Keller: P T T S 21 R

Keller: P T T S 21 R

Uploaded by

Amal AntonyCopyright:

Available Formats

Keller: P T T S 21 R

Keller: P T T S 21 R

Uploaded by

Amal AntonyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Keller: P T T S 21 R

Keller: P T T S 21 R

Uploaded by

Amal AntonyCopyright:

Available Formats

KELLER

PIEZORESISTIVE TRANSMITTERS AND TRANSDUCERS

INDUSTRIAL APPLICATIONS. ABSOLUTE AND GAUGE REFERENCES.

This new range of KELLER OEM pressure transmitters and transducers offers the user the high accuracy and stability of the KELLER piezoresistive pressure capsule in a low cost OEM package. Applications include refridgeration, hydraulic controls, air compressors, ink jet printers, vacuum pumps etc. The silicon sensor is mounted in an all welded oil filled stainless steel capsule, providing a highly stable measuring cell with negligible hysteresis, unrivalled linearity, high output and a life of millions of pressure cycles. The Series 21R use the Series 6 capsule, which is of all welded 316L stainless steel construction. Transducers are supplied with 2 metres of screened cable, or a square connector and mating plug, type mPm-193. Accuracy is achieved by very large scale predictable production quantities of the pressure capsule (over 2 million produced today). Reliability is assured by the inherent properties of the perfectly elastic silicon chip, and ensuring that neither the pressure media nor the reference media (in the gauge version) come into contact with any sensitive parts. Temperature Compensation: Each unit is fully tested and compensated. Span errors are reduced by selecting the semiconductor doping levels so that the gauge factor of the strain gauges (R) is constant with temperature. Thermal zero compensation is achieved by an automatic test procedure which fits a single resistor across one arm of the bridge. Shock and vibration performance is excellent due to the silicon chip being suspended in the oil-filled capsule. It is isolated mechanically from the body. Similarly, the effects of mounting torque are eliminated.

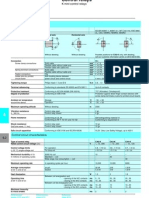

SERIES 21 R

SERIES 21R WITH CABLE (PLAN 80096.2)

G 1/4" 17

ELECTRICAL CONNECTIONS 2-WIRE

GREEN WHITE

3-WIRE GND

4-WIRE GND (WHITE) +OUT (RED) +VCC (BLACK) -OUT (BLUE)

OUT/GND +VCC

+OUT +VCC

18,6 HEX 19

~ 50

Cable Connection

BROWN

SERIES 21R WITH PLUG (PLAN 80096.3)

G 1/4"

HEX 19

mPm-Connector (Contact Spacing 9,4 mm)

2-WIRE 1 2 3 4 OUT/GND +VCC

3-WIRE GND +OUT +VCC

4-WIRE GND +OUT +VCC -OUT

17

12

~ 56

Subject to alterations

4/99

KELLER AG fr Druckmesstechnik KELLER Gesellschaft fr druckmesstechnik mbH

Companies approved to ISO 9001 / EN 29001

St. Gallerstrasse 119 Schwarzwaldstrasse 17

CH-8404 Winterthur D-79798 Jestetten

Tel. 052 - 235 25 25 Tel. 07745 - 9214 - 0

Fax 052 - 235 25 00 Fax 07745 - 9214 - 50

Internet: http://www.keller-druck.ch

druckmesstechnik

KELLER

SPECIFICATIONS SERIES 21 R PR 21 R * PAA 21 R PA 21 R Over Range 2 0,5 1,0 1,0 1,0 2,5 1,6 1,6 1,6 3 2,5 2,5 2,5 6 6 6 6 8 10 10 10 15 16 16 16 25 bar bar 25 60

vented gauge absolute

50 75

100 150

160 250

250 600

400 600 600 800

bar bar

sealed gauge

* mPm connector only, not cable

Transmitter Signal Output Supply Voltage Current required Zero/Span Tolerance Configuration Electrical Connection: mPm 193 micro or cable 2m, 4 core Linearity Total Error Band* +18+22C Total Error Band* 0+50C Total Error Band* -20+80C +Vcc: Pin 3 / Brown up to 20 mA 1% FS 2 wire OUT/GND: Pin 1 / White 1% FS** 420 mA 05 Vdc 828 Vdc 4 mA max. 1% FS 3 wire GND: +OUT: +Vcc: Pin 1 / Green Pin 2 / White Pin 3 / Brown 1% FS** 0,1% FS 4 wire GND: +Vcc: Pin 1 / White Pin 3 / Black +OUT: Pin 2 / Red -OUT: Pin 4 / Blue 0,2 % typ. / 0,5% max. 1% max. / 0,5% typ. 2% max. / 1,0% typ. 4% max. / 2,5% typ. 0,2% typ. / 0,5% max. 0,5% max. 1,0% max. 2,5% max. 16 Vdc 010 Vdc 1330 Vdc Transducer 0100 mV 828 Vdc. 10 Vdc 2 mA max.

* Total error band includes linearity, hysteresis, zero and span offsets, temperature effects and repeatability. **Signal at zero 50 mV --> see chart

Signal at zero for 05 V (010 V) transmitters

5V/10V

50 mV 1%FS

FS

Maximum Temperature Pressure Port Pressure Media Weight Electromagnetic Compatibility Enclosure Protection Insulation Insulation Test

-20+80C (on demand -40100C) G 1/4 male parallel to ISO 228 (1/4BSP) Compatible with 316L stainless steel 75 gramme CE marked: Fully tested to EN 50082-2 and EN 50082-1 IP65 Greater than 100 M at 50 Vdc 1 minute at 500 Vdc

User Notes: Basic 100 mV transducers are calibrated at 10 Vdc to produce 0100 mV signal (nominal), and require a stable voltage supply. They can be operated at 5 Vdc to give 050 mV signal or 20 Vdc to give 0200 mV signal. The circuit is a compensated resistance bridge and is completely passive with no diodes or reactive components. Bridge resistance is 3,5K nominal. The 828 V supply transducer is fitted with an internal regulator. The mPm micro connector has a PG7 cable gland entry suitable for cables between 4 and 6 mm diameter. Screw terminals and solder lags are provided. The G 1/4 pressure connection has an integral Viton seal at the shoulder. Alternatively it may be sealed using a face seal on the flat nose of the pressure port.

Subject to alterations 4/99

KELLER AG fr Druckmesstechnik KELLER Gesellschaft fr druckmesstechnik mbH

Companies approved to ISO 9001 / EN 29001

St. Gallerstrasse 119 Schwarzwaldstrasse 17

CH-8404 Winterthur D-79798 Jestetten

Tel. 052 - 235 25 25 Tel. 07745 - 9214 - 0

Fax 052 - 235 25 00 Fax 07745 - 9214 - 50

Internet: http://www.keller-druck.ch

You might also like

- 3100 GemsDocument6 pages3100 GemsJoão PauloNo ratings yet

- Instruction Manual: Models 7EF and 7HF ControllersDocument48 pagesInstruction Manual: Models 7EF and 7HF ControllerskmpoulosNo ratings yet

- Piezorresistive Transmitters: Model: 21R - 21 SR / MRDocument2 pagesPiezorresistive Transmitters: Model: 21R - 21 SR / MRMarcelo PellizzaNo ratings yet

- 22e KellerDocument1 page22e KellerAghil ThayyilNo ratings yet

- Tecsis 3251Document4 pagesTecsis 3251dsiucNo ratings yet

- Tradutor Diferencial PD-9 DRUCKDocument2 pagesTradutor Diferencial PD-9 DRUCKjcbizarretaNo ratings yet

- 3100 Series and 3200 Heavy Duty Series: Compact OEM Pressure TransmittersDocument5 pages3100 Series and 3200 Heavy Duty Series: Compact OEM Pressure TransmittersAlejandro CagideNo ratings yet

- Mini Mcr-Sl-Pt100-Ui-Nc: Order No.: 2864273Document7 pagesMini Mcr-Sl-Pt100-Ui-Nc: Order No.: 2864273vijicsaNo ratings yet

- P3251 TecsisDocument4 pagesP3251 TecsisJHONNJANNo ratings yet

- V 23079Document10 pagesV 23079Diego FeRnando Q PNo ratings yet

- Druck PT Data SheetDocument7 pagesDruck PT Data Sheethits289No ratings yet

- Pressure Transmitter For General Industrial Applications Model A-10Document7 pagesPressure Transmitter For General Industrial Applications Model A-10brunotavernaNo ratings yet

- Piezoresistive Pressure Tranmitters: Standard and Programmable (Pro) Versions Model: 21 - 21 ProDocument2 pagesPiezoresistive Pressure Tranmitters: Standard and Programmable (Pro) Versions Model: 21 - 21 ProMarcelo PellizzaNo ratings yet

- Pressure Transmitter: FeaturesDocument4 pagesPressure Transmitter: FeaturesIrvin Gnivry RodríguezNo ratings yet

- TECSIS Pressure TransmitterDocument4 pagesTECSIS Pressure TransmitterVijendraAgarNo ratings yet

- Manual Avk enDocument8 pagesManual Avk enali shetaNo ratings yet

- Amisco Pilot ValveDocument8 pagesAmisco Pilot ValveRaul CostiniucNo ratings yet

- Relee ElmarkDocument2 pagesRelee ElmarkwawinNo ratings yet

- 500 Pressure SensorDocument5 pages500 Pressure SensorMabel Lorena Ochoa ContrerasNo ratings yet

- MTL 7700 SeriesDocument17 pagesMTL 7700 Seriescuongphan123No ratings yet

- Position Switches FR Series: Selection DiagramDocument12 pagesPosition Switches FR Series: Selection DiagramMehmetLeventÖzsinanNo ratings yet

- Strain GaugesDocument20 pagesStrain GaugesDragan LazicNo ratings yet

- 699 Pressure Sensor PDFDocument5 pages699 Pressure Sensor PDFEnriqueQNo ratings yet

- Capteur de Pression 4fil HPT906-Datasheet-EN-HOLYKELL-V2021Document6 pagesCapteur de Pression 4fil HPT906-Datasheet-EN-HOLYKELL-V2021join filtreNo ratings yet

- Apr 2000G Al PDFDocument3 pagesApr 2000G Al PDFvan_dall_2No ratings yet

- AWEX e PDFDocument4 pagesAWEX e PDFsureshllsNo ratings yet

- Keeping Pressure Under ControlDocument28 pagesKeeping Pressure Under ControlDANE80No ratings yet

- Snimac Nizkeho Tlaku ADZ SILDocument4 pagesSnimac Nizkeho Tlaku ADZ SILslecka2658No ratings yet

- LIT1126 ACT20M Datasheet 03 14Document16 pagesLIT1126 ACT20M Datasheet 03 14alltheloveintheworldNo ratings yet

- Relee Din Gama 38Document6 pagesRelee Din Gama 38andy175No ratings yet

- Manual - Dvp48eh00r PDFDocument2 pagesManual - Dvp48eh00r PDFMauro KowalczukNo ratings yet

- 895134Document4 pages895134Rorro CervantesNo ratings yet

- Power Factor Correction: Phasecap CompactDocument4 pagesPower Factor Correction: Phasecap CompactvanbaoqnNo ratings yet

- 694 Pressure Sensor HubaDocument5 pages694 Pressure Sensor HubaduiechNo ratings yet

- Sensor de Presión de Acete Marca Tecsis Serir 3354Document5 pagesSensor de Presión de Acete Marca Tecsis Serir 3354Luis G. JaramilloNo ratings yet

- Pressure Transmitter: Principle of OperationDocument4 pagesPressure Transmitter: Principle of OperationAranNo ratings yet

- DC/DC Converters: FeaturesDocument6 pagesDC/DC Converters: FeaturesDalibor CetojevicNo ratings yet

- Transmitter SML 10Document2 pagesTransmitter SML 10alamsyah_syamNo ratings yet

- Features: 46 Series - Miniature Industrial Relays, 8 - 16 ADocument6 pagesFeatures: 46 Series - Miniature Industrial Relays, 8 - 16 AThomas GonzalezNo ratings yet

- PXT Series Pressure Transmitters Installation Instructions: WarningDocument2 pagesPXT Series Pressure Transmitters Installation Instructions: WarningFred JonesNo ratings yet

- Pce 28Document3 pagesPce 28Pop-Coman SimionNo ratings yet

- Instruction Manual: SIL 3 Repeater Power Supply Hart, DIN-Rail and Termination Board, Models D5011S, D5011DDocument6 pagesInstruction Manual: SIL 3 Repeater Power Supply Hart, DIN-Rail and Termination Board, Models D5011S, D5011Dtuandanhbk10No ratings yet

- Time Control Technique: Timer MK 9906N, On Delayed MinitimerDocument4 pagesTime Control Technique: Timer MK 9906N, On Delayed MinitimerKim Hảo Hoàng NguyễnNo ratings yet

- PT-76 Series Temperature Controller Operation Manual - B0Document2 pagesPT-76 Series Temperature Controller Operation Manual - B0jowegNo ratings yet

- 511 Pressure TransmitterDocument5 pages511 Pressure TransmitterDhp CiaNo ratings yet

- Pressure Sensors OEM: Description FeaturesDocument4 pagesPressure Sensors OEM: Description FeaturessmejiagonzalesNo ratings yet

- LIT1424 TERMSeries C1D2 Datasheet v5Document4 pagesLIT1424 TERMSeries C1D2 Datasheet v5alltheloveintheworldNo ratings yet

- Transmisor de Presión PXTKDocument4 pagesTransmisor de Presión PXTKNicolii RamonNo ratings yet

- P P T S 22 DT: Iezoresistive Ressure Ransmitters EriesDocument1 pageP P T S 22 DT: Iezoresistive Ressure Ransmitters EriesNavneet SinghNo ratings yet

- Relay OmronDocument35 pagesRelay Omronhsn9belasNo ratings yet

- Ds Uhp Wuc 1x en Us 20710Document10 pagesDs Uhp Wuc 1x en Us 20710behnamatgNo ratings yet

- Nor GrenDocument5 pagesNor GrenSarlo11No ratings yet

- Precision, Low Cost, High Speed, Bifet Op Amp: Ⴞ0.01% In 1.0 S S Min Slew Rate (Ad711J)Document16 pagesPrecision, Low Cost, High Speed, Bifet Op Amp: Ⴞ0.01% In 1.0 S S Min Slew Rate (Ad711J)egrumelNo ratings yet

- 177232D1Document6 pages177232D1Muhammad Usman SindhuNo ratings yet

- Inductive Proximity Sensors: GeneralDocument4 pagesInductive Proximity Sensors: GeneralJack Agung SihombingNo ratings yet

- Ca3kn22bd Telemecanique - Unit5.relayDocument8 pagesCa3kn22bd Telemecanique - Unit5.relaykapenziNo ratings yet

- High-Quality Pressure Transmitter For General Industrial Applications Model S-10Document8 pagesHigh-Quality Pressure Transmitter For General Industrial Applications Model S-10gliga vasileNo ratings yet

- Assembly Features: Removable Terminals BlueDocument4 pagesAssembly Features: Removable Terminals Blueandmar2011No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Cookies 20120325144006Document6 pagesCookies 20120325144006Prateek DhawanNo ratings yet

- A02Document1 pageA02Salmon Ariyanto BintarnoNo ratings yet

- CRX1 SMS ConfiguracionDocument14 pagesCRX1 SMS ConfiguracionMariano BrandanNo ratings yet

- SM14 DetDocument12 pagesSM14 DetSanjay RajNo ratings yet

- Clase7 - Topo y Geodesia II - 2023Document16 pagesClase7 - Topo y Geodesia II - 2023Benjamin Zacarias ValerioNo ratings yet

- Adr141c PDFDocument11 pagesAdr141c PDFNamrata Shetti100% (1)

- CH45 Suspension SystemsDocument44 pagesCH45 Suspension SystemsSuzan KhouryNo ratings yet

- Data Management ResumeDocument8 pagesData Management Resumefsjk2nvr100% (1)

- Ecopod-D Brochure - K4522Document4 pagesEcopod-D Brochure - K4522Trisha BalonaNo ratings yet

- Assessing The Impact of Mobile Money Services On The Profitability of Banks in Ghana: A Case Study of GCB BankDocument35 pagesAssessing The Impact of Mobile Money Services On The Profitability of Banks in Ghana: A Case Study of GCB Bankindex PubNo ratings yet

- SUNGELDocument2 pagesSUNGELJonny GloverNo ratings yet

- Case 1 DIAD and Case 2 GOOGLEDocument6 pagesCase 1 DIAD and Case 2 GOOGLERenz Mari AcuñaNo ratings yet

- Recycling Passport - Dismantling Instructions: Babylog8000Document10 pagesRecycling Passport - Dismantling Instructions: Babylog8000Jesus DunoNo ratings yet

- Comptia Cs0 003 2Document246 pagesComptia Cs0 003 2Nora the oneNo ratings yet

- Ficha Tecnica Castrol Hyspin AWS RangeDocument2 pagesFicha Tecnica Castrol Hyspin AWS Rangeel pro jajaja GonzalezNo ratings yet

- Maintaining Military VehiclesDocument2 pagesMaintaining Military VehiclesDUTY BOUNDNo ratings yet

- Advancing TechnologyDocument2 pagesAdvancing TechnologyShristi BisaniNo ratings yet

- Internship Report On 'Power Generation, Utilization and Communication System of Marine VesselDocument100 pagesInternship Report On 'Power Generation, Utilization and Communication System of Marine VesselEngr. M. A. Kawsar50% (2)

- Chatbot For Healthcare System Using AI - AshishDocument40 pagesChatbot For Healthcare System Using AI - Ashishaashishdhamala819No ratings yet

- Optical Strain Gage - Os3100: Key Features DescriptionDocument2 pagesOptical Strain Gage - Os3100: Key Features DescriptionYi-jen ChanNo ratings yet

- Government Junior High School Profile, Sy 2020-2021Document65 pagesGovernment Junior High School Profile, Sy 2020-2021Precious KateNo ratings yet

- VHF/UHF Repeater Radio: D4741 D4745 R4741 R4745Document2 pagesVHF/UHF Repeater Radio: D4741 D4745 R4741 R4745Solomon GebreselassieNo ratings yet

- Lesson10 ICT 0417Document25 pagesLesson10 ICT 0417thamalieariyarathnaNo ratings yet

- ErrorDocument36 pagesErrormakaroni ngeheNo ratings yet

- 3com S7900E MIB CompanionDocument299 pages3com S7900E MIB CompanionWagner VictoriaNo ratings yet

- Solutions For Power Switching and Monitoring: March 1 2021Document20 pagesSolutions For Power Switching and Monitoring: March 1 2021mas zak danielNo ratings yet

- Sapthagiri College of Engineering: Tracing Manufacturing Processes Using Blockchain Based Token CompositionsDocument19 pagesSapthagiri College of Engineering: Tracing Manufacturing Processes Using Blockchain Based Token CompositionsYashi FakeNo ratings yet

- 03 Magic 8 Ball AppDocument11 pages03 Magic 8 Ball AppMNo ratings yet

- Daniel Anghel: Ervice AnagerDocument3 pagesDaniel Anghel: Ervice AnagerFirdaus PanthakyNo ratings yet

- Raspberry Pi Measure Record ExploreDocument339 pagesRaspberry Pi Measure Record ExploreAnonymous S6UCpG1ZuP100% (1)