Task Risk Assessment For Sandblasting and Painting of Sheets - Spools

Task Risk Assessment For Sandblasting and Painting of Sheets - Spools

Uploaded by

Lam IneCopyright:

Available Formats

Task Risk Assessment For Sandblasting and Painting of Sheets - Spools

Task Risk Assessment For Sandblasting and Painting of Sheets - Spools

Uploaded by

Lam IneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Task Risk Assessment For Sandblasting and Painting of Sheets - Spools

Task Risk Assessment For Sandblasting and Painting of Sheets - Spools

Uploaded by

Lam IneCopyright:

Available Formats

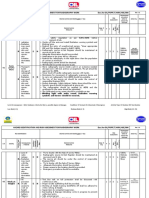

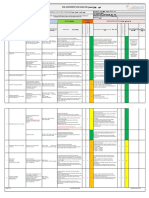

TASK RISK ASSESSMENT

CBMI

TASK TITLE: Sandblasting and painting Date:

Activity: Sand Blasting TRA No.

Location: p 16

Description: Sandblasting and painting

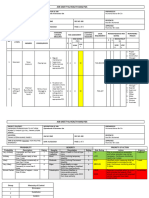

RISK EVALUATION ALAR

ACTION TO BE TAKEN RESIDUAL RISK

(Refer to Evaluation form)

S/No. HAZARD HAZARD EFFECT CONTROLS P

S P R DESCRIBE ACTION MANPOWER S P R Y/N

>Skilled personnel. >Continuous monitoring of activities.

1. PA Supervisor (SPA)

1. Untrained Personnel Personnel Injury G 7 8 >Use of standard manual handling >Adhere to Equipment Handling procedure. G 2 3 Y

2. Safety Supervisor

techniques. >Ensure to barricade the area with signage and barricade tape.

>Dead man handle shall not be modified, to avoid accident

>GCM/Tool Box talk /Task Briefing to be

>The blasting area shall be covered properly with tarpaulin.

conducted before starting activity.

Occupational Illness with > Personal other than specific job

2. Inhalation of dust material G 8 9 >Concerned workforce to wear blasting suit and protective shield for PA Supervisor G 2 3 Yes

respect to lungs restricted.

face and neck

>Waste materials collected immediately

protection.

and bagged.

> Usage of inspected equipment mandatory.

>Safety pins & Whip Lashes at couplings /

connections. >Hoses to be inspected and whiplash checked.

>Prior arrangement of equipment & other >Hose layout minimized and managed to reduce tripping hazards.

related accessories. >Grit blasting equipment certified & calibrated.

>Restrict unauthorized movement of

Personnel Injury, Property SPA: Sand Blasting,

3. High Pressure F 5 7 personnel in the job area. >Use of high pressure industrial hoses according to pressure rating. F 2 4 Yes

loss Supervisor, Safety Watch

>Pressure rating understanding by > Continuous Monitoring for any abnormality during pressure holding.

operator. >Personal training for positioning during Grit blasting.

>Experienced personal involvement in >Establish communication protocol to switch OFF equipment in case of

hazardous jobs. emergency.

>Personal position during grit blasting.

Equipment roll over, Hit

Unsafe placement of compressor SPA: Sand Blasting,

4. people, equipment G 4 5 Safe placement of equipment, Barricaded. Place the equipment at plane location, area barricaded. G 2 3 Yes

with sand blasting equipment Supervisor, Safety Watch

damage,

SPA: Sand Blasting,

5. High Noise Poor audibility > Ear protection > Ensure use of ear plugs / ear muff.

Supervisor, Safety Watch

Equipment roll over, Hit

Unsafe placement of compressor Place the equipment at plane location, area barricaded. SPA: Sand Blasting,

6. people, equipment G 4 5 Safe placement of equipment, Barricaded. G 2 3 Yes

with sand blasting equipment Supervisor, Safety Watch

damage,

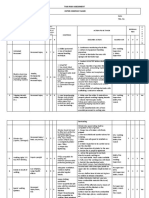

Painting.

1. Personal other than specific job

1. MSDS shall be provided for epoxy and their contents.

restricted.

Dizziness 2. Concerned workforce to wear respirator or dust mask

2.Tool Box talk to be conducted prior to Certified Painter

1. Vapor Inhalation lungs affected G 8 9 3. Drinking/eating in a coating area is prohibited. G 2 3 Yes

start of activity Safety Supervisor

Suffocation 4. Use of cartridge Mask mandatory.

3. MSDS available on site and clearly

5. Ventilation plan cleared to person prior start of job.

understood.

1. Use Rubber gloves

1. Use of suitable Gloves mandatory.

Separation

Thinner/Paint 2. In case of skin contact, rinse affected areas with clean water and

Storage Painting Sup(SPA)

2. Contact with body, Injury G 8 9 wash gently with soap. G 2 3 Yes

2. Tool Box Briefing to be conducted before Safety Watch

Eye, Skin 3. Eye protection, appropriate safety goggles.

starting activity.

4. Follow the instructions as mentioned in the MSDS.

3. Immediate rinsing in the area.

1. Area prohibited near Hot Work activity 1. Fire extinguisher available in the painting area.

Painting Sup(SPA)

3. Fire Serious Injury E 6 9 area. 2. Fire watch deputed in the area of job. E 2 5 Yes

Safety /Fire Watch

2. Epoxy storage not onsite work location. 3. Housekeeping before and after work.

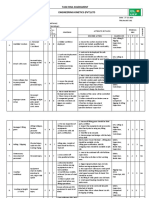

GENERAL COMMENTS:

1. TBT will be conducted prior to start.

2. Unauthorized person are not allowed in work premises.

3. Safety watch man does his designated job.

4. Proper PPE is a must for sand blasting and painting crew.

5. Stand by vehicle with driver must be present at the site in case of emergency.

6. First Aid Box must be in place near the activity.

7. Housekeeping of the area must be done on prior basis.

RISK ASSESSMENT APPROVAL

NAME OF TEAM MEMBERS

I’m satisfied that the safeguard put in place will reduce the level of Risk to an acceptable level and the Task/Action is permitted to proceed.

(Project Manager)

Reviewed by: _________________________

(Sand Blasting ) Date: ________________________ Time: ____________________

HITRA ( HSE Engineer)

Authorizing

S = Severity; P = Probability, R = Risk

Signatory: _______________ DATE: ________________

You might also like

- Risk Assessment For Curtain Wall & Glazing InstallationDocument4 pagesRisk Assessment For Curtain Wall & Glazing InstallationChristos Loutrakis75% (4)

- Risk Assessment For Excavation and BackfillingDocument3 pagesRisk Assessment For Excavation and BackfillingSreyleap Nhet89% (18)

- Radiography Work 004Document6 pagesRadiography Work 004Binay100% (1)

- Jsa Tank CleaningDocument5 pagesJsa Tank CleaningASLAM MULANI100% (1)

- HSE Risk Assessment To The Activity of Welding Cutting & GrindingDocument2 pagesHSE Risk Assessment To The Activity of Welding Cutting & GrindingAbid Rehman100% (7)

- HIRADC - 001 - Installation of Earthing SystemDocument3 pagesHIRADC - 001 - Installation of Earthing SystemZhafri SyazwiNo ratings yet

- Task Risk Assessment For Fabrication, Welding, Cutting and GrindingDocument3 pagesTask Risk Assessment For Fabrication, Welding, Cutting and GrindingAftab Qadir100% (2)

- Sparkle - Safety Data Sheet (SDS) - 2021 EngDocument4 pagesSparkle - Safety Data Sheet (SDS) - 2021 EngSophie TranNo ratings yet

- Task Risk Assessment For Sandblasting and Painting of Sheets SpoolsDocument3 pagesTask Risk Assessment For Sandblasting and Painting of Sheets SpoolsSeapara SathekgeNo ratings yet

- RA Sand BlastingDocument2 pagesRA Sand BlastingAbdus Samad100% (2)

- Task Risk Assessment Form: TASK TITLE: Fire Water Network Naimat Phase VA & VBDocument2 pagesTask Risk Assessment Form: TASK TITLE: Fire Water Network Naimat Phase VA & VBmyo lwinNo ratings yet

- Task Risk Assessment For Sandblasting and Painting of Sheets SpoolsDocument3 pagesTask Risk Assessment For Sandblasting and Painting of Sheets SpoolsAftab Qadir100% (1)

- RA Sandblasting and Painting of SheetsSpoolsDocument3 pagesRA Sandblasting and Painting of SheetsSpoolshashibpervez.shvenergybdNo ratings yet

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- Risk A For Fabrication, Welding, Cutting and GrindingDocument3 pagesRisk A For Fabrication, Welding, Cutting and Grindingsuryo saputroNo ratings yet

- Task Risk Assessment Enter Company Name AMG: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Enter Company Name AMG: Risk Evaluation (Refer To Evaluation Form)Faizan ShabbirNo ratings yet

- Risk A For Fabrication, Welding, Cutting and GrindingDocument3 pagesRisk A For Fabrication, Welding, Cutting and GrindingWelma JohnsonNo ratings yet

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- RA For PaintingDocument3 pagesRA For Paintingsarath SNo ratings yet

- Task Risk Assessment Enter Company Name: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Enter Company Name: Risk Evaluation (Refer To Evaluation Form)Aftab QadirNo ratings yet

- RA For Lifting Assembling of Equipments Skids 1708672388Document4 pagesRA For Lifting Assembling of Equipments Skids 1708672388anilkumaranoop74No ratings yet

- HIRADC - 002 - Utilities Detection MappingDocument3 pagesHIRADC - 002 - Utilities Detection MappingZhafri Syazwi100% (1)

- Risk A For Fabrication, Welding, Cutting and GrindingDocument3 pagesRisk A For Fabrication, Welding, Cutting and GrindingSaravana50% (2)

- TRA for scaffoldingDocument3 pagesTRA for scaffoldingjosect2No ratings yet

- Weekly Progress Report-2 Flipkart Project Kheda, (Ahmedabad), GujraDocument6 pagesWeekly Progress Report-2 Flipkart Project Kheda, (Ahmedabad), GujraPrakhar SenNo ratings yet

- TRA of Lifting of EquipmentsDocument4 pagesTRA of Lifting of Equipmentssuryo saputroNo ratings yet

- RA For Lifting & Assembling of Equipments (Skids)Document3 pagesRA For Lifting & Assembling of Equipments (Skids)andi warsitoNo ratings yet

- Hiradc - Stringing Work (Used Winch Machine)Document32 pagesHiradc - Stringing Work (Used Winch Machine)Suresh Praba PNo ratings yet

- Task Risk Assessment For Confined Space Entry in Storage Tank For Welding, Cutting GrindingDocument3 pagesTask Risk Assessment For Confined Space Entry in Storage Tank For Welding, Cutting Grindingsuryo saputroNo ratings yet

- Task Risk Assessment For Lifting & Installation of Ladder and PlatformDocument3 pagesTask Risk Assessment For Lifting & Installation of Ladder and PlatformAftab QadirNo ratings yet

- Task Risk Assessment Engineering Kinetics (PVT) LTD: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Engineering Kinetics (PVT) LTD: Risk Evaluation (Refer To Evaluation Form)JonasNo ratings yet

- TRA For Fabrication, Cutting, Grinding and WeldingDocument3 pagesTRA For Fabrication, Cutting, Grinding and WeldingSaif Ali100% (2)

- TRA Sand Blasting ReviwedDocument2 pagesTRA Sand Blasting ReviwedSanjeet SinghNo ratings yet

- RA Radiography of Pipe SpoolsDocument3 pagesRA Radiography of Pipe SpoolsQADEER SHANNo ratings yet

- JSA Operational of Generator Set TSKDocument3 pagesJSA Operational of Generator Set TSKrosli muhamadNo ratings yet

- HIRA 66 Installation of Split AC-NewDocument3 pagesHIRA 66 Installation of Split AC-NewAnupam PathakNo ratings yet

- TRA Carpentry Work Ceiling Wooden Ply MGT Dinng HallDocument4 pagesTRA Carpentry Work Ceiling Wooden Ply MGT Dinng Hallabdulhanansamo65No ratings yet

- Exemple Analyse de RisqueDocument2 pagesExemple Analyse de RisquechaimaaNo ratings yet

- TRA of Lifting of EquipmentsDocument3 pagesTRA of Lifting of EquipmentsandreNo ratings yet

- 29 HIRA Annexure HDocument155 pages29 HIRA Annexure HSuraj Singh100% (2)

- Level Two Risk Assesment of Working Inside Drain Pit Non H2SDocument6 pagesLevel Two Risk Assesment of Working Inside Drain Pit Non H2SJoko LelonoNo ratings yet

- 4.HIRARC Cable Trench-Rev0.4Document5 pages4.HIRARC Cable Trench-Rev0.4fatimah beluhiNo ratings yet

- Hiradc - Hot WorkDocument4 pagesHiradc - Hot WorkAlieya MustafaNo ratings yet

- Assembly The Water TankDocument6 pagesAssembly The Water TankferielvpkNo ratings yet

- List All Major/critical TasksDocument4 pagesList All Major/critical TasksIndra Mulyana0% (1)

- JSA - Anti Termite Treatment WorkDocument5 pagesJSA - Anti Termite Treatment WorkRaju Khalifa67% (3)

- TRA of Lifting of EquipmentsDocument4 pagesTRA of Lifting of EquipmentsSatyadip TeraiyaNo ratings yet

- TRA of Lifting - TailDocument3 pagesTRA of Lifting - TailTharaka Perera100% (1)

- JSA No - 55 Temperature MonitoringDocument3 pagesJSA No - 55 Temperature MonitoringMASYITAH HAMJAHNo ratings yet

- Appendix 5.1 JSA VCP Installation Rev 0Document17 pagesAppendix 5.1 JSA VCP Installation Rev 0BELLANo ratings yet

- Trenergy Infrastructure SDN - HiradcDocument5 pagesTrenergy Infrastructure SDN - HiradcIzza HalimNo ratings yet

- TRA For Plumbing WorkDocument8 pagesTRA For Plumbing Workabdulhanansamo65No ratings yet

- RA For Tiling WorkDocument12 pagesRA For Tiling WorkSaeed AhmadNo ratings yet

- JSA Loading UnloadingDocument4 pagesJSA Loading UnloadingAW ChannelNo ratings yet

- Risk Assessment - Installation of Platform at FM1Document14 pagesRisk Assessment - Installation of Platform at FM1Fred Vincent BaldomeroNo ratings yet

- 2.8c Risk Assessment Rev.02 - BlankDocument3 pages2.8c Risk Assessment Rev.02 - BlankShafie ZubierNo ratings yet

- TRA - For Air Condition Prefab BuildingDocument8 pagesTRA - For Air Condition Prefab Buildingabdulhanan86457No ratings yet

- Risk Assessment KURA WEST XINGDocument14 pagesRisk Assessment KURA WEST XINGMamuka ShaorshadzeNo ratings yet

- Pakbaz Engineering Task Risk Assessment Form: Task Title: Date: Activities: Location: Document Number: Annexure: 3Document1 pagePakbaz Engineering Task Risk Assessment Form: Task Title: Date: Activities: Location: Document Number: Annexure: 3talhalatifNo ratings yet

- RA-Installation of GRP Pipe CulvertsDocument6 pagesRA-Installation of GRP Pipe CulvertsArsh NazarNo ratings yet

- Apex Msds - 27 Nov 2019Document6 pagesApex Msds - 27 Nov 2019Jason GlassNo ratings yet

- Steps of FDA Anesthesia Machine Check OutDocument2 pagesSteps of FDA Anesthesia Machine Check OutSydney JenningsNo ratings yet

- Briar Ross G. Abcede Dominador C. Abcede: Ccts Visitor'S Card Ccts Visitor'S CardDocument1 pageBriar Ross G. Abcede Dominador C. Abcede: Ccts Visitor'S Card Ccts Visitor'S CardClarisse EsmoresNo ratings yet

- At-N70 NC006 Tds-En - 071049Document2 pagesAt-N70 NC006 Tds-En - 071049Thunder StromNo ratings yet

- Niveoli & Ciclohale 21-22Document62 pagesNiveoli & Ciclohale 21-22Aditya RounakNo ratings yet

- TB HX Consultation Form A4Document2 pagesTB HX Consultation Form A4Gian Rei MangcucangNo ratings yet

- Respiratory Muscle Training Improves Swimming Endurance in DiversDocument12 pagesRespiratory Muscle Training Improves Swimming Endurance in DiversJsc MauricioNo ratings yet

- Emphysema: Symptoms & Causes Diagnosis & Treatment Doctors & Departments PrintDocument4 pagesEmphysema: Symptoms & Causes Diagnosis & Treatment Doctors & Departments PrintAlfrien Ivanovich LarchsonNo ratings yet

- SFA-BLS With AED OperationDocument5 pagesSFA-BLS With AED OperationSandre CornelioNo ratings yet

- Test Biology 10th Class Ch#10 Gaseous ExchangeDocument1 pageTest Biology 10th Class Ch#10 Gaseous ExchangeASAD73% (11)

- Urogenital and Reproductive Female. Carangian and SiribanDocument14 pagesUrogenital and Reproductive Female. Carangian and SiribanKariza AbuNo ratings yet

- Mcn-Pain Management During LaborDocument3 pagesMcn-Pain Management During LaborBSN 1-N CASTRO, RicciNo ratings yet

- SDS-C8 HCA022 Chartek 2218 Grey Part A - EngDocument11 pagesSDS-C8 HCA022 Chartek 2218 Grey Part A - EngMinha Mubarok Ibn MasduqiNo ratings yet

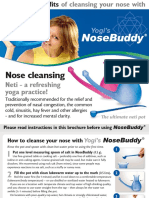

- Nose BuddyDocument6 pagesNose BuddysfdsfdsfdsfNo ratings yet

- September 4-8, 2023Document3 pagesSeptember 4-8, 2023rosemalyn pahamtangNo ratings yet

- EpiglDocument2 pagesEpiglfifiNo ratings yet

- Msds Safety: (MaterialDocument5 pagesMsds Safety: (MaterialDerya GökNo ratings yet

- Priorities - Q With AnswersDocument13 pagesPriorities - Q With AnswerssestramitaNo ratings yet

- CW2500 Part A - ISS 26052015Document10 pagesCW2500 Part A - ISS 26052015mitramgopalNo ratings yet

- Keep A Safe Distance From Others, Even If They Don'T Appear To Be IllDocument1 pageKeep A Safe Distance From Others, Even If They Don'T Appear To Be IllShanne ColleraNo ratings yet

- Thiox SdsDocument8 pagesThiox Sdshp12180No ratings yet

- Nursing Cs CopdDocument1 pageNursing Cs Copderisha.cadagNo ratings yet

- Sds Coconut Oil OrganicDocument3 pagesSds Coconut Oil OrganicAry SukmaNo ratings yet

- Material Safety Data Sheet: Versenate Hardness Indicator Solution Af Grade (50706)Document8 pagesMaterial Safety Data Sheet: Versenate Hardness Indicator Solution Af Grade (50706)jesusruizbadra357No ratings yet

- Graphnet: User'S Instruction ManualDocument96 pagesGraphnet: User'S Instruction ManualGregorio NavarreteNo ratings yet

- 2017 MSDS Procion Golden Yellow PX-GRDocument10 pages2017 MSDS Procion Golden Yellow PX-GRMayank DhawanNo ratings yet

- Ardrox AV 30: Material Safety Data SheetDocument5 pagesArdrox AV 30: Material Safety Data SheetMueed LiaqatNo ratings yet

- Risk Register Peralatan Medik 2022Document8 pagesRisk Register Peralatan Medik 2022maintenance anmedNo ratings yet

- SDS Kapci 835 GBDocument7 pagesSDS Kapci 835 GBAHMED GAMALNo ratings yet