Sds Eng PDF

Sds Eng PDF

Uploaded by

daviko313Copyright:

Available Formats

Sds Eng PDF

Sds Eng PDF

Uploaded by

daviko313Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Sds Eng PDF

Sds Eng PDF

Uploaded by

daviko313Copyright:

Available Formats

EN ISO 9905

SDS

Double Suction Split Case

Centrifugal Pumps

ATEX

SDS 01 04-10 EN

SDS

General Information

Handled Liquids

SDS type pumps are suitable for clean or slightly contaminated liquids with low viscosity.

Design Features

Technical Data

Discharge Nozzle Range

DN 65 up to DN 400 mm

Capacities

up to 3500 m3/h

Heads

up to 180 m

Speed

up to 2900 rpm

Operating Temperature

20 C up to 80 C*

Casing Pressure (Pmax)

16 bar (25 bar)*

( Pmax: Suction Pressure + Shut off Head )

(*) The material of pumps differ according to the type of pumped

liquid , operating temperature and pressure. Contact our company

for detailed information.

Applications

Water supply

Irrigation

Drainage

Suction and discharge flanges are on the same axis at

the bottom casing. Split case design permits easy disassembly

of the rotor group for maintenance or repair without distorting

pump alignment and suction and discharge piping.

Flanges are conforming to ISO 7005-2 / PN 16 or PN 25.

Impeller is of double suction. This feature increases pump

suction performance in addition it provides the balance of

hydraulic axial forces.

All impellers are balanced statically and dynamically

according to ISO 1940 class 6.3.

Bearings

Pump shaft is supported by grease-lubricated rolling

bearings on both sides.

Depending on customer requirement Life-time greaselubricated rolling bearings are available.

Water circulation

Fire fighting

Industrial applications

Power stations

Water treatment plants

Shaft Seal

Different soft packing and mechanical seal types are available.

Rotation

In standard construction the direction of rotation of pump is

clockwise when it is looked from the motor side. In this case,

suction flange is at right and discharge flange is at left. Upon

request the direction of rotation can be reversed, and when

this is done the position of the suction and discharge flanges

are also reversed.

Pump Designation

SDS 200- 500

Pump type

Discharge nozzle (DN)

Nominal impeller diameter (mm)

Performance Range

SDS

Performance Range

SDS

SDS

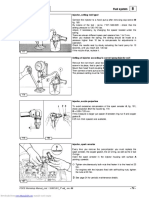

Sectional Drawing

* Mechanical Seal Application

212

013

020

210

231.1

050

231.2

067

Part List

500

400

042

200

*405

036

*422

*048

260

034

035

060

211

391

071

421

030

088

003

070

046

044

003

013

014

020

030

034

035

035

042

044

046

048

050

060

067

070

071

088

200

210

211

212

230

231.1

231.2

260

390

391

400

405

420

421

422

500

Stuffing box

Volute casing (top half)

Volute casing (bottom half)

Wear ring

Bearing bracket

Bearing cover (inboard)

Bearing cover (outboard)

Bearing cover (coupling)

Stuffing box gland

Lantern ring

Stuffing box ring**

Mechanical seal cover*

Impeller

Pump shaft

Spacer sleeve

Shaft protecting sleeve

Shaft protecting sleeve

Thrower

Ball bearing

Impeller key

Coupling key

Spacer key

Drain plug

Air plug

Air plug

Grease Nipple

Pin

Shaft nut & Lock washer

Stuffing box packing

Mechanical seal*

O-Ring

O-Ring

O-Ring*

Flushing pipe

390

420

( * ) Alternative Application

014

( ** ) Optional Application

230

( *** ) Double volute desing is applied to:

*** Double Volute Application

SDS 200-500 , 250-600 , 300-500

300-700 , 350-500 , 350-700

SDS

Technical Data

Volute casing

Impeller

Shaft

Bearing housing

Wear ring (Casing)

Shaft protecting sleeve

Mechanical seal (*)

1.4462

1.4404

1.4401

1.4306

1.4301

1.4021

2.0975.01

2.1050.01

1.4469

1.4517

1.4409

1.4408

1.4308

1.0619

Parts List

0.7040

0.6025

Material Options

EN 12756 / DIN 24960

Standard manufacturing

(*) Optional: Depending on customer requirement or request different types and brands of mechanical seals are applicable.

Optional

Material Equivalents

Description

DIN 17007

Cast iron

Nodular cast iron

Cast steel

Chrome nickel cast steel

Chrome nickel molybdenum cast steel

Chrome nickel molybdenum cast steel (low carbon)

Austenitic-ferritic cast steel (duplex)

Austenitic-ferritic cast steel (super duplex)

Cast bronze

Cast bronze

Chrome steel

Chrome nickel steel

Chrome nickel steel (low carbon)

Chrome nickel molybdenum steel

Chrome nickel molybdenum steel (low carbon)

Duplex (austenitic-ferritic) steel

0.6025

0.7040

1.0619

1.4308

1.4408

1.4409

1.4517

1.4469

2.1050.01

2.0975.01

1.4021

1.4301

1.4306

1.4401

1.4404

1.4462

EN-DIN

GJL-250 (GG 25)

GJS-400-15 (GGG 40)

GP240GH (GS-C 25)

G-X5 Cr Ni 19-10

G-X5 Cr Ni Mo 19-11-2

G-X2 Cr Ni Mo 19-11-2

G-X2 Cr Ni Mo Cu N 25-6-3-3

G-X2 Cr Ni Mo N 26-7-4

G-Cu Sn 10

G-Cu Al 10 Ni

X20 Cr 13

X5 Cr Ni 18-10

X2 Cr Ni 19-11

X5 Cr Ni Mo 17-12-2

X2 Cr Ni Mo 17-12-2

X2 Cr Ni Mo N 22-5-3

ASTM

A 48 Class 40-B

A 536 Gr. 60-40-18

A 216 Gr. WCB

A 351/743/744 Gr. CF8

A 351/743/744 Gr. CF8M

A 351/743/744 CF3M

A 890 Gr. 1B (CD4MCuN)

A 890 Gr. 5A (CE3MN)

B 584 C 90700

B 584 C 95800

A 276 Type 420

A 276 Type 304

A 276 Type 304L

A 276 Type 316

A 276 Type 316 L

A 276 (32205)

Flange Dimensions

Suction & Discharge

(PN 16)

k

s

n

Df

bf

Suction & Discharge

(PN 25)

k

s

n

Df

bf

20

185

145

19

19

22

200

160

19

24

235

190

65

185

145

19

80

200

160

100

220

180

24

19

26

23

28

125

250

210

19

26

270

220

28

30

150

285

240

23

26

300

250

28

34

200

340

295

23

12

30

360

310

28

12

34

36

250

405

355

28

12

32

425

370

31

12

300

460

410

28

12

32

485

430

31

16

40

350

520

470

28

16

36

555

490

34

16

44

400

580

525

31

16

38

620

550

37

16

48

500

715

650

34

20

42

730

660

37

20

52

n number of holes

bf

Df

k

DNe/DNb

DNe/DNb

SDS

Technical Data

l3

l2

a1

l1

a2

m1

m2

Pump Type

65-250

PNe PNb DNe DNb d

16

16 100 65

35

l

80

l1

Dimensions (mm)

a1 a2

l2

l3

400 310 710

16

16 125 80

35

80

400 310 710

100-250

16

16 150 100 42

90

450 350 800

16

16 200 125 55 120 555 420 975

200 150 55 120 555 420 975

16

16

25

25 250 150 65 130 645 500 1145

16

16 250 200 65 130 645 500 1145

200-315

200-400

250-450

250-600

16

16

25

25

16

16

300-500

300-700

m1

m2

360 310

260

235

355 170 250

470

450

470 400

400 480

220

280 340 20

6 5 1 3 0 645 500 1145 600 500

280 460 540

330

540

310

365

660 320 380 22

380

640

410

540 640 320 380 22

315

360

400

540 640

600 300 415 620 720

570

360 420 22

700

360 420 22

65 130 645 500 1145 600 500 630 300 400 620 700 360 420 22

700

700

550 710

750 710

350

450 720

425 700

800 420 520 26

16

16

350-500

500

682

780

25 400 300 100 180 865 675 1540 750 800 710 350 470 720 880 420 520 26

350

575

1190

80 170 755 585 1340

430

800

710 415 485 26

300 75 140 770 615 1385

400

395

430

390

8 0 170 720 540 1260 650 550

230

290

550 500 560 300 445 540 640 360 420 22

500 450 500 240

175

300 460 540

400 200 3 0 0

400 200

165

197

350

500 450

Weight

(kg)

165

25

350-350

350-400

300 250

350

300-315

300-400

n2

550 500 560 300 380 620 720

200-500

250-350

n1

300 140 200 400 460 230 300 20

500

125-450

150-450

150-600

320 280

420 370

125-315

150-315

h3

320 280 300 140 200 400 460 230 300 20

420 370

100-400

125-350

h2

360 300

80-315

100-315

h1

200

80-200

80-250

n1

n2

75 140 770

615 1385 700 550 670 350 450 720 800 420 520

615 1385

80 170 755 585 1340

800 600 800

380 5 0 0 800 960

400 435 740 900

500 600

1125

1500

1650

1100

26

1400

1435

350-700

25

25 500 350 100 180 865 675 1540 850 750 850 450 525 720 880 500 600 26 2000

400-800

16

16 600 400 105 220 1035 810 1845 900 900 880 450 565 950 1120 630 740 26 3400

Note: Dimensions may differ in cast steel and cast bronze pumps. Contact our company for details.

Right reserved to change without notice.

No responsibility is accepted because of printing errors.

You might also like

- Manual de Partes ECM350 IRDocument450 pagesManual de Partes ECM350 IRGUILLERMO SEGURA92% (13)

- KSB WKLNDocument2 pagesKSB WKLNgangruka50% (2)

- Martillo Perforador X2Document10 pagesMartillo Perforador X2Anonymous iu95trpxNNo ratings yet

- Okb Top SeriesDocument4 pagesOkb Top SeriesIrma Pokvić-Ramulj100% (1)

- Jeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20From EverandJeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20No ratings yet

- Kiswire General Purpose RopesDocument28 pagesKiswire General Purpose Ropesdaviko313No ratings yet

- Cranes DEMAG CatalogueDocument160 pagesCranes DEMAG Cataloguelcorao100% (1)

- Hydrotec SKM DDocument8 pagesHydrotec SKM DAmalNo ratings yet

- 070.650-SPC SGC 2011-01Document8 pages070.650-SPC SGC 2011-01Nathan WinansNo ratings yet

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentNo ratings yet

- Pump STDRDocument7 pagesPump STDRsopian320No ratings yet

- AMRI ISORIA 16 Type Series Booklet DataDocument20 pagesAMRI ISORIA 16 Type Series Booklet Datarudiskw456No ratings yet

- 06 SCT Extended PDFDocument40 pages06 SCT Extended PDFSlobodan Antic100% (2)

- 650 SchematicDocument4 pages650 Schematicab5951No ratings yet

- CVP 90spec InformacionDocument7 pagesCVP 90spec InformacionvictorNo ratings yet

- Mixed Flow PumpsDocument2 pagesMixed Flow PumpssahildhingraNo ratings yet

- Goulds Pumps 3355 SeriesDocument7 pagesGoulds Pumps 3355 Seriesmcastillo7385100% (1)

- DAB Pump BookDocument41 pagesDAB Pump BooksuosvannakNo ratings yet

- GISO 50x32-160 4KWDocument6 pagesGISO 50x32-160 4KWjimmy0802No ratings yet

- DSM PDFDocument8 pagesDSM PDFSlobodan AnticNo ratings yet

- 20090610144043A ProductsDocument24 pages20090610144043A Productsidontlikeebooks100% (1)

- NissanDocument3 pagesNissancrower_scribdNo ratings yet

- D VipDocument6 pagesD VipClemente Rafael Marval EscalonaNo ratings yet

- Single-Row Deep Groove Ball Bearings, S-Type: Cage Types and MaterialsDocument16 pagesSingle-Row Deep Groove Ball Bearings, S-Type: Cage Types and MaterialsshahganNo ratings yet

- Roberts Oxygen Welding Industrial Catalog 2011Document104 pagesRoberts Oxygen Welding Industrial Catalog 2011sanjibkrjanaNo ratings yet

- MasterSeries 850 Specification SheetDocument2 pagesMasterSeries 850 Specification SheetFEBCONo ratings yet

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoNo ratings yet

- EBARA Catalogue Fire PumpDocument14 pagesEBARA Catalogue Fire PumpVanja Ivkovic100% (2)

- IMI TRUFLO RONA Fully Welded Ball ValvesDocument12 pagesIMI TRUFLO RONA Fully Welded Ball ValvesAlexandra HarperNo ratings yet

- Ingersoll CAT-009 HoleM TechDocument30 pagesIngersoll CAT-009 HoleM TechLLNo ratings yet

- Goulds Model 3700/3710: High Temperature/High Pressure Process Pumps Designed and Built To Meet Requirements of API-610Document40 pagesGoulds Model 3700/3710: High Temperature/High Pressure Process Pumps Designed and Built To Meet Requirements of API-610Rous MeryNo ratings yet

- 5600 Swing Flex Check ValveDocument16 pages5600 Swing Flex Check ValveMahmoud Abd ElnaeimNo ratings yet

- Fan Adta-En-50hz-March-2018 - 20180315Document52 pagesFan Adta-En-50hz-March-2018 - 20180315Andi JatmikoNo ratings yet

- 01 MF New Pages PDFDocument22 pages01 MF New Pages PDFSlobodan AnticNo ratings yet

- Catalogue FSDA 60 HZDocument7 pagesCatalogue FSDA 60 HZAndres Fitria FarrelNo ratings yet

- Vertical MixerDocument5 pagesVertical MixerTIPAZONo ratings yet

- ARTY - Aubert Et Duval - Produits - Longs - GB PDFDocument6 pagesARTY - Aubert Et Duval - Produits - Longs - GB PDFScott_B4UNo ratings yet

- ROTH EN Metal Expansion Joints CatalogueDocument25 pagesROTH EN Metal Expansion Joints CatalogueLuis De la RosaNo ratings yet

- Wpi Cps SerieDocument48 pagesWpi Cps SerieNour Nour El Islam100% (1)

- 30K Data Sheet North AmericaDocument2 pages30K Data Sheet North AmericaatiqulaNo ratings yet

- 8" Submersible Motors Standard: ApplicationsDocument7 pages8" Submersible Motors Standard: Applicationswpt_meNo ratings yet

- rc33026 D12-UscDocument7 pagesrc33026 D12-Usceww08No ratings yet

- Ensival Moret MP PumpsDocument6 pagesEnsival Moret MP PumpsBenicio Joaquín Ferrero Brebes100% (1)

- Agitator SizingDocument4 pagesAgitator SizingArbee AquinoNo ratings yet

- Slurry Pumps WH Agitator - Models - HSD, KTV, KRS, NKZ, GPN, Gsz-6Document5 pagesSlurry Pumps WH Agitator - Models - HSD, KTV, KRS, NKZ, GPN, Gsz-6Guilherme CamposNo ratings yet

- Pds Productdatasheetactregact-1200 Rev5Document4 pagesPds Productdatasheetactregact-1200 Rev5RAHEEM100% (1)

- Butterfly Valves EgeplastDocument4 pagesButterfly Valves EgeplastdsyashankaNo ratings yet

- As TDS 60Hz MetricDocument4 pagesAs TDS 60Hz MetricMarko Antonio AguilarNo ratings yet

- SPC - Frick XJF Xjs 95 To 151 PDFDocument4 pagesSPC - Frick XJF Xjs 95 To 151 PDFmiguel callata100% (1)

- 30K Data Sheet - 0915 - ComminutorDocument2 pages30K Data Sheet - 0915 - ComminutorJamil Kaynu KamilNo ratings yet

- Manual Aire Acondiciona SamsungDocument46 pagesManual Aire Acondiciona Samsung5deivid5No ratings yet

- Tech LeaderDocument6 pagesTech LeadermachineCanNo ratings yet

- Control Choke Valve 9000Document8 pagesControl Choke Valve 9000sabi_shi100% (2)

- Especificacion API 5lDocument44 pagesEspecificacion API 5ljpcc1986100% (1)

- Advul EnusDocument17 pagesAdvul EnusErlangga PrabowoNo ratings yet

- Din Reactors CEDocument3 pagesDin Reactors CEvallamreddyNo ratings yet

- Mech Van Catalogue PDFDocument26 pagesMech Van Catalogue PDFVan Nguyen Huu VanNo ratings yet

- How to Power Tune the BMC/BL/Rover 998 A-Series Engine for Road and TrackFrom EverandHow to Power Tune the BMC/BL/Rover 998 A-Series Engine for Road and TrackNo ratings yet

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- LeadSolar Gateway Superior v1.0Document173 pagesLeadSolar Gateway Superior v1.0daviko313No ratings yet

- Microinverter LS600 Specification: Input Data (DC) LS600 LS600-AU LS600-EU LS600-NADocument1 pageMicroinverter LS600 Specification: Input Data (DC) LS600 LS600-AU LS600-EU LS600-NAdaviko313No ratings yet

- Column Speaker - T304Document2 pagesColumn Speaker - T304daviko313No ratings yet

- Simple Pressure VesselsDocument38 pagesSimple Pressure VesselsCristian BorcanescuNo ratings yet

- 1 enDocument32 pages1 endaviko313No ratings yet

- Steca TR 0201 Instruction enDocument40 pagesSteca TR 0201 Instruction endaviko313No ratings yet

- Guide Line For Inspection of Overhead Crane StructureDocument43 pagesGuide Line For Inspection of Overhead Crane StructurePranoy Barua100% (1)

- 4 THE OCCUPATIONAL SAFETY AND HEALTH ACT Amendment Fee For FCERTDocument2 pages4 THE OCCUPATIONAL SAFETY AND HEALTH ACT Amendment Fee For FCERTdaviko313No ratings yet

- ASHRAE Workshop Control WilliamYick Part 2Document48 pagesASHRAE Workshop Control WilliamYick Part 2daviko313No ratings yet

- Sds-Bakim Kilavuzu enDocument24 pagesSds-Bakim Kilavuzu endaviko313No ratings yet

- Material Clarification Q345Document1 pageMaterial Clarification Q345daviko313No ratings yet

- Catalogue of Industrial DehumidifierDocument8 pagesCatalogue of Industrial Dehumidifierdaviko313No ratings yet

- VENT AXIA System CalculatorDocument38 pagesVENT AXIA System Calculatordaviko313No ratings yet

- HVAC Accurate Load Calcs StrategyDocument47 pagesHVAC Accurate Load Calcs StrategySharon LambertNo ratings yet

- KTS ArDocument106 pagesKTS Ardaviko313No ratings yet

- Get Started With Solar EnergyDocument76 pagesGet Started With Solar EnergySolar Nation100% (2)

- Swisspump Sewage 50hzDocument92 pagesSwisspump Sewage 50hzdaviko313No ratings yet

- AirstageDocument76 pagesAirstagedaviko313No ratings yet

- 1p5hhays87m8npu234ii PDFDocument277 pages1p5hhays87m8npu234ii PDFjwNo ratings yet

- Plastic Piping Handbook1Document359 pagesPlastic Piping Handbook1ddadara100% (2)

- Fire SPRKLR Train ManDocument81 pagesFire SPRKLR Train ManHESuarez100% (1)

- Pipeline System DesignDocument75 pagesPipeline System Designjoreli50% (2)

- 182268644-CW-Pump-CalculationDocument18 pages182268644-CW-Pump-CalculationPinak ProjectsNo ratings yet

- Hole CleaningDocument8 pagesHole Cleaninganon_850924421No ratings yet

- LSM AP Brochure - 02.23Document8 pagesLSM AP Brochure - 02.23pios.helectorNo ratings yet

- MAGNUMDocument60 pagesMAGNUMeaglego00No ratings yet

- Resol FlowSol B BrochureDocument2 pagesResol FlowSol B BrochureDan JungNo ratings yet

- Valves PDFDocument2 pagesValves PDFANGELNo ratings yet

- RDM All Makes Parts Catalog 2016.10.01 - DIGITALDocument550 pagesRDM All Makes Parts Catalog 2016.10.01 - DIGITALNestor Oyaga BarriosNo ratings yet

- Gold Cup Pumps KeysheetDocument2 pagesGold Cup Pumps KeysheetmecambNo ratings yet

- LDW - 502 79 83Document5 pagesLDW - 502 79 83Bane RadovicNo ratings yet

- CP Fino A 11 KW - EN - 50Hz PDFDocument10 pagesCP Fino A 11 KW - EN - 50Hz PDFمعين عزامNo ratings yet

- Tar - 2011 - WoDocument3 pagesTar - 2011 - Wohamza brahmiNo ratings yet

- MTM CW 3004 3MGHDocument16 pagesMTM CW 3004 3MGHdcprice7684No ratings yet

- Operation ManualDocument116 pagesOperation ManualEnrique MurgiaNo ratings yet

- 4 PRESENTATION - Hydraulic Modeling PDFDocument29 pages4 PRESENTATION - Hydraulic Modeling PDFDario Monteiro100% (1)

- K CS KLRC125 - 1st - 3 21Document4 pagesK CS KLRC125 - 1st - 3 21macaco logoNo ratings yet

- SKF 729124 Hydraulic PumpDocument8 pagesSKF 729124 Hydraulic PumpAlvaro ZilianiNo ratings yet

- Main Bilge PumpDocument20 pagesMain Bilge Pumptim kaminskyNo ratings yet

- 卧式离心泵说明书英文(大连双龙)Document16 pages卧式离心泵说明书英文(大连双龙)kamal arabNo ratings yet

- Unpriced BOQ EAST Storage TankDocument27 pagesUnpriced BOQ EAST Storage TankwasNo ratings yet

- Unit 15 Electro Pneumatic and Hydraulic Systems and DevicesDocument13 pagesUnit 15 Electro Pneumatic and Hydraulic Systems and Devicesaabatiancila0% (1)

- PumpDocument15 pagesPumpSandip KadoliNo ratings yet

- Pump Installation Guide LLC1Document11 pagesPump Installation Guide LLC1zulmas100% (1)

- Blackmer Power Pumps: Models: Xl2B, Xl3B, Xl4CDocument12 pagesBlackmer Power Pumps: Models: Xl2B, Xl3B, Xl4CKhoh Kai ShengNo ratings yet

- Bearing Reliability Improvement SKF PDFDocument55 pagesBearing Reliability Improvement SKF PDFPandhuNo ratings yet

- Mech and Electrical Final22-23 - 1-Copy - 0Document85 pagesMech and Electrical Final22-23 - 1-Copy - 0Darshan MaheshwariNo ratings yet

- Impulse 4.0Document554 pagesImpulse 4.0Ivo Kostov100% (1)

- C4000 Hydraulic Drive Circuit ExplainedDocument18 pagesC4000 Hydraulic Drive Circuit ExplainedDavid CraigNo ratings yet

- Furnace Design and Operation: Fuel Handling SystemsDocument45 pagesFurnace Design and Operation: Fuel Handling SystemskINGNo ratings yet