S Poc LV - 00

S Poc LV - 00

Uploaded by

rtcrtc067Copyright:

Available Formats

S Poc LV - 00

S Poc LV - 00

Uploaded by

rtcrtc067Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

S Poc LV - 00

S Poc LV - 00

Uploaded by

rtcrtc067Copyright:

Available Formats

TECHNICAL SPECIFICATIONS FOR ELECTRIC WORKS

Specification for

Controlled LV Capacitor Bank

Group: Power Compensation

Subject: Controlled LV Capacitor Bank

0 JAN 2022 First Issue

Rev. Date Description/issued for

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 1 of: 21

INDEX

TECHNICAL SPECIFICATIONS FOR ELECTRIC WORKS .................................................. 1

1 SCOPE.............................................................................................................................. 4

2 APPLICATION FIELD .................................................................................................. 4

3 REFERENCE DOCUMENTS ....................................................................................... 4

3.1 ADDC/AADC specifications ............................................................................................ 4

3.2 Reference standards........................................................................................................... 5

3.3 Regulation and law ............................................................................................................ 5

4 SERVICE CONDITIONS .............................................................................................. 5

5 TECHNICAL FEATURES AND RATINGS ................................................................ 6

5.1 Rated power and number of stages .................................................................................... 6

5.2 Capacitor Units .................................................................................................................. 7

5.3 Series Reactors .................................................................................................................. 8

5.4 Switching devices .............................................................................................................. 8

5.5 HRC (High Rupturing Capacity) fuse ............................................................................... 8

5.5.1 Overvoltage protection and SPD ....................................................................................... 9

5.6 Busbars and Internal Connections ...................................................................................... 9

5.7 Connection arrangement to the LV switchgear ................................................................. 9

5.8 Relays, alarms ................................................................................................................... 9

5.8.1 Overload Protection/alarm .............................................................................................. 10

5.8.2 Overcurrent Protection .................................................................................................... 10

5.8.3 Undervoltage Protection .................................................................................................. 10

5.8.4 Over-temperature protection ........................................................................................... 10

5.9 Power Factor Controller .................................................................................................. 10

5.10 Interlocking and Earthing ................................................................................................ 11

5.11 Losses and Temperature Rise .......................................................................................... 11

5.12 Indoor and outdoor application ....................................................................................... 11

5.13 Housing of indoor and enclosure of outdoor banks......................................................... 11

6 CONSTRUCTION AND DESIGN REQUIREMENTS ............................................. 12

6.1 Capacitor Units ................................................................................................................ 12

6.1.1 Elements .......................................................................................................................... 12

6.1.2 Container ......................................................................................................................... 12

6.1.3 Capacitor Unit Terminals ................................................................................................ 12

6.1.4 Connections between capacitor units .............................................................................. 12

6.2 Capacitor Bank Housing/Enclosure ................................................................................ 13

6.2.1 Corrosion Protection........................................................................................................ 13

6.3 Termination of Auxiliary Cables and Identification of Cores ......................................... 13

6.4 Labels and Plates ............................................................................................................. 13

6.5 Inspection and maintenance ............................................................................................ 13

7 TEST ............................................................................................................................... 14

7.1 Routine tests .................................................................................................................... 14

7.2 Type and special tests ...................................................................................................... 15

7.3 Site Tests ......................................................................................................................... 16

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 2 of: 21

7.3.1 General Requirements ..................................................................................................... 16

7.3.2 General Checks................................................................................................................ 17

7.3.3 Continuity of Cable Connections and Phasing ................................................................ 17

7.3.4 Insulation between Phases, Insulation to Earth ............................................................... 17

7.3.5 Testing of Current Transformers on the Capacitor Bank ................................................ 17

7.3.6 Protection and power factor regulator ............................................................................. 17

7.3.7 System Measurements of Harmonics .............................................................................. 18

7.3.8 Power Factor.................................................................................................................... 18

7.3.9 On Load Tests ................................................................................................................. 18

7.3.10 Tests on Completion........................................................................................................ 18

8 QUALITY AND CERTIFICATION ........................................................................... 19

8.1 Documentation supplied during the tender...................................................................... 19

8.2 Document to be supplied after the order ......................................................................... 19

8.3 General – Evaluation of the cost ..................................................................................... 20

8.4 Compensation for Loss Beyond Quoted Value ............................................................... 20

9 DELIVERY, HANDLING AND LOGISTIC ISSUE ................................................. 20

9.1 Packaging and transportation .......................................................................................... 20

9.2 Installation and erection .................................................................................................. 20

10 EXCEPTIONS ............................................................................................................... 20

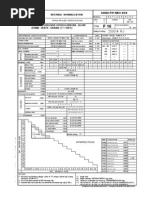

ANNEX A SINGLE LINE .............................................................................................................. 21

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 3 of: 21

1 SCOPE

The scope of this specification is to provide the technical requirements for the design,

manufacturing, inspection, factory tests, packing, shipping, delivery to site, installation and

commissioning for public LV Capacitors Banks to be used, only when required by specific project,

in the distribution networks of ADDC/AADC.

2 APPLICATION FIELD

This specification refers to both indoor and outdoor LV capacitors banks installed in public

distribution substations for the improvement of the power factor in the bus where they are

connected to. This kind of devices consists of both power equipment (capacitors, reactors, fuses,

switches/contactors/breakers), the associated protection and a control system for the regulation of

the compensation through connection/disconnections of capacitor stages. The suitable housing for

indoor and enclosure for outdoor application of this device is included in this specification, too.

3 REFERENCE DOCUMENTS

The list of the reference documents is indicated in the following paragraphs.

In case of discrepancy between these Specifications and any of the applicable Codes and

Standards, the following order of precedence shall apply:

1) ADDC/AADC specifications

2) applicable reference standards

3) other documents.

The Supplier shall note that compliance of the manufacturer with the provision of these

specifications does not relieve him from his responsibility to supply the equipment and accessories

of proper design, electrically and mechanically suited to meet the operating guarantees at the

specified service conditions.

3.1 ADDC/AADC specifications

Table 1 – List of ADDC/AADC specifications

S-GEN-SER S-GEN-ID

S-GEN-NET S-CPS-SCMS

S-GEN-COR S-GEN-ENC

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 4 of: 21

3.2 Reference standards

The last edition of the standards mentioned in Table 2 shall be taken into consideration.

Table 2 – List of standards

Standard Description

IEC 60529 Degree of protection provided by enclosures (IP code)

IEC 61000 series Set of standards on Electromagnetic Compatibility (EMC)

Industrial, scientific and medical radio-frequency equipment – Electromagnetic disturbance

IEC CISPR 11

characteristics – Limits and methods of measurement

IEC 60870-5-101 Transmission Protocols – Companion Standard for Basic Tele control Tasks

IEC 61869 series Set of standards on Instrument transformers

IEC 60076-6 Power transformers – Part 6: Reactors

IEC 60085 Electrical insulation – Thermal evaluation and designation

IEC 60143 series Set of standards on Series capacitors for power systems

IEC 60364 series Set of standards on Low-voltage electrical installations

IEC 60664 series Set of standards on Insulation coordination for equipment within low-voltage systems

Surge protective devices connected to low-voltage power systems - Requirements and test

IEC 61643-11

methods

Surge protective devices connected to low-voltage power systems - Selection and application

IEC 61643-12

principles

IEC 60076-6 Reactors

IEC 61642 Application of filters and shunt capacitors

IEC 60269 series Set of standards on LV fuses

IEC 61439 LV switchgear and control gear assemblies

IEC 60947 series Set of standards on Low Voltage Switchgear

IEC 61921 Power capacitors - Low-voltage power factor correction banks

IEC 60831 series Set of standards on Shunt power capacitors of the self-healing type for a.c. systems having a

rated voltage up to and including 1000 V

IEC 60502 series Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um

= 1.2 kV) up to 30 kV (Um = 36 kV)

3.3 Regulation and law

During the creation of this specification no known regulations or laws were available related to

power compensation banks.

The Supplier shall note that compliance with the provision of these specifications does not relieve

him from his responsibility to supply the equipment and accessories of proper design, electrically

and mechanically, so as to meet the specifications and guaranteed parameters during the service

conditions.

4 SERVICE CONDITIONS

The service conditions are specified in S-GEN-SER, in case something is not or not properly

specified regarding the service conditions, the Reference Standards prescriptions shall be

considered.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 5 of: 21

5 TECHNICAL FEATURES AND RATINGS

This specification covers the design, manufacture, factory testing, marking, packing, shipping,

transportation to site, installation, site testing and commissioning of LV capacitor banks for

improvement of power factor.

The capacitor banks shall be connected/installed at LV busbars in LV switchgear indoors or

outdoors as specified.

The LV capacitor banks shall include all the equipment and accessories necessary for their

effective and trouble-free operation when connected to the LV system.

The 3-phase capacitor bank shall be composed of individual capacitor units connected together

internally in delta form and associated with iron cored de-tuning reactors to protect against

excessive loading due to harmonics. The de-tuning reactors shall be rated in such a way that the

resonance frequency of the reactor and capacitor shall be enough below any harmonic frequency.

A dominant 5th harmonic is expected to be present in the system. A de-tuning factor (XL/XC) of

minimum of 5.67% provides a resonance frequency of 210 Hz.

The capacitor bank alarm, indication and control system shall be provided with interfacing to the

DMS (Distribution Monitoring System).

The LV capacitor bank cubicle shall be installed indoors or outdoors, and shall include but not

limited to:

• Capacitor bank consisting of several stages/steps (based upon scope of works number of stages shall

be decided using study report)

• Capacitors units with built-in discharge resistors

• Series Reactors

• Fast acting stage contactors with damping resistors (re-striking free during breaking operation).

• External HRC Fuses

• Non-Auto MCCB Incomer (with thermal and magnetic protection)

• Capacitor bank internal bus bars connecting the stages contactors to the MCCB and the external cable

terminals.

• Protection and power factor controller equipment

• Mechanical Interlocking with main door opening when the Non-Auto MCCB is ON

• Other hardware and accessories required for complete functionally installation

• Complete connection arrangement to the LV switchgear

5.1 Rated power and number of stages

The maximum number of stages (steps) for each bank is 10.

The power rating for each LV three-phase capacitor bank is selected among the following set of

values, as required by ADDC/AADC:

• 200/400/600/800/1000 kVAr

The selected number of stages depends on the reactive compensation needs in the specific LV

switchgear in order to meet the power compensation target. The Supplier is responsible of the

selection of the number of stages that is subject to TAQA/ADDC/AADC approval.

The usual target value for the power factor is 0.95.

A stage consists of one or more capacitor units in parallel, connected in delta form.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 6 of: 21

5.2 Capacitor Units

Capacitor Units shall consist of:

• Capacitor elements, assembled in parallel and series connected groups

• Over pressure tear-off fuse for protection against failure of internal element

• Discharge resistor

• Stainless steel container with two terminals (bushings).

A common and interchangeable design of capacitor unit shall be utilised for all banks.

The supplier shall provide supportive calculations to confirm that the internal ambient temperature

will not exceed the maximum operating temperature of the capacitor unit.

The maximum ambient temperature for reference, as per IEC, is 55 °C (category D), both indoor

and outdoor. The Supplier shall give demonstration of complying with the thermal requirements

to TAQA/ADDC/AADC for approval. The thermal stability test (type test) shall be made to prove

the suitability of the design for the site conditions.

Each capacitor units shall be designed to meet the following minimum requirements:

• Permanently connected across the capacitor elements built-in resistor to discharge the unit voltage after

disconnecting to a value of less than 50 V within 1 minute.

• Suitable for continuous operation at voltage between terminals of 1.15 times the rated voltage,

excluding transients.

• Suitable for continuous operation at line current of 1.30 times the current which occurs at rated

sinusoidal voltage and rated frequency excluding transients.

• Suitable to withstand the inrush peak current up to 2 times the maximum inrush current limited by the

reactor only (with 40 MVA short circuit power source at 1.15 times the rated voltage).

• Identical and of the same capacity.

Unless otherwise specified the reference temperature for capacitor performance is 40°C.

The reactive power output (kVAr) computed from the measured capacitance, at 40°C, rated

voltage and frequency, shall not be less than the rated declared value and not more than 115 % of

this value for each capacitor unit. The capacitor unit having output kVAr beyond these limits shall

not be accepted.

The entire capacitor unit shall not have to be changed due to single capacitor element failure. It

shall be able to continue in operation.

Isolation of one capacitor element in a group should not cause voltage unbalance of more than

110% rated voltage on the remaining capacitors in the group. During the design stage the Supplier

shall submit the detailed calculation for selection of the capacitor unit rating and total number of

units to be used for each stage of the capacitor bank for the approval of TAQA/ADDC/AADC.

The capacitor units shall have a record of production and field experience of not less than three

years. Reference lists of supply and failure rate of capacitor of the same design and material shall

be submitted with the bid.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 7 of: 21

5.3 Series Reactors

The transient current that flows on energising shall not exceed the rated making current of the

contactor or breaker switching the bank. Current limiting/detuning reactors shall be connected in

series with each stage to limit the inrush current to an acceptable value and reduce harmonics to

an acceptable level with respect to the maximum acceptable instantaneous voltage variation

(ΔV=3%) and harmonic voltage disturbance. The current which flows upon energising shall be

declared and shall consider the contribution from parallel connected capacitors.

The reactors shall be iron-core type. They shall comply with IEC 60076-6 and their insulation shall

be Class “H” rated at 180oC as per IEC 60085. The maximum temperature of the reactor at

maximum continuous current shall be no higher than 145oC with a 45 oC ambient. The maximum

continuous current of the reactor shall be sized to match the maximum continuous current of the

capacitors.

The reactor shall be capable of withstanding the inrush currents, which can occur during the life

of the capacitor bank.

5.4 Switching devices

The capacitor bank shall be equipped with a non-auto MCCB (Moulded Case Circuit Breaker) at

the incomer. Each stage of the bank shall have a suitably rated contactor (or circuit breaker). This

switching device shall be adjusted to trip if the RMS current exceeds 130% of the nominal current

of the stage.

Both main breaker (non-auto MCCB) and stage switching devices (contactors/breaker) shall be

rated for a minimum insulation voltage of 660 V. They shall be three-pole type and shall fully

comply with the requirements of the IEC 60947-1 & 2. The current rating shall be at least 1.5 times

the full load current of the capacitor bank and capacitor stage, respectively. They shall be suited

to withstand the inrush peak current (as per capacitor units requirements here above).

The MCCB shall have a mechanical endurance of a minimum 1000 operations, maintenance free.

The mechanical endurance of the contactors shall not be less than 3 million operating cycles at no

load. The electrical endurance at normal utilization duty for capacitor shall not be less than 200.000

operations.

5.5 HRC (High Rupturing Capacity) fuse

HRC Fuses conforming to IEC Standards shall be provided for the capacitor unit and must be

designed to isolate faulted capacitor unit of the respective stage, to allow operation of the

remaining stages of that capacitor bank.

The external fuse links of each stage shall have the following characteristics:

• Suitable for continuous operation at 1.15 times the rated voltage of the capacitor stage, excluding

transients

• Capable of withstanding inrush current due to switching on.

• Capable of withstanding discharge current, due to short-circuit faults external to the capacitor unit, and

outrush current due to switching of any other element.

• Time-current clearing characteristics in the safe-zone of the capacitor case rupture curve.

• Capable of carrying 130 per cent of rated current of the capacitor stage

• Suitable to be replaced without removing busbars or any other component.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 8 of: 21

5.5.1 Overvoltage protection and SPD

The Supplier shall propose and demonstrate that all components of the bank are protected against

overvoltage of any kind (lightning and switching, internal and external) stressing the insulation.

In case, the Supplier can provide SPD to attain the protection. Such SPD can be connected phase-

to-ground and phase-to-phase.

The demonstration of overvoltage protection is subject to the approval of TAQA/ADDC/AADC.

In case of adoption of SPD, the Supplier shall demonstrate the correctness of the selected SPD.

5.6 Busbars and Internal Connections

The main busbar connections and their supports shall be of an approved type and shall be capable

of carrying the rated short circuit duty of the installation. All connections (copper conductor, cable,

flat busbar etc,) from HRC fuses to the remaining part for each stage shall have a minimum

continuous current rating of not less than 200% of the respective stage rating.

5.7 Connection arrangement to the LV switchgear

The Supplier shall provide and install the complete connection between the capacitor bank and the

LV switchgear, with a suitable connection arrangement to carry the maximum currents (steady-

state, inrush, outrush and short-circuit ones) and to withstand the voltage stresses, in the specified

environmental conditions. The Supplier is responsible of the design of such an arrangement that is

subject to the approval of TAQA/ADDC/AADC.

5.8 Relays, alarms

The following explicit protection relays shall be provided for each Capacitor Bank:

• Overload Protection for each stage (tripping the stage contactor)

• Over-voltage / Under-voltage protection of the whole Capacitor bank (tripping the MCCB).

Furthermore, the following alarms with programmable threshold shall be provided for each

Capacitor Bank:

• Under-compensation alarm: it is activated if, with all the steps of power factor correction switched on,

the power factor is lower than the stated value

• Over-compensation: the alarm is activated if, with all the steps of power factor correction switched off,

the power factor is greater than the stated value

• Minimum and maximum current alarm (thresholds coordinated with the overload protection)

• Minimum and maximum voltage alarm (thresholds coordinated with the overvoltage and undervoltage

protection)

• Maximum THD%:

• Maximum temperature in the enclosure:

• Short interruptions of voltage.

The Supplier shall co-ordinate the tripping scheme with main LV switchgear protection system.

Over-voltage / under-voltage, over-load protections may be combined within a single numerical

relay designed specifically for protection of capacitor banks.

Protection relays shall be of numerical type with serial port for remote communication with DMS.

The detailed design of the protection scheme and the recommended relay settings with calculations

shall be submitted for approval.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 9 of: 21

5.8.1 Overload Protection/alarm

A first alarm shall be given at a current of approx. 110 to 120 % of the rated current if applied for

more than approx. 30 min. A second alarm (selectable by links for tripping as well) shall be

initiated at currents of 120 to 140 % of the rated current suitably time delayed avoiding spurious

alarms (tripping’s) during short time disturbances.

Each threshold of the overload protection shall be independently adjustable.

5.8.2 Overcurrent Protection

For currents above 140 % of the rated current a time delayed protection shall initiate tripping.

Instantaneous tripping at currents above 200 % of rated current and also co-ordinated with HRC

fuses shall be provided. It shall be properly secured against tripping due to inrush currents.

5.8.3 Undervoltage Protection

A three-phase under-voltage relay with a 60% drop-off and time delay of 1-20 sec (in 1 sec steps)

shall detect the complete loss of LV supply and trip all LV contactors.

5.8.4 Over-temperature protection

Internal ambient temperature sensors shall be provided. Detected over temperature condition shall

result in the disconnection of the power supply to the power factor controller and initialization of

an alarm indication on the capacitor bank.

5.9 Power Factor Controller

Automatic power factor control units shall be rated for operation on 400V 15%. Since the

proposed automatic control unit has to be mounted in the same cubicle of the capacitor bank, the

control unit shall be suitable for very high ambient temperature (up to 60C) with humidity

condition exceeding 90% and shall have the following features.

• Insensitive to harmonics

• Programmable to many steps (minimum of 10 steps) and adjustable for different switching times

between steps (1 minute to 120 minutes)

• Built-in digital power factor meter

• Selection for manual / automatic switching steps

• Power factor setting range (0.70 inductive to 0.70 capacitive)

• Built-in fault indicator

• Display of voltage, current, apparent power and reactive power

• LED indicator for each of the capacitor step

• No-volt release to reset switching sequence to all contactors.

Current and voltage signal shall be derived from the respective incomer and busbar of the LVAC

installation. For Overvoltage/Undervoltage relay, capacitor bank bus voltage shall be used.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 10 of: 21

5.10 Interlocking and Earthing

Interlocking scheme shall be provided for:

• Prevent closing the capacitor bank feeder circuit breaker when any door of the capacitor bank enclosure

is open

• Prevent opening of any door directly to the capacitor bank enclosure unless the capacitor bank feeder

earth switch is closed.

• Design of the control scheme shall be such that, all stages of contactors shall be closed automatically

to ensure earth continuity of the complete bank for safe maintenance.

• The contactors shall close automatically with time delay of 10 minutes after the capacitor bank feeder

earth switch is closed.

After de-energising and closing the capacitor bank feeder earth switch, an interlocking time delay

of 5 minutes shall be provided before access to the capacitor bank compound can be achieved.

5.11 Losses and Temperature Rise

Losses shall not exceed the value stated in Technical Datasheet D-POC-LV under rated conditions.

The guaranteed value of losses of the capacitor unit shall include the losses of the internal

discharge resistor. The temperature rise of any part of the capacitor bank and associated equipment

shall not exceed the maximum permissible temperatures specified in the associated IEC Standards

for the various components when operating under site conditions.

5.12 Indoor and outdoor application

5.13 Housing of indoor and enclosure of outdoor banks

Indoor capacitor banks shall be installed in metallic housings as per S-GEN-ENC (with IP43

protection degree); outdoor capacitor banks shall include metallic enclosures as per S-GEN-ENC

(with IP 54 Protection Degree). Natural ventilation of the housing/enclosure is preferred for heat

dissipation, but forced cooling is acceptable, subject to preliminary approval. The losses for the

eventual forced cooling shall be accounted for in the overall losses.

The housing/enclosure shall have pressure relief facilities in case of a fault and it shall be safe for

the operator.

Each stage of the capacitor bank must be completely segregated from the other stages to avoid

extension of fire in case of any fault.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 11 of: 21

6 CONSTRUCTION AND DESIGN REQUIREMENTS

Concerning the LV Capacitor Bank Identification, reference shall be made to Standard Technical

Specification: S-GEN-ID, components identification and markings

6.1 Capacitor Units

6.1.1 Elements

The dielectric material of a capacitor element shall consist of an all film material being suitable to

operate the capacitors on continuous load under the specified ambient conditions. The capacitor

should be completely leakage proof. The impregnant shall be according to IEC 60871 of a

hydrocarbon type fluid characterised by high electrical strength (class III B – OSHA classification)

and adequate physical and chemical properties and shall be non-PCB (Poly-Chlorinated-

Biphenyl), but rapidly biologically degradable, non-poisonous, of trouble-free disposal and have

a flash point >1500C. In order to ensure good ionisation performance, the aluminium foils shall

be folded at the edge.

The metallized electrode in the capacitor elements shall be of self-healing type.

Each capacitor (element) shall have an internal fuse combined with a secondary solid foil electrode

to ensure safe disconnection from the circuit at the end of its normal working life.

The Supplier shall provide supportive calculations to confirm that the internal temperature will not

exceed the maximum operating temperature of the capacitor elements.

The capacitor units shall be built with over pressure tear-off fuses in all three phases.

Facilities shall be provided to allow for safe simple and quick identification of defective capacitor

units. Portable test equipment or other means shall be supplied being able to detect defective units

without need for breaking any connection of the capacitor banks.

6.1.2 Container

The capacitor elements container shall be constructed as specified in Technical Datasheet D-POC-

LV. The capacitor elements shall be enclosed in a stainless-steel housing with all joints welded

and tested for liquid tightness. Corrosion protection shall comply with S-GEN-COR; other kind of

protection of the supplier may be acceptable but subject to approval of TAQA/ADDC/AADC

based upon the submission of the complete factory painting procedure.

6.1.3 Capacitor Unit Terminals

Each capacitor unit of indoor and outdoor capacitors banks shall have two terminals which shall

be hermetically soldered to the case. Connections between the terminals and elements and between

the terminals and container shall not rely on soldered joints for mechanical support. Sealing gaskets

shall not be accepted.

6.1.4 Connections between capacitor units

The connection between individual capacitor units in the same block shall be such that a failed

capacitor unit can be easily replaced.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 12 of: 21

6.2 Capacitor Bank Housing/Enclosure

The housing/enclosure design shall be such that there is adequate dissipation by radiation and

convection of the heat generated by capacitor losses. The maximum temperature of all components

shall not exceed the specified values under all site conditions.

The supplier shall provide supportive calculations for the outdoor capacitor banks, to confirm that

the internal ambient temperature within the capacitor bank enclosure will not exceed the maximum

operating temperature of the capacitor unit.

The arrangement of the housing/enclosure and its equipment shall be such as to provide easy

replacement of the equipment units and safety of operating staff shall be ensured.

6.2.1 Corrosion Protection

For Corrosion Protection, reference shall be made to the standard technical specification S-GEN-

COR.

6.3 Termination of Auxiliary Cables and Identification of Cores

The ends of each cable shall be terminated in brass, compression type cable glands of the correct

size, which shall secure the cable inner sheath and ensure effective electrical continuity between

the cable armouring wires and the metal enclosures on which the cable is terminated. Cable glands

fitted on outdoor equipment shall also incorporate suitable compression seals to secure the outer

sheath and shall be so designed and fitted that water cannot enter the cable or the equipment via

the cable termination. Where required, a barrier shall be incorporated to prevent ingress of

moisture via the interstitial spaces in the cable. At all rising terminations, the cable inner sheath

shall pass through the gland to terminate approximately 6 mm above the gland. Insulated glands

and glands not in an environmentally controlled atmosphere, shall be supplied complete with close

fitting insulating shrouds.

6.4 Labels and Plates

Rating plates, labels and other markings shall comply with S-GEN-ID.

Capacitor unit nameplate marking shall indicate the corresponding purchase contract number, year

of manufacture, type of insulating liquid, rated capacitance, and ratio of measured capacitance to

rated capacitance.

6.5 Inspection and maintenance

The indoor capacitors banks shall not require periodic inspection. The outdoor capacitors banks

are expected to be inspected periodically (once a year).

Maintenance such as replacement of failed capacitor units or blown fuses shall be done as required,

but major maintenance intervals shall not be less than 10 years.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 13 of: 21

7 TEST

LV capacitor banks for power factor compensation are subject to Routine, Type and Special tests

prior to delivery and then tests on site prior to commissioning and tests along the life during

maintenance.

For the purpose of testing the capacitor bank and its main components, the following standards are

the main reference, but many other standards are involved, too:

• Capacitor Bank IEC 61921

• Capacitors IEC 60831-1.2

• Series reactors IEC 60076-6

• Contactors and Circuit Breakers IEC 60947-1.2

• HRC Fuses IEC 60269

In the supply stage, after units are tested, capacitance and power factor measurements will again

be made and compared with benchmark recordings. If the capacitors fail to pass test as stated in

the manufacture proposal, the proposed design, construction, manufacturing process, or all of the

above will be rejected. If this is the case, a more conservative design shall be developed.

For each rejected shunt capacitor unit, the Supplier shall be obliged to make any necessary

corrections or alterations to it or to replace it forthwith. Any and all expenses that might result by

the supply and installation of new parts or by modification of existing parts and any and all

expenses resulting in additional tests made necessary by failure of equipment to meet the

guarantees and other requirements of the specification shall be borne by the Supplier.

The Supplier shall ascertain that necessary factory inspection, adjustment; conformance with IEC

test criteria and assembly is made in order to assure the proper fit and assembly of the component

parts of each capacitor bank.

7.1 Routine tests

The following routine tests shall be witnessed by TAQA/ADDC/AADC unless otherwise waived

in writing.

• Capacitor Unit

o Dielectric strength tests, DC Withstand (Terminal-to-terminal) Test shall apply 4.3 times rated

voltage

o Capacitance measurement

o Loss angle (tan δ) measurement

o AC or DC voltage test between terminals and container

o Discharge test of the internal resistor

o Leakage test.

• Capacitor Bank

o Inspection of the assembly including inspection of wiring and, if necessary, an electrical operation

test

o Dielectric test

o Checking of protective measures and of the electrical continuity of the protective circuit

o Verification of insulation resistance.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 14 of: 21

This pre-production run shall have been manufactured in the facility that is to be used for all

production units.

Data applicable to the capacitors shall be furnished to ADDC/AADC prior to the start of test. This

data shall include:

• Serial number of each unit

• Date of manufacture

• Date subjected to final electric test

• Routine Tests on the capacitor bank as per IEC 61921

• Design Calculation on the kVAr capacity of the capacitor

• Design Calculation on Harmonic Distortion

• Results of the following test:

o Capacitance - at room temperature

o Power factor at rated voltage at room temperature.

7.2 Type and special tests

Type tests may be omitted if acceptable test records can be submitted, unless specified otherwise.

The tests shall conform with IEC and must include at least the following:

• Capacitor Unit: Type tests on the Capacitor Unit shall conform to IEC 60831:

o Thermal stability test

o Capacitor loss angle (tan δ)

o A.C. voltage test between terminals and container

o Lightning impulse voltage test between terminals and container

o Short circuit discharge test.

• Type tests on the capacitor bank shall conform to IEC 61921 (cl 7.2):

o Temperature Rise Test

o Dielectric Test

o Short-circuit withstand strength

o Effectiveness of the protective circuit

o Clearances and creepage distances

o Mechanical operation

o Verification of Degree of Protection

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 15 of: 21

7.3 Site Tests

7.3.1 General Requirements

Not less than one month prior to the commencement of site testing, the Supplier shall submit to

TAQA/ADDC/AADC the Site Test and Commissioning procedure (SAT).

The tests shall be carried out as per approved SAT document.

No testing shall commence until the format and test procedures are agreed and all results shall be

submitted on the approved form.

Testing shall be carried out during normal working hours as far as practicable. Tests, which involve

existing apparatus and outages, may be carried out outside normal working hours. The Supplier

shall give sufficient notice to allow for the necessary outage arrangements to be made in

conformity with the testing programme.

The Supplier shall advise TAQA/ADDC/AADC in writing at the time of commencement of site

erection of the site supplies, which will be required for the operation of the test equipment.

The Supplier shall provide the requisite experienced test personnel and all relevant test equipment,

unless otherwise agreed by TAQA/ADDC/AADC or stated in the Schedules.

On completion of any group of tests the Supplier shall submit two clean copies of the test results

recorded on the approved form. TAQA/ADDC/AADC shall countersign the test sheets found to

be satisfactory and retain one copy.

The Supplier shall subsequently provide to TAQA/ADDC/AADC six bound copies of all site test

sheets as final records. The test sheets shall be grouped by substation sub-divided by plant type

and further on a circuit-by-circuit basis.

Since the records may be used for maintenance tests, the final records shall be provided as soon as

possible after completion of testing.

No tests as agreed under the programme of tests shall be waived except upon the instruction of

TAQA/ADDC/AADC in writing.

All tests shall be carried out in the presence of TAQA/ADDC/AADC unless otherwise agreed.

The Supplier shall carry out all the necessary tests for the Capacitor bank units, cables and other

associated equipment and submit a report that they are ready for commissioning. Tests on the

Capacitor Bank Units will be carried out by the Supplier under the supervision of the supplier and

energised by the Engineer from TAQA/ADDC/AADC, after witnessing necessary commissioning

tests carried out by the Supplier. Any defects noticed during commissioning due to poor

workmanship, wrong phasing or any other reason shall be made good by the Supplier immediately.

Any defects noticed due to poor workmanship in the guarantee period must be rectified by the

Supplier to the satisfaction of TAQA/ADDC/AADC.

The Site Tests shall include but not limited to the following.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 16 of: 21

7.3.2 General Checks

A general check of all the main switchgear, labelling and ancillary equipment shall be made and

shall include a check of the completeness, correctness and condition of earth connections, painted

surfaces, cables, wiring, plates and all other auxiliary and ancillary items. Checks shall be made

for any leaks, and that equipment are clean and free from external damage. A check shall be made

that items which are to be taken over by TAQA/ADDC/AADC, e.g. tools, spares, are in order and

are correctly stored for taking over.

Shutters, interlocking, earthing procedures and the interchangeability of components shall be

checked.

7.3.3 Continuity of Cable Connections and Phasing

Continuity of cable connections and phasing sequence to be checked.

7.3.4 Insulation between Phases, Insulation to Earth

Insulation resistance between phases and to earth shall be measured.

7.3.5 Testing of Current Transformers on the Capacitor Bank

The Supplier shall be responsible for performing all required tests on the Current transformers

installed in the Capacitor Bank Unit.

7.3.6 Protection and power factor regulator

The Supplier shall be responsible for carrying out required tests to prove the correct operation of

the following equipment under the Supplier’s supervision:

• Capacitor Bank Feeder MCCB

• Capacitor stage Contactor

• External HRC Fuse Failure Indication

• Overvoltage Protection

• Under voltage Protection

• Overload Protection

• Over temperature protection

• Relay settings (provided by the Supplier of the capacitor bank).

7.3.6.1 Wiring

Inter-relay, inter-unit and cubicle wiring, shall be checked to the appropriate circuit wiring

diagram. Where it is found necessary during pre-commissioning work, to effect site modifications

to the secondary wiring, site copies of the appropriate schematic and wiring diagrams shall be

suitably marked as agreed with TAQA/ADDC/AADC before the circuit is commissioned.

7.3.6.2 Operation of Power Factor Regulator

Functional testing of the power factor regulator shall be carried out.

7.3.6.3 Interlocking and Trip Tests

All interlocking arrangements both electrical and mechanical shall be fully checked and tested.

Tripping of LV Capacitor Bank Feeder Circuit Breaker ensured by operation of all associated

protections.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 17 of: 21

7.3.7 System Measurements of Harmonics

In order to ensure that installation of the Capacitor Banks has not badly affected the system, system

measurement of harmonics shall be carried out by the Supplier in the substation where the power

compensation capacitor bank is connected.

7.3.8 Power Factor

Measurement of power factor after capacitor bank commissioning shall be carried out for duration

of 24 hours and various electrical parameters should be recorded including system power factor.

If the average power factor is found to be less than the ADDC/AADC limits, then additional stages

would have to be installed in the capacitor bank.

7.3.9 On Load Tests

In view of the hazards inherent in these tests, they shall be carried out under the direct supervision

of TAQA/ADDC/AADC. An operation and stability test shall be carried out for on load

commissioning of each bank. On load checks shall be made after the protection gear has been

placed in service to ensure that all connections and test links have been replaced and test leads

removed as well as to confirm the integrity of the current transformer circuits. Where necessary

voltage and current readings shall be taken at the terminals on each relay to ensure that loop

connections between the relays are complete.

7.3.10 Tests on Completion

The Supplier shall be responsible to perform functional tests, with actual system conditions, of the

discharge devices under manufacturer’s supervision.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 18 of: 21

8 QUALITY AND CERTIFICATION

8.1 Documentation supplied during the tender

The technical documentations to be produced by the Supplier for the economical offer shall contain

the following items:

• The datasheet D-POC-LV

o Preliminary general arrangement

o Equipment list and associated technical material

o Reference list, with the same ratings of the ones requested in the offer, in the last 10 years

o Type test reports list

o Corrosion protection method

o List of deviation from tender specification

8.2 Document to be supplied after the order

The technical documentation to be produced by the Supplier after the order shall contain the

following items:

• The technical datasheet D-POC-LV filled with the design values.

• General arrangement

• Detailed drawing (layout, section, interface an installation)

• LV schematics and wiring

• Corrosion protection procedure approved by ADDC/AADC

• Manufacturing and test quality plan

• Type test certificate of the accessories installed (bushing, control cabinet etc.)

• Routine test certificate of each component of the boards

• Factory tests procedure

• Installation and Commissioning test procedure and report

• Factory test report (to be submitted after witness tests)

• Operation and maintenance manual including test reports witnesses by ADDC/AADC or their

representative.

• Datasheet of all accessories installed

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 19 of: 21

8.3 General – Evaluation of the cost

Evaluated cost of the capacitor bank shall be based on the following equation:

• A = B + 1530 C * total bank kVAR where:

o A = Evaluation cost of capacitor bank and equipment in DIRHAM.

o B = Cost of capacitor bank and equipment in DIRHAM.

o C = Capacitor loss tan δ of capacitor unit with discharge resistor, measured at evaluated temperature

in %.

In case the capacitor bank is equipped with forced ventilation, the cost of the relevant losses shall

be added, assuming the fan working at full power full time:

• D = ventilation losses (kW), hence:

o A = B + 1530 (C * total bank kVAR + D)

8.4 Compensation for Loss Beyond Quoted Value

The Supplier shall quote capacitor losses measured at elevated temperature otherwise such offer

shall be rejected. If the quoted value is lower than the average value witnessed by

TAQA/ADDC/AADC during FAT, compensation to TAQA/ADDC/AADC shall be made at the

rate of 300 DIRHAMs per % for the exceeding loss tan δ times total purchased kVAr.

9 DELIVERY, HANDLING AND LOGISTIC ISSUE

9.1 Packaging and transportation

The Supplier is responsible for all the delivery procedures and provisions for storage of the

equipment in factory after the tests and until the transport operations.

The supplier shall pack the equipment with a suitable cases and protective measures granting the

safe delivery of the good at the final place of installation.

9.2 Installation and erection

The capacitor banks shall be factory pre-assembled as far as possible to minimize the work

required at site.

10 EXCEPTIONS

Possible exceptions to the present prescriptions, concerning the adoption of technical and/or

manufacturing aspects different from the ones prescribed in the present GS, can be evaluated by

ADDC/AADC.

In such a case, ADDC/AADC will take into account the opportunity to require additional tests

with regard to the technical/manufacturing proposed solutions.

Such exceptions can be approved by ADDC/AADC.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 20 of: 21

ANNEX A SINGLE LINE

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: SPECIFICATION FOR CONTROLLED LV CAPACITOR BANK

DOCUMENT NO: S-POC-LV_00.DOCX Rev: 0-2022 Sheet: 21 of: 21

You might also like

- 210GLC Catálogo de PeçasDocument1,104 pages210GLC Catálogo de Peçasjuliano100% (6)

- Volvo - S60 - Workshop Manual - 2000 - 2003Document3,231 pagesVolvo - S60 - Workshop Manual - 2000 - 2003James Staff100% (1)

- LV 216-1 - EnglishDocument17 pagesLV 216-1 - EnglishCarl Samuel Reyes100% (3)

- S Civ Concrete - 00Document28 pagesS Civ Concrete - 00HARINo ratings yet

- Kawasaki PL PDFDocument20 pagesKawasaki PL PDFVictor Hemz100% (2)

- Vocational Training Report On CSPTCLDocument38 pagesVocational Training Report On CSPTCLchanchal Jha67% (3)

- S TR PTR - 00Document48 pagesS TR PTR - 00kinsleen1995No ratings yet

- S LV SWG Aux - 00Document35 pagesS LV SWG Aux - 00afsar.erNo ratings yet

- S LV SWG Pub - 00Document31 pagesS LV SWG Pub - 00afsar.erNo ratings yet

- S Poc MV - Ohl Man - 00Document16 pagesS Poc MV - Ohl Man - 00rtcrtc067No ratings yet

- S TRD Gmo - 00Document23 pagesS TRD Gmo - 00firraass.mNo ratings yet

- S TRD Pmo - 00Document24 pagesS TRD Pmo - 00raviaggrawalla8727No ratings yet

- S LV SWG Vip - 00Document35 pagesS LV SWG Vip - 00afsar.er100% (1)

- S Met Stem DC 1P 1C - 00Document18 pagesS Met Stem DC 1P 1C - 00HARINo ratings yet

- S Poc MV - 00Document29 pagesS Poc MV - 00rtcrtc067No ratings yet

- S Poc MV Ohl Aut - 00Document17 pagesS Poc MV Ohl Aut - 00rtcrtc067No ratings yet

- S MVS Prim Pu - 00Document49 pagesS MVS Prim Pu - 00afsar.erNo ratings yet

- S MVS DSTR - 00Document45 pagesS MVS DSTR - 00afsar.erNo ratings yet

- S MVS Temp Pu - 00Document51 pagesS MVS Temp Pu - 00afsar.erNo ratings yet

- S Met Stem CT 3p 1c 00Document19 pagesS Met Stem CT 3p 1c 00HARINo ratings yet

- S MVS Prim BRB - 00Document55 pagesS MVS Prim BRB - 00afsar.erNo ratings yet

- S MVS Rmu33 - 00Document32 pagesS MVS Rmu33 - 00afsar.erNo ratings yet

- S MVS SWS - 00Document37 pagesS MVS SWS - 00afsar.erNo ratings yet

- Q2118121 01 El CRT 00001Document25 pagesQ2118121 01 El CRT 00001haitam terribleNo ratings yet

- S-LV-SWG-Outdoor Ds - 00Document51 pagesS-LV-SWG-Outdoor Ds - 00Sachin PrakashNo ratings yet

- Infineon-ApplicationNote 45W 20V Adapter Reference board-ApplicationNotes-v01 00-ENDocument34 pagesInfineon-ApplicationNote 45W 20V Adapter Reference board-ApplicationNotes-v01 00-ENamekadmi2024No ratings yet

- TP 7191Document48 pagesTP 7191lmessiNo ratings yet

- A6V10361918 - Desigo - Room Automation - BR - Engineering Mounting - enDocument87 pagesA6V10361918 - Desigo - Room Automation - BR - Engineering Mounting - enLap Vo NhuNo ratings yet

- Nix SeriesDocument124 pagesNix SeriesyazeediptvNo ratings yet

- S Gen Qsa - 00Document38 pagesS Gen Qsa - 00kinsleen1995No ratings yet

- Skra - 06 001 LowVoltDocument42 pagesSkra - 06 001 LowVoltTotoroNo ratings yet

- NEKTS606-202x DRAFT V2-HoringsdokumentDocument39 pagesNEKTS606-202x DRAFT V2-HoringsdokumentJulia SartorioNo ratings yet

- Electrical Equipment CodeDocument106 pagesElectrical Equipment CodeHminhKen100% (1)

- Bardac PLXD Manual v7.0Document30 pagesBardac PLXD Manual v7.0Adam MaherNo ratings yet

- iTC-5 Installation Instructions 87138 (Rev 4) (EN)Document76 pagesiTC-5 Installation Instructions 87138 (Rev 4) (EN)Jim WilletteNo ratings yet

- TP 6834Document48 pagesTP 6834Brandon AtzNo ratings yet

- Manual Ats - Tp6834Document48 pagesManual Ats - Tp6834Manuel RodriguezNo ratings yet

- Ansi Esda Jedec JS 002 2022 TocDocument3 pagesAnsi Esda Jedec JS 002 2022 TocJohn0% (1)

- TLE8208Document41 pagesTLE8208Luis VilchezNo ratings yet

- 2020-10-22 Planning Guidline For MV ProtectionDocument62 pages2020-10-22 Planning Guidline For MV ProtectionThilina Rajapaksha100% (1)

- Um en Ev PLCC Ac1 dc1 107068 en 06Document75 pagesUm en Ev PLCC Ac1 dc1 107068 en 06Fikri FirmansyahNo ratings yet

- RDT 200 Owners Manual - MPAC 500Document88 pagesRDT 200 Owners Manual - MPAC 500MP Diesel100% (1)

- Sapcon Instruments Level Sensor Coat Endure ManualDocument30 pagesSapcon Instruments Level Sensor Coat Endure Manualtawaretanaji123No ratings yet

- Operators Instructions FlexiROC D50, D55, D60, D65 T3Document212 pagesOperators Instructions FlexiROC D50, D55, D60, D65 T3wouter1100% (1)

- Substations - Part 1 - Procedural: DisclaimerDocument44 pagesSubstations - Part 1 - Procedural: DisclaimerSergio Henrique F. CArniettoNo ratings yet

- S Ohl Woo - 00Document25 pagesS Ohl Woo - 00rtcrtc067No ratings yet

- preview_iec60364-8-1{ed2.0}enDocument10 pagespreview_iec60364-8-1{ed2.0}enhse0145No ratings yet

- WIT 50-100K User Manual EN 202310Document66 pagesWIT 50-100K User Manual EN 202310nina.bestenertechNo ratings yet

- Saso Iec 60051 1 2020 eDocument55 pagesSaso Iec 60051 1 2020 earunkumar.a641No ratings yet

- ICS 1 Industrial Control and Systems General RequirementsDocument101 pagesICS 1 Industrial Control and Systems General RequirementsSureshKumarNo ratings yet

- AIS700 Installation Instructions 87326 (Rev 6) (en)Document86 pagesAIS700 Installation Instructions 87326 (Rev 6) (en)denissanthosh2No ratings yet

- Desktop SSHD: Product ManualDocument42 pagesDesktop SSHD: Product ManualrapaialaNo ratings yet

- Terra AC Installation Manual V001Document58 pagesTerra AC Installation Manual V001Venkata Saiveer Reddy GuthaNo ratings yet

- S-Met-Stem-To-3p-0.2s - 0.5S - 00Document19 pagesS-Met-Stem-To-3p-0.2s - 0.5S - 00HARI100% (1)

- LRV 175-1 / 350-1 / 700-1 Lift Control Valve: NTA-1 Power Supply Unit and Delta Controller DELCONDocument44 pagesLRV 175-1 / 350-1 / 700-1 Lift Control Valve: NTA-1 Power Supply Unit and Delta Controller DELCONraymon janszen100% (2)

- South African National Standard On Battery ChargersDocument51 pagesSouth African National Standard On Battery ChargersjohnNo ratings yet

- Momentus Thin: Product ManualDocument38 pagesMomentus Thin: Product ManualjabbanNo ratings yet

- Manual Do Sistema SG6250HV-MVDocument120 pagesManual Do Sistema SG6250HV-MVJoão Gomes100% (1)

- El 18 XxenDocument154 pagesEl 18 Xxenswd14janNo ratings yet

- dEF STN 61-12-0 Issue 3 WithdrawnDocument44 pagesdEF STN 61-12-0 Issue 3 WithdrawnHattar MNo ratings yet

- DC/DC Converter Handbook: SMPS topologies from an EMC point of viewFrom EverandDC/DC Converter Handbook: SMPS topologies from an EMC point of viewNo ratings yet

- Next Generation SDH/SONET: Evolution or Revolution?From EverandNext Generation SDH/SONET: Evolution or Revolution?Rating: 2.5 out of 5 stars2.5/5 (2)

- S Ohl Spo - 00Document16 pagesS Ohl Spo - 00rtcrtc067No ratings yet

- S Ohl Woo - 00Document25 pagesS Ohl Woo - 00rtcrtc067No ratings yet

- D Poc MV - 00Document38 pagesD Poc MV - 00rtcrtc067No ratings yet

- D Poc LV - 00Document32 pagesD Poc LV - 00rtcrtc067No ratings yet

- SG sgx121 Datasheet 1 5Document2 pagesSG sgx121 Datasheet 1 5Joe AndreNo ratings yet

- Sl. No. Scholar Name Guide Name Research Field Month & Year of Regn. AwardedDocument4 pagesSl. No. Scholar Name Guide Name Research Field Month & Year of Regn. AwardedSamuel Pakianathan EEENo ratings yet

- DB41-126m MSOCDocument20 pagesDB41-126m MSOCEdward NewgateNo ratings yet

- Unit 2 - Automobile Suspension System: 1-Leaf Springs Absorb Shocks byDocument5 pagesUnit 2 - Automobile Suspension System: 1-Leaf Springs Absorb Shocks byDipak ZopeNo ratings yet

- Types of Computer Network: What Is LAN, MAN and WANDocument28 pagesTypes of Computer Network: What Is LAN, MAN and WANsalem salehNo ratings yet

- Boot Basket in EnglishDocument2 pagesBoot Basket in Englishyeruar 07No ratings yet

- Eagle 160 TCS BidSpec ENG 72dpiDocument1 pageEagle 160 TCS BidSpec ENG 72dpiGaudencio BoniceliNo ratings yet

- Connectors and Cables: Connector SpecificationsDocument12 pagesConnectors and Cables: Connector SpecificationsokbaNo ratings yet

- PVT VariationsDocument17 pagesPVT VariationsnarendraNo ratings yet

- University of Engineering and Technology Lahore: Voice Control Robot & Obstacle Avoidance ProjectDocument9 pagesUniversity of Engineering and Technology Lahore: Voice Control Robot & Obstacle Avoidance ProjecttalhaNo ratings yet

- Rotair Spare Parts 72DDocument43 pagesRotair Spare Parts 72DThomas Joseph Vellanjilickal100% (1)

- Pressure Temperature Regulating Valve: Model 4504Document9 pagesPressure Temperature Regulating Valve: Model 4504AlexNo ratings yet

- Method Statement For Near Field Test: DCSM Project 2019Document5 pagesMethod Statement For Near Field Test: DCSM Project 2019Thinh NguyenNo ratings yet

- Electrical Power WSDocument5 pagesElectrical Power WSAnonymous QvdxO5XTRNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Buying Guide Wire and Cable at The Home DepotDocument6 pagesBuying Guide Wire and Cable at The Home DepotRicardo NovondoNo ratings yet

- Viper Slider 1016SE MANUAL - PartsDocument18 pagesViper Slider 1016SE MANUAL - PartsNestor Marquez-DiazNo ratings yet

- List of Item Control by Mechanical Directorates PDFDocument11 pagesList of Item Control by Mechanical Directorates PDFsumitshyamalNo ratings yet

- BMW 330i M Sport.: From RM 3,758 / MonthDocument2 pagesBMW 330i M Sport.: From RM 3,758 / MonthrizNo ratings yet

- Almex Pro Brochure 106Document4 pagesAlmex Pro Brochure 106Enrique GutierrezNo ratings yet

- Operation Manual RTP9007S EUDocument44 pagesOperation Manual RTP9007S EULeiden O'SullivanNo ratings yet

- Sandevices E682 Pixel Controller With Version 4 Firmware Operating ManualDocument25 pagesSandevices E682 Pixel Controller With Version 4 Firmware Operating ManualHowardWrightNo ratings yet

- Ge MD800Document6 pagesGe MD800idontlikeebooksNo ratings yet

- AK-190 DIY LED MUSIC KitDocument4 pagesAK-190 DIY LED MUSIC Kitjose ambiorixNo ratings yet

- PAIGEDocument1 pagePAIGEGUSTAVONo ratings yet

- TC-FJ Running Manual 2021 Rev. DDocument9 pagesTC-FJ Running Manual 2021 Rev. DGouldNo ratings yet