocument8 pagesS Auction DTGupta GuptaNo ratings yet

- Auction Catalogue: Post Auction Related Contact DetailsDocument24 pagesAuction Catalogue: Post Auction Related Contact DetailsGupta GuptaNo ratings yet

- Kinetic Theory of GasesDocument8 pagesKinetic Theory of GasesGupta GuptaNo ratings yet

- Ref: Dev: IDPC: A-143, Sushant Lok - II, Sector - 55, Gurgaon (Haryana) - India. PH: 0124-4216606, Fax: 0124-4216605Document2 pagesRef: Dev: IDPC: A-143, Sushant Lok - II, Sector - 55, Gurgaon (Haryana) - India. PH: 0124-4216606, Fax: 0124-4216605Gupta GuptaNo ratings yet

- Raw Materials of Tyre Industry - Overview (FY 2010-11) : Cord, Polyester Tyre Cord Insufficient To Meet Domestic DemandDocument9 pagesRaw Materials of Tyre Industry - Overview (FY 2010-11) : Cord, Polyester Tyre Cord Insufficient To Meet Domestic DemandGupta GuptaNo ratings yet

- Customer of CrgoDocument18 pagesCustomer of CrgoGupta GuptaNo ratings yet

- Sumit..Builder List in NoidaDocument6 pagesSumit..Builder List in NoidaGupta GuptaNo ratings yet

- Why R U The Best Person For This Job?: ProfessionalDocument25 pagesWhy R U The Best Person For This Job?: ProfessionalGupta Gupta100% (1)

- Main ProjectDocument89 pagesMain ProjectGupta Gupta100% (1)

- Lean Six Sigma Project - A Beginner's Guide: - NilakantasrinivasanDocument8 pagesLean Six Sigma Project - A Beginner's Guide: - NilakantasrinivasanRHTi BDNo ratings yet

- Design and Development of Cylinder and Cylinder Head of 4-Stroke SI Engine For Weight ReductionDocument7 pagesDesign and Development of Cylinder and Cylinder Head of 4-Stroke SI Engine For Weight ReductionPrashant GuptaNo ratings yet

- BS 1377-5 - 1990 - Compressibility Permeability and Durability Tests For SoilDocument40 pagesBS 1377-5 - 1990 - Compressibility Permeability and Durability Tests For SoilOMEGA CONSULTANTNo ratings yet

- Old Gui With SwingDocument319 pagesOld Gui With SwingPajith PajithNo ratings yet

- Reliability, Availability andDocument82 pagesReliability, Availability andCaleb FalcoteloNo ratings yet

- T PZ 1670410340 Escape Room The Enigma Puzzle - Ver - 2Document21 pagesT PZ 1670410340 Escape Room The Enigma Puzzle - Ver - 2andres perezNo ratings yet

- Migracion WAS8Document472 pagesMigracion WAS8ikronos0No ratings yet

- Measurement 1DDocument27 pagesMeasurement 1Dmohd razif ibrahimNo ratings yet

- Electricity and MagnetismDocument13 pagesElectricity and Magnetismapi-293515856100% (1)

- EE214 EndSem PartBDocument3 pagesEE214 EndSem PartBbhanothpreetamNo ratings yet

- A two-parameter analysis of S-N fatigue life using Δσ and σmaxDocument12 pagesA two-parameter analysis of S-N fatigue life using Δσ and σmaxEngels OchoaNo ratings yet

- Assignemnt 2Document4 pagesAssignemnt 2utkarshrajput64No ratings yet

- Heuristic Design of Pressure Swing AdsorptionDocument19 pagesHeuristic Design of Pressure Swing AdsorptionGenoa SweatersNo ratings yet

- CryptoBench User's GuideDocument6 pagesCryptoBench User's GuideEmilianoNo ratings yet

- Ni Olivine - Thermal Behavior of LiebengergiteDocument7 pagesNi Olivine - Thermal Behavior of LiebengergiteEduardo CandelaNo ratings yet

- Management Accounting 2 Handout #2 TheoriesDocument4 pagesManagement Accounting 2 Handout #2 TheoriesCyrille MananghayaNo ratings yet

- Determination of Blood Glucose ConcentrationDocument23 pagesDetermination of Blood Glucose ConcentrationdeasyahNo ratings yet

- 3 MULTIPLEXING Part1Document34 pages3 MULTIPLEXING Part1Brian Edward HarrisNo ratings yet

- Functions and Linear ModelsDocument61 pagesFunctions and Linear ModelsAbigaelFider100% (1)

- WISENT Cidds Technical ReportDocument8 pagesWISENT Cidds Technical ReportsantiNo ratings yet

- C3 June 2014Document6 pagesC3 June 2014Kareem MohamedNo ratings yet

- Relativistic Kinematics: Raghunath Sahoo Indian Institute of Technology Indore, India-452020Document41 pagesRelativistic Kinematics: Raghunath Sahoo Indian Institute of Technology Indore, India-452020aleacunia87No ratings yet

- RE18303-01 LC04Z NloDocument10 pagesRE18303-01 LC04Z NloR.Ashwin R.AshwinNo ratings yet

- VFD For Centrifugal PumpsDocument11 pagesVFD For Centrifugal PumpsChem.EnggNo ratings yet

- Ch-2 RD MathsDocument60 pagesCh-2 RD MathsThe VRAJ GAMESNo ratings yet

- Points and Its TypesDocument26 pagesPoints and Its TypesZaid KhalidNo ratings yet

- Physical Properties of Milk: John SherbonDocument52 pagesPhysical Properties of Milk: John SherbonELI ALEXIS GONZALEZ HERNANDEZNo ratings yet

- Project Management Lecturenote c5 CostDocument35 pagesProject Management Lecturenote c5 CostTâm ĐặngNo ratings yet

- 2022 CMT Program GuideDocument69 pages2022 CMT Program GuideManav KelaNo ratings yet

- Practical 3Document5 pagesPractical 3Shekhar JadhavNo ratings yet