0 ratings0% found this document useful (0 votes)

430 viewsWaste Heat Recovery

Waste Heat Recovery

Uploaded by

Ravi DeshmukhThis document provides information on waste heat recovery techniques. It discusses different types of waste heat recovery equipment and systems including recuperators, regenerators, heat wheels, heat pipes, economizers, shell and tube heat exchangers, plate heat exchangers, run around coil exchangers, waste heat boilers, and heat pumps. It also discusses assessing waste heat sources based on temperature and quantity.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Waste Heat Recovery

Waste Heat Recovery

Uploaded by

Ravi Deshmukh0 ratings0% found this document useful (0 votes)

430 views32 pagesThis document provides information on waste heat recovery techniques. It discusses different types of waste heat recovery equipment and systems including recuperators, regenerators, heat wheels, heat pipes, economizers, shell and tube heat exchangers, plate heat exchangers, run around coil exchangers, waste heat boilers, and heat pumps. It also discusses assessing waste heat sources based on temperature and quantity.

Original Description:

about waste heat recovery boiler.

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides information on waste heat recovery techniques. It discusses different types of waste heat recovery equipment and systems including recuperators, regenerators, heat wheels, heat pipes, economizers, shell and tube heat exchangers, plate heat exchangers, run around coil exchangers, waste heat boilers, and heat pumps. It also discusses assessing waste heat sources based on temperature and quantity.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

430 views32 pagesWaste Heat Recovery

Waste Heat Recovery

Uploaded by

Ravi DeshmukhThis document provides information on waste heat recovery techniques. It discusses different types of waste heat recovery equipment and systems including recuperators, regenerators, heat wheels, heat pipes, economizers, shell and tube heat exchangers, plate heat exchangers, run around coil exchangers, waste heat boilers, and heat pumps. It also discusses assessing waste heat sources based on temperature and quantity.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 32

At a glance

Powered by AI

The key takeaways are that waste heat recovery can save fuel by reusing otherwise wasted heat, higher temperature waste heat has greater potential value, and the quality and quantity of recoverable heat depends on its source and temperature.

The different types of waste heat that can be recovered include heat from flue gases, vapor streams, exterior equipment surfaces, cooling water, and heat stored in products leaving a process. The quality depends on factors like temperature and contamination level.

The quantity of recoverable heat (Q) is calculated as: Q = heat content in kCal, V = flow rate of the substance in m3/hr, ρ = density of the substance in kg/m3, Cp = specific heat of the substance in kCal/kg°C, T = temperature difference in °C.

1

Training Session on Energy

Equipment

Waste Heat Recovery

Presentation from the

Energy Efficiency Guide for Industry in Asia

www.energyefficiencyasia.org

UNEP 2006

2

Training Agenda: Waste

Introduction

Type of waste heat recovery

Assessment of waste heat recovery

UNEP 2006

3

UNEP 2006

Introduction

Dumped heat that can still be

reused

Value (quality) more important than

quantity

Waste heat recovery saves fuel

What is Waste Heat?

4

UNEP 2006

Introduction

Source and Quality

Table: Waste heat source and quality

S. No Source of Waste Heat Quality of Waste Heat

1 Heat in flue gases The higher the temperature, the greater the

potential value for heat recovery

2 Heat in vapour streams As above but when condensed, latent heat

also recoverable

3 Convective & radiant heat lost

from exterior of equipment

Low grade if collected may be used for

space heating or air preheats

4 Heat losses in cooling water Low grade useful gains if heat is exchanged

with incoming fresh water

5 Heat losses in providing

chilled water or in the

disposal of chilled water

1.High grade if it can be utilized to reduce

demand for refrigeration

2.Low grade if refrigeration unit used as a

form of Heat pump

6 Heat stored in products

leaving the process

Quality depends upon temperature

7 Heat in gaseous & liquid

effluents leaving process

Poor if heavily contaminated & thus requiring

alloy heat exchanger

5

UNEP 2006

Introduction

High Temperature Heat Recovery

Table: Typical waste heat temperature at high temperature

range from various sources

Types of Devices Temperature (

0

C)

Nickel refining furnace 1370 1650

Aluminium refining furnace 650 760

Zinc refining furnace 760 1100

Copper refining furnace 760 815

Steel heating furnace 925 1050

Copper reverberatory furnace 900 1100

Open hearth furnace 650 700

Cement kiln (Dry process) 620 730

Glass melting furnace 1000 1550

Hydrogen plants 650 1000

Solid waste incinerators 650 1000

Fume incinerators 650 1450

6

UNEP 2006

Introduction

Medium Temperature Heat

Recovery

Table: Typical waste heat temperature at medium temperature range

from various sources

Types of Devices Temperature (

0

C)

Steam boiler exhaust 230 480

Gas turbine exhaust 370 540

Reciprocating engine exhaust 315 600

Reciprocating engine exhaust (turbo

charged)

230 370

Heat treatment furnace 425 650

Drying & baking ovens 230 600

Catalytic crackers 425 650

Annealing furnace cooling systems 425 650

7

UNEP 2006

Introduction

Low Temperature Heat Recovery

Source Temperature

0

C

Process steam condensate 55-88

Cooling water from: Furnace doors 32-55

Bearings 32-88

Welding machines 32-88

Injection molding machines 32-88

Annealing furnaces 66-230

Forming dies 27-88

Air compressors 27-50

Pumps 27-88

Internal combustion engines 66-120

Air conditioning and refrigeration condensers 3243

Liquid still condensers 32-88

Drying, baking and curing ovens 93-230

Hot processed liquids 32-232

Hot processed solids 93-232

T

a

b

l

e

:

T

y

p

i

c

a

l

w

a

s

t

e

h

e

a

t

t

e

m

p

e

r

a

t

u

r

e

a

t

l

o

w

t

e

m

p

e

r

a

t

u

r

e

r

a

n

g

e

f

r

o

m

v

a

r

i

o

u

s

s

o

u

r

c

e

s

8

UNEP 2006

Training Agenda: Waste

Introduction

Type of waste heat recovery

Performance evaluation

9

UNEP 2006

Type of Waste Heat Recovery

Commercial Waste Heat Recovery

Recuperators

Heat exchange

between flue gases and

the air through

metallic/ceramic walls

Ducts/tubes carry

combustion air for

preheating

Waste heat stream on

other side

Inlet air from

atmosphere

Outside

ducting

Tune plate

Preheated

air

Centre tube plate

Exhaust gas

from process

Figure 1 : Waste heat recovery

using recuperator, Source: SEAV

10

UNEP 2006

Type of Waste Heat Recovery

Commercial Waste

Heat Recovery

Metallic radiation

recuperators

F

i

g

u

r

e

2

.

M

e

t

a

l

l

i

c

R

a

d

i

a

t

i

o

n

R

e

c

u

p

e

r

a

t

o

r

(

H

a

r

d

t

e

c

h

G

r

o

u

p

)

Simplest recuperator

Two metal tubes

Less fuel is burned per

furnace load

Heat transfer mosly by

radiation

11

UNEP 2006

Type of Waste Heat Recovery

Commercial Waste Heat Recovery

Convective

recuperators

Figure 3. Convective

Recuperator

(Reay, D.A., 1996)

Hot gas through

parallel small diameter

tubes

Tubes can be baffled

to allow gas to pass

over them again

Baffling increases heat

exchange but more

expensive exchanger

is needed

12

UNEP 2006

Type of Waste Heat Recovery

Commercial Waste Heat Recovery

Radiation/convective

hybrid recuperators

Figure 4. Hybrid Recuperator

(Reay, D.A., 1996)

Combinations of

radiation & convection

More effective heat

transfer

More expensive but less

bulky than simple

metallic radiation

recuperators

13

UNEP 2006

Type of Waste Heat Recovery

Commercial Waste Heat Recovery

Ceramic recuperators

Less temperature limitations:

Operation on gas side up to 1550 C

Operation on preheated air side to 815 C

New designs

Last two years

Air preheat temperatures <700 C

Lower leakage rates

14

UNEP 2006

Type of Waste Heat Recovery

Regenerator

Figure 5. Regenerator

(Department of Coal, India, 1985)

Large capacities

Glass and steel melting

furnaces

Time between the

reversals important to

reduce costs

Heat transfer in old

regenerators reduced by

Dust & slagging on

surfaces

heat losses from the

walls

15

UNEP 2006

Type of Waste Heat Recovery

Heat Wheels

Figure 6. Heat Wheel

(SADC, 1999)

Porous disk rotating

between two side-by-

side ducts

Low to medium

temperature waste

heat recovery

systems

Heat transfer

efficiency up to 85 %

16

UNEP 2006

Type of Waste Heat Recovery

Heat Pipe

Figure 7. Heat Pipe

(SADC, 1999)

Transfer up to 100

times more thermal

energy than copper

Three elements:

- sealed container

- capillary wick

structure

- working fluid

Works with

evaporation and

condensation

17

UNEP 2006

Type of Waste Heat Recovery

Heat Pipe

Performance and advantage

Lightweight and compact

No need for mechanical maintenance, input power,

cooling water and lubrication systems

Lowers the fan horsepower requirement and

increases the overall thermal efficiency of the

system

Can operate at 315 C with 60% to 80% heat

recovery

18

UNEP 2006

Type of Waste Heat Recovery

Heat Pipe

Typical application

Process to space heating

- Transfers thermal energy from process

exhaust for building heating

Process to process

- Transfers recovered waste thermal energy from

the process to the incoming process air

HVAC applications

- Cooling and heating by recovering thermal

energy

19

UNEP 2006

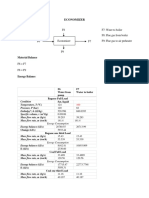

Type of Waste Heat Recovery

Economizer

Figure 8. Economizer

(Bureau of Energy Efficiency,

2004)

Utilize the flue gas heat for pre-heating the boiler

feed water

1% fuel savings if

60 C rise of feed

water

200 C rise in

combustion air temp

20

UNEP 2006

Type of Waste Heat Recovery

Economizer

Shell and tube heat exchanger

Used when the medium containing waste heat is a

liquid or a vapor that heats another liquid

Figure 9. Shell & Tube Heat Exchanger

(King Fahad University of Petroleum & Minerals,

2003)

Shell contains

the tube bundle,

and usually

internal baffles

to direct the

fluid

Vapor

contained

within the shell

21

UNEP 2006

Type of Waste Heat Recovery

Plate Heat Exchanger

Figure 10. Plate Heat Exchanger

(Canada Agriculture and Agri-Food)

Parallel plates forming a thin flow pass

Avoids high cost of heat exchange surfaces

Corrugated

plates to

improve heat

transfer

When directions

of hot and cold

fluids are

opposite, the

arrangement is

counter current

22

UNEP 2006

Type of Waste Heat Recovery

Plate Heat Exchanger

Run around coil exchanger

Figure 11. Run Around Coil Exchanger

(SADC , 1999)

Heat transfer

from hot to

colder fluid via

heat transfer

fluid

One coil in hot

stream

One coil in cold

stream

23

UNEP 2006

Type of Waste Heat Recovery

Plate Heat Exchanger

Waste heat boiler

Figure 12. Two-Pass Water Tube Waste

Heat Recovery Boiler

(Canada Agriculture and Agri-Food)

Water tube boiler: hot

exhaust gases pass

over parallel tubes

with water

Capacities: 25 m3 to

30,000 m3 /min of

exhaust gas

24

UNEP 2006

Type of Waste Heat Recovery

Heat Pump

Figure 13. Heat Pump Arrangement

(SADC, 1999)

The vapour

compression cycle

25

UNEP 2006

Type of Waste Heat Recovery

Heat Pump

Developed as a space heating system

Can upgrade heat >2X the energy

consumed by the device

Most promising when heating and cooling

capabilities are combined

26

UNEP 2006

Type of Waste Heat Recovery

Heat Pump

Thermo compressor

Compress low-pressure steam by very high-

pressure steam and reuse as medium pressure

steam

Nozzle for acceleration of HP steam to a high

velocity fluid.

Figure: Thermo compressor

27

UNEP 2006

Training Agenda: Waste

Introduction

Type of waste heat recovery

Assessment of waste heat recovery

28

Assessment of waste heat

recovery

Quality:

Higher temperatures = Higher quality = Lower heat

recovery costs

Quantity:

The amount of recoverable heat can be calculated as:

Heat Losses

Q = heat content in kCal

V = the flow rate of the substance in m3/hr

= density of the flue gas in kg/m3

Cp = the specific heat of the substance in

kCal/kg oC

T = the temperature difference in oC

Cp (Specific heat of flue gas) = 0.24

kCal/kg/oC

Q = V x x Cp x T

UNEP 2006

29

UNEP 2006

Heat Saving Calculation Example

Saving money by recovering heat from hot waste

water:

Q = m x Cp x T x

Discharge of the waste water is 10000 kg/hr at 75C

Preheat 10000 kg/hr of cold inlet water of 20C

A heat recovery factor of 58%

An operation of 5000 hours per year

The annual heat saving (Q) is:

Assessment of waste heat

recovery

30

UNEP 2006

Heat Saving Calculation Example

m = 1000 kg/hr = 10000 x 5000 kg/yr = 50000000

kg/year

Cp = 1 kCal/kg C

T = (75 20) C = 55 C

= Heat Recovery Factor = 58% or 0.58

GCV of Oil = 10,200 kCal/kg

Equivalent Oil Savings = 159500000 / 10200 =

156372 L

Cost of Oil = 0.35 USD/L

Monetary Savings = 54730 USD/Annum

Q = 50000000 x 1 x 55 x 0.58

= 1595000000 kCal/year

Assessment of waste heat

recovery

31

Training Session on Energy

Equipment

Waste Heat Recovery

THANK YOU

FOR YOUR ATTENTION

UNEP

32

UNEP 2006

Disclaimer and References

This PowerPoint training session was prepared as part of

the project Greenhouse Gas Emission Reduction from

Industry in Asia and the Pacific (GERIAP). While

reasonable efforts have been made to ensure that the

contents of this publication are factually correct and

properly referenced, UNEP does not accept responsibility for

the accuracy or completeness of the contents, and shall not

be liable for any loss or damage that may be occasioned

directly or indirectly through the use of, or reliance on, the

contents of this publication. UNEP, 2006.

The GERI AP project was funded by the Swedish

I nternational Development Cooperation Agency (Sida)

Full references are included in the textbook chapter that is

available on www.energyefficiencyasia.org

You might also like

- D93-20 - Flash Point by PMCC (Upgraded Feb 2021)Document18 pagesD93-20 - Flash Point by PMCC (Upgraded Feb 2021)ridermate100% (3)

- Boiler Cost Per Hour CalculationDocument1 pageBoiler Cost Per Hour Calculationsreelu100% (3)

- CBEND - Ankur WBG 400 Operation and Maintenance ManualDocument78 pagesCBEND - Ankur WBG 400 Operation and Maintenance ManualSanjivi Jagadish KumarNo ratings yet

- FD Fan Efficiency CalculationDocument6 pagesFD Fan Efficiency CalculationPraveen VaratharajanNo ratings yet

- Homework 2Document7 pagesHomework 2Chinny LyheangNo ratings yet

- C C++ in UrduDocument160 pagesC C++ in Urdumigatron74181% (32)

- Heat Exchangers & Waste Heat RecoveryDocument30 pagesHeat Exchangers & Waste Heat RecoveryrsahayNo ratings yet

- Co Generation Unit 4Document52 pagesCo Generation Unit 4Johnson Johnson100% (2)

- Power Plant and Calculations - STEAM CONDENSER, VACUUM AND CALCULATIONSDocument7 pagesPower Plant and Calculations - STEAM CONDENSER, VACUUM AND CALCULATIONSRajesh100% (1)

- Fuel Savings and Efficiency CalculatorDocument6 pagesFuel Savings and Efficiency Calculatorrajayu20002724No ratings yet

- Waste Heat Recovery BoilerDocument28 pagesWaste Heat Recovery Boilerapi-19908130100% (1)

- Boiler Thermal CalculationDocument83 pagesBoiler Thermal Calculation9913489806100% (1)

- Boiler Efficiency CalculationDocument5 pagesBoiler Efficiency CalculationMutiara ValentinaNo ratings yet

- Cyclone SeparatorDocument1 pageCyclone SeparatordadNo ratings yet

- Boilers and Steam Systems ..BoeDocument151 pagesBoilers and Steam Systems ..BoeMV AmohanAKarthicK100% (3)

- Sample Calculations of Boiler Pumps and IDDocument5 pagesSample Calculations of Boiler Pumps and IDMelvinDapitanonNo ratings yet

- Biomass Energy InstallationsDocument7 pagesBiomass Energy Installationsdrroo100% (1)

- Draft of Boiler Efficiency CalculationsDocument8 pagesDraft of Boiler Efficiency CalculationsMohsin MajeedNo ratings yet

- Boiler ReferenceDocument29 pagesBoiler ReferencetagolimotNo ratings yet

- Air HeatersDocument34 pagesAir HeatersNaveen KamatNo ratings yet

- Boiler Efficiency CalculationDocument44 pagesBoiler Efficiency CalculationgARRY100% (1)

- Plate Heat Exchanger CalculationDocument6 pagesPlate Heat Exchanger CalculationNgoVietCuongNo ratings yet

- Interpretation of Natural Draft Burner Data.: FiringDocument1 pageInterpretation of Natural Draft Burner Data.: Firingmehul10941No ratings yet

- Thermal Design of Economizer For Waste Heat Recovery Boiler WHRB IJERTV7IS100037Document7 pagesThermal Design of Economizer For Waste Heat Recovery Boiler WHRB IJERTV7IS100037Khushnood100% (1)

- Heat Balance DiagramDocument10 pagesHeat Balance DiagramJitendra Bhatia100% (5)

- Boiler Books NamesDocument12 pagesBoiler Books NamesSikander GirgoukarNo ratings yet

- Calculation of Boiler EfficiencyDocument43 pagesCalculation of Boiler EfficiencyTamer Abd Elrasoul100% (1)

- CalculationsDocument14 pagesCalculationsPratyush BadrinarayanNo ratings yet

- Huskpac UltraDocument4 pagesHuskpac UltrasebinNo ratings yet

- Use of Rice Husk As Fuel in Process Steam BoilersDocument5 pagesUse of Rice Husk As Fuel in Process Steam BoilersHinaAmanNo ratings yet

- DheerajDocument7 pagesDheerajSaksham KakarNo ratings yet

- Economize R 3 TrialDocument19 pagesEconomize R 3 TrialNitish AmnerkarNo ratings yet

- Waste Heat Recovery TechniquesDocument62 pagesWaste Heat Recovery Techniquesdhruv100% (1)

- Steam Boiler ProjectDocument32 pagesSteam Boiler ProjectSwastik BhokareNo ratings yet

- Heat BalanceDocument10 pagesHeat BalanceHoang VAN SI100% (2)

- Design of Heat ExchangerDocument26 pagesDesign of Heat ExchangerSatish YadavNo ratings yet

- Rice Brochure V1Document36 pagesRice Brochure V1Naveenraj KrishnamoorthyNo ratings yet

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNo ratings yet

- Boiler Performance CalculationDocument1 pageBoiler Performance Calculationagusnnn50% (2)

- SOx and NOx in CFBC BoilerDocument2 pagesSOx and NOx in CFBC BoilerVirendra Patil100% (3)

- Gas Flow CalculationDocument59 pagesGas Flow CalculationOmprakaash MokideNo ratings yet

- Docslide. Successful Commissioning of An Afbc BoilerDocument72 pagesDocslide. Successful Commissioning of An Afbc BoilerRakesh GairolaNo ratings yet

- 1.5 NPS RecuperatorDocument7 pages1.5 NPS RecuperatorAnonymous pVoSWn8yh0No ratings yet

- Biomass (Rice Straw) Fired BoilerDocument9 pagesBiomass (Rice Straw) Fired BoilerSnehashis MaityNo ratings yet

- Heat & Mass BalanceDocument2 pagesHeat & Mass Balancesneha_21100% (1)

- DTS - Air To Air Heat Exchanger Data SheetxlsDocument1 pageDTS - Air To Air Heat Exchanger Data SheetxlspawanroyalNo ratings yet

- (How To) Calculate The Required Blower Capacity For FBD - Pharma EngineeringDocument11 pages(How To) Calculate The Required Blower Capacity For FBD - Pharma EngineeringTerrence Terry BhengoeNo ratings yet

- Boilers and Thermic Fluid HeatersDocument42 pagesBoilers and Thermic Fluid HeatersQasimWarisNo ratings yet

- Sample Computation For Boiler EfficiencyDocument6 pagesSample Computation For Boiler Efficiencyra_tagolimotNo ratings yet

- Combustion Air Fan CalculationDocument2 pagesCombustion Air Fan CalculationVijay Bhan100% (1)

- Specific Gas Ratio - SwapnilDocument33 pagesSpecific Gas Ratio - SwapnilYhane100% (1)

- Gas Fired BoilersDocument2 pagesGas Fired BoilersCristi PopNo ratings yet

- Steam TablesDocument23 pagesSteam TablesNoerby AntoNo ratings yet

- Steam Cost Calculations 2020Document3 pagesSteam Cost Calculations 2020Malwadkar P.B.No ratings yet

- 78 - Triumph Stoker BrochureDocument2 pages78 - Triumph Stoker BrochureMatias MancillaNo ratings yet

- Best Practices in Energy Efficiency in Cement Sector CFD Final PDFDocument53 pagesBest Practices in Energy Efficiency in Cement Sector CFD Final PDFPradeepNo ratings yet

- Boiler Alkali BoiloutDocument4 pagesBoiler Alkali BoiloutBalaji PillaiNo ratings yet

- Assement of Bag Filter Vs ESP CPCBDocument133 pagesAssement of Bag Filter Vs ESP CPCBdehriya100% (1)

- Chemical Reactor Analysis and Applications for the Practicing EngineerFrom EverandChemical Reactor Analysis and Applications for the Practicing EngineerNo ratings yet

- Waste Heat RecoveryDocument32 pagesWaste Heat RecoveryManish Tiwari100% (1)

- Boilers and Thermic Fluid HeatersDocument54 pagesBoilers and Thermic Fluid HeatersAmit ChauhanNo ratings yet

- Boilers and Thermic Fluid HeatersDocument54 pagesBoilers and Thermic Fluid HeatersG.RameshNo ratings yet

- Resignation Letter Example FinalDocument2 pagesResignation Letter Example FinalRavi DeshmukhNo ratings yet

- Steam TableDocument1 pageSteam TableRavi DeshmukhNo ratings yet

- Chapter 2: Water TreatmentDocument9 pagesChapter 2: Water TreatmentRavi DeshmukhNo ratings yet

- Fan VibrationDocument6 pagesFan VibrationRavi Deshmukh100% (2)

- Ngineering ATA: Fan Sound & Sound RatingsDocument8 pagesNgineering ATA: Fan Sound & Sound RatingsRavi DeshmukhNo ratings yet

- PGDC Program BrochureDocument14 pagesPGDC Program BrochureRavi DeshmukhNo ratings yet

- Electrostatic PrecipitatorsDocument31 pagesElectrostatic PrecipitatorsRavi DeshmukhNo ratings yet

- Energy EfficiencyDocument207 pagesEnergy EfficiencyRavi Deshmukh100% (2)

- Ejector PrincipleDocument13 pagesEjector Principlekhoshya7100% (1)

- Boiler FeedwaterDocument5 pagesBoiler FeedwaterRavi DeshmukhNo ratings yet

- Bok - 978 981 15 7031 5Document1,126 pagesBok - 978 981 15 7031 5Arkendu MitraNo ratings yet

- Product Catalog: Compact Screen, Single Screen & Multi Screen FiltersDocument26 pagesProduct Catalog: Compact Screen, Single Screen & Multi Screen FiltersLuan NguyenNo ratings yet

- 01-05 Data PlanDocument19 pages01-05 Data PlanhugobiarNo ratings yet

- Lab Book Checkpoint 2Document14 pagesLab Book Checkpoint 2Ace Writer1No ratings yet

- Troubleshooting and Prevention of Cracking in Induction Hardening Os Steels - Part 2Document8 pagesTroubleshooting and Prevention of Cracking in Induction Hardening Os Steels - Part 2Jader PitangueiraNo ratings yet

- Capacitor 2Document31 pagesCapacitor 2Shaheer MirzaNo ratings yet

- SOLIDWORKS Electrical Getting StartedDocument31 pagesSOLIDWORKS Electrical Getting StartedIsaias Israel HernandezNo ratings yet

- 4 Radiobiology of Brachytherapy and The Dose-Rate EffectDocument27 pages4 Radiobiology of Brachytherapy and The Dose-Rate EffectDiana MitreaNo ratings yet

- Alignment Calculation V 107Document16 pagesAlignment Calculation V 107thummadharani66980% (1)

- K Ekkkjfffffffffffffnergy and WorkDocument33 pagesK Ekkkjfffffffffffffnergy and WorkRavi YadavNo ratings yet

- ABS 5. 3 BOSCH Braking System Training Board - Simulator: Technical Specifications and FunctionsDocument1 pageABS 5. 3 BOSCH Braking System Training Board - Simulator: Technical Specifications and FunctionsFaziri Abdul HaqNo ratings yet

- HUAWEI DBS3900 Dual Mode Base Station Hardware Structure and PincipleDocument79 pagesHUAWEI DBS3900 Dual Mode Base Station Hardware Structure and PincipleCarlos CrisostomoNo ratings yet

- VSC Catalog - EngDocument5 pagesVSC Catalog - EngmonaharaNo ratings yet

- 12 Simple Notes (EM) - 2 MarksDocument10 pages12 Simple Notes (EM) - 2 MarksNidhi100% (1)

- Number Series Coding and Decoding and Odd Man Out SeriesDocument2 pagesNumber Series Coding and Decoding and Odd Man Out SeriesSambhav GargNo ratings yet

- World's Tallest Steel Shear Walled Building: Mark Sarkisian Dasui WangDocument6 pagesWorld's Tallest Steel Shear Walled Building: Mark Sarkisian Dasui WangMichael Murfinator MurphyNo ratings yet

- Components/Parts of A System Unit: Shiela Jean Alumbro Bpa 1-CDocument2 pagesComponents/Parts of A System Unit: Shiela Jean Alumbro Bpa 1-CSHIELANo ratings yet

- 04-053-063 Grooved GasketsDocument11 pages04-053-063 Grooved Gasketsritesh sharmaNo ratings yet

- PH Meter Calibration PDFDocument2 pagesPH Meter Calibration PDFparikhjigarNo ratings yet

- Investor Sentiment Market Volatilityand IPOInitial ReturnsDocument12 pagesInvestor Sentiment Market Volatilityand IPOInitial ReturnsReact EmotNo ratings yet

- Polynomial Applications:: Perimeter, Area, and VolumeDocument4 pagesPolynomial Applications:: Perimeter, Area, and VolumeJohn Paul Basiño100% (1)

- Lecture 28 PDFDocument13 pagesLecture 28 PDFAlson BenhuraNo ratings yet

- History of The Pythagorean TheoremDocument5 pagesHistory of The Pythagorean TheoremRandy RandomNo ratings yet

- 6120be6daea4490011abe4aa-1629537650-Module 1-Lesson 2 - Part 1Document5 pages6120be6daea4490011abe4aa-1629537650-Module 1-Lesson 2 - Part 1Aldvin Jan AlcasidNo ratings yet

- D-AAA-SWG-MV-SWST-WD (Rev.0-2015)Document14 pagesD-AAA-SWG-MV-SWST-WD (Rev.0-2015)Muhammad hussainNo ratings yet

- Project Report: Faculty of Electrical and Electronic EngineeringDocument16 pagesProject Report: Faculty of Electrical and Electronic Engineeringabdikadir hassanNo ratings yet

- Leneo Fusion Instrument: Keeping Ahead Through Expertise in Sample Preparation by FusionDocument5 pagesLeneo Fusion Instrument: Keeping Ahead Through Expertise in Sample Preparation by FusionCaio JokoNo ratings yet