100%(1)100% found this document useful (1 vote)

61 viewsSafe Scaffold1

Safe Scaffold1

Uploaded by

Anonymous 3VTQm3TgybWorking at heights poses serious safety risks. Scaffolds must be properly erected and inspected regularly by experienced workers. Scaffolds require secure foundations and framing, fully boarded working platforms with railings, and safe access such as secured ladders. Safety precautions are needed for all equipment used at heights such as ladders, steps and tubular access scaffolds. Proper inspection and use of quality materials is important to ensure scaffold safety.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Safe Scaffold1

Safe Scaffold1

Uploaded by

Anonymous 3VTQm3Tgyb100%(1)100% found this document useful (1 vote)

61 views40 pagesWorking at heights poses serious safety risks. Scaffolds must be properly erected and inspected regularly by experienced workers. Scaffolds require secure foundations and framing, fully boarded working platforms with railings, and safe access such as secured ladders. Safety precautions are needed for all equipment used at heights such as ladders, steps and tubular access scaffolds. Proper inspection and use of quality materials is important to ensure scaffold safety.

Original Description:

working at height

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Working at heights poses serious safety risks. Scaffolds must be properly erected and inspected regularly by experienced workers. Scaffolds require secure foundations and framing, fully boarded working platforms with railings, and safe access such as secured ladders. Safety precautions are needed for all equipment used at heights such as ladders, steps and tubular access scaffolds. Proper inspection and use of quality materials is important to ensure scaffold safety.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

100%(1)100% found this document useful (1 vote)

61 views40 pagesSafe Scaffold1

Safe Scaffold1

Uploaded by

Anonymous 3VTQm3TgybWorking at heights poses serious safety risks. Scaffolds must be properly erected and inspected regularly by experienced workers. Scaffolds require secure foundations and framing, fully boarded working platforms with railings, and safe access such as secured ladders. Safety precautions are needed for all equipment used at heights such as ladders, steps and tubular access scaffolds. Proper inspection and use of quality materials is important to ensure scaffold safety.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 40

WORKING AT HEIGHTS

SAFE SCAFFOLD WORKING

General: Working at

height is the largest single

cause of serious accidents

in the construction

industry and therefore all

appropriate measures to be

taken to ensure that

whenever workers are

working at a height,from

which they can fall

,suitable safety

precautions have been

taken.

USE OF SCAFFOLDS

All scaffolds shall be

erected and dismantled by

workmen who are

thoroughly experienced in

erection and dismantling

of scaffolding.

All scaffolds shall be

inspected on regular basis.

All scaffolds shall be

constructed of sound

materials free from patent

defects.

The following measures shall also be taken:

The scaffold shall be constructed for the correct

use(Light or Heavy duty)

Securely fixed to existing structures or adequately

buttressed;

The use of barrels,boxes,loose tiles or other

unsuitable material shall not be used as supports

for working platforms;

All working platforms shall be fully boarded;

All working platforms shall have guard rails at one

meter height and shall also have an intermediate

rail at half height.

All working platforms shall be kept free of

unnecessary obstruction or rubbish.

Secure ladder access shall be provided.

LADDERS,STEPS&TRESTLES

Ladders,steps&trestles are in common use

throughout the construction industry.Most

tradesmen need to use ladders or steps in their

work-either working from a ladder or using it to

gain access to the workplace.Probably because

ladders are familiar and widely used,they are often

neglected and misused.The fact that almost

anybody can obtain and set up a ladder of a pair of

steps (and may do so a number of time in the

working day)makes it no less important that it

should be done safely and properly.

The injuries suffered in falling from a

ladder,even from height of only a few feet

can be quite serious and may result in

permanent disability.It is very important that

the equipment should be sound and fit for

the job;and that the correct procedures are

followed in erecting and using it.

TYPES OF LADDERS

The main types of ladder are:

Standing ladders:-Single section ladder of up to

7.300m(24ft).The rungs may be rectangular or

round.

Pole Ladders:-Single section ladder but with the

stiles made from a whitewood pole cut down in

the middle.This ensures strength and

flexibility.Used mainly as an access ladder for

scaffolding.

Extension Ladders:-Have two or three sections

coupled together which extended by sliding over

or inside each other and secured by a latch.The

ladder may be extended by means of a rope and

pulley.

Roof Ladders:-Designed for use on

pitched(sloping)roofs,these ladders have a hook at

the top end for securing over the ridge of the roof.

Step Ladders:-Are free standing(i.e.they do not

have to be erected against wall,etc.)and have flat

rectangular treads which gives a secure

footing.they are mainly used to reach walls and

ceiling-especially for the purpose of fixing.

Aluminium Ladders:-Most types of ladder are

available in aluminium,e.g.steps,roofs

ladders,extension ladders,etc.They are lighter to

carry than timber ladders,are strong and will not

warp,but should not be used near electrical

equipment or an electrical supply because of

possibility of electric shock.

LADDERWAYS

(Fixed rungs or loops to

masts etc.)

Look for damaged welds.

Look for missing rungs

Report any problems to your

supervisor.Get repairs made

urgently.

Wear a safety belt or harness

when work has to be done

from any ladder way.

SCAFFOLDING

The main reason for erecting a scaffold is to

support working platform.Most construction work

involves working at heights which cannot be

easily or safely reached from the ground or part of

the building,therefore a scaffold is usually the

most convenient way of gaining access.

Scaffold may only be erected,altered or dismantled

under the supervision of a competent person or

experienced scaffolder.Scaffold must be rigid,built

of sound materials on good foundations and if

required,be well secured to the building or

structure.In public places,scaffolds must be well lit

or have warning lights fitted to the base.

Warning notices must be displayed on incomplete

scaffolds and precaution taken to ensure that no

unauthorised person can gain access to the

scaffold at any time.

INDEPENDENT SCAFFOLDS:-

As its name implies ,the independent scaffold is

“independent” of the building or structure.It has

two rows of parallel standards ,so that it is self-

supporting,although dependant on its

height,location and use ,it may be ‘tied’ to the

building or structure to give additional stability.

MATERIALS

All scaffolding materials must be inspected by an

experienced and competent person before use,any

unsound and unserviceable material should be

clearly marked and removed from site.

Materials used to build a scaffold must be in good

condition:the ends preferably bound and not

split,warped or twisted.Scaffold boards should not

be painted or treated in any way to conceal

defects.Other materials ,ropes,gin

wheels,ladders,etc.must all be in sound,serviceable

condition.

FOUNDATIONS:

Every scaffold structure must be “well

founded”.The foundation must be capable

of carrying the imposed load for the entire

life of the scaffold.On hard surface such as

steel or concrete of sufficient strength and

thickness,standards may be placed directly

on the surface.On other surfaces,base plates

and sole boards must be used to spread the

load.the ground beneath the sole plate must

be level and properly compacted.

THE SCAFFOLD FRAME:

The frame work of the scaffold is built from

metal tubes of varying lengths,joined

together with a variety of couplers or

clips(commonly called fittings).The actual

design and shape of the structure will

depend on the intended purpose of the

scaffold and the load it might be expected to

bear.However,there are certain basic

principles that are common to all types of

scaffold.

Safety Checklist

Base

Line of standards and ledgers

Line and spacing of transoms

Diagonal bracing(in both

directions)

Ties

Security of boards,toe boards and

guardrails.Maximum gap at wall

Security and correct use of couplers

and fittings.

Condition of tubes and fittings

Even spread of load on platform.

Means of access

Overloading

Security of stacked materials

TUBULAR ACCESS

SCAFFOLDS.

STANDARDS

Standards are the vertical elements of the scaffold

framework and as such carry the entire weight of the

structure and its load.Standards must be vertical,or lean

slightly towards the building.

The spacing of standards is determined by the intended use

of the scaffold,the distance between the standards being

reduced as the expected load increases.

The width of the working platform is also determined by

the purpose for which the scaffold is intended.This is

usually expressed in terms of ‘the number of boards wide’.

Joints in standards should be staggered :that is joints

should not occur at the same level in adjacent

standards.joints may be made with spigots,but if they are

likely to be subjected to tension,they should be

strengthened with lapped tubes,or sleeve couples should be

used.

LEDGERS:Ledgers are the main horizontal tubes

and provide lateral support to the structure.They

must be level,and fixed to the inside of the

standards with right angle,load-bearing couplers.

Ledgers should be joined with sleeve couplers,as

close to the node points(the points at which the

ledger is fixed to the standard) as possible :and

never more than one third of the bay distance from

a standard.All joints must be staggered.

A kicker lift or foot tie is normally used only on

heavy duty or long term scaffolds ,or where there

is a possibility that a standard could be displaced

by something striking it.

TRANSOMS

Main transoms are fixed ,either directly across to every

pair of standards,using right angle couplers,or laid across

and fixed to ledgers with putlog couplers(single fitting).In

this case,transoms should be fixed within 300 mm of

standards.Main transoms hold the two rows of standards in

position and are an integral of the structure.they must not

be removed unless expert advice is sought.

If the lift is to be boarded out as a working

platform,intermediate transoms will be required to support

the boards.These are fixed across ledgers with putlog

couplers,normally in the centre of each bay although

additional intermediate transoms may be required to

support short boards.

BRACES:

A scaffold must be braced in both directions,ledgers(or

cross bracing) must be fixed to (or adjacent to) alternate

pairs of standards along the entire length of the scaffold

and on each lift ,to the full height of the scaffold.

Face (or sway bracing) should be fixed along the face of

the scaffold ,either in zig-zag(or dog leg)fashion or as one

continuous sloping tube.It must be connected at the base

and every lift to extended transoms with right angle

couplers,or to every standard with swivel couplers.There

should be one such brace assembly along the face of the

scaffold every 30mts.or less.All joints in a continuous

brace must be made with a sleeve coupler or spliced with

lapped tube.

All braces form an integral part of the scaffold structure

and must not be removed without expert advice.

TIES:

To ensure that the scaffold framework cannot

move away from,or towards the building or

structure it must be stabilised.This is normally

achieved by securing the scaffold framework to

the structure with positive two-way ties.

Ties must not be removed except by an

experienced and competent scaffolder ,who must

ensure that the stability of the scaffold is not

jeopardised.They must be checked at regular

intervals to make sure they are secure.

WORKING PLATFORMS:

As previously stated the main purpose of scaffold is to

support a working platform.It is a requirement that such

working platforms should be suitable for the type of work

,provide security for the operative and secure that safety of

other-people passing below or near the scaffold.

If the platform is more than 2 mts.above the ground,it must

be close boarded and be fitted with guard rails and toe

boards.The guard rail should be set at height of 1mtr.above

the platform and the toe board be at least 150mm

high.Where materials are stocked above toe board height,a

suitable barrier(such as brick guards) must be erected to

prevent materials falling off.

Care should be taken to see that a working

platform and its scaffold are not

overloaded.Materials should be distributed as

evenly as possible with heavy items placed as near

to the standards as possible.

A working platform must be provided with a safe

and proper means of access.This is usually some

form of ladder,which must be firmly fixed and

extend above the level of the platform by a

minimum of five rungs(1mtr.)unless other

adequate hand-holds are provided.Landings

should be fitted with guard rails and toe boards

and should be kept clear.

INSPECTION

Every scaffold should be inspected by an

experienced and competent person,at least

once every seven days;after any substantial

alteration or adaptation and after storms or

bad weather conditions.A record of the

inspection must be kept.

SYSTEM SCAFFOLDS

System scaffolds are governed by the same

rules and regulation as previously stated.It

is important that manufacturers

recommendations are followed and that

different systems are not mixed on the same

scaffold.

SCAFFOLD TOWERS AND

MOBILE TOWERS

Scaffold towers may be constructed from

basic scaffold components or may be

specially designed ‘proprietary’ towers

made from lightweight alloys.They may be

mobile-fitted with wheels or castors for

easy movement-or static towers not

intended to be moved.

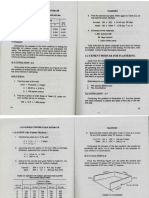

MOBILE SCAFFOLD

The stability of a tower depends very much

on the size of the base in relation to its

height :

Stationary internal tower 4:1

Stationary external tower 3.5:1

Mobile internal tower 3.5:1

Mobile external tower 3:1

The recommended maximum height for

mobile towers is 9.60m except that this may

be increased to 12m if it is tied to a

structure.

A static access tower should not be exceed a

maximum of 12m free standing.Above this

height the tower should be tied or be

specially designed to ensure stability by

means of ground anchors,guys or kentledge.

Working platforms must be close

boarded,hand rails and toeboards should

fitted. A ladder for access can be lashed

vertically to one of the narrow sides.

WHEN IN USE

Mobile towers should only be used on ground

which is firm and level.

Moving the structure should only be done by

pulling or pushing at the base.

Working platforms should be clear of men and

heavy materials when the scaffold is being moved.

Wheels should be turned outwards to provide

maximum base dimensions and wheel brakes must

be ‘on’ and locked when the scaffold is in use.

You might also like

- Kwikstage Scaffolding Plan and Method StatementDocument9 pagesKwikstage Scaffolding Plan and Method StatementDarren O HanlonNo ratings yet

- PIP PNE00003 (2019) - Process Unit and Offsites Layout GuideDocument23 pagesPIP PNE00003 (2019) - Process Unit and Offsites Layout GuideRichard Gutierrez100% (2)

- Scaff TrainingDocument29 pagesScaff TrainingrakeshNo ratings yet

- LLM - EH - STD - 1210 - 00.00 (00) - Safe Work Method StatementDocument5 pagesLLM - EH - STD - 1210 - 00.00 (00) - Safe Work Method StatementMatthew Mohan PerumalNo ratings yet

- RA Tower 0004 Dec 2011Document8 pagesRA Tower 0004 Dec 2011grandeNo ratings yet

- Scaffolding SafetyDocument4 pagesScaffolding Safetyrguy3223No ratings yet

- GL 17 ScaffoldingDocument18 pagesGL 17 Scaffoldingtp101267No ratings yet

- ScaffoldingDocument38 pagesScaffoldingCheNieAmir90% (21)

- Scaffolding Safety Instruction (498 A)Document5 pagesScaffolding Safety Instruction (498 A)Mythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Rescue Plan: Hot Oil Drain DrumDocument3 pagesRescue Plan: Hot Oil Drain DrumNaveed AhmedNo ratings yet

- Edge Protection Manual With ApprovalDocument12 pagesEdge Protection Manual With ApprovalClaudioKAD100% (1)

- Fall Protection EngDocument1 pageFall Protection EngsrdrhsrcNo ratings yet

- Working at Heights: Engr. Jobelle B MalaygayDocument50 pagesWorking at Heights: Engr. Jobelle B MalaygayJohn Cedrik Retardo100% (1)

- Alu DeckDocument20 pagesAlu DeckYasserMohsen100% (1)

- WAH ToolkitDocument74 pagesWAH ToolkitKhuda BukshNo ratings yet

- WSH Guidelines - Landscape and Horticulture ManagementDocument35 pagesWSH Guidelines - Landscape and Horticulture Managementlwin_oo2435No ratings yet

- Scaffolding Safety: Erection of Mobile ScaffoldingDocument18 pagesScaffolding Safety: Erection of Mobile Scaffoldingmuzica muzNo ratings yet

- Duty of Care Act: Occupational Health and Safety Act 1984Document24 pagesDuty of Care Act: Occupational Health and Safety Act 1984Hoanghon BacNo ratings yet

- Scaffold Inspection Report 1Document2 pagesScaffold Inspection Report 1ronachaif3191No ratings yet

- Product Brochure - 2016-2017 - CompressedDocument24 pagesProduct Brochure - 2016-2017 - CompressedDeepu RavikumarNo ratings yet

- Edge Protection Concrete Structures-Brochure-DownloadDocument48 pagesEdge Protection Concrete Structures-Brochure-DownloadMrs MigginsNo ratings yet

- 1st Aid Training Siemens ContractorDocument11 pages1st Aid Training Siemens ContractorTigor GurningNo ratings yet

- K LockDocument16 pagesK LockA JoshiNo ratings yet

- En AuV Allround-2018Document60 pagesEn AuV Allround-2018ArdamitNo ratings yet

- Fallarrest Catalogue, CosmoPetra, CMCODocument30 pagesFallarrest Catalogue, CosmoPetra, CMCOSafe Lifting Solutions50% (2)

- 1-Construction Personal Protective Equipment (PPE) CatalogDocument92 pages1-Construction Personal Protective Equipment (PPE) CatalogMohamed AdelNo ratings yet

- Osh 3200Document245 pagesOsh 3200Chun Yip LauNo ratings yet

- Moabi Scaffolding Company ProfileDocument14 pagesMoabi Scaffolding Company ProfileISRAR SHAHNo ratings yet

- New Scaffold TagsDocument36 pagesNew Scaffold TagsPaolo AzurinNo ratings yet

- What Is ScaffoldDocument47 pagesWhat Is Scaffoldkolli.99995891No ratings yet

- Gen ScaffoldingsafetyDocument43 pagesGen ScaffoldingsafetyvhlactaotaoNo ratings yet

- Scaffolds: OSHA Office of Training & Education 1Document34 pagesScaffolds: OSHA Office of Training & Education 1khaan1830No ratings yet

- Construction - Scaffold Checklist - HSEDocument6 pagesConstruction - Scaffold Checklist - HSEtarek_bouzayaniNo ratings yet

- 3M Fall Protection Regional Catalogue 2017 FULL en WEB4 19.04.17Document71 pages3M Fall Protection Regional Catalogue 2017 FULL en WEB4 19.04.17George Lapusneanu100% (1)

- TRADStair User GuideDocument36 pagesTRADStair User GuideMark JeavensNo ratings yet

- Osha3722 PDFDocument2 pagesOsha3722 PDFTharaka Perera100% (1)

- Slide ScaffoldOverviewDocument32 pagesSlide ScaffoldOverviewVijayakumarVageesanNo ratings yet

- CG3 18 ProgrammesDocument2 pagesCG3 18 ProgrammesArdamitNo ratings yet

- Scaffold TrainingDocument34 pagesScaffold TraininggilNo ratings yet

- Scaffold User Safety: FN000681/CR/01Document51 pagesScaffold User Safety: FN000681/CR/01Ryan Au YongNo ratings yet

- Abtech Safety 2010 EmailDocument32 pagesAbtech Safety 2010 EmailpnsanatNo ratings yet

- Excavation Safety Precautions Trenching and Excavation Safety GuidelinesDocument6 pagesExcavation Safety Precautions Trenching and Excavation Safety GuidelinesJonathanNo ratings yet

- Woodlands N5C23 - FPP-TPWDocument29 pagesWoodlands N5C23 - FPP-TPWSuresh ThevanNo ratings yet

- Frame Scaffold Erection GuideDocument2 pagesFrame Scaffold Erection Guideputra2azanNo ratings yet

- Working at Heights: Dr.P.MuralidharDocument48 pagesWorking at Heights: Dr.P.MuralidharRituraj SinghNo ratings yet

- LLM - EH - STD - 1209 - 00.00 (00) - Environmental Management PlanDocument35 pagesLLM - EH - STD - 1209 - 00.00 (00) - Environmental Management PlanMatthew Mohan PerumalNo ratings yet

- CPCCPB3026 PresentationDocument85 pagesCPCCPB3026 PresentationAbdul Haseeb100% (1)

- ABB Scaffold Competent TestDocument4 pagesABB Scaffold Competent Testvasucristal100% (2)

- Method Statement ST100Document6 pagesMethod Statement ST100tarekNo ratings yet

- Fall ProtectionDocument105 pagesFall ProtectionvhlactaotaoNo ratings yet

- 2011 Dbi-Sala CatalogDocument77 pages2011 Dbi-Sala CatalogNelsongs52No ratings yet

- Company Profile 2024 Rev1Document32 pagesCompany Profile 2024 Rev1R ArcegaNo ratings yet

- Scaffolding: Smart Scaffolding For Innovative ConstructionDocument5 pagesScaffolding: Smart Scaffolding For Innovative ConstructionEbrahimAbuZaidNo ratings yet

- Scaffolding CourseDocument6 pagesScaffolding Course4gen_5No ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- ScaffoldingDocument4 pagesScaffoldingolvernejacobs9741No ratings yet

- 6 Temporary StructuresDocument54 pages6 Temporary Structuresvox busmente100% (1)

- Scaffolding: Submittedby, Akhilesh. A Productionoperator (TR), Forbesbu MiarmadalimitedDocument42 pagesScaffolding: Submittedby, Akhilesh. A Productionoperator (TR), Forbesbu MiarmadalimitedChandan Kumar Singh100% (1)

- Erect Modular Sacffold NotesDocument16 pagesErect Modular Sacffold NotesAfifi YusoffNo ratings yet

- Scaff and Mewp and HeightDocument24 pagesScaff and Mewp and HeightRmr ReyesNo ratings yet

- Work at Height and "Scaffolding": WWW - Trivediassociates.co - inDocument22 pagesWork at Height and "Scaffolding": WWW - Trivediassociates.co - inReaz UddinNo ratings yet

- PlasteringDocument3 pagesPlasteringHerwinn Ruiz ReyesNo ratings yet

- PC130-7 SPC 10-09-2012Document352 pagesPC130-7 SPC 10-09-2012Plr. BaswapurNo ratings yet

- DoP Ref 0756-CPD-0322 Soudafix VE380-SF ENDocument3 pagesDoP Ref 0756-CPD-0322 Soudafix VE380-SF ENPranshu JainNo ratings yet

- EA9395Document4 pagesEA9395lacsmm982No ratings yet

- Comparison of Characteristcs and Use of Urea Formaldehyde, Phenol Formaldehyde and Melamine UreaDocument2 pagesComparison of Characteristcs and Use of Urea Formaldehyde, Phenol Formaldehyde and Melamine UreaAniq SyauqiNo ratings yet

- Beams and Other Flexural Members PDFDocument52 pagesBeams and Other Flexural Members PDFJeyjay BarnuevoNo ratings yet

- CNC Machine Img - 20230403 - 0005Document32 pagesCNC Machine Img - 20230403 - 0005abrahamNo ratings yet

- VRV Testing Check SheetDocument2 pagesVRV Testing Check SheetJahangir Hassan100% (1)

- REODATA40Document76 pagesREODATA40chanakaNo ratings yet

- SIRe Advance Quick GuideDocument25 pagesSIRe Advance Quick GuideJasperken2xNo ratings yet

- Campbell Haushfield Compressor Parts ListDocument3 pagesCampbell Haushfield Compressor Parts ListAnonymous rKtpSR3No ratings yet

- Orthodontic Wires - Properties / Orthodontic Courses by Indian Dental AcademyDocument226 pagesOrthodontic Wires - Properties / Orthodontic Courses by Indian Dental Academyindian dental academy100% (1)

- Final Report, NarayanganjDocument125 pagesFinal Report, NarayanganjNaim ParvejNo ratings yet

- Deep FoundationsDocument23 pagesDeep FoundationsMushaid Ali SyedNo ratings yet

- Unit 7 - Week 6: Assignment 06Document3 pagesUnit 7 - Week 6: Assignment 06SaurabhNo ratings yet

- Organization of American States General Secretariat Secretariat For Administration and Finance Office of General ServicesDocument23 pagesOrganization of American States General Secretariat Secretariat For Administration and Finance Office of General ServicesthirumalNo ratings yet

- 3.1-Pile Design Calculation For Boundary (p1 To p50)Document24 pages3.1-Pile Design Calculation For Boundary (p1 To p50)layaljamal2No ratings yet

- LG 35 40Document117 pagesLG 35 40tariku kirosNo ratings yet

- 40rr 72dpiDocument8 pages40rr 72dpiRONELNo ratings yet

- Handbook of Practical Smithing and ForgingDocument314 pagesHandbook of Practical Smithing and ForgingArtisan Ideas100% (2)

- 4.0 Anchoring Systems (128-389) r021Document265 pages4.0 Anchoring Systems (128-389) r021Anonymous SWOmOE8No ratings yet

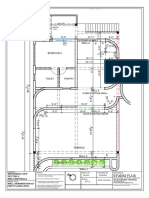

- First Floor Revised Demarkation PlanDocument1 pageFirst Floor Revised Demarkation Planshubhamthakral56No ratings yet

- Tegangan Geser, Lengkung Dan PuntirDocument16 pagesTegangan Geser, Lengkung Dan PuntirAji ZanettiNo ratings yet

- 01-B - Centrifugal PumpsDocument44 pages01-B - Centrifugal Pumps81q1iyNo ratings yet

- Flint KoteDocument3 pagesFlint KoteDhim131267No ratings yet

- Influence of Semi-Rigidity of Joints On The Behaviour of Timber StructuresDocument11 pagesInfluence of Semi-Rigidity of Joints On The Behaviour of Timber StructuresnevinkoshyNo ratings yet

- National CAD Standards-SymbolsDocument136 pagesNational CAD Standards-SymbolsVania Natalie50% (2)

- Akhbar AlDar Oct - Dec #37 V7 20&21Document2 pagesAkhbar AlDar Oct - Dec #37 V7 20&21Abdulkareem TawiliNo ratings yet

- Set - 4Document8 pagesSet - 4Game LoveNo ratings yet