Abstract

To investigate the influence of high temperatures on the bond performance of recycled concrete and steel bar, this article considers the influence of different concrete types (ordinary concrete and recycled concrete) and different temperatures (20, 100, 150, 200, 250, and 300°C) on the concrete compressive strength and the bond performance of concrete and steel bar. On this basis, the calculation formula of bond strength and bond slip between concrete and steel bar after the high temperature is established. The test results show that the concrete compressive strength presents a downward trend with the increase in temperature; the compressive strength loss of recycled concrete is higher than that of ordinary concrete; when the temperature reached 300°C, the compressive strength loss of ordinary concrete is 24.4%, while that of recycled concrete is 41.6%. The bond strength of pull-out specimens decreases with the increase of temperature, while the bond slip increases with the increase of temperature; the bond strength between recycled concrete and steel bar is lower than that between ordinary concrete and steel bar, while the bond slip between recycled concrete and steel bar is higher than that between ordinary concrete and steel bar. This article can provide a theoretical basis for the application of recycled concrete in high-temperature environment.

1 Introduction

The rapid development of the construction industry not only consumes a lot of sand and stone resources [1] but also generates a lot of construction waste, causing serious environmental problems [2]. Large numbers of studies have proved that recycled concrete can not only save sand and stone resources, but also effectively treat construction waste and realize the sustainable development of the construction industry [3]. Fire has always been one of the main threats to reinforced concrete structures [4], especially with the rapid rise of high-rise buildings [5], which increases the probability of various building fires and the difficulty of fighting them [6,7]. Therefore, it is of great significance to study the performance of concrete structures under high temperatures [8]. The combination of reinforcement and concrete makes up for each other’s shortcomings [9]. The good bond performance between concrete and steel bars can ensure the safety of concrete structures [10]. When the bond performance between reinforcement and concrete was damaged, the reinforced concrete structure would be damaged in advance. Therefore, it was of great significance to investigate the bond performance between recycled concrete and steel bar under high temperatures.

Many scholars have studied the bond performance of concrete and reinforcement after high temperature [11,12]. Niu et al. [13], Tang et al. [14], and Are1 and Yasici [15] obtained the bond–slip curve of concrete and steel bar after high temperature and then analyzed the influence of concrete strength, relative protective layer thickness, anchorage length, reinforcement diameter, cooling method, and stirrup ratio on the bond performance of concrete and steel bar after high temperature. Yuan et al. [16] found that the bond strength between concrete and steel bar showed a downward trend after high temperatures. The shape of the bond–slip curve of reinforced concrete after the high temperature was similar to that after normal temperature, but the bond–slip curve tended to be flat; that is, the bond strength decreased, and the slip value corresponding to the ultimate bond stress decreased. Xiao et al. [17] and Bingöl and Gül [18] pointed out that with the increase in temperature, the bond strength first increased and then decreased. In addition, when the temperature was high, the residual bond strength of water spray cooling decreased more than that of natural cooling. Wang et al. [19] and Hadadl et al. [20] analyzed the degradation law of the bond performance between concrete and steel bar with different steel bar diameters after high temperatures through experimental research. Royles and Morley [21] compared the relationship between the bond performance of concrete with steel bar and the mechanical properties of concrete under high temperatures. The results show that the bond performance of concrete and steel bar had a certain relationship with the concrete compressive strength. Xu and Liu [22] found that the steel bar diameter, the aggregate performance, and the water–cement ratio of concrete all had an impact on the bond performance of concrete and steel bar after high temperature, but the impact was small. Wang and Song [23] analyzed the relationship between the bond strength of concrete with steel bar and temperature and established a calculation model for the bond strength of concrete with steel bar after high temperatures. Yuan et al. [24] analyzed the influence of ambient temperature and cooling mode on the bond performance of concrete with steel bar and proposed a calculation model of bond strength between concrete and steel bar under different cooling modes after high temperatures. Morley and Royles [25] improved the test loading method based on summarizing the previous research results and proposed a test method suitable for different working conditions. Xu [26] investigated the bond performance of corroded steel bar and concrete after high temperatures, and the results showed that the corrosion rate of the steel bar, the temperature experienced, and the thickness of a protective layer of steel bar would affect the bond strength of concrete and steel bar. With the increase in temperature, the bond strength between concrete and steel bars first increased and then decreased. The bond–slip constitutive relation model of concrete and steel bar after the high temperature was also established. Zhou [27] used the finite element calculation software ABAQUS to carry out a numerical simulation on the bond performance of concrete and reinforcement under high temperatures and analyzed the change of concrete stress and the influence of concrete strength on the bond performance.

In recent years, some scholars began to investigate the performance of recycled concrete after high temperatures. Ohba et al. [28] studied the fire resistance of recycled concrete, and the results show that the compressive strength of recycled concrete after high temperature was lower than that of ordinary concrete. In addition, the strength loss rate increased with the increase of recycled aggregate replacement rate [29]. Xiao [30,31] obtained the relationship formula between the compressive strength of recycled concrete and temperature, and the relationship formula between the residual flexural strength and temperature. Wu et al. [32] found that the strength of recycled concrete with a water–binder ratio of 0.34 after high temperature was lower than that with a water–binder ratio of 0.4. Cao et al. [33] and Yang and Hou [34] found that recycled concrete-filled steel tubular short columns still had the high axial bearing capacity and good resistance to deformation after high temperatures. Huang and Xu [35] and Deng [36] studied the fire resistance of recycled concrete simply supported beams. The results show that recycled concrete could improve the fire resistance of beams.

At present, the research on the bond performance between recycled concrete and steel bar has gradually deepened [37,38,39], and some valuable research results have been obtained [40,41]. However, there were few studies focused on the bond performance between recycled concrete and steel bar after high temperatures [42]. Good bond performance between recycled concrete and steel bar was the key to the application of recycled concrete structures in high-temperature environment [43]. In this article, the bond performance between recycled concrete and steel bar after the high temperature was investigated, and the impact of different concrete types (ordinary concrete and recycled concrete) and the different temperature (20, 100, 150, 200, 250, and 300°C) on the bond performance after the high temperature was considered. The bond strength calculation expression and bond slip calculation expression were presented, which could provide a theoretical basis for the application of recycled concrete in high-temperature environment.

2 Test introduction

2.1 Materials and concrete mix

Ordinary coarse aggregate: Ordinary coarse aggregate is purchased from a stone field in Xuzhou City. The aggregate size is 5–31.5 mm, the water absorption rate is 1.5%, the mud content is 0.9%, and the crushing index is 11.2%.

Recycled coarse aggregate: recycled coarse aggregate is obtained by crushing, cleaning, and grading waste concrete. The aggregate size is 5–31.5 mm, the water absorption is 4.8%, the mud content is 1.4%, and the crushing index is 16.9%.

Fine aggregate: The fine aggregate adopts natural river sand with a particle size of 0.16–4.35 mm, fineness modulus of 2.8, and mud content of 1.1%.

Cement: P.O 42.5 Ordinary Portland Cement is used as the cementing material, 28 d compressive strength is 49.1 MPa, and 28 d flexural strength is 9.1 MPa.

Steel bar: HRB400 deformed steel bar with a diameter of 20 mm is used as the steel bar. Its tensile strength is 710 MPa, yield strength is 520 MPa, and elastic modulus is 200 GPa. The stirrup adopts an HPB300 plain round steel bar with a diameter of 6 mm, tensile strength is 425 MPa, yield strength is 310 MPa, and elastic modulus is 200 GPa.

The mix of ordinary concrete and recycled concrete is shown in Table 1 [44] (RC is recycled concrete; NC is ordinary concrete).

Concrete mix

| Type | Cement, (kg/m3) | Fine aggregate, (kg/m3) | Ordinary coarse aggregate (kg/m3) | Recycled coarse aggregate (kg/m3) | Water (kg/m3) |

|---|---|---|---|---|---|

| RC | 425 | 435 | 0 | 985 | 185 |

| NC | 425 | 435 | 985 | 0 | 185 |

2.2 Specimens design

The specimens of 150 mm × 150 mm × 150 mm were used to measure the concrete compressive strength before and after high temperature. The pull-out specimens of 150 mm × 150 mm × 300 mm were used to determine the bond performance of concrete and steel bars after high temperature, as shown in Figure 1. The specimen grouping is shown in Table 2.

Size of specimens (mm).

Specimen grouping

| Type | Specimen size (mm) | Temperature (°C) |

|---|---|---|

| RC | 150 × 150 × 150 | 20, 100, 150, 200, 250, 300 |

| 150 × 150 × 300 | ||

| NC | 150 × 150 × 150 | 20, 100, 150, 200, 250, 300 |

| 150 × 150 × 300 |

2.3 Test method

The test heating device is an industrial resistance furnace. The initial temperature in the furnace is room temperature (20°C), and the heating rate is 10°C/min [45]. After rising to the set temperature, the temperature is kept constant for 4 h and then the power supply of the resistance furnace is cut off. When the specimen is naturally cooled to 20°C, the specimen is taken out.

The pull-out test is carried out on the hydraulic servo testing machine. The applied load is controlled by displacement, and the displacement rate of the whole process is 0.3 mm/min [46]. The loading diagram is shown in Figure 2. Displacement sensors are set at the loading end and free end of the steel bar to obtain the average bond slip between concrete and steel bar. The displacement sensors are fixed on the loading frame through magnetic support. The bond strength can be calculated by Formula (1) (F is the load; d is the steel bar diameter; l a is the bond length).

Loading diagram.

The average bond slip can be calculated by Formula (2) (S f is the free end slip; S l is the load end slip).

3 Results and analysis

3.1 Compressive strength

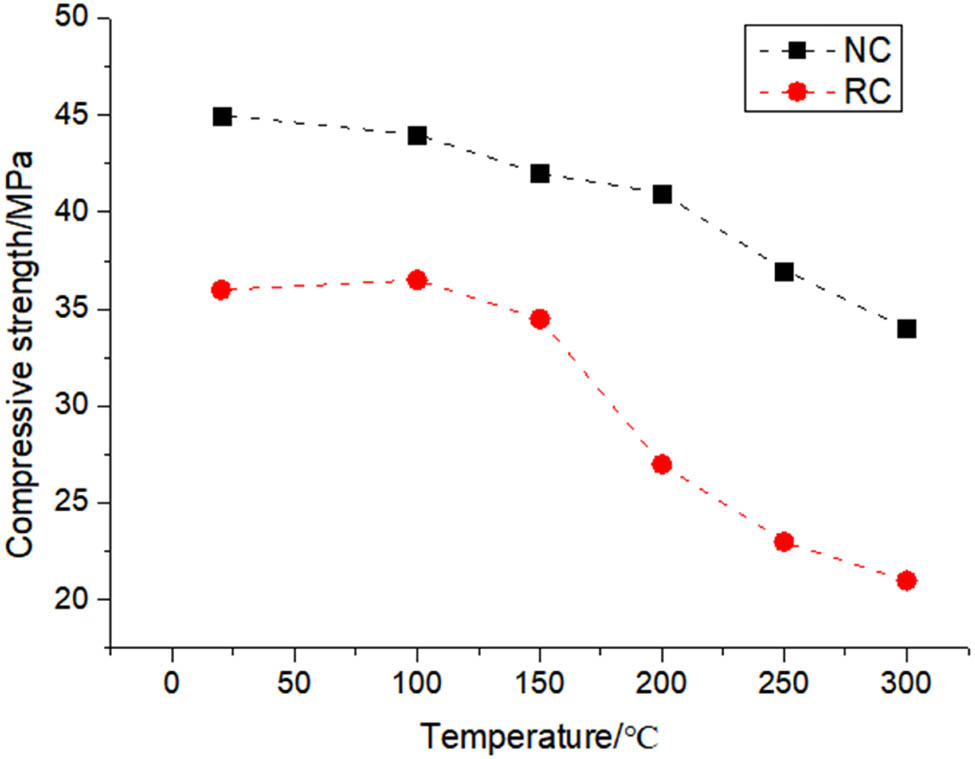

According to the relevant requirements in the Standard for Test Methods of Physical and Mechanical Properties of Concrete (GBT 50081-2019) [47], the compressive strength test of concrete specimens after the high temperature was carried out. The change of cube compressive strength with temperature is shown in Figure 3.

Compressive strength after high temperature.

It can be seen from Figure 3 that with the increase in temperature, the concrete compressive strength presented a downward trend. When the temperature was lower than 150°C, the concrete compressive strength did not decrease significantly; when the temperature exceeded 150°C, the concrete compressive strength decreased sharply. When the temperature reached 150°C, the compressive strength loss of recycled concrete reached 4.17%; When the temperature reached 300°C, the compressive strength loss reached 41.6%.

In addition, it can be seen from Figure 3 that the compressive strength loss of recycled concrete was higher than that of ordinary concrete. When the temperature reached 300°C, the compressive strength loss of ordinary concrete was 24.4%, while that of recycled concrete was 41.6%. The reason is that the micro-cracks and internal damage caused by recycled aggregate in the production process, resulting in the mechanical properties of concrete defects. After the high temperature, the internal damage is further intensified, resulting in the loss of concrete compressive strength. However, when the temperature reached 100°C, unlike ordinary concrete, the compressive strength of recycled concrete tended to rise. This is due to the high water absorption of recycled coarse aggregate, which leads to the high water content of recycled concrete. The evaporation of water under the action of high temperature slows down the internal temperature of concrete, accelerates the hydration of cement, and improves the compressive strength of concrete to a certain extent.

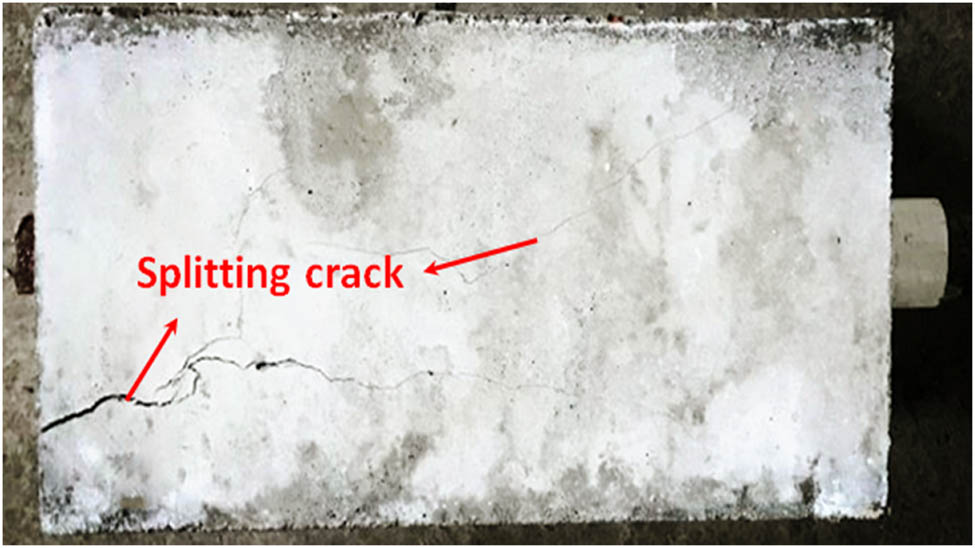

3.2 Bond failure modes

After high temperatures, the failure modes of ordinary concrete specimens and recycled concrete specimens were the same, both of which were the pull-out failure. In addition, when the ultimate load was reached, the surface of the pull-out specimen was accompanied by the appearance of splitting cracks, which were basically strip-shaped and have a small width. Due to the restraint of stirrups, the pull-out specimen was basically maintained as a whole, as shown in Figure 4.

Failure modes after high temperature.

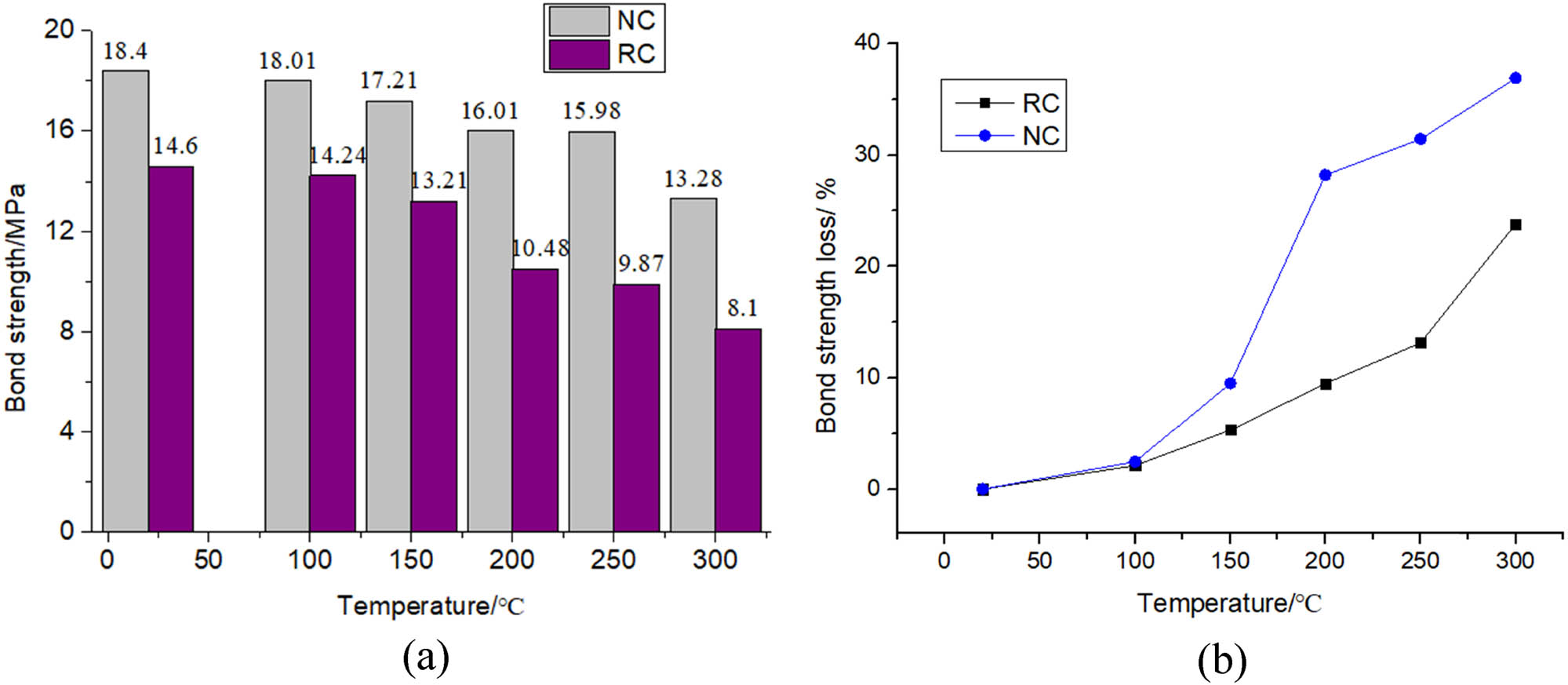

3.3 Bond strength

The variation of bond strength of concrete specimen with temperature is shown in Figure 5. It can be seen from Figure 5 that the bond strength of pull-out specimens showed a downward trend with the increase in temperature. After the temperature reached 200°C, the bond strength decreased most obviously. This is because when the concrete temperature exceeds 200°C, the cement gel will be damaged, which will lead to a significant reduction in the bond performance between reinforcement and concrete, leading to a significant deterioration of the bond performance [48]. In addition, it can also be seen that the loss of bond strength between concrete and reinforcement after the high temperature was higher than the loss of compressive strength of concrete, which indicated that the bond performance was affected not only by concrete strength, but also by the interaction between concrete and steel bar.

Bond strength after high temperature: (a) bond strength, (b) bond strength loss.

After the same temperature, the bond strength between recycled concrete and steel bar was significantly lower than that between ordinary concrete and steel bar. When the temperature was raised from 20 to 300°C, the bond strength between ordinary concrete and steel bar decreased by 27.8%, and that between recycled concrete and steel bar decreased by 44.5%. The reasons for this situation are as follows: on the one hand, recycled concrete has initial internal damage, and the internal damage continues to develop under the action of high temperature, resulting in more serious degradation of bond strength with steel bar; on the other hand, the initial strength of recycled concrete is lower than that of ordinary concrete, resulting in the initial bond strength of recycled concrete and steel bar is lower than that of ordinary concrete and steel bar [9,10].

3.4 Bond slip

The variation of the bond slip of the concrete specimen after the high temperature is shown in Figure 6. It can be seen from Figure 6 that the bond slip of the pull-out specimen increased with the increase in temperature. When the temperature reached 200°C, the bond slip increased most obviously. This is because when the temperature of the concrete exceeds 200°C, the bond strength of concrete and steel bar deteriorates significantly, resulting in a significant reduction in the bonding capacity of the concrete to the steel bar, resulting in a large relative slip.

Bond slip after high temperature.

It can also be seen from Figure 6 that after the same temperature, the bond slip between recycled concrete and steel bar was significantly higher than that between ordinary concrete and steel bar. When the temperature raised from 20 to 300°C, the bond slip between ordinary concrete and steel bar increased by 7.1%, and the bond slip between recycled concrete and steel bar increased by 7.9%. This is because the recycled concrete strength decreases more significantly after high temperature, and the contact surface between concrete and steel bar looser, resulting in a greater slip value of steel bar.

3.5 Calculation expression

The bond strength between concrete and steel bar after the high temperature was fitted by the linear function (as shown in Figure 7):

Linear fitting results of bond strength.

The bond slip between concrete and steel bar after the high temperature was fitted by the linear function (as shown in Figure 8):

Linear fitting results of bond slip.

Table 3 shows the bond strength experimental values

Bond strength experimental values

| F–T Cycles |

|

|

|

|---|---|---|---|

| 20 | 14.60 | 15.48 | 0.943 |

| 100 | 14.24 | 13.49 | 1.0567 |

| 150 | 13.21 | 12.25 | 1.078 |

| 200 | 10.48 | 11.00 | 0.953 |

| 250 | 9.87 | 9.78 | 1.009 |

| 300 | 8.10 | 8.51 | 0.952 |

Bond slip experimental values

| F–T Cycles |

|

|

|

|---|---|---|---|

| 20 | 0.314 | 0.256 | 1.227 |

| 100 | 0.424 | 0.464 | 0.914 |

| 150 | 0.562 | 0.594 | 0.946 |

| 200 | 0.714 | 0.724 | 0.986 |

| 250 | 0.867 | 0.854 | 1.015 |

| 300 | 1.034 | 0.984 | 1.051 |

4 Conclusions

The concrete compressive strength presented a downward trend with the increase in temperature. When the temperature reached 300°C, the compressive strength loss of recycled concrete reached 41.6%.

The compressive strength loss of recycled concrete was higher than that of ordinary concrete. When the temperature reached 300°C, the compressive strength loss of ordinary concrete was 24.4%, while that of recycled concrete was 41.6%.

The bond strength of pull-out specimens decreased with the increase of temperature, while the bond slip increased with the increase of temperature. When the temperature was raised from 20 to 300°C, the bond strength between recycled concrete and steel bar decreased by 44.5%, while the bond slip between recycled concrete and steel bar increased by 7.9%.

The bond strength between recycled concrete and steel bar was lower than that between ordinary concrete and steel bar, while the bond slip between recycled concrete and steel bar was higher than that between ordinary concrete and steel bar;

The bond strength calculation expression and bond slip calculation expression were presented, which could provide a theoretical basis for the application of recycled concrete in high temperature environment.

Acknowledgements

The study was carried out with the support of the Scientific research fund of Xuzhou College of Industrial Technology (XGY2021A008).

-

Author contributions: Qihao Wang: investigation, methodology, writing; Ting Wang and Xiaoyu Zhou: writing; Qunyu Cheng: visualization.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: All data used during the study appear in the submitted article.

References

[1] Arun A, Chekravarty D, Murali K. Comparative analysis on natural and recycled coarse aggregate concrete. Mater Today Proc. 2021. ahead-of-print. 10.1016/j.matpr.2021.04.352.Search in Google Scholar

[2] Su T, Wang T, Wang CC, Yi HH. The influence of salt-frost cycles on the bond behavior distribution between rebar and recycled coarse aggregate concrete. J Build Eng. 2022;45:103568.10.1016/j.jobe.2021.103568Search in Google Scholar

[3] Su T, Wu J, Yang GX, Zou ZH. Bond behavior between recycled coarse aggregate concrete and steel bar after salt-frost cycles. Constr Build Mater. 2019;226(11):673–85.10.1016/j.conbuildmat.2019.07.301Search in Google Scholar

[4] Bassam A, Ahmad H, Mohamed A, Abdullah M, Ibrahim S. Effect of air agent on mechanical properties and microstructure of lightweight geopolymer concrete under high temperature. Case Stud Constr Mat. 2022;16:00951.Search in Google Scholar

[5] Akhtar M, Halahla A, Almasri A. Experimental Study on Compressive Strength of Recycled Aggregate Concrete Under High Temperature. Struct Durab Health Monit. 2021;15(4):335–48.10.32604/sdhm.2021.015988Search in Google Scholar

[6] Parthasarathi N, Satyanarayanan KS, Thamilarau V, Prakash M, Punnapu A. Linear analysis of a two-dimensional multistorey reinforced concrete frame under high temperature at different column locations. J Struct Fire Eng. 2019;10(3):317–23.10.1108/JSFE-03-2018-0007Search in Google Scholar

[7] Parthasarathi N, Satyanarayanan KS. Progressive collapse behavior of reinforced concrete frame exposed to high temperature. J Struct Fire Eng. 2021;12(1):110–24.10.1108/JSFE-05-2020-0016Search in Google Scholar

[8] Jernimo VA, Piccinini AC, Silva BV, Godinho D, Vargas A. Influence of concrete admixture on the bond strength of reinforced concrete submitted to high temperature. Revista IBRACON de Estruturas e Materiais. 2020;13(2):212–21.10.1590/s1983-41952020000200003Search in Google Scholar

[9] Su T, Wang CX, Cao FB, Zou ZH, Wang CG, Wang J, et al. An overview of bond behavior of recycled coarse aggregate concrete with steel bar. Rev Adv Mater Sci. 2021;60(1):127–44.10.1515/rams-2021-0018Search in Google Scholar

[10] Su T, Huang ZF, Yuan JF, Zou ZH, Wang CG, Yi HH. Bond properties of deformed rebar in frost-damaged recycled coarse aggregate concrete under repeated loadings. J Mater Civ Eng. 2022;34(10):04022257.10.1061/(ASCE)MT.1943-5533.0004401Search in Google Scholar

[11] Deng CX, Daud JR, Yuan CX. Bonding between high strength rebar and reactive powder concrete. Comput Concr. 2014;13(3):411–21.10.12989/cac.2014.13.3.411Search in Google Scholar

[12] Ahangarnazha BH, Pourbaba M, Afkar A. Bond behavior between steel and glass fiber reinforced polymer (GFRP) bars and ultra high performance concrete reinforced by multi-walled carbon nanotube (MWCNT). Steel Compos Struct An Int J. 2020;35(4):463–74.Search in Google Scholar

[13] Niu XY, Wang QF, Yang YX. Experimental study on bond-anchorage properties of fine grain steel bars in common concrete after high temperature. Build Struct. 2012;42(3):116–8. (in Chinese)Search in Google Scholar

[14] Tang RR, Xie FD, Liu DD. Study on the bond performance between reinforcement and concrete after high temperature. Build Struct. 2013;43(S):1475–8. (in Chinese)Search in Google Scholar

[15] Arel HS, Yazici S. Effect of different parameters on concrete-bar bond under high temperature. ACI Mater J. 2014;111(6):633–9.10.14359/51686992Search in Google Scholar

[16] Yuan GL, Guo C, Lv ZT. Experimental study on bonding performance of reinforced concrete after high temperature. J Hehai Univ (Nat Sci Ed). 2006;34(3):290–4. (in Chinese)Search in Google Scholar

[17] Xiao J, Hou Y, Huang Z. Beam test on bond behavior between high-grade rebar and high-strength concrete after elevated temperatures. Fire Saf J. 2014;69:23–35.10.1016/j.firesaf.2014.07.001Search in Google Scholar

[18] Bingöl AF, Gül R. Residual bond strength between steel bars and concrete after elevated temperatures. Fire Saf J. 2009;44(6):854–9.10.1016/j.firesaf.2009.04.001Search in Google Scholar

[19] Wang KF, Xu QF, Liu TL. Experimental study on bond strength between reinforcement and concrete after natural cooling at high temperature. Constr Technol. 2005;34(8):6–11. (in Chinese)Search in Google Scholar

[20] Haddad RH, Al-Saleh RJ, Al-Akhras NM. Effect of elevated temperature on bond between steel reinforcement and fiber reinforced concrete. Fire Saf J. 2008;43(5):334–43.10.1016/j.firesaf.2007.11.002Search in Google Scholar

[21] Royles R, Morley PD. Further response of the bond in reinforced concrete to high temperatures. Mag Concr Res. 1985;35(124):157–63.10.1680/macr.1983.35.124.157Search in Google Scholar

[22] Xu QF, Liu TL. Experimental study on bond strength between reinforcement and concrete after natural cooling at high temperature. Constr Technol. 2005;34(8):6–11.Search in Google Scholar

[23] Wang Z, Song YP. Experimental study on the effect of high temperature on the tensile strength and bonding strength of concrete. Concrete. 2010;8:51–3. (in Chinese)Search in Google Scholar

[24] Yuan GL, Guo C, Li QT, Lv ZT. The damage of cooling environment after high temperature on the bonding performance of reinforced concrete. J China Univ Min Technol. 2005;5:605–8. (in Chinese)Search in Google Scholar

[25] Morley PD, Royles R. Response of the bond in reinforced concrete to high temperatures. Mag Concr Res. 1985;35(123):67–74.10.1680/macr.1983.35.123.67Search in Google Scholar

[26] Xu XC. Experimental study on bond performance of corroded steel bars and concrete after high temperature [dissertation]. Harbin: Harbin Institute of Technology; 2019. (in Chinese)Search in Google Scholar

[27] Zhou ZJ. Experimental study on dynamic bond properties between steel reinforcement and concrete at and after elevated temperature [dissertation]. Changsha: Hunan University; 2017. (in Chinese)Search in Google Scholar

[28] Ohba T, Kikuchi M, Dosho Y, Akiba J, Mizutani T, Miura T. Applicability of Recycled aggregate concrete for Structural concrete: Part3. The tensile properties. Summaries of technical papers of Annual Meeting Architectural Institute of Japan. A-1, Materials and construction. Architectural Institute of Japan; 1998.Search in Google Scholar

[29] Xie H, Geng O, Yuan J. Experimental study on the performance of recycled concrete after high temperature. Concrete. 2010;10:18–9 + 59. (in Chinese)Search in Google Scholar

[30] Xiao JZ, Huang YB. Residual compressive strength of recycled concrete after high temperature. J Build Mater. 2006;3:255–9. (in Chinese)Search in Google Scholar

[31] Xiao JZ, Huang YB, Zheng YC. Residual flexural strength of recycled concrete after high temperature. J Build Sci Eng. 2009;26(3):32–6. (in Chinese)Search in Google Scholar

[32] Wu YP, Li XL, Jiang HW, Zhang C. Residual compressive strength of recycled concrete with different mix proportions after high temperature. J Xi’an Univ Archit Technol (Nat Sci Ed). 2017;49(3):375–81. (in Chinese)Search in Google Scholar

[33] Cao WL, Bian JH, Dong HY, Zhang JW, Ni ZP. Fire resistance test and theoretical analysis of recycled coarse aggregate concrete columns. J Nat Disasters. 2012;21(2):207–14. (in Chinese)Search in Google Scholar

[34] Yang YF, Hou R. Theoretical analysis and experimental study of recycled concrete filled steel tubular short columns after high temperature. J Disaster Prev Mitig Eng. 2012;32(1):71–6. (in Chinese)Search in Google Scholar

[35] Huang Z, Xu M. Experimental study and analysis of flexural performance of recycled concrete beams under fire. Jiangsu Archit. 2012;5:16–9. (in Chinese)Search in Google Scholar

[36] Deng JJ. Experimental study on fire resistance of recycled concrete simply-supported beams [dissertation]. Beijing: Beijing Institute of Architecture and Engineering; 2012. (in Chinese)Search in Google Scholar

[37] Butler L, West JS, Tighe SL. The effect of recycled concrete aggregate properties on the bond strength between RCA concrete and steel reinforcement. Cem Concr Res. 2011;41(10):1037–49.10.1016/j.cemconres.2011.06.004Search in Google Scholar

[38] Wardeh G, Ghorbel E, Gomart H, Fiorio B. Experimental and analytical study of bond behavior between recycled aggregate concrete and steel bars using a pullout test. Struct Concr. 2017;18(5):811–24.10.1002/suco.201600155Search in Google Scholar

[39] Prince MJR, Singh B. Bond strength of deformed steel bars in high-strength recycled aggregate concrete. Mater Struct. 2015;48(12):3913–28.10.1617/s11527-014-0452-ySearch in Google Scholar

[40] Pour SM, Alam MS. Investigation of compressive bond behavior of steel rebar Embedded in concrete with partial recycled aggregate replacement. Structures. 2016;7:153–64.10.1016/j.istruc.2016.06.010Search in Google Scholar

[41] Prince MJR, Singh B. Bond behaviour of normal- and high-strength recycled aggregate concrete. Struct Concr. 2015;16(1):56–70.10.1002/suco.201300101Search in Google Scholar

[42] Yang O, Zhang B, Yan G, Chen J. Bond performance between slightly corroded steel bar and concrete after exposure to high temperature. J Struct Eng. 2018;144(11):04018209.1–10.10.1061/(ASCE)ST.1943-541X.0002217Search in Google Scholar

[43] Xu LL, Li XD, Gao LT, Wei X, Zhou LC. Study on the bonding properties of steel bars and recycled concrete under high temperature environment. Build Sci. 2022;38(11):112–20. (in Chinese)Search in Google Scholar

[44] Concrete admixture (GB8076-2008), China Standardization Administration, Beijing; 2007. (in Chinese)Search in Google Scholar

[45] Li Q, Huang X, Huang Z, Yuan G. Bond characteristics between early aged fly ash concrete and reinforcing steel bar after fire. Constr Build Mater. 2017;147:701–12.10.1016/j.conbuildmat.2017.04.184Search in Google Scholar

[46] Su T, Wu J, Zou ZH, Yuan JF. Bond performance of steel bar in RAC under salt-frost and repeated loading. J Mater Civ Eng. 2020;32(9):04020261.10.1061/(ASCE)MT.1943-5533.0003303Search in Google Scholar

[47] GBT 50081-2019. Standard for test methods of physical and mechanical properties of concrete. Beijing: China Construction Industry Press; 2019. (in Chinese)Search in Google Scholar

[48] Wu H, Chen LG. Experimental investigation on bond behavior of reinforced concrete after fire. Ind Build. 2010; 40(2):105–8. (in Chinese)Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.