100%(1)100% found this document useful (1 vote)

916 viewsGym Area Boq For Nri Club House

Gym Area Boq For Nri Club House

Uploaded by

Santosh ThakurThis document provides a bill of quantities (BOQ) for electrical work including a club house main power panel and gym area electrical system for an NRI club house project. The summary includes:

1. Supply, installation, testing and commissioning of main LT panels, distribution boards, MCBs, and associated cabling and wiring for power distribution.

2. Supply and installation of power cables in PVC conduits of various sizes to distribute power from the main panels to distribution boards and equipment.

3. Termination of power cables and connection to panels and boards.

4. Conduit wiring for lights, fans, sockets and other points originating from distribution boards.

5. Supply and

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Gym Area Boq For Nri Club House

Gym Area Boq For Nri Club House

Uploaded by

Santosh Thakur100%(1)100% found this document useful (1 vote)

916 views5 pagesThis document provides a bill of quantities (BOQ) for electrical work including a club house main power panel and gym area electrical system for an NRI club house project. The summary includes:

1. Supply, installation, testing and commissioning of main LT panels, distribution boards, MCBs, and associated cabling and wiring for power distribution.

2. Supply and installation of power cables in PVC conduits of various sizes to distribute power from the main panels to distribution boards and equipment.

3. Termination of power cables and connection to panels and boards.

4. Conduit wiring for lights, fans, sockets and other points originating from distribution boards.

5. Supply and

Original Description:

Df

Original Title

Gym Area Boq for Nri Club House

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides a bill of quantities (BOQ) for electrical work including a club house main power panel and gym area electrical system for an NRI club house project. The summary includes:

1. Supply, installation, testing and commissioning of main LT panels, distribution boards, MCBs, and associated cabling and wiring for power distribution.

2. Supply and installation of power cables in PVC conduits of various sizes to distribute power from the main panels to distribution boards and equipment.

3. Termination of power cables and connection to panels and boards.

4. Conduit wiring for lights, fans, sockets and other points originating from distribution boards.

5. Supply and

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(1)100% found this document useful (1 vote)

916 views5 pagesGym Area Boq For Nri Club House

Gym Area Boq For Nri Club House

Uploaded by

Santosh ThakurThis document provides a bill of quantities (BOQ) for electrical work including a club house main power panel and gym area electrical system for an NRI club house project. The summary includes:

1. Supply, installation, testing and commissioning of main LT panels, distribution boards, MCBs, and associated cabling and wiring for power distribution.

2. Supply and installation of power cables in PVC conduits of various sizes to distribute power from the main panels to distribution boards and equipment.

3. Termination of power cables and connection to panels and boards.

4. Conduit wiring for lights, fans, sockets and other points originating from distribution boards.

5. Supply and

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

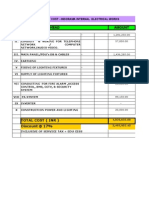

Item Pay Description Total Total

No. Unit Qty. mat lab Rate Amount

CLUB HOUSE - MAIN POWER PANEL

1.0 MV SWITCHGEAR & POWER PANELS

1.1 Supply, installation, testing and

commissioning of cubicle type panels

as specified and shown on drawing.

i) Main busbars with bar type feeder

connections & all internal wiring and

connections.

ii) Earthing all components, frame etc. to

a common internal earth bar.

iii) Painting all sheet metal works.

iv) All accessories & supporting structure.

v) Brass glands for sending and receiving

ends.

(Crimping lugs forming part of

the termination)

vi) All ammeters with C.T's and voltmeter

and energy meters with necessary

fuses.

vii) Panel components as specified.

viii) MS base frame.

ix) All switch gear to have short circuit

levels as specified.

1.1.1 Each Main LT Panel with Capacitor - as specified 1 425,000 18,000 443,000 443,000

and shown on the drawings complete

as per drawing L261 - E - 502

Total for 1.0 443,000

2.0 DISTRIBUTION BOARDS

2.1 Supply, installation, testing & commissioning

of 500V Distribution Boards as specified &

shown on drawing with

i) Copper busbars together with tapped neutral

bar for individual phases.

ii) Copper earth strip with tapping for EEC

iii) Interconnections and earthing.

iv) Sheet steel enclosure suitable for recessed

or surface mounting with hinged lockable

doors interlocked with the incomer switch.

v) Phase to phase barriers in case of 3Ph boards.

vi) Necessary support frame & painting, labeling,

phase indicating lamps with fuses etc.

complete.

2.1.1 Each Power Distribution Board for GYM area 1 11,500 1,400 12,900 12,900

Incomer

I) 1# 63A TPN ELMCB(30 mA)

Outgoing :

i) 8 x 3 = 16/20A SP MCB

2.1.2 Each Lighting Distribution Board 1 10,550 1400 11,950 11,950

Rate

BOQ FOR ELECTRICAL WORK WITH CLUB HOUSE MAIN POWER PANEL & GYM AREA - NRI CLUB HOUSE PROJECT

Incomer

I) 1# 40A TPN ELMCB (30 mA)

Outgoing :

iii) 6 x 3# 10A SP MCB

2.1.3 Each 63 A TPN MCB WITH Enclouser 6 4,300 500 4,800 28,800

2.1.4 Each 40 A TPN MCB WITH Enclouser 3 4800 500 5,300 15,900

2.1.5 Each 6 Way VTPN Steam DB 1 18500 1600 20,100 20,100

as per drawing L261 - E - 502

Total for 2.0 89650

3 CABLING

3.1 Power Cabling (PVC)

Supply and laying heavy duty

1100V grade PVC insulated sheathed

& armoured Fire Retarded

AL / Cu conductors as specified and

shown on drgs. complete with:

a) Cable clamps on walls,trays columns,

beams, built-up trenches, cable

markers etc. for indoor cables.

b) Covering bricks or tiles, cable markers

etc. for outdoor cables.

c) Earthing the glands armouring etc.

3.1.1 m 3.5 C 185 sqmm XL - AL R.O.

3.1.2 m 3.5 C 300 sqmm XLPE-AL 24 1250 160 1,410 33,840

3.1.3 m 3.5 C 150 sqmm XLPE-AL R.O.

3.1.4 m 3.5 C 120 sqmm XLPE-AL R.O.

3.1.5 m 3.5 C 95 sqmm XLPE-AL R.O.

3.1.6 m 3.5 C 70 sqmm XLPE-AL 40 210 60 270 10,800

3.1.7 m 3.5 C 25 sqmm XLPE-AL R.O.

3.1.8 m 3.0 C 35 sqmm XLPE-AL R.O.

3.1.9 m 3.5 C 25 sqmm XLPE-AL R.O.

3.1.10 m 4 C 10 sqmm YRY 35 410 30 440 15,400

3.1.11 m 4 C 6 sqmm YRY R.O.

3.1.12 m 4 C 4 sqmm YRY R.O.

3.1.13 m 4 C 2.5 sqmm YRY R.O.

3.1.14 m 4 C 16 sqmm YRY 120 570 45 615 73,800

3.1.15 m 3 C 10 sqmm YRY R.O.

3.1.16 m 3 C 6 sqmm YRY R.O.

Total for 3.0 133840

4 Cable Termination

4.1 Making cable end terminations

including brass double compression

crimping type copper lugs for

cable sizes mentioned below of

(Glands form part of Panels / DB's)

4.1.1 Each 3C, 3.5C, 4C 300 4 2550 750 3,300 13,200

4.1.2 Each 3C, 3.5C, 4C 185 R.O.

4.1.3 Each 3C, 3.5C, 4C 150 R.O.

4.1.4 Each 3C, 3.5C, 4C 120 R.O.

4.1.5 Each 3C, 3.5C, 4C 95 R.O.

4.1.6 Each 3C, 3.5C, 4C 70 2 1200 125 1,325 2,650

4.1.7 Each 3C, 3.5C, 4C 35 R.O.

4.1.8 Each 3C, 3.5C, 4C 25 R.O.

4.1.9 Each 3C, 3.5C, 4C 16 10 390 90 480 4,800

4.1.10 Each 3C, 3.5C, 4C 10 2 280 65 345 690

4.1.11 Each 3C, 3.5C, 4C 6 R.O.

4.1.12 Each 3C, 3.5C, 4C 4 R.O.

Total for 4.0 21340

5.0 CONDUIT WIRING

5.1 Supply & ITC of Conduit wiring for lights, fans, socket outlets

consisting of:

a) FR Wiring with PVC MMS conduit with all it's necessary

junction box, couplers, bend etc.

b) 1100V grade PVC copper wires as specified. The PVC

wires should comply IS :694-1990. The PVC conduits should

comply with IS 3418-1989 for rigid conduits. The interiors of

the PVC coduits should be free from obstruction and should

be ISI marked. No PVC conduit less than 20mm in diameter

shall be used.

c) Conduiting and wiring excluding switches, sockets &

including supply & fixing of pipe conduits with junction box,

couplers, bends, elbows, PVC plates, wires etc. complete with

box earthing, interconnections etc.

d) Connecter of angle holder / ceiling rose as required shall be

provided.

e) The point rate shall include submains wiring from DB to

switchboard with Copper PVC insulated stranded wire. This

also includes wires used for switchboard interconnections.

f) NOTE:-

Secondary Light Point : Looping from Primary Light Point will

be considered as Secondary Light Point and will be controlled

from the same switch provided for Primary Light Point.

5.1 GYM AREA POINT WIRING

5.1.1 Pt. Primary Points (From DB):- 10 1100 220 1,320 13,200

The final subcircuit wiring commencing from the distribution

board feeder to the first light point (With 2R X 2.5Sq.mm and

1R X 1.5Sq.mm and 25mm FR PVC conduits).

5.1.2 Pt. Secondary Points (From DB):- 25 760 115 875 21,875

1-way secondary light point from above primary point,

subsequent points controlled by same DB feeder switch (With

2R X 1.5Sq.mm and 1R X 1.5Sq.mm and 20mm FR PVC

conduits).

5.1.3 Pt. Primary Points (From Switch Box):- 30 1120 220 1,340 40,200

The final subcircuit wiring commencing from the distribution

board feeder to the first light point (With 2R X 2.5Sq.mm and

1R X 1.5Sq.mm and 20/25mm FR PVC rigid conduits) and

from there to the light point complete with switch drop (With

2R X 1.5Sq.mm and 1R X 1.5Sq.mm and 20mm FR PVC

conduits).

5.1.4 Pt. Secondary Points (From Switch Box):- 31 760 115 875 27,125

1-way secondary light point from above primary point,

subsequent points controlled by same switch (With 2R X

1.5Sq.mm and 1R X 1.5Sq.mm and 20/25mm FR PVC

conduits).

5.1.5 Pt. Ceiling fan point complete R.O.

(With 2Rx1.5Sq.mm and 1Rx1.5Sq.mm and PVC mm conduits)

5.1.6 Pt. Exhaust fan point with 5A socket near fan controlled by 6A

SP switch 1.5 sq mm

4

1450 260 1,710 6,840

located on lighting switch board(With 2Rx1.5Sq.mm and

20mm conduits)

5.1.7 Pt. 20A Socket with 20A SP neon indicator Switch for AC spilt

unit IDU

8

3050 330 3,380 27,040

(with 2Rx4Sq.mm+1Rx1.5Sq.mm and 25mm conduit)

5.1.8 Pt. 6A Plug Point 4 1450 260 1,710 6,840

(2Rx1.5Sq.mm+1Rx1.5Sq.mm and 20mm conduit)

5.1.9 Pt. 16A Power Plug Point 16 1500 260 1,760 28,160

(2Rx2.5Sq.mm+1Rx1.5Sq.mm and 20mm conduit)

Total for 5.0 171280

6.1 Supply & Installation of switches, sockets,

mild steel electro galvanised back box etc.

complete with box earthing, interconnections

etc.

6.1.1 Each 1# - 5A Switch 25 185 60 245 6,125

6.1.2 Each 1# - 5A Switch & 1# 3P 5A 6 365 70 435 2,610

socket

6.1.3 Each 1# 15A switch & 5/15A 20 335 70 405 8,100

socket with indicator.

Total for 6.0 16835

7 LIGHT FIXTURES

7.1 Supply, installation, testing &

commissioning of light fixtures

complete with:

a) All fixing accessories

mounting bracket

b) Earthing of fittings

7.1.1 Each 1 x 28w Fluroscent light fitting similar 10 2,580 80 2,660 26,600

to WIPRO make WIF 21128 APF or

equivalent (Surface mounted / suspended)

7.1.2 Each 1 x 18w Recess mounted CFL down 45 1,500 80 1,580 71,100

lighter similar to WIPRO make

WCP 32118SGW

7.1.3 Each 2 x 18w Recess mounted CFL down 20 1,700 100 1,800 36,000

lighter similar to WIPRO make

WCP 32218SGW

7.1.4 Each 1 x 18w wall mounted light similar to 4 2,580 80 2,660 10,640

7.1.5 Each 2 x 11w surface mounted light similar R.O.

to WIPRO make WVP 41211

Total for 7.0 144340

8 EARTHING

8.1 Earthing Stations

-

8.1.1 Providing plate earthing stations for 2 14500 4900 19,400 38,800

Transformer body and neutral and also

for equipment earthing with 600 x 600

x 3mm copper plate as specified and

as per IS 3043 - 1987 complete with

a) Excavation in hard murram

b) Electrode with disconnecting

link arrangement.

c) Watering pipe.

d) Brick masonary chamber with C.I

frame and hinged covers.

e) Bentonite fill.

8.2 Earth wire/strips

Supply & laying Cu earthing strips for

interconnecting the earthing stations,

panels, DB's etc. in built-up trenches,

on walls/ceiling, buried in ground,

generally as specified & shown

on drawings complete with;

a) Fixing accessories.

b) Corrosion protection of

buried conductors with

bituminous coating and

covered with PVC tapes.

8.2.1 m 25 x 6 mm Cu 150 555 65 620 93,000

8.2.2 m 25 x 4 mm Cu R.O

8.2.3 m 25 x 3 mm Cu R.O

8.2.4 m 20 x 6 mm Cu R.O

8.2.5 m No. 8 SWG Cu bare wire 150 110 20 130 19,500

8.2.6 m No. 6 SWG Cu bare wire R.O.

Total for 8.0 151300

9.1 FIRE SAFETY AUXILIARIES

9.1,1 m

2

b) Supply and installation of 1000 V 6 1,550 150 1,700 10,200

grade rubber matting in front of

panels

9.1.2 Each Supply and installation of First aid 4 1,050 175 1,225 4,900

box & framed first aid chart in

LT panel room

9.1.3 Each Supply and instalaltion of shock 4 875 175 1,050 4,200

treatment chart in LT room

9.1.4 Each Supply & Installation of 440V 10 520 135 655 6,550

Danger boards

Total for 9.0 3,995 635 25,850

You might also like

- Boq For LED Lights Category ADocument10 pagesBoq For LED Lights Category AvenkateswararaoNo ratings yet

- Final Offer ElectricalDocument107 pagesFinal Offer Electricalnaam9100% (1)

- Summary of Cost For Internal Plumbing/Sanitary Works: S.NO. Description Supply Installation Total Amount (RS)Document5 pagesSummary of Cost For Internal Plumbing/Sanitary Works: S.NO. Description Supply Installation Total Amount (RS)pravin patilNo ratings yet

- Cable Laying Work Boq For Slice-101 Existing Rates: The Rate Shall Also Include The FollowingDocument4 pagesCable Laying Work Boq For Slice-101 Existing Rates: The Rate Shall Also Include The FollowingAmit JhaNo ratings yet

- Estimation For Store RoomDocument17 pagesEstimation For Store RoompviccuNo ratings yet

- INDORAMA INTERNAL ELEC BOQ JANUS 28 Aug 2009Document23 pagesINDORAMA INTERNAL ELEC BOQ JANUS 28 Aug 2009api-26636519No ratings yet

- Proforma of SchedulesDocument13 pagesProforma of SchedulesAmit Sharma100% (1)

- Electrical BOQDocument22 pagesElectrical BOQRahul Kumar100% (1)

- DATE: 30-01-15 Project: Aspire International Shool Services: Electrical Systems Price Summary Sr. No. Description Amount Amount in Words HT WorkDocument53 pagesDATE: 30-01-15 Project: Aspire International Shool Services: Electrical Systems Price Summary Sr. No. Description Amount Amount in Words HT WorkaniketNo ratings yet

- Electrical BOQDocument3 pagesElectrical BOQRakesh Mitra100% (1)

- Schedule of QuantityDocument9 pagesSchedule of Quantityexecutive engineerNo ratings yet

- Nagendra Ji QuotationDocument2 pagesNagendra Ji QuotationWhole Solar100% (1)

- Tender Schedule For Electrical Work PDFDocument6 pagesTender Schedule For Electrical Work PDFnakul4491_88890127No ratings yet

- QUOTATION Mabelah HealhtDocument6 pagesQUOTATION Mabelah HealhtDelwar Hossain100% (1)

- Electrical Boq SF With Assembly HallDocument5 pagesElectrical Boq SF With Assembly HallSUSOVAN BISWASNo ratings yet

- BOQ ElectricalDocument2 pagesBOQ ElectricalSachin ShindeNo ratings yet

- 8th Floor Plumbing BOQDocument6 pages8th Floor Plumbing BOQsathish virupaksheNo ratings yet

- Boq Civil Plumbing 2019Document27 pagesBoq Civil Plumbing 2019faisal riaz100% (1)

- Lighting BOQ Offer 14.11.19Document3 pagesLighting BOQ Offer 14.11.19Akd Deshmukh100% (1)

- Quotation RK-QUO-2022-005 Rev 00 - Ahamd YatiDocument2 pagesQuotation RK-QUO-2022-005 Rev 00 - Ahamd YatiG RajakumarNo ratings yet

- Providing AC Facilities and Power Plugs To Insurance Ward at District Head Quarters Hospital in RamanathapuramDocument3 pagesProviding AC Facilities and Power Plugs To Insurance Ward at District Head Quarters Hospital in RamanathapuramRajaDurai Ramakrishnan100% (1)

- Electrical BOQDocument22 pagesElectrical BOQSAI ASSOCIATE100% (1)

- BOQ Trunking Tray ConduitDocument2 pagesBOQ Trunking Tray ConduitOanh NguyenNo ratings yet

- BOQ For Electrical WorksDocument2 pagesBOQ For Electrical Workskkundan52No ratings yet

- Internal LightingDocument52 pagesInternal Lightingaeliusmano100% (1)

- Electrical Estimate & BOQDocument22 pagesElectrical Estimate & BOQkiran raghukiran100% (1)

- Electrical BOQ Purulia Warehouse - SURENDRA JI - 12.10.2019Document6 pagesElectrical BOQ Purulia Warehouse - SURENDRA JI - 12.10.2019aiplNo ratings yet

- 31-05-2024 - VA-KURK - TEND-BOQ-401-T0 (For RFP)Document25 pages31-05-2024 - VA-KURK - TEND-BOQ-401-T0 (For RFP)newattelectricNo ratings yet

- Bill of QuantityDocument2 pagesBill of QuantityMuhammad Shakil JanNo ratings yet

- BSR Electrical 2017Document37 pagesBSR Electrical 2017sunmayu100% (2)

- Electrical Estimate Rev1 TemplateDocument13 pagesElectrical Estimate Rev1 TemplateFerdinand UbaldoNo ratings yet

- Engineering Projects India Limited Hal Project, Nasik: Boq No Description Unit Quantity Rate AmountDocument11 pagesEngineering Projects India Limited Hal Project, Nasik: Boq No Description Unit Quantity Rate AmountBaseer AnsariNo ratings yet

- Bill of Quantities (BOQ) For Supply and Installation of Diesel Generator For CPP/ UNDPDocument3 pagesBill of Quantities (BOQ) For Supply and Installation of Diesel Generator For CPP/ UNDPsani priadiNo ratings yet

- Rate Analysis ElectricalDocument8 pagesRate Analysis ElectricalLahiru Prabash GunawardanaNo ratings yet

- S.No Description Qty Rate (RS.) Amount (RS.) RXQ12ARY6 - Daikin VRV X 12HP ODU Cooling OnlyDocument10 pagesS.No Description Qty Rate (RS.) Amount (RS.) RXQ12ARY6 - Daikin VRV X 12HP ODU Cooling Onlysenthil kumarNo ratings yet

- Contractor Rate List DetailsDocument6 pagesContractor Rate List DetailsaeliusmanoNo ratings yet

- Electrical Quotation Template ContractorbhaiDocument1 pageElectrical Quotation Template ContractorbhaishilpaNo ratings yet

- Elecrical Rate 072-073 (KTM)Document116 pagesElecrical Rate 072-073 (KTM)surendramaharjan100% (2)

- Abstract Estimate: DescriptionDocument24 pagesAbstract Estimate: DescriptionSafa AliNo ratings yet

- Rate AnalysisDocument3 pagesRate AnalysisDnyanesh SNo ratings yet

- Quotation 615-4078 BabulalDocument14 pagesQuotation 615-4078 Babulaldevrajan631No ratings yet

- Gupsum Board PDFDocument2 pagesGupsum Board PDFMuhammadYehiaNo ratings yet

- Regency Hotel BoqDocument5 pagesRegency Hotel BoqJohn Chester GayetaNo ratings yet

- Wamanwadi - Electrical & FAPA BOQDocument51 pagesWamanwadi - Electrical & FAPA BOQCoral bhaiNo ratings yet

- Sungai Merab PDFDocument1 pageSungai Merab PDFKiey WanNo ratings yet

- R1-External Electrical BOQ - ComparativeDocument8 pagesR1-External Electrical BOQ - ComparativeyogeshNo ratings yet

- Final BOQ - Sky Pool Project 19 Feb 2023Document8 pagesFinal BOQ - Sky Pool Project 19 Feb 2023Hebatallah NassarNo ratings yet

- Ele-Hiside Installation BoqDocument20 pagesEle-Hiside Installation BoqjobswithkumarNo ratings yet

- Pinnacle Plumbing QuotationDocument4 pagesPinnacle Plumbing QuotationNakimera JosephineNo ratings yet

- Sample BOQ For Panel & EarthingDocument10 pagesSample BOQ For Panel & EarthingMEP - Arena ConsultantsNo ratings yet

- Boq AtsDocument1 pageBoq AtsMHD FAJRINo ratings yet

- Electrical Installation For 2nd and 3rd Floor QDocument2 pagesElectrical Installation For 2nd and 3rd Floor QWelday GebremichaelNo ratings yet

- Quotation Portacabin-NormalDocument4 pagesQuotation Portacabin-NormalBhavanishankar ShettyNo ratings yet

- Elec BoqDocument4 pagesElec BoqSarvajeet VermaNo ratings yet

- Kitec Price ListDocument10 pagesKitec Price ListvipinabrolNo ratings yet

- New VERTEX - E2 VILLA-ELEC BOQDocument4 pagesNew VERTEX - E2 VILLA-ELEC BOQsanjeev janagamaNo ratings yet

- Load Distribution ScheduleDocument10 pagesLoad Distribution SchedulehafizrahimmitNo ratings yet

- Electrical BOQ150710Document11 pagesElectrical BOQ150710Jaime Manalili LandinginNo ratings yet

- Plumbing BOQ 1Document72 pagesPlumbing BOQ 1Rajshekhar Kategar0% (1)

- WiringDocument8 pagesWiringANKIT KUMAR RAJNo ratings yet

- 24th Sep 2017 Loose Furniture With Fabricating CostingDocument20 pages24th Sep 2017 Loose Furniture With Fabricating CostingSantosh ThakurNo ratings yet

- Due Diligence Report - AW RefurbDocument32 pagesDue Diligence Report - AW RefurbSantosh ThakurNo ratings yet

- Research On DesignDocument1 pageResearch On DesignSantosh ThakurNo ratings yet

- Ar. Santosh Thakur: Key Business SkillsDocument3 pagesAr. Santosh Thakur: Key Business SkillsSantosh ThakurNo ratings yet

- E Commerce 311 v1Document408 pagesE Commerce 311 v1Santosh ThakurNo ratings yet

- InvoiceDocument1 pageInvoiceSantosh ThakurNo ratings yet

- Connect Mail - Re - Space Matrix - Savills Office Refurbish at Capital - MOM - 03 - DrainDocument6 pagesConnect Mail - Re - Space Matrix - Savills Office Refurbish at Capital - MOM - 03 - DrainSantosh ThakurNo ratings yet

- A Voice / Data / Signal Unit Qty Rate Amount: Notes Sub Total 45,990.00 Taxes TaxesDocument1 pageA Voice / Data / Signal Unit Qty Rate Amount: Notes Sub Total 45,990.00 Taxes TaxesSantosh Thakur100% (1)

- SITE:-Sodexo 6 FL - Andheri: Additional WorkDocument3 pagesSITE:-Sodexo 6 FL - Andheri: Additional WorkSantosh ThakurNo ratings yet

- 5.6.1 Lessons Learnt TemplateDocument1 page5.6.1 Lessons Learnt TemplateSantosh ThakurNo ratings yet

- Fire Alarm SystemDocument3 pagesFire Alarm SystemSantosh ThakurNo ratings yet

- Storage FORUM 2Document1 pageStorage FORUM 2Santosh ThakurNo ratings yet

- Final Revised BOQ 12062014Document5 pagesFinal Revised BOQ 12062014Santosh ThakurNo ratings yet

- Ar. Santosh Thakur: Key Business SkillsDocument2 pagesAr. Santosh Thakur: Key Business SkillsSantosh ThakurNo ratings yet

- Summary of Accounts Held Under Cust ID: 530111494 As On April 30, 2014Document2 pagesSummary of Accounts Held Under Cust ID: 530111494 As On April 30, 2014Santosh ThakurNo ratings yet

- Plumbing Work: Shop No: - 01 Khokar House Naya Nagar, Mira Road (East) Thane 401107Document4 pagesPlumbing Work: Shop No: - 01 Khokar House Naya Nagar, Mira Road (East) Thane 401107Santosh ThakurNo ratings yet

- Storage FORUM 1Document1 pageStorage FORUM 1Santosh ThakurNo ratings yet

- Megas Architectural Services PVT - LTD.: A Civil /interior WorksDocument3 pagesMegas Architectural Services PVT - LTD.: A Civil /interior WorksSantosh ThakurNo ratings yet

- The Syllabus of The Course Is As Follows: Module 1: Company LawDocument1 pageThe Syllabus of The Course Is As Follows: Module 1: Company LawSantosh ThakurNo ratings yet

- Architect / Consultant Sandeep Govalkar Design Associates Client: Central Bank of India Project: - Proposed Air Conditioning Work of Vikhroli BranchDocument2 pagesArchitect / Consultant Sandeep Govalkar Design Associates Client: Central Bank of India Project: - Proposed Air Conditioning Work of Vikhroli BranchSantosh ThakurNo ratings yet

- DateDocument1 pageDateSantosh ThakurNo ratings yet

- BOQ-CIVIL Sample LucknowDocument25 pagesBOQ-CIVIL Sample LucknowSantosh Thakur100% (1)

- Area Calculation NagpurDocument2 pagesArea Calculation NagpurSantosh ThakurNo ratings yet

- Preservation of Isparta Yılan Kırkan (Yılan Kıran) Fountain Within The Scope of SustainabilityDocument1 pagePreservation of Isparta Yılan Kırkan (Yılan Kıran) Fountain Within The Scope of SustainabilitySantosh ThakurNo ratings yet

- Indian Institute of Technology Kanpur Institute Works Department Division - IDocument12 pagesIndian Institute of Technology Kanpur Institute Works Department Division - ISantosh ThakurNo ratings yet

- Marutisuzukirjobcare@live - In: Maruti Suzuki India LTD (Msil)Document2 pagesMarutisuzukirjobcare@live - In: Maruti Suzuki India LTD (Msil)Santosh ThakurNo ratings yet

- 3218d DIGIDRIVE enDocument100 pages3218d DIGIDRIVE enAlberto Bronstein AleakisNo ratings yet

- 162 SL ManualDocument31 pages162 SL ManualZoranNo ratings yet

- Wireless Charging of Electric VehiclesDocument7 pagesWireless Charging of Electric VehiclesElena Paul ElenaNo ratings yet

- Oral Question Bank For Class IV ExaminationsDocument35 pagesOral Question Bank For Class IV ExaminationsSwarg VibhaNo ratings yet

- 36v 1000w Brushless DC Motor - Buy 36v 1000w Brushless DC Motor, 36v 1000w Brushless DC Motor, 36v 1000w Brushless DC Motor Product OnDocument10 pages36v 1000w Brushless DC Motor - Buy 36v 1000w Brushless DC Motor, 36v 1000w Brushless DC Motor, 36v 1000w Brushless DC Motor Product Onjenn besana TataNo ratings yet

- 8.2.7 Undervoltage Tripping by Means of An Emergency Stop Device - Category 1 - PL C (Example 7)Document2 pages8.2.7 Undervoltage Tripping by Means of An Emergency Stop Device - Category 1 - PL C (Example 7)TorteskiNo ratings yet

- TNEI Transmission and Distribution Services Brochure B2Document4 pagesTNEI Transmission and Distribution Services Brochure B2royclhorNo ratings yet

- Open Loop and Closed Loop Control SystemDocument7 pagesOpen Loop and Closed Loop Control SystemNishant GuptaNo ratings yet

- Current Electricity DPP 02 of Lec 03 Lakshya JEE 202464770310dfe3ce001844b07bDocument3 pagesCurrent Electricity DPP 02 of Lec 03 Lakshya JEE 202464770310dfe3ce001844b07bkaushikkundu8587No ratings yet

- CDHD2 ECT CAN fw2.15.x Rev.1.0 PDFDocument499 pagesCDHD2 ECT CAN fw2.15.x Rev.1.0 PDFDon BozarthNo ratings yet

- UNIT2L2SDocument20 pagesUNIT2L2SJack CardiagNo ratings yet

- Data Sheet - Quantran Dimmer RacksDocument2 pagesData Sheet - Quantran Dimmer Racksmuqtar4uNo ratings yet

- Distribution Transformers EMCDocument8 pagesDistribution Transformers EMCmazinmaazNo ratings yet

- Oct 2022 Unit 3 QPDocument20 pagesOct 2022 Unit 3 QPOmarNo ratings yet

- Powersub Vacuum Substation Circuit Breaker, Type FVR: 15-38 KV, 110-150 KV BIL, 1200-4000 A Class 6065Document80 pagesPowersub Vacuum Substation Circuit Breaker, Type FVR: 15-38 KV, 110-150 KV BIL, 1200-4000 A Class 6065Andika Permana NugrahaNo ratings yet

- BJT BiasingDocument26 pagesBJT BiasingShafiul Huda Eraz100% (1)

- Sub Sec 1 To 9Document1 pageSub Sec 1 To 9khan4luvNo ratings yet

- V24-Tty Passive ManualDocument1 pageV24-Tty Passive ManualJair PinhoNo ratings yet

- Sales SMA Products 2-En-123910 - WebDocument104 pagesSales SMA Products 2-En-123910 - WebMohammad Talib Maqatif100% (1)

- Electronic Ballasts and Inrush Current Technical BulletinDocument2 pagesElectronic Ballasts and Inrush Current Technical Bulletindbogantesg9710No ratings yet

- L&T Make RelayDocument31 pagesL&T Make RelayKishore KrishnaNo ratings yet

- 'Meter Bus Transceiver Tss721a 1Document4 pages'Meter Bus Transceiver Tss721a 1Florian_AngererNo ratings yet

- NAEST 2022 Prelims EXPERIMENT-3Document3 pagesNAEST 2022 Prelims EXPERIMENT-3Prapanj KtNo ratings yet

- Tutorial - DC SystemDocument50 pagesTutorial - DC SystemCarlos Puerto100% (1)

- CHAPTER 2: System Modeling in Frequency DomainDocument98 pagesCHAPTER 2: System Modeling in Frequency DomainSanji KarunaNo ratings yet

- Moog D633Document16 pagesMoog D633Balu M100% (1)

- Tmx-r1000 Service ManualDocument61 pagesTmx-r1000 Service Manualroca9o100% (1)

- EEE241L - Lab 6 - RLC ResonanceDocument4 pagesEEE241L - Lab 6 - RLC ResonanceMd. Imdadul Haque Nayan 2222846643No ratings yet

- SERSDocument10 pagesSERS李攀No ratings yet