Full Paper

Confinement Effect on the

Body-Centered-Cubic Phase of Diblock

Copolymers in Film

Hongge Tan,* Qinggong Song, Shuang Yang, Dadong Yan,* An-Chang Shi

In this paper, we study the morphology of diblock copolymers with the body-centered-cubic

(bcc) phase confined between two flat surfaces. Employing the Landau–Brazovskii mean field

theory and the single mode approximation, we obtain three amplitude parameters as

functions of temperature, surface field strength, and film thickness. Because of the effect

of confinement size and the surface inducement, the morphology of confined diblock copolymers is different from the bulk structure. By

controlling confinement size and surface field

strength, lamella, undulated lamella, cylinder,

and distorted cylinder can be observed in the

bcc bulk phase of diblock copolymers. Also, we

construct a ‘‘phase diagram’’ of confinementinduced structures at different surface field

strengths. We compare the present theoretical

results with the other relevant theoretical results.

The predictions about these interesting confinement-induced structures should be observable in

the experiments under suitable conditions.

Introduction

The self-assembly of diblock copolymers has drawn more

and more attention because of the rich ordered microstructures.[1–6] The ordered microstructures can be applied

H. Tan, Q. Song

College of Science, Civil Aviation University of China,

Tianjin 300300, China

E-mail: thg@iccas.ac.cn

S. Yang, D. Yan

State Key Laboratory of Polymer Physics and Chemistry, Institute

of Chemistry, Chinese Academy of Sciences, Beijing 100080,

China

E-mail: yandd@iccas.ac.cn

A.-C. Shi

Department of Physics and Astronomy, McMaster University,

Hamilton, Ontario L8S 4M1, Canada

Macromol. Theory Simul. 2008, 17, 45–51

ß 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

in nanotechnology.[7,8] For bulk diblock copolymers,

lamellae, hexagonal arrays of cylinders, body-centeredcubic (bcc) arrays of spheres, and the bicontinuous gyroid

have been obtained in turn by changing the interactions

between the distinct blocks and architectures of those

blocks.[1–6] A good understanding of the bulk phase behavior has been obtained. For diblock copolymers confined

by the environment of a system, the self-assembly process

is more complicated and interesting due to the confinement geometry and the interactions between the block

copolymer and the surface. The self-assembly in confined

environment is a new approach toward preparing ordered

periodic nanostructured materials and has attracted

considerable interest in recent years.[7–31]

Much attention has been focused on the self-assembly

of symmetric diblock copolymers in a confined environment.[9–18] Their phase behavior has been understood

DOI: 10.1002/mats.200700064

45

�H. Tan, Q. Song, S. Yang, D. Yan, A.-C. Shi

fairly well. For confined asymmetric block copolymers

with cylindrical bulk morphology, some studies have also

been carried out theoretically[19–23] and experimentally.[24–27] Under confinement, diblock copolymers with

cylindrical bulk phase cannot only change the orientation

of cylinders, but also alternate between different morphologies.

In contrast to the lamellar bulk phase and the cylindrical

bulk phase, confined diblock copolymers with the spherical bulk phase receive less attention. Although a few

papers appeared which deal with some aspects of the bcc

phase in thin film, the emphases of these papers are

different from that of our work.[28–31] Recently, we studied

theoretically the surface effect on the bcc spherical bulk

phase.[32] As a continuation of the previous study,[32] in

this paper, we devote to the confinement effect on the bcc

forming asymmetric diblock copolymers under the interactions between surfaces and diblock copolymers.

This paper is organized as follows. In the next section, in

weak segregation limit we induce the model in which the

diblock copolymer melt with bcc bulk phase is confined

between two flat surfaces with surface interaction. In the

subsequent section, we study the structure evolution

under different film thicknesses and different surface field

strengths. The corresponding discussions are also given in

this section. In the last section, we give the conclusions.

Theory

As a continuation of the previous study, the model we

describe here is the same as that in ref.[32] We consider an

incompressible melt of n AB diblock copolymers in a

volume V0 at a temperature T. The total degree of polymerization of the diblock copolymer is N. The degree of

polymerization of the A block is fAN, where fA is the

fraction of segments on each chain that are of type A.

The effective interaction between statistical segments of

type A and type B is characterized by the dimensionless Flory–Huggins parameter x in kBT units. The order

parameter of diblock copolymers is defined as

fðrÞ � fA ðrÞ � fA , the deviation of the local A monomer

concentration from its average value. In the weak

segregation regime, the Landau–Brazovskii model can be

used. Specifically, the Landau–Brazovskii free energy per

block copolymer f ½fðrÞ� is given by

f ½fðrÞ� ¼

1

V

Z

dr

� 2

�

j

t

g

1

½ðr2 þ 1Þf�2 þ f2 � f3 þ f4

2

2

3!

4!

(1)

Here, the details of the parameters in Equation (1) can be

found in ref.[1–3] and[32–34]. j and g are functions of fA; t is a

46

Macromol. Theory Simul. 2008, 17, 45–51

ß 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

function of xN and fA. When xN ¼ xNs (the disorder to order

spindal point), t ¼ 0. In the weak segregation limit, fA

and xN are chosen close to the order–disorder critical

temperature. For a bcc structure in the weak segregation

regime, it is sufficient to restrict ourselves to the first mode

in the reciprocal space with the reciprocal lattice vectors

pffiffiffi

~ i j ¼ q0 ¼ 2p=ðb= 2Þ (b is the lattice parameter and

jG

~ i j ¼ 1 in scaled units), instead of using the complete set

jG

~ i . In the single mode approximation, the bulk

of vectors G

bcc spherical phase can be described by the order

parameter (see Equation (16) in ref.[32])

~ 1 � rÞ þ 2a2 ðrÞ½cosðG

~ 2 � rÞ

fðrÞ ¼ 2a1 ðrÞ cosðG

~

~

þ cosðG3 � rÞ� þ 2a3 ðrÞ½cosðG4 � rÞ

~ 5 � rÞ þ cosðG

~ 6 � r�

þ cosðG

(2)

with

~1

G

~2

G

~3

G

~

G4

~5

G

¼ z^; pffiffiffi

¼ 12 ð 3x^ þ z^Þ;

pffiffiffi

¼ 12 ð� 3x^ þ z^Þ;

pffiffiffi

¼ p1ffiffi3 ðx^ þ 2y^Þ;

pffiffiffi

pffiffiffi

¼ 2p1 ffiffi3 ðx^ � 2 2y^ þ 3z^Þ;

pffiffiffi

pffiffiffi

~ 6 ¼ p1 ffiffi ð�x^ þ 2 2y^ þ 3z^Þ

G

2 3

where a1 (r), a2 (r), and a3 (r) are space-dependent

amplitude functions describing the variation of microstructures. In the bcc bulk melt, a1 ¼ a2 ¼ a3 ¼ abcc, with

which the order parameter describes bcc spheres. Furthermore, when a1 ¼ a2 ¼ ahex and a3 ¼ 0, the order parameter

describes the hexagonal arrays of cylinders. When

a1 ¼ alam and a2 ¼ a3 ¼ 0, the order parameter describes

the lamellae.

When the diblock copolymer melt is put in contact with

two flat surfaces, the translational symmetry is broken. In

order to study the confinement-induced structures in the

bcc spherical phase explicitly under interactions between

polymers and the surfaces, we choose surface plane as the

z ¼ 0 and z ¼ l planes and assume that the surface is

presented by a surface potential. Thus, the free energy of

the system is given by

V¼

1

V

Z

drðf�fðrÞDu½dðzÞ þ dðz � lÞ�g þ f ½fðrÞ�Þ

(3)

Du is the differential affinity of surface tensions with

respect to one block of the copolymer.[21] If uAS and uBS are

the surface tensions of polymers A and B with respect to

the surface, one has Du ¼ uBS � uAS . By uAS and uBS, Du can

be related to any available material. d(z) and d(z � l) are

delta functions, which mean that the interactions are short

range and only exist on the surfaces (z ¼ 0 plane and z ¼ l

plane). We assume that the amplitudes a1, a2, and a3 are

only z-dependent, and vary slowly on the scale of l0, which

DOI: 10.1002/mats.200700064

�Confinement Effect on the BCC Phase of Diblock Copolymers . . .

is the characteristic period of the lamellar component in

the bulk melt. Also, we neglect the effect of the incommensurability between l and l0, although this incommensurability affects the orientation on the

microstructure, which is the result of the competition

between the surface interaction and the incommensurability. Under the above two assumptions, we can separate

the length scale for variations in the amplitude from the

length scale of the microstructure. Since we have assumed

the amplitudes vary slowly on the scale of l0, we only

retain gradient terms up to quadratic order in the

Landau–Brazovskii free energy. Thus the free energy per

unit surface can be written as (see Equation (26) in ref.[32])

~ ¼ �sXð0Þ � sXðLÞ

V

!2

� �

� �

Z L (

dX

1 dY 2 1 dZ 2

dt

þ

þ

þ

dt

2 dt

2 dt

0

)

þ f ½XðtÞ; YðtÞ; ZðtÞ�

values of s ¼ 0.9 and 2 corresponding to weaker and

stronger surface fields, respectively, as we did in ref.[32]

Results and Discussion

In this section, we show that how the film thickness affects

the bulk structure under different surface field strengths.

As the first step, we linearize the free energy of bulk phase

f(X, Y, Z) around the bcc structure. Minimizing the total free

energy given by Equation (4), we obtain three linear

Euler–Lagrange equations. Under the boundary conditions,

we obtain the general solutions of these linear equations,

DXðtÞ ¼ XðtÞ � Xbulk

¼s

3 h

i

X

CXi ða; LÞe�li ðaÞt þ CXiþ3 ða; LÞeli ðaÞt

i¼1

(5)

ð4Þ

DYðtÞ ¼ YðtÞ � Ybulk

with

X ¼ a1 =g;

t ¼ zg=2j;

s ¼ Du=jg 2 ;

Y ¼ a2 =g;

L ¼ lg=2j;

~ ¼ V=2jg 3

V

Z ¼ a3 =g;

Here, the parameters g and j can be determined by

f(X, Y, Z) is the free energy of the bulk diblock

fA.

copolymers and the expression can be found in ref.[32] Thus

X(t), Y(t), and Z(t) are related to the variation of the

structures since they are proportional to a1(z), a2(z), and

a3(z), respectively. The reduced distance t, the effective film

thickness L and the reduced surface field strength s are

used instead of z, the film thickness l and Du which can be

obtained from the experiments, respectively. Minimizing

the free energy in Equation 4, we obtain three-coupled

Euler–Lagrange equations for the amplitudes of X(t), Y(t),

and Z(t). The formation of these three Euler–Lagrange

equations are the same as Equation (27)–(29) in ref.[32]

From Equation 4, we can obtain the boundary conditions

�

�

dX ��

dX ��

¼ � � ¼ �s

dt �t¼0

dt t¼L

¼s

In the following section, we can solve these threecoupled Euler–Lagrange equations and discuss the results

with the parameters L, s and effective temperature a,

which appears in f (X, Y, Z) and is defined as t/g 2 in ref.[32]

Although we cannot relate these values to any available

materials at the moment, we can still select two typical

Macromol. Theory Simul. 2008, 17, 45–51

ß 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

(6)

i¼1

DZðtÞ ¼ ZðtÞ � Zbulk

[1–3,32,34]

�

�

�

�

dY ��

dY ��

dZ ��

dZ ��

¼

¼

¼

¼0

dt �t¼0

dt �t¼L dt �t¼0 dt �t¼L

3 h

i

X

CYi ða; LÞe�li ðaÞt þ CYiþ3 ða; LÞeli ðaÞt

¼s

3 h

i

X

CZi ða; LÞe�li ðaÞt þ CZiþ3 ða; LÞeli ðaÞt

(7)

i¼1

where CXi(a, L), etc. are the coefficients of the solutions of

the linear equations and are determined by a and L.

In order to study the confinement effect, first we fix the

effective interaction s ¼ 0.9 and the effective temperature

a ¼ �0.02 (far from the effective transition temperature

a� ¼ �0:07345, as mentioned in ref.[32]). We obtain

Xbulk ¼ Ybulk ¼ Zbulk ¼ 0.27613,[32] l1 ¼ 1.7046, l2 ¼ 1.1034,

and l3 ¼ 0.5997. We change the film thickness and consider

three different cases as follows.

The first case is for a thick film in which we choose

L ¼ 12. In this case, by solving the linear Euler–Lagrange

equations, the corresponding coefficients are CX1 ¼

2.783 � 10�3, CX2 ¼ 0.1104, CX3 ¼ 1.457, CX4 ¼ 3.638 �

10�12, CX5 ¼ 1.962 � 10�7, CX6 ¼ 1.091 � 10�3, CY1 ¼ 3.268 �

� 10�2, CY2 ¼ �0.3496, CY3 ¼ 0.5507, CY4 ¼ 4.271 � 10�11,

CY5 ¼ �6.212 � 10�7, CY6 ¼ 4.124 � 10�4, CZ1 ¼ 4.671 � 10�2,

CZ2 ¼ 0.2314, CZ3 ¼ �0.5589, CZ4 ¼ 6.105 � 10�11, CZ5 ¼

4.112 � 10�7, and CZ6 ¼ �4.186 � 10�4. These asymptotic

solutions can be used as the initial conditions to obtain the

exact numerical solutions of three Euler–Lagrange equations and then we obtain the amplitudes X(t), Y(t), and Z(t)

varying with t. The results are shown in Figure 1. On the

surfaces, Y ¼ 0.208 and Z ¼ 0.005, which indicate the

www.mts-journal.de

47

�H. Tan, Q. Song, S. Yang, D. Yan, A.-C. Shi

Figure 1. Reduced amplitudes X(t), Y(t), and Z(t) as functions of t

for a ¼ �0.02, s ¼ 0.9, and L ¼ 12.

Figure 3. Reduced amplitudes X(t), Y(t), and Z(t) as functions of t

for a ¼ �0.02, s ¼ 0.9, and L ¼ 1.

cylindrical component exists and the spherical component

is negligible.

The second case is for the medium thickness film,

in which we choose L ¼ 6. In this case, the corresponding coefficients are CX1 ¼ 2.783 � 10�3, CX2 ¼ 0.1106,

CX3 ¼ 1.497, CX4 ¼ 1.006 � 10�7, CX5 ¼ 1.474 � 10�4, CX6 ¼

0.0410, CY1 ¼ 3.268 � 10�2, CY2 ¼ �0.3501, CY3 ¼ 0.5658,

CY4 ¼ 1.181 � 10�6, CY5 ¼ �4.667 � 10�4, CY6 ¼ 1.548 �

10�2, CZ1 ¼ 4.671 � 10�2, CZ2 ¼ 0.2317, CZ3 ¼ �0.5742,

CZ4 ¼ 1.689 � 10�6, CZ5 ¼ 3.089 � 10�4, and CZ6 ¼ �1.571 �

10�2. Following the same process as above, we obtain the

amplitudes X(t), Y(t), and Z(t) varying with t. The results are

shown in Figure 2. On the surfaces, Y ¼ 0.191 and

Z ¼ 0.0008, which are smaller than those in the first case

and indicate the cylindrical component still exists while

the spherical component is nearly negligible. Furthermore,

all the values of Z(t) are almost zero, which means that the

spherical component hardly exists throughout the whole

film.

The third case is for a thin film, in which we choose L ¼ 1.

In this case, the corresponding coefficients are CX1 ¼

3.402 � 10�3, CX2 ¼ 0.1652, CX3 ¼ 3.229, CX4 ¼ 6.186 � 10�4,

CX5 ¼ 5.482 � 10�2, CX6 ¼ 1.772, CY1 ¼ 3.994 � 10�2, CY2 ¼

�0.5232, CY3 ¼ 1.220, CY4 ¼ 7.263 � 10�3, CY5 ¼ �1.736,

CY6 ¼ 0.6698, CZ1 ¼ 0.0571, CZ2 ¼ 0.3462, CZ3 ¼ �1.238,

CZ4 ¼ 1.038 � 10�2, CZ5 ¼ 0.1149, and CZ6 ¼ �0.6797. We

also obtain the amplitudes X(t), Y(t), and Z(t) varying with t

shown in Figure 3. Note that all the values of Y(t) and Z(t)

become negligible, which indicate that the cylindrical

component and the spherical component disappear in the

film.

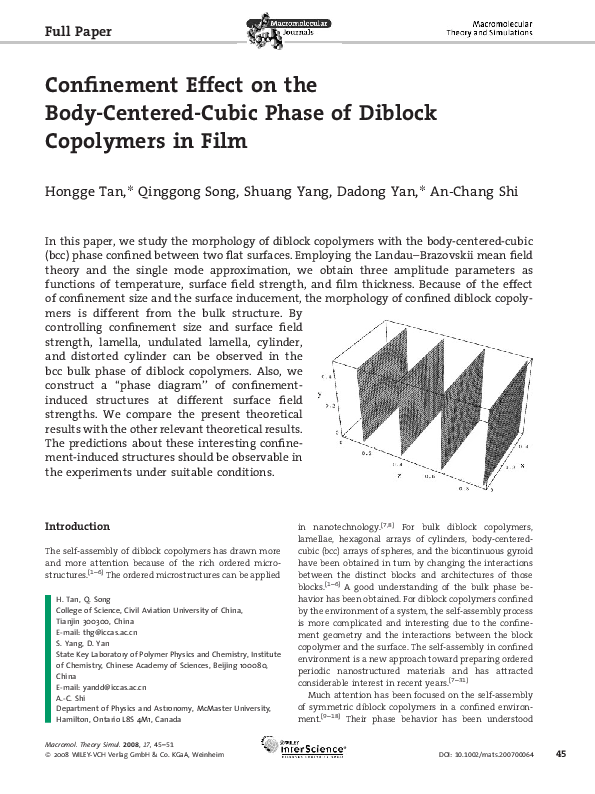

To demonstrate the evolution of the confinementinduced structures explicitly, the real space profiles of

the system are presented in Figure 4–6 for L ¼ 12, 6, and 1,

respectively. From Figure 4, we find that when L is large,

the structures in the film change from undulated lamellae

near the surfaces to cylindrical structures, then to the

distorted cylindrical structures, and finally to the spherical

structures near the center of the thin film. From Figure 5,

we can find that the spherical structures disappear, and

cylindrical structures appear near the center of the film

and then convert to undulated lamellar structures near the

surfaces. Figure 6 shows that when L is small enough,

lamellar phases extend throughout the film.

The results for s ¼ 2 are only quantitatively different

from those for s ¼ 0.9. To save space, we do not present the

results here. In order to illustrate the structure variation

with film thickness, we construct a phase diagram for

a ¼ �0.02 with s ¼ 0.9 and 2, respectively, as shown in

Figure 7. Lines L1 and L2 describe the positions where the

amplitudes Y(t) reach 10% of X(t) from the surfaces

(t ¼ 0 and L) for s ¼ 0.9 and 2, respectively. To the right of

Figure 2. Reduced amplitudes X(t), Y(t), and Z(t) as functions of t

for a ¼ �0.02, s ¼ 0.9, and L ¼ 6.

48

Macromol. Theory Simul. 2008, 17, 45–51

ß 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

DOI: 10.1002/mats.200700064

�Confinement Effect on the BCC Phase of Diblock Copolymers . . .

Figure 4. Three-dimensional contour plot of the order parameter fðx; y; zÞ in the region with amplitudes from the solid lines in Figure 1. z is

taken as t (in length unit of q�1

0 ¼ 4p).

these lines, the cylindrical components begin to be

appreciable. Lines C1 and C2 describe the positions where

the amplitudes Z(t) reach 10% of X(t) for s ¼ 0.9 and 2,

respectively. To the right of these lines, the spherical

components begin to appear.

From Figure 7 one can find that the effect of confinement for weaker and stronger surface field are different.

The region where the lamellar phase exists for s ¼ 0.9 is

smaller than that for s ¼ 2. The critical thickness Lc1 for

s ¼ 0.9, below which the lamellar phases extend throughout the film, is smaller than Lc2 for s ¼ 2. It is because the

stronger surface field strength can induce lamellar phases

easily.

The structures in the confinement film are different

from those in ref.[32] First, the main difference comes from

the cusp of lines L1, L2, C1, and C2. According to ref.,[32] these

lines should always keep the same distances from the

surfaces (t ¼ 0 and L) and intersect directly at a point which

is in front of the cusp of the lines in Figure 7. This can be

considered as the effect of confinement. Secondly, the

values of Y(t) and Z(t) near the surface decrease with a

decrease in the film thickness (see Figure 1–3), which

indicates that the cylindrical component exists for thicker

films and then disappears little by little near the boundary

with the decrease in the film thickness. Finally, the

lamellar phase appears in a thin enough film even for a

weaker surface field. This means that the confinement

makes the lamellar phase appear for a weaker surface field.

In other studies, Pereira also proved that the cubic to

cylindrical transition was possible in diblock copolymers

confined in the thin film.[28] His theoretical analysis was

carried out in the strong segregation limit and confining

Figure 5. Three-dimensional contour plot of the order parameter fðx; y; zÞ in the region with amplitudes from the solid lines in Figure 2.

Macromol. Theory Simul. 2008, 17, 45–51

ß 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.mts-journal.de

49

�H. Tan, Q. Song, S. Yang, D. Yan, A.-C. Shi

Figure 6. Three-dimensional contour plot of the order parameter fðx; y; zÞ in the region with amplitudes from the solid lines in Figure 3.

plates were neutral with respect to each block, which

disagreed with our theoretical work. He predicted that the

cylindrical phase should appear in thin films and the bcc

phase should be observed in thicker film. The conclusion

there is in agreement with some of the present results.

Therefore, our work and Pereira’s work should be seen as

complementary to each other. Tsori reported that the

external electric fields could be used to induce a phase

transition from the bcc spheres to the hexagonal array of

cylinders, which also proves indirectly the present results

are reasonable.[29] Till date, a systematic experimental

study of the evolution of confinement-induced structures

in bcc spherical phase of diblock copolymers was lacking.

We expect that the present prediction should be observable under appropriate experimental conditions.

Conclusion

Figure 7. Phase diagram, i.e., reduced film thickness L versus

reduced distance t, for a ¼ �0.02 with s ¼ 0.9 (solid lines) and

2 (dashed lines), respectively. Lines L1 and L2 describe the positions

where the amplitudes Y(t) reach 10% of X(t) from the surfaces

(t ¼ 0 and L) for s ¼ 0.9 and 2, respectively. Lines C1 and C2

describe the positions where the amplitudes Z(t) reach 10% of

X(t) for s ¼ 0.9 and 2, respectively.

50

Macromol. Theory Simul. 2008, 17, 45–51

ß 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

In summary, the evolution of confinement-induced structures is studied based on the Landau–Brazovskii theory in

the weak segregation limit. For a weaker surface field

strength, in a thick film, undulated lamellae, cylinders, and

distorted cylinders appear in sequence near the surfaces

and then convert to the spherical structure at the center of

the film. With the decrease in film thickness, cylindrical

phases appear near the center of the film and then convert

to undulated lamellae near the surface. If we continue to

decrease the film thickness, lamellar phases appear near

the surfaces at first and then extend throughout the film.

For a stronger surface field, the results are only quantitatively different from those for a weaker surface field. In

both cases, the confinement has obvious effect, especially

in the regions around the cusps of the lines in the phase

diagram. These predictions can be compared directly with

the experimental results.

DOI: 10.1002/mats.200700064

�Confinement Effect on the BCC Phase of Diblock Copolymers . . .

Acknowledgements: We acknowledge the support from National

Natural Science Foundation of China (NSFC) 20504027, 20474074,

20574085. A.-C. S. acknowledges the support from Natural Science

and Engineering Research Council (NSERC) of Canada.

Received: October 24, 2007; Revised: December 1, 2007; Accepted:

December 3, 2007; DOI: 10.1002/mats.200700064

Keywords: block copolymers; film; mean field; surfaces; theory

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

L. Leibler, Macromolecules 1980, 13, 1602.

K. Ohta, K. Kawasaki, Macromolecules 1986, 19, 2621.

G. H. Fredrickson, E. Helfand, J. Chem. Phys. 1987, 87, 697.

F. S. Bates, G. H. Fresrickson, Annu. Rev. Phys. Chem. 1990, 41,

525.

M. W. Matsen, F. S. Bates, Macromolecules 1996, 29, 7641.

M. W. Matsen, J. Phys. Condens. Matter 2002, 14, R21.

M. Park, C. Harrison, P. M. Chaikin, R. A. Register, D. H.

Adamson, Science 1997, 276, 1401.

T. Thurn-Albrecht, J. Schotter, G. A. Kästle, N. Emley, T.

Shibauchi, L. Krusin-Elbaum, K. Guarini, C. T. Black,

M. T. Tuominen, T. P. Russell, Science 2000, 290, 2126.

G. H. Fredrickson, Macromolecules 1987, 20, 2535.

M. W. Matsen, J. Chem. Phys. 1997, 106, 7781.

M. S. Turner, Phys. Rev. Lett. 1992, 69, 1788.

Y. Tsori, D. Andelman, J. Chem. Phys. 2001, 115, 1970.

T. Geisinger, M. Muller, K. Binder, J. Chem. Phys. 1999, 111,

5251.

G. T. Pickett, A. C. Balazs, Macromolecules 1997, 30, 3097.

Q. Wang, Q. L. Yan, P. F. Nealey, J. J. de Pablo, J. Chem. Phys.

2000, 112, 450.

G. Coulon, T. P. Russell, V. R. Deline, P. F. Green, Macromolecules 1989, 22, 2581.

Macromol. Theory Simul. 2008, 17, 45–51

ß 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

[17] T. P. Russell, G. Coulon, V. R. Deline, D. C. Miller, Macromolecules 1989, 22, 4600.

[18] B. Miao, D. D. Yan, R. A. Wickham, A.-C. Shi, Polymer 2007,

48, 4278.

[19] H. P. Huinink, J. C. M. Brokken-Zijp, M. A. van Dijk,

G. J. A. Sevink, J. Chem. Phys. 2000, 112, 2452.

[20] Q. Wang, P. F. Nealey, J. J. de Pablo, Macromolecules 2001, 34,

3458.

[21] M. S. Turner, M. Rubinstein, C. M. Marques, Macromolecules

1994, 27, 4986.

[22] Y. Z. Yang, F. Qiu, H. D. Zhang, Y. L. Yang, Polymer 2006, 47,

2205.

[23] B. Miao, D. D. Yan, C. C. Han, A.-C. Shi, J. Chem. Phys. 2006,

124, 144902.

[24] Y. Liu, W. Zhao, X. Zheng, A. King, A. Singh, M. H.

Rafailovich, J. Sokolov, K. H. Dai, E. J. S. Kramer, A. Schwarz,

O. Gebizlioglu, S. K. Sinha, Macromolecules 1994, 27, 4000.

[25] A. Karim, N. Singh, M. Sikka, F. S. Bates, W. D. Dozier,

G. P. Felcher, J. Chem. Phys. 1994, 100, 1620.

[26] M. Konrad, A. Knoll, G. Krausch, R. Magerle, Macromolecules

2000, 33, 5518.

[27] [27a] C. Harrison, M. Park, P. Chaikin, R. A. Register, D. H.

Adamson, N. Yao, Macromolecules 1998, 31, 2185; [27b] C.

Harrison, M. Park, P. M. Chaikin, R. A. Register, D. H.

Adamson, N. Yao, Polymer 1998, 39, 2733.

[28] G. G. Pereira, Macromolecules 2004, 37, 1611.

[29] [29a] Y. Tsori, D. Andelman, J. Polym. Sci. Polym. Phys. 2006,

44, 2725; [29b] Y. Tsori, F. Tournilhac, D. Andelman,

L. Leibler, Phys. Rev. Lett. 2003, 90, 145504.

[30] V. P. Chuang, J. Y. Cheng, T. A. Savas, C. A. Ross, Nano Lett.

2006, 6, 2332.

[31] J. Y. Cheng, A. M. Mayes, C. A. Ross, Nat. Mater. 2004, 3, 823.

[32] H. G. Tan, D. D. Yan, A. C. Shi, Macromolecules 2004, 37, 9646.

[33] S. A. Brazovskii, Sov. Phys. JETP 1975, 41, 85.

[34] R. A. Wickham, A. C. Shi, Z. G. Wang, J. Chem. Phys. 2003, 118,

10293.

www.mts-journal.de

51

�

An-Chang Shi

An-Chang Shi