1 - UTP 614 KB

1 - UTP 614 KB

Uploaded by

Krishna VachaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 - UTP 614 KB

1 - UTP 614 KB

Uploaded by

Krishna VachaCopyright:

Available Formats

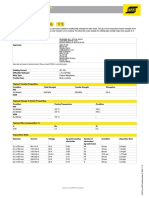

UTP 614 Kb

basic coated stick electrode, AC-weldable

Classifications

EN ISO 2560-A

AWS A5.1

E 42 3 B32 H10

E 7018

Characteristics and field of use

UTP 614 Kb is a double coated stick electrode with a universally suited application field. It is used

in industry, trade, as well as in production and repair welds for diverse base materials.

Due to a special coating formula UTP 614 Kb shows a smooth and finely rippled weld seam, a

stable arc, easy slag removal, and a very slight increase of the weld, as well as a notch-free seam.

The weld metal is little affected by steel impurities. Due to the double coating the stick electrode is

excellently suited for root- and out-of-position welding. Recovery 120%, H2 content < 8 ml/100g.

Base materials

Unalloyed construction steels

S235JRG2 S355J2; E295, E335, St35, St 45, St 35.8, St45.8, St50-2

Boiler steels

P235GH, P265GH, P295GH

Fine-grained

steels up to S355N

Shipbuilding

steels A E, AH - EH

Cast steels

C 35, GS-38, GS-45

Typical analysis in %

C

Si

Mn

Fe

0,06

0,7

0,9

balance

Mechanical properties of the weld metal

Yield strength RP0,2

Tensile strength Rm

Elongation A

Impact strength KV

MPa

MPa

-30C

> 420

> 510

> 22

> 100

> 47

Welding instruction

Ignite the electrode and stay at the ignition point until the electric arc is fully stabilised. Keep a short

arc during the welding process. Hold stick electrode vertical to the weldment with slight weaving.

Redrying: 2 3 h at 250 300C. Only use dry stick electrodes

Welding positions

Current type DC (+) / AC

Approvals

TV (No. 10571), DB (No. 10.138.03), GL, BV, DNV, ABS, LR

Recommended welding parameters

Electrodes x L [mm]

2,5 x 350

3,2 x 350

3,2 x 450

4,0 x 450

5,0 x 450

Amperage [A]

60 90

100 140

100 140

140 180

190 250

All information provided is based upon careful investigation and intensive research.

However, we do not assume any liability for correctness and information is subject to change without notice.

03/2014 Rev. 0

www.voestalpine.com/welding

You might also like

- Welding Wires & Rods: MIG/MAG - Low Alloyed Steels: ClassificationDocument6 pagesWelding Wires & Rods: MIG/MAG - Low Alloyed Steels: ClassificationTaufikWibowoNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Eutectrode 6666: Manual Arc Welding ElectrodeDocument1 pageEutectrode 6666: Manual Arc Welding ElectrodemortezaheidarianNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- Welding Technology Steelconstr - EngDocument32 pagesWelding Technology Steelconstr - EngLukman Tarigan SumatraNo ratings yet

- Официальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@Document1 pageОфициальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@brayanNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- Utp 7015 NKDocument1 pageUtp 7015 NKsergey.pu4kaNo ratings yet

- Select Arc Catalogue Part 2Document10 pagesSelect Arc Catalogue Part 2lionheartedNo ratings yet

- مكونات نقط اللحام شامل بنط اللحامDocument2 pagesمكونات نقط اللحام شامل بنط اللحامdaha333No ratings yet

- Mild Steel Welding Electrodes: Salient FeaturesDocument16 pagesMild Steel Welding Electrodes: Salient FeaturesHandrea Hadi SaputraNo ratings yet

- MIP Bohler Welding Austwqrwq2332e3eddwria 98Document1 pageMIP Bohler Welding Austwqrwq2332e3eddwria 98maxi27No ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- Böhler Foxa7 Fox A 7Cn: DescriptionDocument1 pageBöhler Foxa7 Fox A 7Cn: Description2003vinayNo ratings yet

- DT-1.4462 WP 380: Stainless Steel Subarc Wire Fused Welding FluxDocument1 pageDT-1.4462 WP 380: Stainless Steel Subarc Wire Fused Welding Fluxmarketing.automatizatNo ratings yet

- Mild Steel 490mpa High Tensile Strength SteelDocument38 pagesMild Steel 490mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- L1 34258 en T Union S 2 - UV 418 TT en MDPK 5aDocument2 pagesL1 34258 en T Union S 2 - UV 418 TT en MDPK 5aKrishna VachaNo ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeNguyen Anh TuanNo ratings yet

- Welding Consumables For Hydro Power StationsDocument16 pagesWelding Consumables For Hydro Power StationsMohamed FaragNo ratings yet

- 01112015000000B - Boehler EMK 8 - Solid WireDocument2 pages01112015000000B - Boehler EMK 8 - Solid WirePopa RobertNo ratings yet

- Supercito 7018S: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageSupercito 7018S: MMA Electrodes C-MN and Low-Alloy SteelsDante Coloma JimenezNo ratings yet

- Electrode Equivalaent NumbersDocument2 pagesElectrode Equivalaent NumbersRamdas100% (2)

- CW CAT TABEL25!08!09 BewerkversieDocument46 pagesCW CAT TABEL25!08!09 BewerkversieAdeKusumahNo ratings yet

- GMAW Welding ParametersDocument32 pagesGMAW Welding Parametersnarutothunderjet216No ratings yet

- Utp 7015Document1 pageUtp 7015cesarlopezpolysiusNo ratings yet

- UTP 641 KBDocument1 pageUTP 641 KBVIRPOPNo ratings yet

- Utp 630Document1 pageUtp 630brayanNo ratings yet

- Tenacito R: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageTenacito R: MMA Electrodes C-MN and Low-Alloy SteelsAnonymous hNpF6INo ratings yet

- Electrodes EnglishDocument139 pagesElectrodes Englishcostelino72No ratings yet

- Select Arc Catalogue Part 1Document10 pagesSelect Arc Catalogue Part 1lionheartedNo ratings yet

- Esab Ferroweld1Document1 pageEsab Ferroweld1Gokul RajanNo ratings yet

- Utp 63Document1 pageUtp 63brayanNo ratings yet

- Utp Ledurit 65Document1 pageUtp Ledurit 65Ulisses SilvaNo ratings yet

- ESAB Consumable PDFDocument165 pagesESAB Consumable PDFbond8031No ratings yet

- Fox CN 23-12-ADocument1 pageFox CN 23-12-AVIRPOPNo ratings yet

- Avesta 2205 - MIGDocument1 pageAvesta 2205 - MIGgonzomapsNo ratings yet

- OK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWDocument1 pageOK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWGokul RajanNo ratings yet

- Böhler 7018-1 h4r enDocument1 pageBöhler 7018-1 h4r enValentin Hernández TrianoNo ratings yet

- Katalogas enDocument20 pagesKatalogas enEman AdelNo ratings yet

- M El p0.2 2Document3 pagesM El p0.2 2Gopal RamalingamNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- Utp Ledurit 65Document1 pageUtp Ledurit 65brayanNo ratings yet

- Catalogue MetalweldDocument17 pagesCatalogue MetalweldRadivojevic SasaNo ratings yet

- Avesta 2205 AC DCDocument1 pageAvesta 2205 AC DCpipedown456No ratings yet

- A-80 RailrodDocument1 pageA-80 RailrodSyed AbudhakirNo ratings yet

- Utp 86 FNDocument1 pageUtp 86 FNc131508No ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- MIP Bohler Welding Austria 62Document1 pageMIP Bohler Welding Austria 62Pradeepta MohantyNo ratings yet

- CERTILAS EN Edition2023 313Document1 pageCERTILAS EN Edition2023 313Alireza KhodabandehNo ratings yet

- Dual Shield 8000b2Document1 pageDual Shield 8000b2Gokul RajanNo ratings yet

- 570 950mpa High Tensile Strength SteelDocument32 pages570 950mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- Special Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresDocument10 pagesSpecial Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresCarlos PadillaNo ratings yet

- How To Use This Catalog: Have A Soundcard? - Click On MeDocument234 pagesHow To Use This Catalog: Have A Soundcard? - Click On MeitalangeloNo ratings yet

- Catalog ElectrDocument140 pagesCatalog ElectrMocanu Stefan ArtemonNo ratings yet

- Böhler Ti 2 Ni T-FD: Seamless Cored WireDocument2 pagesBöhler Ti 2 Ni T-FD: Seamless Cored WireThanh TamNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- PD Cen TS 16539-2012Document16 pagesPD Cen TS 16539-2012Krishna VachaNo ratings yet

- Surface Preparation Standard No. 1: SSPC: The Society For Protective Coatings Solvent CleaningDocument2 pagesSurface Preparation Standard No. 1: SSPC: The Society For Protective Coatings Solvent CleaningKrishna VachaNo ratings yet

- AWS D1.1 Welder Quallification RequirementsDocument3 pagesAWS D1.1 Welder Quallification RequirementsKrishna Vacha100% (1)

- Atom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesAtom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesKrishna VachaNo ratings yet

- BS en Iso 01514-2016Document22 pagesBS en Iso 01514-2016Krishna Vacha50% (2)

- Tigrod ER80S-B8: Typical Tensile PropertiesDocument1 pageTigrod ER80S-B8: Typical Tensile PropertiesKrishna VachaNo ratings yet

- Rfi No. Area Location Unit Date Inspection Item Result IR Date Remarks Accp Rej Can 0 0 0 0 0Document1 pageRfi No. Area Location Unit Date Inspection Item Result IR Date Remarks Accp Rej Can 0 0 0 0 0Krishna VachaNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesKrishna VachaNo ratings yet

- Welding Tehnology PDFDocument35 pagesWelding Tehnology PDFKrishna VachaNo ratings yet

- AWS D1.1 Welder Quallification RequirementsDocument3 pagesAWS D1.1 Welder Quallification RequirementsKrishna Vacha100% (1)

- TDS - Sadovac SP (F8102102)Document2 pagesTDS - Sadovac SP (F8102102)Krishna Vacha67% (3)

- TDS - Yacht Varnish Exterior (F65xxx) PDFDocument2 pagesTDS - Yacht Varnish Exterior (F65xxx) PDFKrishna VachaNo ratings yet

- API Q1 Approved InterpretationsDocument4 pagesAPI Q1 Approved InterpretationsKrishna VachaNo ratings yet

- TDS - 2 Pack PU Clear Sealer - Exterior (F92N0ECS)Document2 pagesTDS - 2 Pack PU Clear Sealer - Exterior (F92N0ECS)Krishna Vacha100% (1)

- Magnafloc LT-7990: Technical Information Water SolutionsDocument2 pagesMagnafloc LT-7990: Technical Information Water SolutionsfemiNo ratings yet

- Lab Thermo - Marcet BoilerDocument6 pagesLab Thermo - Marcet BoilernorsiahNo ratings yet

- Brakes and ClutchesDocument22 pagesBrakes and ClutchesPappuRamaSubramaniamNo ratings yet

- Engineering & Operating Guide - DOWTHERM SR-1 - 4000Document44 pagesEngineering & Operating Guide - DOWTHERM SR-1 - 4000carlone07No ratings yet

- TH Ermostatic Expansion Valves: Type T 2 and TE 2Document20 pagesTH Ermostatic Expansion Valves: Type T 2 and TE 2JasminkoCvitešićNo ratings yet

- PDIL LPG Bullet PDFDocument1,033 pagesPDIL LPG Bullet PDFNilesh Pathare100% (3)

- Research Into Concrete Blocks With Waste Glass PDFDocument7 pagesResearch Into Concrete Blocks With Waste Glass PDFYuliusRiefAlkhalyNo ratings yet

- Distillation Absorption StrippingDocument12 pagesDistillation Absorption StrippingLulav BarwaryNo ratings yet

- Instructions Natural Gas Boiler Calculations: AcknowledgementsDocument17 pagesInstructions Natural Gas Boiler Calculations: AcknowledgementsDavid Muñoz CastroNo ratings yet

- SLAD-MXf ManualDocument10 pagesSLAD-MXf ManualReiky Aji ShaputraNo ratings yet

- AIR Filter: Filtration. Separation. SolutionsDocument15 pagesAIR Filter: Filtration. Separation. Solutionssiva ramakrishnanNo ratings yet

- MODEL 496: Nfpa Gravimetric Coal FeederDocument2 pagesMODEL 496: Nfpa Gravimetric Coal FeederZahoor Ahmed100% (1)

- Watlow FLUENT HeaterDocument1 pageWatlow FLUENT HeaterchipulinoNo ratings yet

- L150 180 220FDocument36 pagesL150 180 220Fdalibor_bogdan33% (3)

- 02.utilize Waste Oil Mix in ANFODocument18 pages02.utilize Waste Oil Mix in ANFOHendry Christianto100% (1)

- 2.00 Power::: 1.5HPX13A: 1.5HPX13A-3-2: KO Drum Pump: 1Document3 pages2.00 Power::: 1.5HPX13A: 1.5HPX13A-3-2: KO Drum Pump: 1Aldeline SungahidNo ratings yet

- Expancure AB: Acrylic Based Curing CompoundDocument2 pagesExpancure AB: Acrylic Based Curing CompoundAmar Wadood KhanNo ratings yet

- Plastic and EconomyDocument8 pagesPlastic and Economyhrithaya sureshNo ratings yet

- SD3 Electrical SchematicsDocument29 pagesSD3 Electrical SchematicsjairoNo ratings yet

- Column Detail and Foundation PlanDocument7 pagesColumn Detail and Foundation PlanAnoopNo ratings yet

- Methanator Catalyst Replacement European Plant HTHA p1 MaterialDocument1 pageMethanator Catalyst Replacement European Plant HTHA p1 MaterialshahgardezNo ratings yet

- SPJ Sub Section 6.3: Road Marking: JKR/SPJ/2008-S4 SSRW 1988 Difference Remark Clause Description ClauseDocument1 pageSPJ Sub Section 6.3: Road Marking: JKR/SPJ/2008-S4 SSRW 1988 Difference Remark Clause Description ClausechinhonNo ratings yet

- Wax Defects in Investment Casting - and It's Minimization - Ajay Bhardwaj - Academia - Edu PDFDocument5 pagesWax Defects in Investment Casting - and It's Minimization - Ajay Bhardwaj - Academia - Edu PDFAgus PurwantoNo ratings yet

- Sport TechDocument4 pagesSport Techila03100% (1)

- HLR 7970 PDFDocument17 pagesHLR 7970 PDFMargaret Daugherty100% (1)

- Astm D5462 - 13Document6 pagesAstm D5462 - 13Ali Saleh Saad AL-isawi100% (1)

- HVAC, PHE & FF Eqpt - Elect LoadDocument13 pagesHVAC, PHE & FF Eqpt - Elect LoadSaurabh DwivediNo ratings yet

- ROTOFLEXI Couplings: Operating Instruction Valid For Type G and GNDocument8 pagesROTOFLEXI Couplings: Operating Instruction Valid For Type G and GNIzzi Al-AkbarNo ratings yet

- Technical Inquiry PTC 4.1 - 1964 (R1991) Steam Generating UnitsDocument2 pagesTechnical Inquiry PTC 4.1 - 1964 (R1991) Steam Generating UnitsDaniel AlvarezNo ratings yet

- Barangay Assembly March 2019Document4 pagesBarangay Assembly March 2019Rosenie MalibagoNo ratings yet