Kiln Ins Pection Sheet

Kiln Ins Pection Sheet

Uploaded by

Abul Qasim QasimCopyright:

Available Formats

Kiln Ins Pection Sheet

Kiln Ins Pection Sheet

Uploaded by

Abul Qasim QasimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Kiln Ins Pection Sheet

Kiln Ins Pection Sheet

Uploaded by

Abul Qasim QasimCopyright:

Available Formats

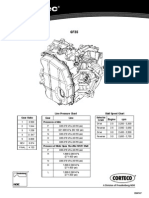

Kiln supporting roller bearing adjustment and bearing inspection sheet

Working parameters

7.5 22.9

42.7 35.2

22.8 2.0

31.6 33.6

1-2

1-3

Date

Kiln capacity

310 /h

KilnRPM

Main motor amps

Trust roller preasure

Kiln axial position

2,48

480

55

6,46

Ambient temp.

Time

2/13/2014

rpm

A

Bar

Support rollers adjustment

14.00-16.00

Roller

Bearing

Data

Movements,

-3

1-1

1-2

1-3

Left

Axial movements of

the kiln, mm

5

Right

Sup. 2

1-4

38.0 33.4

4.6 22.3

1-1

t t t1 -

1-4

Left

29.4 35.4

21.8 6.0

11.1 24.1

47.8 36.7

22.9 3.8

36.1 39.9

2-2

Sup.

Migration, /round

1

2

3

Tyres Migration

tire temps. (avr.)

shells temp. (Max.)

Cooling water preasure,

Mpa

6.0

inlet side

153.0

outlet side

216.0

inlet side

275.0

outlet side

276.0

In

out

11.0

19.0

182.6

172.0

180.0

186.0

291.6

324.0

340.0

353.0

0.35

0.20

Bearing

Contact (X)

Reaction

direction

1-1

1-2

1-3

o

o

1-4

2-1

2-2

2-3

2-4

Right

3-1

3-2

downwords

Left

3-3

3-4

upwords

2-2

2-3

2-4

Right

Sup. 3

3-1

Left

3-2

3-3

Right

3-4

+ movements in

movements out

Kiln bearing inspection sheet

2-3

Roller

Temperature

Shaft

Tr. Should

oil

Oil condition

oil level

Shaft condition

Sup 1

2-1

2-4

42.5 37.0

33.5 38.8

5.5 24.3

22.8 5.3

5.3 26.5

41.7 36.4

21.5 9.0

25.7 34.7

3-2

3-1

48.1 36.7

11.4 22.8

Right

Left

Sup 2

Right

Left

3-3

upwords

upwords

upwords

downwords

4.6

7.5

2.0

38.0

42.7

33.6

33.4

35.2

31.6

22.3

22.9

22.8

OK

OK

foam

OK

OK

OK

1- 25 grooves

6.0

35.4

29.4

21.8

OK

OK

1- 100 grooves

5.5

11.1

3.8

42.5

47.8

39.9

38.8

37.0

36.7

36.1

33.5

24.3

24.1

22.9

22.8

OK

OK

foam

OK

OK

OK

2 - 250 grooves

OK

OK

OK

48.1

41.7

36.7

36.4

22.8

26.5

25.7

35.3

21.5

21.4

OK

OK

OK

OK

34.7

38.3

OK

OK

OK

foam

OK

OK

5.3

bronze on the shaft

1 - 200 grooves

OK

1 - 200 grooves

Sup 3

3-4

35.3 38.3

21.4 3.0

additional comments:

11.4

5.3

9.0

3.0

70

3.5

2-1

1-1

30

Sup. 1

grooves 100-250

grooves 100-200

comments

38.0 33.4 t1 20 .

4.6 22.3 t2 250-300 .

You might also like

- 6F35 Boletín TécnicoDocument8 pages6F35 Boletín TécnicoReydeEspa1100% (2)

- Agitator DesignDocument7 pagesAgitator DesignTint Tiger100% (4)

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- XQ89 3YC英文说明书Document25 pagesXQ89 3YC英文说明书ADM MTC100% (1)

- Operation Manual: ZQ203-125 POWER TONGSDocument25 pagesOperation Manual: ZQ203-125 POWER TONGSMohamed Anwar100% (2)

- VOLVO EC360C HR EC360CHR EXCAVATOR Service Repair Manual PDFDocument19 pagesVOLVO EC360C HR EC360CHR EXCAVATOR Service Repair Manual PDFfjjsjekdmme0% (1)

- S4L2-Z363SP (H) (SPC-S4L-279 Rev 2) MEEDocument14 pagesS4L2-Z363SP (H) (SPC-S4L-279 Rev 2) MEERusmiyanto YantoNo ratings yet

- VOLVO EC235D NL EC235DNL EXCAVATOR Service Repair Manual PDFDocument19 pagesVOLVO EC235D NL EC235DNL EXCAVATOR Service Repair Manual PDFfjjsjekdmme100% (1)

- Technical Diary 200mwDocument165 pagesTechnical Diary 200mwSaurabh Kumar100% (1)

- 16procedure of Boiler Steam Blowing OK (Only Oil) PASSEDDocument65 pages16procedure of Boiler Steam Blowing OK (Only Oil) PASSEDfirmanallisan100% (1)

- Bricks Calculation of Mixing Ratio (ISOand VDZ Shapes)Document9 pagesBricks Calculation of Mixing Ratio (ISOand VDZ Shapes)Abul Qasim Qasim100% (1)

- PPSDocument22 pagesPPSSam100% (1)

- Inj - Pump C Alibratio N Data: 1.test ConditionsDocument2 pagesInj - Pump C Alibratio N Data: 1.test ConditionsDavid Carlos Dady0% (1)

- Katalog Harga Mesin Es, Cold Storage & Abf RPM Periode September-Desember 2018Document19 pagesKatalog Harga Mesin Es, Cold Storage & Abf RPM Periode September-Desember 2018Iman JuniantoNo ratings yet

- Operation Manual: ZQ203 - 100 Drill Pipe Power TongDocument24 pagesOperation Manual: ZQ203 - 100 Drill Pipe Power TongNgwe Min TheinNo ratings yet

- Accent Compession Pressure InspectionDocument12 pagesAccent Compession Pressure Inspectionflash_24014910No ratings yet

- HCS3-MaintenanceManual1 0Document175 pagesHCS3-MaintenanceManual1 0JoseNo ratings yet

- mainteESAO301 2 0Document191 pagesmainteESAO301 2 0Enrique PeraltaNo ratings yet

- Camshaft Timing SIS 2.0Document7 pagesCamshaft Timing SIS 2.0isaac989No ratings yet

- SEBF8375 головка 3300Document12 pagesSEBF8375 головка 3300Евгений АбрамовNo ratings yet

- Analysis of Performance and Reliability of BPPT 3MW Condensing Type Geothermal Power Plant - Kamojang During 3x24 Hours Continuous Synchronous TestingDocument7 pagesAnalysis of Performance and Reliability of BPPT 3MW Condensing Type Geothermal Power Plant - Kamojang During 3x24 Hours Continuous Synchronous TestingDony DamaraNo ratings yet

- Energy Turbine Perpormance SpecificationDocument49 pagesEnergy Turbine Perpormance Specificationv.aravindharajan7No ratings yet

- TorsionalVibration PresentationDocument20 pagesTorsionalVibration PresentationValentin JonovNo ratings yet

- S4S-61SD (SPC-S4S-255 Rev 1) For Reference OnlyDocument15 pagesS4S-61SD (SPC-S4S-255 Rev 1) For Reference OnlyJorge luisNo ratings yet

- YanmarDocument2 pagesYanmarRicardo Barbosa100% (2)

- Technical Diary TurbineDocument29 pagesTechnical Diary TurbineDurjoy Chakraborty100% (1)

- TERZ 94OMManualRev0107 PDFDocument66 pagesTERZ 94OMManualRev0107 PDFImran Ahmed KhanNo ratings yet

- Es62 5aDocument28 pagesEs62 5aRichardReveloNo ratings yet

- S3Q2-Y3T61DP (SPC-S3Q-016 Rev 2) MEE StandardDocument15 pagesS3Q2-Y3T61DP (SPC-S3Q-016 Rev 2) MEE StandardGeorge TekinovNo ratings yet

- BoqDocument18 pagesBoqPradeep Yallanki100% (1)

- Servicemanual CS E9E12CKPDocument94 pagesServicemanual CS E9E12CKPDiego CucuzzaNo ratings yet

- 992D Valve Set InstructionsDocument7 pages992D Valve Set InstructionsJohn GrayNo ratings yet

- Atmospheric Distillation Unit-2 (Au-Ii)Document8 pagesAtmospheric Distillation Unit-2 (Au-Ii)rameshkarthik810No ratings yet

- Carriage-Mounted Unwinding Station With Pneumatic Mandrel and BrakeDocument19 pagesCarriage-Mounted Unwinding Station With Pneumatic Mandrel and BrakeDeniMestiWidiantoNo ratings yet

- Tja20 50 Bucking UnitDocument20 pagesTja20 50 Bucking UnitHussein_ipsNo ratings yet

- Subaru Eh025 Engine Parts ManualDocument78 pagesSubaru Eh025 Engine Parts ManualJose SanchezNo ratings yet

- AIP 2227 XR (H) (V) HP Element GasketDocument2 pagesAIP 2227 XR (H) (V) HP Element Gasketmohammed ridhaNo ratings yet

- Hyundai D6GA Engine Mechanical SystemDocument97 pagesHyundai D6GA Engine Mechanical SystemBigfair HD7890% (29)

- Temperature, Pressure, & Speed Sensing Systems of A Gas Turbine First Stage Rotor BladeDocument9 pagesTemperature, Pressure, & Speed Sensing Systems of A Gas Turbine First Stage Rotor BladeYussif NawafNo ratings yet

- Terz94 - Manual - GB Status 05 05Document47 pagesTerz94 - Manual - GB Status 05 05Matias Van Balen BlankenNo ratings yet

- Qurayyah Fail Free Commissioning-STG-General SpecificDocument73 pagesQurayyah Fail Free Commissioning-STG-General SpecificPrabhudhasanNo ratings yet

- Examples of Balancing Method - Four-Run and Least-Squares Influence CoefficientsDocument44 pagesExamples of Balancing Method - Four-Run and Least-Squares Influence CoefficientsNguyen Anh TuNo ratings yet

- Technical Diary Turbine KSKDocument31 pagesTechnical Diary Turbine KSKdreamboy87100% (2)

- r40gs10 Riello GasDocument11 pagesr40gs10 Riello GasPablo MartinezNo ratings yet

- Pipeline SelectionDocument3 pagesPipeline SelectionSainath NilajkarNo ratings yet

- 300 Mod 2Document19 pages300 Mod 2gherksrNo ratings yet

- 800 MWDocument6 pages800 MWRamesh Babu K100% (2)

- Experiment No.03-1Document6 pagesExperiment No.03-1Nauman AsifNo ratings yet

- Designand Executionofa Test Rigfor Studyingthe Vibrationsofa GearboxDocument8 pagesDesignand Executionofa Test Rigfor Studyingthe Vibrationsofa GearboxduongnnNo ratings yet

- Archivo PDFDocument8 pagesArchivo PDFhomero castroNo ratings yet

- Shape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationFrom EverandShape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationNo ratings yet

- Analytical Troubleshooting of Process Machinery and Pressure Vessels: Including Real-World Case StudiesFrom EverandAnalytical Troubleshooting of Process Machinery and Pressure Vessels: Including Real-World Case StudiesRating: 3 out of 5 stars3/5 (1)

- Hybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignFrom EverandHybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignNo ratings yet

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferFrom EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferRating: 5 out of 5 stars5/5 (2)

- The Red Baron’s Ultimate Ducati Desmo Manual: BELT-DRIVEN CAMSHAFTS L-TWINS 1979 TO 2017From EverandThe Red Baron’s Ultimate Ducati Desmo Manual: BELT-DRIVEN CAMSHAFTS L-TWINS 1979 TO 2017No ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Shimming of Chair PadsDocument5 pagesShimming of Chair PadsRamsai ChigurupatiNo ratings yet

- Ringformationinkilns 140529065933 Phpapp01Document2 pagesRingformationinkilns 140529065933 Phpapp01Abul Qasim QasimNo ratings yet

- Shimming of Chair PadsDocument5 pagesShimming of Chair PadsRamsai ChigurupatiNo ratings yet

- Philips Kiln ServicesDocument20 pagesPhilips Kiln ServicesAbul Qasim QasimNo ratings yet

- Base Case Diameter Volume Litres KG/L Mass Per Ball KG Number Per Tonne % Comp No. BallsDocument2 pagesBase Case Diameter Volume Litres KG/L Mass Per Ball KG Number Per Tonne % Comp No. BallsAbul Qasim QasimNo ratings yet

- Argument Against MM BallsDocument2 pagesArgument Against MM BallsAbul Qasim QasimNo ratings yet

- Lucky Cement Ltd. Unit 2: Location Aqc 1 Aqc 2Document1 pageLucky Cement Ltd. Unit 2: Location Aqc 1 Aqc 2Abul Qasim QasimNo ratings yet

- Ovality MeasurmentDocument11 pagesOvality MeasurmentAbul Qasim Qasim0% (1)

- Fuel & Energy Comparison Between B/E & Air LiftDocument1 pageFuel & Energy Comparison Between B/E & Air LiftAbul Qasim QasimNo ratings yet