Capacities of Various Plant and Machinery

Capacities of Various Plant and Machinery

Uploaded by

Srikar SandilyaCopyright:

Available Formats

Capacities of Various Plant and Machinery

Capacities of Various Plant and Machinery

Uploaded by

Srikar SandilyaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Capacities of Various Plant and Machinery

Capacities of Various Plant and Machinery

Uploaded by

Srikar SandilyaCopyright:

Available Formats

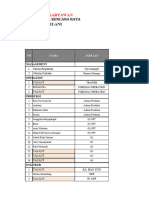

CAPACITIES OF VARIOUS PLANT AND MACHINERY

1.

DOZER (D 6)

Speed

No. of Passes

=

=

Width of Blade

Operating Efficiency

2 Mtr.

=

CAPACITY

1.5 Km / Hr.

75%

(1500 X 2 X 0.75) /3

Levelling Earth (750 x 0.2) 150 Cum / Hr.

2.

LOADER

(a) 3.1 cum. Bucket

Bucket

3.1 Cum

Cycle Time in Plat= 1 Minute

Efficiency

80%

CAPACITY = (3.1 X 0.8 X 60) /1 =

(b) 1.7 Cum Bucket

Bucket

Cycle Time in Plant =

Efficiency

1.7 Cum

2.5 Minute

80%

150 Cum / Hr.

CAPACITY = (1.7 X 0.8 X 60) /2.5 =

3.

35 Cum / Hr.

EXCAVATOR

Ck 90 (0.9 Cum Bucket)

Bucket

Cycle Time in Plant =

Efficiency

0.9 Cum

35 Sec.

80%

CAPACITY = (0.9 X 60 X 0.8X 60) /35 = 75 Cum / Hr.

4.

GRADER (Spreading & Grading) BEML 165 HP

Speed

Blade

3 Km / Hr.

1.7 Mtrs.

Layer Thickness

0.25 Mtrs.

No. of Passes

5 efficiency=75%

CAPACITY = (3000 X 1.7 X 0.75 X 0.25) /5 = 192 Cum /Hr.

5.

VIBRATORY COMPACTOR (Compaction) 8 to 10 T

Static wt. Dual Frequency,

Speed

Drum Width

=

=

2 Km /Hr.

2 Mtrs.

Layer Thickness

0.25 Mtrs.

Efficiency

80%

No. of Passes

CAPACITY = (2000 X 2.0 X 0.80 X 0.25) /6 = 130 Cum / Hr

6.

TIPPERS

Earth Work

Tipper capacity

7.5 Cum.

5.5 Km (11 KM Bothway)

Cycle Time

Average Lead

Loading Time & Turning On=

7 Mins.

Leading Average Speed (20 Km / Hr) = 33 Mins.

Unloading & Turning On

5 Mins

Total Cycle Time

45 Mins. Say 45 Min.

CAPACITY = (7.5 X 60) / 45 = 10 Cum / hour

7.

Batching Plant Cp 30

Batching Plant Capacity

8.

= 30 Cum/ Hr.

Efficiency

= 80%

Capacity

= 24 Cum/Hr.

Concrete Pump

Concrete Pump Capacity

= 30 Cum/ Hr.

9.

Efficiency

= 80%

Capacity

= 24 Cum/Hr

Transit Mixer

Transit Mixer capacity

6 Cum.

5.5 Km (11 KM Bothway)

Cycle Time

Average Lead

Loading Time & Turning On=

3.5 Mins.

Leading Average Speed (20 Km / Hr) = 33 Mins.

Unloading & Turning On

35 Mins

Total Cycle Time

71.5 Mins. Say 72 Min.

CAPACITY = (6 X 60) / 72 = 5 Cum / hour

ESTIMATING REQUIREMENT OF MACHINES ON THE PROJECT

ASSUMPTIONS

1.

2.

3.

4.

5.

Out Put of the machines to be taken as calculated before,.

Working day per month = 26 days

Working hours per day = 12 hours

Monsoon season is taken as 3 months.

Monsoon season efficiency is 75%

REQUIREMENT OF MACHINES

EXCAVATION

QUANTITY Maximum = 20000 CUM/ Months

QUANTITY Average

= 10378 Cum/ Months

Duration = 1 x 26 x 12 = 312 hours

Sr.No

Machines

Capacity

Peak

Average

Final

Excavator

75 cum/hr

0.85

0.44

Dozer

150 cum/hr

0.42

0.22

Loader

35 cum/hr

1.831

0.950

Tipper

10 cum/hr

6.410

3.32

FILLING , SPREADING AND COMPACTION

QUANTITY Maximum = 20000 CUM/ Months

QUANTITY Average

= 12681 Cum/ Months

Duration = 1 x 26 x 12 = 312 hours

CONCRETE

Sr.No

Machines

Capacity

Peak

Average

Final

Dozer

150 cum/hr

0.42

0.27

Grader

192 cum/hr

0.33

0.21

Compactor

130 cum/hr

0.49

0.31

Tipper

10 cum/hr

6.410

4.06

Duration = 1 x 26 x 8 = 208 hours

Sr.No

Machines

Uom

Peak

Average

Canal Bed

Cum/Months

90

54

Canal Slopes

Cum/Months

550

371

Total

Cum/Months

640

425

Sr.No

Machines

Capacity

Peak

Average

Final

Batching

Plant

24 cum/hr

0.12

0.08

Concrete

Pump

24 cum/hr

0.12

0.12

Transit

Mixer

5 cum/hr

0.615

0.40

Plate

Vibrator

You might also like

- Productivity of Plant and MachineryDocument65 pagesProductivity of Plant and Machinerynebiyu100% (2)

- BS Databook2002Document93 pagesBS Databook2002Dani WijayaNo ratings yet

- 33638-New - Holland - 8160 - 8260 - 8360 - 8560 - Manual - Download 2Document1,426 pages33638-New - Holland - 8160 - 8260 - 8360 - 8560 - Manual - Download 2Jennifer Goddard100% (2)

- Preambles To Daywork Rates and Daywork Rates For Labour and PlantDocument7 pagesPreambles To Daywork Rates and Daywork Rates For Labour and PlantGnabBangNo ratings yet

- Fire Fighting Work - Man HourDocument2 pagesFire Fighting Work - Man HourkdpmansiNo ratings yet

- Pow 17J00016Document48 pagesPow 17J00016amroussyNo ratings yet

- CraneDocument10 pagesCraneAvishek Sen Gupta100% (1)

- Method StatementDocument6 pagesMethod StatementAsyraf HakeemNo ratings yet

- Cycle Times of Different Equipment SequenceDocument5 pagesCycle Times of Different Equipment Sequencekonkashiva100% (1)

- Capacities of Various Plant and MachineryDocument7 pagesCapacities of Various Plant and MachineryBujjibabu KattaNo ratings yet

- Ch.3 - Earth Work & Equipment529015Document41 pagesCh.3 - Earth Work & Equipment529015Ahmed Amedi100% (1)

- Hauling & Disposal of Unsuitable Materials EstimateDocument2 pagesHauling & Disposal of Unsuitable Materials EstimatereynoldNo ratings yet

- Examples On Cycle TimeDocument27 pagesExamples On Cycle TimeNaty Griffin100% (1)

- Schdule B P2 PDFDocument52 pagesSchdule B P2 PDFYogeshDuttNo ratings yet

- Project Title: Automatic Fire Sprinkler System Location: Total Project Cost: 624,043.09Document6 pagesProject Title: Automatic Fire Sprinkler System Location: Total Project Cost: 624,043.09Reynaldo PesqueraNo ratings yet

- Chapter 1 - Construction EconomicsDocument41 pagesChapter 1 - Construction EconomicsNejib Ghazouani50% (2)

- Cost and Estimates - Proposed Power House 2 and Electrical SystemDocument3 pagesCost and Estimates - Proposed Power House 2 and Electrical SystemMa. Jessa DolladoNo ratings yet

- Bar Bending Schedule For RCC Beam: by Priyadharshini RajagopalDocument6 pagesBar Bending Schedule For RCC Beam: by Priyadharshini RajagopalSuresh DevarajanNo ratings yet

- ULAS - Fire Protection BOQ - Fire Pump Assembly Additional WorksDocument1 pageULAS - Fire Protection BOQ - Fire Pump Assembly Additional Workslito pacatangNo ratings yet

- BLDG Rates 72 73Document55 pagesBLDG Rates 72 73SarinNo ratings yet

- BSR New - Bahrain Rate AnalysisDocument67 pagesBSR New - Bahrain Rate AnalysistituskgNo ratings yet

- BUR Build Up RateDocument66 pagesBUR Build Up RateIzzul HaqeemiNo ratings yet

- Capabilities of EquipmentDocument2 pagesCapabilities of EquipmentmhergonzalesNo ratings yet

- Unit Rates For Excavation and EarthworkDocument5 pagesUnit Rates For Excavation and EarthworkOrion Jeremy0% (1)

- Gantt Chart - Project Management - Christal WongDocument3 pagesGantt Chart - Project Management - Christal WongChristal WongNo ratings yet

- (3964) - 103 B.E. (Civil) Quantity Surveying Contracts & TendersDocument4 pages(3964) - 103 B.E. (Civil) Quantity Surveying Contracts & TendersikushalpatilNo ratings yet

- Item:Ready Mix Concrete (3000 Psi) Ordinary Design Unit:Cubic MeterDocument51 pagesItem:Ready Mix Concrete (3000 Psi) Ordinary Design Unit:Cubic MeterCristina Dangla CruzNo ratings yet

- Schedule of Manpower Rates: SN Description Unit Rate (Aed) Rate (Usd)Document4 pagesSchedule of Manpower Rates: SN Description Unit Rate (Aed) Rate (Usd)Abdul RafeyNo ratings yet

- Earthworks Operation and EquipmentDocument37 pagesEarthworks Operation and EquipmentCarol Tumaneng100% (1)

- BMI Paraplast S DatasheetDocument3 pagesBMI Paraplast S DatasheetAndri RakotoNo ratings yet

- Build Up Rate I 1819Document5 pagesBuild Up Rate I 1819Norhafizah Khairol AnuarNo ratings yet

- Installation of New Caustic Soda PipelineDocument2 pagesInstallation of New Caustic Soda PipelineWilliam LimNo ratings yet

- Master List For Labor Eqpt MatlsDocument2 pagesMaster List For Labor Eqpt MatlsroldskiNo ratings yet

- Uni QS 3 Question PaperDocument2 pagesUni QS 3 Question PaperRrgs BandaraNo ratings yet

- 29 05 13 PDFDocument1 page29 05 13 PDFebsmsartNo ratings yet

- Cost of Handling and Transporting MaterialDocument30 pagesCost of Handling and Transporting MaterialPrince Ahmed Diboo100% (1)

- KnaufDocument28 pagesKnaufprokaNo ratings yet

- Analysis of Material Cost in Road ConstructionDocument8 pagesAnalysis of Material Cost in Road ConstructionMahesh JayawardanaNo ratings yet

- EandC Rate AnlysisDocument19 pagesEandC Rate AnlysisVenkata Tharun GangulaNo ratings yet

- HABIB RAFIQ (PVT.) Limited: List of Direct Labour (Hourly Cost)Document9 pagesHABIB RAFIQ (PVT.) Limited: List of Direct Labour (Hourly Cost)bolsamirNo ratings yet

- Output Per HourDocument19 pagesOutput Per HourGhian Carlo Garcia CalibuyotNo ratings yet

- Cost of Handling and TR Ansporting Material: 1 - Loading 2 - Hauling, Loaded 3 - Unloading 4 - Returning, EmptyDocument29 pagesCost of Handling and TR Ansporting Material: 1 - Loading 2 - Hauling, Loaded 3 - Unloading 4 - Returning, Emptyascom asNo ratings yet

- Quotation For CG Kerbstone 165 MM PDFDocument1 pageQuotation For CG Kerbstone 165 MM PDFGovind GyawaliNo ratings yet

- Trench Excavation Productive RateDocument1 pageTrench Excavation Productive RateIshan AththanayakeNo ratings yet

- Rates For Rate Analysis Excel FormatDocument23 pagesRates For Rate Analysis Excel FormatIswers GuptaNo ratings yet

- Detailed Estimates: Construction of 1-Unit Multipurpose Building Brgy. San Jose, Borbon, CebuDocument12 pagesDetailed Estimates: Construction of 1-Unit Multipurpose Building Brgy. San Jose, Borbon, CebuAnna Rose PueblaNo ratings yet

- Rate Analysis-RevDocument8 pagesRate Analysis-Revsrinivasa raoNo ratings yet

- BOQ - Civil, Structural and ArchitecturalDocument46 pagesBOQ - Civil, Structural and ArchitecturalVincent SaysonNo ratings yet

- Assignment Nicmar / Sode Office: Name: Mr. Prabhakar Prakash Shingrut Course: GPCBM Reg. No. 217-04-22-50914-2183Document18 pagesAssignment Nicmar / Sode Office: Name: Mr. Prabhakar Prakash Shingrut Course: GPCBM Reg. No. 217-04-22-50914-2183Prabhakar Shingrut100% (1)

- 20mm-Thick Cement Plastering in Cement MortarDocument4 pages20mm-Thick Cement Plastering in Cement Mortarksquare constructionNo ratings yet

- Labor Productivity and AnalysisDocument27 pagesLabor Productivity and AnalysisBasit AnwarNo ratings yet

- RCC (1:2:4) (Mechanical)Document2 pagesRCC (1:2:4) (Mechanical)micku72No ratings yet

- Abstract of Cost: Division Road Office, BiratnagarDocument8 pagesAbstract of Cost: Division Road Office, Biratnagarnitish JhaNo ratings yet

- Schedule of RatesDocument42 pagesSchedule of RatesShaukat Ali KhanNo ratings yet

- Mining and Earthmoving: Estimating Production Off-the-Job Example Problem (English) Example Problem (Metric)Document4 pagesMining and Earthmoving: Estimating Production Off-the-Job Example Problem (English) Example Problem (Metric)ali alilouNo ratings yet

- FE TQ Set 68Document17 pagesFE TQ Set 68Aris TesoroNo ratings yet

- 1 Earth Works: Description Rate UnitDocument4 pages1 Earth Works: Description Rate UnitPrakash Rao GurpurNo ratings yet

- Estimating Costing VDocument4 pagesEstimating Costing Vशंकर थापाNo ratings yet

- Estimating CostingDocument15 pagesEstimating CostingAarush MauryaNo ratings yet

- ACT 540 Ghana Highway Authority Act, 1997Document16 pagesACT 540 Ghana Highway Authority Act, 1997Thomas KutinNo ratings yet

- DSR Analizer Ver.12Document368 pagesDSR Analizer Ver.12sunil777tvpm100% (3)

- Construction UpdatesDocument5 pagesConstruction Updatesshivaprasadhm90No ratings yet

- Capacities of Various Plant and Machinery: 1. Dozer (D - 6)Document9 pagesCapacities of Various Plant and Machinery: 1. Dozer (D - 6)Abdul RafeyNo ratings yet

- Capacities of Various Plant and Machinery666Document21 pagesCapacities of Various Plant and Machinery666Marvin MessiNo ratings yet

- Lathe MachineDocument27 pagesLathe MachineRAGHVENDRA SINGHNo ratings yet

- JD 5603Document314 pagesJD 5603Kassio SalesNo ratings yet

- Unit 2 Earth Work EquipmentDocument25 pagesUnit 2 Earth Work EquipmentSrijaJuluruNo ratings yet

- CNC Turret Punch Press Import SampleDocument13 pagesCNC Turret Punch Press Import Samplealiroindia12No ratings yet

- Final CPM Sem1Document11 pagesFinal CPM Sem1Fatin HazwaniNo ratings yet

- Catalogo Kits Turbo ATUALIZADO 19-07-2018-Ilovepdf-CompressedDocument62 pagesCatalogo Kits Turbo ATUALIZADO 19-07-2018-Ilovepdf-CompressedOrimak Maquina100% (1)

- Time Sheet ExchavatorDocument2 pagesTime Sheet Exchavatorabu ubaidahNo ratings yet

- Hafiz Bintang From Classed Si-2cDocument4 pagesHafiz Bintang From Classed Si-2cBrian Christoper S. PanggorgaNo ratings yet

- Plan MPP, Gaji, Trans THN 2024Document39 pagesPlan MPP, Gaji, Trans THN 2024Sisca SiraitNo ratings yet

- Lathe Project - Cannon Barrel (TMJ 209)Document7 pagesLathe Project - Cannon Barrel (TMJ 209)sanu7blyNo ratings yet

- Project Management Timeline TemplateDocument18 pagesProject Management Timeline TemplatejizuNo ratings yet

- Carraro 707 P1Document1 pageCarraro 707 P1davi henrique boaz100% (1)

- 55ton Sany Crane Crawler Bekas Scc550e - Buy 55ton Sany Crane, 55ton Sany Crawler Crane, 55ton Sany Scc550e Product OnDocument5 pages55ton Sany Crane Crawler Bekas Scc550e - Buy 55ton Sany Crane, 55ton Sany Crawler Crane, 55ton Sany Scc550e Product OnBudi PrayitnoNo ratings yet

- Electro Motion Sheet Metal Fabrication Stock ListDocument12 pagesElectro Motion Sheet Metal Fabrication Stock ListElectro Motion UK (Export) LtdNo ratings yet

- Hydril Blowout Preventers Ram AssembliesDocument2 pagesHydril Blowout Preventers Ram AssembliesJIN WANGNo ratings yet

- Faculty RoomDocument1 pageFaculty RoomDavid ReyesNo ratings yet

- Pala Cable CAT - UNI Servicios Auxiliares 2015-1 PDFDocument45 pagesPala Cable CAT - UNI Servicios Auxiliares 2015-1 PDFPedro Vasquez AcevedoNo ratings yet

- TNN CNC Lathe Machine CatalogueDocument3 pagesTNN CNC Lathe Machine Catalogueneda100% (2)

- Fleet Matching and SynchronisingDocument22 pagesFleet Matching and SynchronisingAMPamasengiNo ratings yet

- 2x Gildemeister CTV 250 Mit Roboter - 89-000489 - en-GB PDFDocument3 pages2x Gildemeister CTV 250 Mit Roboter - 89-000489 - en-GB PDFАлександра КваснинаNo ratings yet

- FAM Ball - Mills - E - 2021Document2 pagesFAM Ball - Mills - E - 2021ramecatronicaNo ratings yet

- NPI PIPO Report - ADSD-S (September 2018)Document8 pagesNPI PIPO Report - ADSD-S (September 2018)Victor PinedoNo ratings yet

- Group Group Description Asset - Code Asset DescriptionDocument39 pagesGroup Group Description Asset - Code Asset DescriptionM V BHASKARARAONo ratings yet

- PC W130B 08 EUDocument178 pagesPC W130B 08 EUОблачно100% (1)

- 2a. Performance Traksi CKMT September 2023Document109 pages2a. Performance Traksi CKMT September 2023yadiky12No ratings yet

- Earth Moving Catalogue 2015-2016Document381 pagesEarth Moving Catalogue 2015-2016Latonya Ross100% (1)