Application of The - Theory of Cathodic To Practical Corrosion Systems

Application of The - Theory of Cathodic To Practical Corrosion Systems

Uploaded by

ardeshir yarakzadehCopyright:

Available Formats

Application of The - Theory of Cathodic To Practical Corrosion Systems

Application of The - Theory of Cathodic To Practical Corrosion Systems

Uploaded by

ardeshir yarakzadehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Application of The - Theory of Cathodic To Practical Corrosion Systems

Application of The - Theory of Cathodic To Practical Corrosion Systems

Uploaded by

ardeshir yarakzadehCopyright:

Available Formats

Downloaded from https://iranpaper.

ir

https://www.tarjomano.com https://www.tarjomano.com

Application of the -Theory of Cathodic Protection- to Practical Corrosion

Systems

by L. Krivian

Research Institute/or Heavy Chemical Industries, Veszprem, Hungary

(Manuscript received 13 April, 1983; revised manuscript 19 September, 1983)

A review of the theories of cathodic protection has shown that a gradual improvement has taken place in the

description of the fundamental principles. At the present time electrode kineticsprovide the most suitable basis

for further improvement of the theory. Experimental results show that 'jullprotection' cannot be achieved,

and so the criteria of protection have to be associated with a permitted value of corrosion rate. Criteria for

cathodic protection have been determined for corrosion systems of steel-potable water saturated with air,

steel-potable water saturated with hydrogen sulphide, and steel-potable water saturated with sodium

chloride. In practice the form of corrosion damage is very important and this depends on the formation of

corrosion cells. The operation of corrosion cells is incorporated in the improved theory of cathodic

protection.

Introduction Review of Theories of Cathodic Protection

THE theory of cathodic protection has _gradually been -clarified The oldest theory of cathodic protection10 has already

during the past 150 years. The development of electrochemistry embodied the fundamental principle in elegant wording: ... 'a

has enabled an acceptable description of the processes very weak chemical action would be destroyed by a very weak

involved to be reached. However, there are 'significant electrical force' ... 'and whatever the difference between the

discrepancies in the proposed criteria of protection: kinds of copper sheeting and their consequent reaction on each

other, all chemical action will be prevented if the whole surface

For steel structures the NACE standard 1 proposes five

is rendered negative'. These sentences contain, some hint as to

different criteria but gives no instruction for the selection of

the possibility of the formation of corrosion cells, but they deal

the recommended one. The first of these criteria refers to the

with the problem while neglecting this point. Although some of

ohmic drop as a possible source of an erroneous reading but

the conclusions are useful even today, the author's formulation

does not refer to an accepted method for its elimination.

of the criteria of protection, based on the ratio of anode to

According to. the standard of the GDR2 the structure is surface structure area, cannot be generally applied.

protected when the structure to soil potential is within the A theory based on electrical engineering 11 stresses the role of.

region of - 0·85 V to - 1·6 V vs the Cu/CuSOisat) corrosion cells: 'In practically all corrosion processes on iron

electrode. This standard does not refer to the ohmic drop. and steel, galvanic elec~ricity passes from the metal at the exact

point of corrosion to the surrounding soil or moist environment,

The BSI Code of Practice3 gives the potentials for full

flows through the soil or. moist environment for some distance -

protection and describes a method for the elimination of the

depending upon the type of corrosion - then returns to the site

ohmic drop. It makes a distinction between ·criteria for

of -the corrosion, to complete the circuit'. .. 'The principle of

aerobic and anaerobic corrosive. environments.

cathodic protection is based upon reversing the direction of the

The USSR standard4 gives only one protective potential galvanic currents on the surface of the pipeline by applying an

for any corrosive environment and defines the use of the external negative potential' ... 'To protect a line from corrosion

auxiliary electrode for the measurement of the polarisation the electrical potential must be lowered by about 0·4 volts'. This

potential. The protective potential ranges are defined for theory does not distinguish between the potentials of the anodic

uncoated and coated steel structures. and cathodic surfaces, but the corrosion -rate must primarily

depend on the potential of the anodic areas.

Thus a revision of the theory is needed.

A theory based on electrochemistry, 12 that is, on anodic and

The form of corrosion damage is a very important point in cathodic reactions, is based on the assumption that ... 'The

practice. The field tests of the NBS have clearly shown that the total cathodic and anodic areas at any instant may be

pattern of corrosion damage and the rate of corrosion depend on considered as being of the same order of magnitude', their sum,

the composition and structure of the soil. 5 A statistical analysis of course, being 'the total area of the metal/electrolyte interface'.

of data6 based on exposure tests has given some important ... Consider now the effect of applying a cathodic current from

particulars on soil corrosion.7 The average corrosion rate, an outside source on to a corroding metal. The potential of the

calculated from the mass-loss of specimens laid in 47 different metal will move in the negative direction ... but the anodic and

soils, is 0·056 f.Jm/d, that is, a 1 mm thick layer of a steel object cathodic areas, in this view, are both part of the metal surface

would be converted into corrosion product in 49 years. The where only one reaction is proceeding. There are further

average corrosion rate, corresponding to the rate of perforation, unjustified conditions, e.g., although the anodic and cathodic

for the same specimens, calculated from the depth of the deepest areas may be represented by anodic and cathodic polarisation

pits, is 0·41 f.Jm/ d, Le., the rate of perforation is seven times curves, the electrode potential at all points of the metal surface

higher than the rate of general corrosion. The pitting of metallic is the same and the metallic -surface remains equipotential

structures is caused by the operation of corrosion cells due to during polarisation. Nevertheless this theory reaches. the

differences in the rate of diffusion of oxygen.8,9 This point essentials of the situation.

emphasises the' importance of the role of corrosion -cells in the A theory based on electrochemical equilibria13 was envisaged

theory of cathodic protection. Thus it is necessary to assess the as follows. 'A diagram of electrochemical equilibria can be

theories in the light of -their ability to incorporate the role of calculated for each metal or metalloid, plotted as a function of

corrosion cells. the electrode potential of the metal and the pH of the solution in-

Dr. Corros. J., 1984, Vol. 19, No. I

Downloaded from https://iranpaper.ir

https://www.tarjomano.com https://www.tarjomano.com

Krivian: Application of the Theory of Cathodic Protection to Practical Corrosion Systems 31

contact with it, which will show the conditions of equilibrium for TABLE I

all the reactions that could occur between the metal or metalloid Important potentials in relation to soil corrosion

and the solution, at a given temperature' ... 'There is immunity

when the metal is thermodynamically stable, in which case

corrosion is thermodynamically impossible. The areas of Value of the

potential, E, in

immunity represented on these diagrams correspond to the state Name of the potential volts vs standard

known as 'cathodic protection'. Since these areas of immunity hydrogen electrode,

are generally located below the areas of corrosion, a corroding V(SHE)

metal can usually be put in a state of immunity by lowering its

Equilibrium potential of the electrode +0·816

electrode potential, Le., by 'cathodic treatment'. But every point reaction

. on an equilibrium diagram (pH vs potential for a specified 40H- ~ O2 + H20 +4e-atpH7

concentration) represents an equilibrium; thus no macroscopic Free corrosion potential of a steel probe -0·075

process can be occurring. The demarkation of frontiers between immediately after immersion in potable

the areas of corrosion, passivity and immunity is arbitrary. Only water

electrode kinetics can establish any relation between electrode Free corrosion potential of a buried -0·250

potential and the rate of the process. Furthermore the equilibrium steel structure

potential c'alculated from free enthalpies cannot be treated as the Equilibrium potential of the electrode -0·414

equivalent of the electrode potential used in practice because the reaction

measured 'electrode potentials', which are corrosion potentials, 1/2H2 + H20 ;=H30+ + e- at pH 7

are mixed potentials in the electrochemical sense. So it is not Equilibrium potential of the electrode -0·440

surprising that the criterion of protection derived from this reaction

Fe2+ + 2e- ~ Fe

theory (-0.62 V referred to the standard hydrogen electrode at 1 mol/dm3 activity of Fe2+ ions

(SHE» does not coincide with the criterion (-0·85 V referred to

Free corrosion potential of a steel probe -0·500

the Cu/CuSOisat) electrode) accepted in practice. submerged in deoxygenated potable

The theory based on electrode kinetics14 offers an up-to-date water

explanation of the processes involved in cathodic protection: Equilibrium potential of the electrode -0·620

'The electrochemical theory of corrosion states that corrosion reactiun

proceeds by two electrochemical reactions, one an oxidation or Fe2+ + 2e- ;= Fe

dissolution (anodic) reaction, the other a reduction (cathodic) at 1.10-6 mol/dm3 activity of Fe2+ ions

reaction. A simple system might be:

M-4M++e- (1)

Z2+ + e--4 Z+ (2)

I Jo (Aim'} I

Reaction (1) represents metal atoms, M, which dissolve as

metal ions, M+, liberating within the metal an electron, e-. To

compensate, an electron is consumed simultaneously on the

surface by reaction (2), the reduction of some arbitrary ionic

species, Z2+ to Z +, ... 'The principle of cathodic protection is

evident from inspection of reactions (1) and (2). When the metal

potential is made more negative (cathodic polarisation) more

electrons are made available to both (1) and (2). By the law of

mass action, this higher concentration of electrons will· depress

the rate of (1) while accelerating (2). Thus the dissolution or

corrosion rate is lessened and the metal is 'cathodically

protected'. Although this theory is not suitable for describing the

role of the corrosion cell, its principle may be applied to Fig.1. Schematic diagram of the rates of electrode reactions

corrosion systems consisting of homogenous metallic surfaces representing corrosion

and homogeneous corrosive environments.

represents the polarisation curve of a probe under given'

Laboratory Experiments conditions. At the free corrosion potential (E~orr)the anodic and

The most important practical application of cathodic cathodic reactions are in electrical equilibrium causing the

protection is the protection of steel structures immersed in an anodic dissolution of iron to take place at a rate of J~orr.

aqueous solution. The following electrode reactions: A set of tests 15 was performed to determine the parameters of

the corrosion of mild steel (quality conforming to the Hungarian

Fe2+ + 2e- Fe (3) standard MSz 4213 ASz 2L) in contact with potable water

(Table II).

40H- O2 + 2H20 + 4e- . (4)

The steel specimen was made of 1·2 mm thick sheet in the

tH2 + H20 H30+ +e- . (5) form of a disc. After the usual surface treatment its mass was

determined with an accuracy of 0·05 mg. The specimen was

may proceed simultaneously on an iron surface in contact with fixed in a specimen holder shown in Fig. 2. The test cell, which

an aqueous solution. The theoretical equilibrium potentials of held two specimens, is shown in Fig. 3. One specimen was

these reactions and 'some corrosion potentials give some idea of polaris~d and the other allowed to corrode freely as a control

the role of these reactions (Table I). A diagram (Fig. 1) of specimen.

electrode reactions may be drawn taking into consideration that The electrode potential of the steel specimen was maintained

the cathodic reduction of Fe2+ ions and of dissolved oxygen, and at a constant level by the potentiostat (Fig. 4) which auto-

also the anodic oxidation of dissolved hydrogen, are all matically compensated for the ohmic drop between the working

controlled by diffusion. The dotted line (_. - . -) in the diagram and reference electrodes. The polarising current was integrated

Br. Corros. J., 1984, Vol. 19, No. I

Downloaded from https://iranpaper.ir

https://www.tarjomano.com https://www.tarjomano.com

32 Krivian: Application of the Theory of Cathodic Protection to Practical Corrosion Systems

TABLE II

Characteristics of potable water used for experiments

Value

Unit of

Quantity measurement Min Max

Conductivity ,uS.cm-1 490 580

Resistivity Q.m 17·2 20·4

pH - 7·2 7·8

Hardness as CaC03

Total mg/l 35·7 44·6

Calcium mg/l 33·9 35·7

Alkalinity

Ph. mmol/l 0 0

M.a. m moIll 6·8 7·4

Constituent

Bicarbonate mg/l 415 450

Carbonate mg/l 0 0

Chloride mg/l 22 27

Nitrate mg/l 28 33

Fig. 3. Test cell

1. Glass body 5. Glass strainer

2. Specimen holder 6. Thermometer

3. Reference electrode 7. Nipple

4.Auxiliary electrode

Fig. 2. Structure of the specimen holder

1. Specimen

2. Gasket

3. Sealing body with spring controlled connection

4. Cap

by the coulometer, which made it possible to calculate the

coulometric current density (JQ)' The mass losses of the

specimens were converted to corrosion current densities (Jeorr) Fig. 4. Electronic equipment

by Faraday's law. In the first series the period of each test was 1. Potentiostat 4. Oscilloscope

2. Digital voltage and current meter 5. Recorder

94 h. At the end of the test the polarising current was measured 3. Coulometer 6. Voltage stabiliser

and the polarising current density (Jp) calculated. The data are

plotted in a diagram 16 shown in Fig. 5. The polarisation curve is

similar to the one shown in Fig. 1.

The behaviour of the anode of a corrosion cell can be of water. The· pH of the corrosive environment sharply increases

reproduced by cathodically polarising the specimen. As can be and the deposition of carbonates is triggered.

seen, Jeorr is higher than JQ by Jgor~,i.e., near to the free corrosion Plotting the logarithm of corrosion rate (v) vs potential (E),

potential the anodic dissolution current density, caused by the the curve. is a straight line around the free corrosion potential

reduction of dissolved oxygen, and the applied anodic current (Egorr) (Fig. 6). This holds true at lower corrosion potentials as

density, are superimposed. indicated in this figure. At the widely used protection potential,

Similarly the -behaviour of the cathode can be reproduced by Eprot = -0·85 V vs Cu/CuS04 (sat) electrode, that is, at -0·53 V

cathodically polarising a specimen. In Fig. 5 it can be seen (SHE), the corrosion rate is 0·02 J.lm/d. The shape of the curve

that the cathodic polarisation decreases the rate of dissolution, shows that 'full protection' cannot be achieved, so the criterion

and the coulometric c.d. (JO) is almost equal to Jgorr' J Q is of protection may be that value of corrosion potential at which

constant from -0·53 V (SHE) to -0·725 V (SHE), i.e., the the corrosion rate does not surpass an accepted value. If 0·02

cathodic reduction of dissolved oxygen is controlled by diffusion J.lm/d is accepted as·a permissible corrosion rate - 1 mm thick

within this range. The polarising current density (Jp), owing to layer of a metallic object being transformed into corrosion

the formation of a calcareous deposit, decreases to a small product· in 137 years - then the protective potential for any

value, -0·03 A/m2• Below -0·75 V' (SHE) the predominant corrosion system may be determined from a diagram similar to

reaction is the evolution of hydrogen gas by the decomposition that shown in Fig. 6.

Dr. Corros. J., 1984, Vol. 19, No. I

Downloaded from https://iranpaper.ir

https://www.tarjomano.com https://www.tarjomano.com

Krivian: Application o/the Theory o/Cathodic Protection to Practical Corrosion Systems 33

I

5

I J" (Alm 2

) I I j !

I

Q3 I

-0: sfeel+ wofer

I

+ air (91,h)

t

0.2

+: steel + wo fer + air + NoCl (166 h) ef

0,1

I

0,0 II

- 0,1 I I I J

a

,o'~iO'i+OtO'

-0,2

I

-0,3 I

Fig. 5. Current density-corrosion potential curves of the corrosion I

system steel-water saturated with air

£(V/SH£J

-5

-Q9 -as -0,7 -0,6 -0,5 -0,1, -0,3

Fig. 7. Polarisation curves of two corrosion systems

10

10

l:sfee/+ wafer + air (94h)

+:sfee/ + wofer+ air + NoCI f166h J

0,1

0,1

-0,6 -0,5 -0.4

0.01

Fig. 6. Corrosion rate-corrosion potential curve of the corrosion

system steel-water saturated with air

-0,6 -0,5 -0.1,

Sets of potentiostatic tests were performed on further

corrosion systems. In the case of steel immersed in saturated Fig. 8. Corrosion rate-corrosion potential curves of two corrosion

systems

NaCI solution the polarisation curve cannot be distinguished

from the curve plotted for steel immersed in potable water (Fig.

7). This proves that the same electrode reactions are proceeding.

for cathodic protection. The free corrosion potential and the

Although the concentration of oxygen, dissolved in saturated

corrosion rate are important corrosion parameters. The

NaCI solution at 25°c, is smaller than in drinking water, the

protective potential and the polarising current density are the

polarising current density does not differ significantly.

key-parameters of cathodic protection. But the range of

Presumably the diffusion coefficients are the same for the two

electrode potential, in which the protected state may be

solutions. The diagram (Fig. 8) showing the corrosion rate vs

maintained by approximately the same current density, is useful

electrode potential definitely indicates a decrease in corrosion

too. Recent results are summarised in Table III.

rate in the presence of NaCI. Perhaps this may be explained by

the smaller concentration of oxygen at the surface of the

specimen. Role of Corrosion Cells

Another corrosion system consisting of steel-water saturated The model of a corrosion cell and its equivalent circuit are

with hydrogen-sulphide was tested in the same way. The indicated in Fig. 11. The corrosion cell arises from the differing

polarisation curve (Fig. 9) differs markedly from the polarisation concentrations of the reducing agent. The electrode potential is

curve of the previous corrosion system. Obviously the electrode low at those places where the concentration of the reducing

reactions are different. The free corrosion potential has shifted agent is small. These are the anodic areas. Both anodic and

from 4)·475 V (SHE) to 4)·550 V (SHE) but the corrosion rate cathodic areas may be characterised by a polarisation curve.

has not changed significantly (Fig. 10). The protective potential Plotting the respective curves on the same diagram (Fig. 12) the

is lower than in the previous cases, at the same time the operation of the corrosion cell can easily be interpreted. The

polarising current density is. much higher. electromotive force (Ea - Ee) of the cell produces a current (I)

From a practical point of view it is useful to summarise the which polarises both the anodic and the cathodic areas, thus the

data characterising the process of corrosion. and the conditions electromotive force of the cell decreases. A relatively constant

Br. Corros. J., 1984, Vol. 19, No.1

Downloaded from https://iranpaper.ir

https://www.tarjomano.com https://www.tarjomano.com

34 Krivian: Application of the Theory of Cathodic Protection to Practical Corrosion Systems

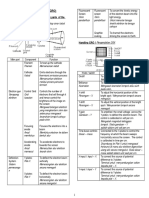

TABLE III

Data characterising the conditions of cathodic protection of some corrosion systems

Free Polarising Protective

corrosion Corrosion Protective current potential

Corrosion system potential, rate, potential, density, range,

E2orr, v, ESrot' J, .6. E,

V(SHE) pm/day V( HE) A/m2 V(SHE)

-0·475 -0·530 -0·03 -0·530

Steel +water+air 0·25 -0·725

-0·475 -0·03 -0·520

Steel +water + NaCI 0·13 -0·520 -0·725

Steel + water + hydrogen-sulphide -0·550 0·23 -0·615 -0·30 -0·615

-0·700

5 I

I JD( A 1m I 2

)

1:sfeel.,. wafer.,. air (94h)

I 10.0

1'steel+ water+ air (94 h)

2:sfeel.,. wafer.,.H2S (9I,h)

+} P 2:stee/+ woter.,.H1S (94 h)

I ~ ~

II 1.0

a

d

}J = ~ -?J6.{)

+",+-i'

I~ 0,1

/

0,01

£ (VISHE)

-5

-0,9 - Q8 -0,7 -Q6 -0,5 -at. -0,3 -0,6 -0,5 -0.4

Fig. 9. Polarisation curves of two corrosion systems Fig. 10. Corrosion rate-corrosion potential curves of two corrosion

systems

current (I') is maintained· by the difference in the polarisation

potentials (~ - ~). At the same time this difference is equal to function of diameter is plotted in Fig. 13. It is important to note

U, which is the ohmic drop (I' (Ra + Rc)) within the cell. that the current density is inversely proportional to the diameter

The metallic structures buried in the soil are usually wrapped of the holiday, i.e., the smaller the holiday the higher the current

with a protective coating. The metal touches the soil through the density.

holidays in the protective coating. Each of these holidays may

be characterised as a corrosion system having a ground

Effect of Cathodic Polarisation

resistance.

The current flowing through the holiday thus depends also on Where a coated metallic structure is. cathodically protected

the ground resistance. When the diameter of the holiday is the protective current is flowing through the holidays. The

greater than the thickness of the coating the holiday may be equivalent cathodic protection circuit may be seen in Fig. 14.

represented by a disc in contact with the soil· whose ground Applying Kirchhoff's law to any part of the closed circuit

resistance (R) can be calculated from the formula: shown in Fig. 14, the current density is given by:

P

R=

2D

where Uo = terminal voltage of the current source

where p = the resistivity of the soil Us = the ohmic drop on the ground resistance of the

and D = the diameter of the disc. anode (Rs)'

The current density on the disc may be calculated in the ~ depends on Jj, but when Uo-Us is· much higher than Ei, the

following way: current density is proportional to Uo'

Ei is the crucial parameter of corrosion and protection. Its

4' 4 U· 8U· changes may be easily followed. The free corrosion potential of

J=-I=-·-=-- the metal depends on the parameters of the corrosion system.

D27t D27t R, P 7tD The concentration of the reducing agent is one of the most

important parameters. Owing to the differences in free corrosion

where U· is the ohmic drop developed by the current flowing potentials, current is flowing through the holidays. Thus some of

through the ground resistance. The order of magnitude of the them are anodically polarised, and others are cathodically

ohmic drop (V· = I R) is 0·1 V. The current density as a polarised. The electrode potential of the metal at the holiday is

Br. Corros. J., 1984, Vol. 19, No.1

Downloaded from https://iranpaper.ir

https://www.tarjomano.com https://www.tarjomano.com

Krivian: Application of the Theory of Cathodic Protection to Practical Corrosion Systems 35

Fig. 11. Model of a corrosion cell and its equivalent circuit

sfeel.,.water",oir

Fig..14. Equivalent cathodic protection circuit

Jo

~c I JpfAlm') I

steel., water.,. air

I £{V/SH£JI

o

£oE:'af!cEc

Fig. 12. Schematic polarisation curves of a corrosion cell

10 1:g=10 ohm m,lft0,1 V -0,7 -0.5 ~~S £prot2 -0,1.

2:g=20ohm m, If=O,1'I

S 3: g=5O ohm ~ tftO,1 V Fig. 15. Schematic diagram of polarisation curves of a metallic

structure

2

J=~~ The criteria of protection may differ according to the aim of

gTrD the corrosion· protection. In a homogeneous corrosion system

QS the protected state is realised when the corrosion potential is

equal to:

Q2

Eprot }.

0,1 Q2 as 2 S 10

If the limitation of pitting is sufficient a higher value of corrosion

Fig. 13. Diagram ofcurrent density versus diameter of holiday potential may be sufficient. When the electrode potential of the

cathodic areas reaches the minimum free corrosion potential of

the anodic areas no current flows in the corrosion cells, thus:

usually shifted away from the free corrosion potential. When an

external source of current is connected to the metallic structure £prot 2 = min Ecorr'

and the anode, the currents flowing through the holidays are

changed and the electrode potentials of the metal are also

Acknowledgments

changed.

Thanks are due to the Ministry of Industry for financial

support and the Director of the Research Institute for Heavy

Improved Theory of Cathodic Protection Chemical Industries for permission to publish.

The mechanism of cathodic protection may be easily

understood from Fig. 15. Any spot of the protected structure References

may be treated as a corrosion system. Each spot is characterised 1. NACE RP-QI-69

by a polarisation curve which is determined by all the electro- 2. TGL 18 790-1972

chemical reactions proceeding on the metallic surface. The 3. BSI CP 1021: 1973

4. GOST 9.015-74

working point of a corrosion system is located at (Egom Ip = 0). 5. Logan, K. H., Trans. electrochem. Soc., 1933,64, 113

The operation of corrosion cells moves their working points to 6. Romanoff, M., 'Underground Corrosion', Bull. natn. Bur. Stand.

points denoted by O. When Uo-Us is greater than Ei, the Circular 579. 1957. p. 2(?(Washi..ngton:U.S. Printing Office)

cathodic polarisation of the areas begins and the working points 7. Kriviim, L., Korrozios Figyelo, 1980, 20, 201

8. Rogers, W. F., Ind. Engng Chem., 1938,30,1181

move along the polarisation curves towards the points denoted 9. Tomashov, N. D., Uspekhi Him;;, 1957,26, 139

by@. 10. Davy, Sir H., Phil. Trans.R. Soc., 1824,114,151

When the current density reaches the limiting current density 11. Kuhn, R. J., Proc. Am. Petrol. Inst. 1933, Sect. IV, p. 153

of the reducing agent the working point swiftly moves from the 12. Hoar, T. P., J. Electrodep. Soc., 1938, 14,33

right side to the left side. As the current density is inversely 13. Pourbaix, M., Corros. PrevoControl, 1960, 7(10),43

14. Jones, D. A., Corros. Sci., 1971, 11,439

proportional to the diame~er of the holiday, the smaller anodic· 15. Krivian, L., Korrozios Figyelo, 1981,21,8

areas are more easily polarised. 16. Krivian, L., 8th Int. Congr. metall. Corros., Mainz, 1981, p. 1153

Dr. Corros. J., 1984, Vol. 19, No.1

You might also like

- 77 ArticleText 153 1 10 20190722Document9 pages77 ArticleText 153 1 10 20190722Syril Gabrielle BelaguinNo ratings yet

- Unit-5 BeeDocument37 pagesUnit-5 BeeAliNo ratings yet

- Cathodic Protection Marshall E. Parker PDFDocument177 pagesCathodic Protection Marshall E. Parker PDFyebriNo ratings yet

- Calculating Cable Fault RatingsDocument8 pagesCalculating Cable Fault Ratingswaqas_a_shaikh4348No ratings yet

- Test Methods For On Site Measurement of Resistivity of Concrete A RILEM TC-154 Technical RecommendationDocument7 pagesTest Methods For On Site Measurement of Resistivity of Concrete A RILEM TC-154 Technical RecommendationCharnjeet SinghNo ratings yet

- Andrade - 2020 - Electrochemical Methods For On Site Corrosion DeteDocument11 pagesAndrade - 2020 - Electrochemical Methods For On Site Corrosion DetezhongtaotaojiayouNo ratings yet

- Porosity Evaluation of Protective Coatings Onto Steel, ThroughDocument9 pagesPorosity Evaluation of Protective Coatings Onto Steel, ThroughNassima JagharNo ratings yet

- Çok Önemli̇ KaynakDocument6 pagesÇok Önemli̇ KaynakYesim YilmazNo ratings yet

- Articulo Corrosion 2Document15 pagesArticulo Corrosion 2Juan Pablo AponteNo ratings yet

- Spr06 - p24-26 What Is CorrosionDocument3 pagesSpr06 - p24-26 What Is CorrosionReynaldo CruzNo ratings yet

- Impedance Monitoring of Carbon Steel Cavitation Erosion Under The Influence of Corrosive FactorsDocument7 pagesImpedance Monitoring of Carbon Steel Cavitation Erosion Under The Influence of Corrosive FactorsSutanwi LahiriNo ratings yet

- Yong SunDocument15 pagesYong SunFandy SetiawanNo ratings yet

- Monitoring Methods of Cathodic Protection of Pipelines PDFDocument13 pagesMonitoring Methods of Cathodic Protection of Pipelines PDFMarcos LeiteNo ratings yet

- Coatings 13 01349Document16 pagesCoatings 13 01349cpucheNo ratings yet

- What Is Corrosion?: Electrochemical Society Interface March 2006Document4 pagesWhat Is Corrosion?: Electrochemical Society Interface March 2006Jahzerah PoochieNo ratings yet

- P Cathodic ProtectionDocument118 pagesP Cathodic Protectiondian astuti100% (6)

- IP Influence of Temp On ZnNi Dep. Cyclic Voltametry 2020Document11 pagesIP Influence of Temp On ZnNi Dep. Cyclic Voltametry 2020Sorin SorinNo ratings yet

- Corrosion Science: SciencedirectDocument13 pagesCorrosion Science: SciencedirectMANo ratings yet

- Lecture Corrosion PreventionDocument39 pagesLecture Corrosion PreventionLakshay JangraNo ratings yet

- ShawKelly 2006 WhatisCorrosionDocument4 pagesShawKelly 2006 WhatisCorrosionAldair FranciscoNo ratings yet

- Overview of Corrosion and Advanced Corro PDFDocument6 pagesOverview of Corrosion and Advanced Corro PDFStefanos DiamantisNo ratings yet

- What Is Corrosion?: Electrochemical Society Interface March 2006Document4 pagesWhat Is Corrosion?: Electrochemical Society Interface March 2006Behayle TerayeNo ratings yet

- Intergranular Pitting Corrosion of Cocrmo Biomedical Implant AlloyDocument10 pagesIntergranular Pitting Corrosion of Cocrmo Biomedical Implant AlloyshameekaNo ratings yet

- MatCorr56 (6) (2005)Document9 pagesMatCorr56 (6) (2005)Pako RosasNo ratings yet

- Effect of Anode Type and Position On The Cathodic Protection of Carbon Steel in Sea WaterDocument8 pagesEffect of Anode Type and Position On The Cathodic Protection of Carbon Steel in Sea WatersaishankarlNo ratings yet

- Ab Initio Monte Carlo Simulations of The Acidic Dissolution of Stainless Steels in Uence of The Alloying ElementsDocument8 pagesAb Initio Monte Carlo Simulations of The Acidic Dissolution of Stainless Steels in Uence of The Alloying Elementsbmalki68No ratings yet

- The Basics of Cathodic ProtectionDocument17 pagesThe Basics of Cathodic ProtectionfernandoiescNo ratings yet

- Cathodic ProtectionDocument22 pagesCathodic ProtectiondevanbongiriNo ratings yet

- 202me472 Oh 6Document63 pages202me472 Oh 6Hussain Al-DawoodNo ratings yet

- 25Document4 pages25Jesus MaestreNo ratings yet

- Electrochemical Studies in Laboratory Determination of Behaviour To Corrosion of Some Chrome-Based Alloys For Surgical Implants Prof. Dr. Ing. LIDIA CRISTEADocument7 pagesElectrochemical Studies in Laboratory Determination of Behaviour To Corrosion of Some Chrome-Based Alloys For Surgical Implants Prof. Dr. Ing. LIDIA CRISTEAAnonymous 1hOgJqwZuzNo ratings yet

- A Holistic Model To Address Corrosion in Nuclear Power PlantsDocument44 pagesA Holistic Model To Address Corrosion in Nuclear Power PlantsHeramb TrifaleyNo ratings yet

- Introduction To Corrosion Science and Engineering-Unit-1: CHE-545-172 DR Ime B.ObotDocument14 pagesIntroduction To Corrosion Science and Engineering-Unit-1: CHE-545-172 DR Ime B.ObotAnonymous NxpnI6jCNo ratings yet

- The Basics of Cathodic ProtectionDocument6 pagesThe Basics of Cathodic ProtectionKhanh DTNo ratings yet

- In Uence of CR and Ni Elements On The Electrochemical and Early Corrosion Behavior of Femnalc Low-Density SteelDocument16 pagesIn Uence of CR and Ni Elements On The Electrochemical and Early Corrosion Behavior of Femnalc Low-Density Steelrozalina amranNo ratings yet

- 1 s2.0 S0142112319300453 MainDocument12 pages1 s2.0 S0142112319300453 MainMila KartikaNo ratings yet

- Annibaldi2012 Checar PDFDocument7 pagesAnnibaldi2012 Checar PDFAnonymous BSViVGUNo ratings yet

- 28 ZhengDocument5 pages28 Zhengs.mallonNo ratings yet

- Evidence of Hydrogen Gas Evolution Accelerating The Cat - 2022 - Corrosion CommuDocument7 pagesEvidence of Hydrogen Gas Evolution Accelerating The Cat - 2022 - Corrosion Commu41322110070No ratings yet

- Effect of Chloride Concentration On The Corrosion Rate in Carbon SteelDocument7 pagesEffect of Chloride Concentration On The Corrosion Rate in Carbon SteelAziz SaputraNo ratings yet

- Corrosion Basics Expalained in DepthDocument1 pageCorrosion Basics Expalained in DepthAli Asghar100% (1)

- 1-s2.0-S0010938X23008120-main 腐蚀-疲劳分析Document12 pages1-s2.0-S0010938X23008120-main 腐蚀-疲劳分析parkersun5566No ratings yet

- Corrosion EngineeringDocument44 pagesCorrosion EngineeringanubhavsundarrayNo ratings yet

- Conducting Polymers For Corrosion Protection A ReviewDocument22 pagesConducting Polymers For Corrosion Protection A ReviewSudsiri HemsriNo ratings yet

- Corrosion Testing Lab - 20MT30019Document7 pagesCorrosion Testing Lab - 20MT30019productNo ratings yet

- 5E. CP.... P CATHODIC PROTECTION, - Add - B4TDocument120 pages5E. CP.... P CATHODIC PROTECTION, - Add - B4Tdwi sutiknoNo ratings yet

- Cathodic Disbondment PDFDocument25 pagesCathodic Disbondment PDFsanjayaNo ratings yet

- Electrochemical Tomography As A Nondestructive Technique To Study Localized Corrosion of Metalsnpj Materials DegradationDocument12 pagesElectrochemical Tomography As A Nondestructive Technique To Study Localized Corrosion of Metalsnpj Materials DegradationHeyner Sanchez ArbaizaNo ratings yet

- The Basics of Cathodic ProtectionDocument2 pagesThe Basics of Cathodic ProtectionlsatchithananthanNo ratings yet

- Electrohemical Study of Corrosion Rate of Steel in Soil Barbalat2012Document8 pagesElectrohemical Study of Corrosion Rate of Steel in Soil Barbalat2012Nicholas FeatherstonNo ratings yet

- 2006-Computational Modeling of Active Corrosion Inhibitor Release - Kelly & SkullyDocument14 pages2006-Computational Modeling of Active Corrosion Inhibitor Release - Kelly & SkullyCarlos OliveiraNo ratings yet

- Lecture Corrosion PreventionDocument39 pagesLecture Corrosion Preventionshoaib1985No ratings yet

- Electrochemical Characterisation of The Porosity and Corrosion PDFDocument11 pagesElectrochemical Characterisation of The Porosity and Corrosion PDFCicero Gomes de SouzaNo ratings yet

- Current State of Electrochemical Techniques and Corrosion Rate AnalysisDocument8 pagesCurrent State of Electrochemical Techniques and Corrosion Rate Analysiscarlos gomezNo ratings yet

- UAS Korosi Resume PDFDocument8 pagesUAS Korosi Resume PDFMochamad FijayNo ratings yet

- The Basic Cathodic Protection PDFDocument2 pagesThe Basic Cathodic Protection PDFCristian CisternasNo ratings yet

- Cathodic Protection PDFDocument24 pagesCathodic Protection PDFJorge Luis Clavijo Iturri67% (3)

- Miller, Lillard - 2019 - An Investigation IntoDocument12 pagesMiller, Lillard - 2019 - An Investigation IntoEdgar HornusNo ratings yet

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionFrom EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 6, Slice 8 "Conduction, Electric"From EverandEncyclopaedia Britannica, 11th Edition, Volume 6, Slice 8 "Conduction, Electric"No ratings yet

- FisherDocument22 pagesFisherardeshir yarakzadehNo ratings yet

- NGWK 0001 Enpi Sppa 2308 D12Document50 pagesNGWK 0001 Enpi Sppa 2308 D12ardeshir yarakzadehNo ratings yet

- Yang 2022 Mater. Res. Express 9 125310Document10 pagesYang 2022 Mater. Res. Express 9 125310ardeshir yarakzadehNo ratings yet

- Sigma Handbook WastageDocument1 pageSigma Handbook Wastageardeshir yarakzadehNo ratings yet

- Microstructure and Properties of Quenched-and-Aged Plates Produced From A Copper-Bearing HSLA SteelDocument7 pagesMicrostructure and Properties of Quenched-and-Aged Plates Produced From A Copper-Bearing HSLA Steelardeshir yarakzadehNo ratings yet

- Ronass High-Build Epoxy Polyamide Coating: Rtb-976-R (A&B Components)Document1 pageRonass High-Build Epoxy Polyamide Coating: Rtb-976-R (A&B Components)ardeshir yarakzadehNo ratings yet

- Chemistr Y Notes: - Solencia HamiltonDocument56 pagesChemistr Y Notes: - Solencia HamiltonManushka ThomasNo ratings yet

- Mod 5 SensorsDocument37 pagesMod 5 Sensorsrsyed2704No ratings yet

- Lithium-Ion BatteriesDocument97 pagesLithium-Ion Batteriessanketh100% (13)

- Lecture 03 - Electrochemical Kinetics - Voice OverDocument57 pagesLecture 03 - Electrochemical Kinetics - Voice OverWashington Sta RosaNo ratings yet

- Naval Material Science and Engineering USNA PDFDocument250 pagesNaval Material Science and Engineering USNA PDFSaurabh Tripathi100% (1)

- Electron Beam Machining: D.Palani Kumar, Assistant Prof. / Mech. Engg., Kamaraj College of Engg. & Tech. VirudhunagarDocument26 pagesElectron Beam Machining: D.Palani Kumar, Assistant Prof. / Mech. Engg., Kamaraj College of Engg. & Tech. VirudhunagarvaniNo ratings yet

- Pradeep Jaiswal M.Sc. Part-1 Sem-1 Roll No. 6Document18 pagesPradeep Jaiswal M.Sc. Part-1 Sem-1 Roll No. 6Kailash VeerappanNo ratings yet

- Chem16 - 2ndLE Reviewers PDFDocument9 pagesChem16 - 2ndLE Reviewers PDFlylwennmacalaladNo ratings yet

- Bruce Logan MFCDocument9 pagesBruce Logan MFCdavid_tomy_1No ratings yet

- Li2020 Article WaterSplittingFromElectrodeToGDocument29 pagesLi2020 Article WaterSplittingFromElectrodeToGAbroo KhattakNo ratings yet

- TV-7 ManualDocument79 pagesTV-7 Manualtrkonjic50% (2)

- Corrosion and Its ControlDocument23 pagesCorrosion and Its Controlapi-26041653No ratings yet

- Electrochemistry LatestDocument36 pagesElectrochemistry Latestteodoruunona609No ratings yet

- DPP Electrochemistry L-1 (Harsh Sir) (03-05-2021)Document77 pagesDPP Electrochemistry L-1 (Harsh Sir) (03-05-2021)Tejasvi MahuleNo ratings yet

- 9.1 Oxidation and Reduction 9.1.1 Definitions: Oxidation and Reduction Take Place Together at The Same Time in The SameDocument22 pages9.1 Oxidation and Reduction 9.1.1 Definitions: Oxidation and Reduction Take Place Together at The Same Time in The SameJaimin SuraniNo ratings yet

- 1 To Study Various Factors On Which The Internal resistanceEMF of A Cell Depends.Document11 pages1 To Study Various Factors On Which The Internal resistanceEMF of A Cell Depends.shiva nayak100% (5)

- Multifunctional Tio Coating For A Sio Anode in Li-Ion BatteriesDocument6 pagesMultifunctional Tio Coating For A Sio Anode in Li-Ion BatteriesLu YuNo ratings yet

- Cathode Ray Oscilloscope (Cro)Document2 pagesCathode Ray Oscilloscope (Cro)jesunathan44@yahoo.comNo ratings yet

- Lecture 2: Basic Physics of Galvanic Cells & Electrochemical Energy ConversionDocument11 pagesLecture 2: Basic Physics of Galvanic Cells & Electrochemical Energy Conversionanup chauhanNo ratings yet

- Hydrogen Releasing Law and in Situ Computed Tomography Inv - 2024 - Journal of EDocument9 pagesHydrogen Releasing Law and in Situ Computed Tomography Inv - 2024 - Journal of Emosab.backkupNo ratings yet

- Corrosion ControlDocument41 pagesCorrosion ControldigecaNo ratings yet

- Electrolysis LabDocument8 pagesElectrolysis Labapi-244114360No ratings yet

- Chapter Four Electronic Devices: Tel. 01016211255 T. Ehab SalamaDocument23 pagesChapter Four Electronic Devices: Tel. 01016211255 T. Ehab SalamaAbdalluh MohammedNo ratings yet

- ElectrochemistryDocument85 pagesElectrochemistryolive clarintaNo ratings yet

- Department of Oral Medicine and Radiology MCQ 1Document14 pagesDepartment of Oral Medicine and Radiology MCQ 1Gokul RavichandranNo ratings yet

- Chang ElectrochemistryDocument1 pageChang Electrochemistryg bhargaviNo ratings yet

- VRFB and SSBDocument3 pagesVRFB and SSBTriveni M KNo ratings yet

- Sheet # Current Electricity (Theory + Exercises)Document182 pagesSheet # Current Electricity (Theory + Exercises)madhavji003No ratings yet