Steel Pushover Analysis

Steel Pushover Analysis

Uploaded by

Dario Manrique GamarraCopyright:

Available Formats

Steel Pushover Analysis

Steel Pushover Analysis

Uploaded by

Dario Manrique GamarraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Steel Pushover Analysis

Steel Pushover Analysis

Uploaded by

Dario Manrique GamarraCopyright:

Available Formats

Pushover Analysis as per EC8:2004

Gen Training Series

Pushover Analysis of steel structure

as per EC8:2004

DL

Program Version

V7.4.1

Program License

Registered, Trial

Revision Date

SD

NC

2008.12.26

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

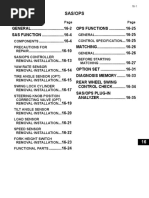

Overview

Pushover analysis is one of the performance-based design

Optimal Design Procedure

The pushover analysis procedure is as follows:

methods, recently attracting practicing structural engineers

engaged in the field of seismic design. The objective of a

performance-based design is achieved after the owner and the

Modeling & Design

designer collectively select a target performance for the

- Details of Building

structure in question. The engineer carries out the conventional

- Perform analysis

design and subsequently performs a pushover (elasto-plastic)

- Perform steel code checking

analysis to evaluate if the selected performance objective has

been met.

Pushover Analysis

- Pushover Global Control

In midas Gen V741, pushover analysis as per EN1998:2004

- Pushover Load Cases

is newly added, and analysis performance and usability are

- Define Hinge Properties

significantly improved. This tutorial explains the method and

- Assign Hinge Properties

procedure for pushover analysis of 3-dimensional Steel

- Perform Pushover Analysis

structures as per EN1998:2004. For this reason, the procedure

- Pushover Curve

for modeling and analysis were not explained in detail. For the

- Pushover Hinge Status Results

users who are not familiar with the basic functions for modeling

- Safety Verification Table

and analysis, it is recommended to review Application 1

tutorial before following this tutorial.

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Details of the example structure

Section Name

Section ID

Section DB

Section Size

C1

UNI

HEA240

C2

UNI

HEA300

G1

21

UNI

HEA280

G2

22

UNI

IPE240

Brace1

31

UNI

HEA160

Brace2

32

UNI

HEA120

Figure 1. Three-dimensional structural model

3,000

BR1

10,000

2,500

2,500

2,500

2,500

BR

BR1

3,000

G1

C2

BR2

G2

A

C2

BR

G2

C1

Figure 2. Structural plan

3

9,000

G2

G1

C1

G1

6,000

C2

3,000

G2

C2

Figure 3. Elevation

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Applied Design Code

Eurocode3:2005

Materials

Column: S235

Beam: S235

Brace: S235

Applied Loads

Gravity loads

Dead load: 4.9kN/m2

Live load : 2.5kN/m2

Unit Load Cases

Load

Static Wind Loads

Applied code: Eurocode1:2005

Terrain Category : II

Fundamental Basic Wind Velocity (Vb,o): 26m/s

Static Seismic Loads

Applied code: Eurocode8:2004

Ground Type: B

Design Ground Acceleration: 0.08g

Behavior Factor (q): 1.5

Lower Bound Factor (b): 0.2

Importance Factor (I) : 1

4

Static

Load

Cases

Name

Details

DL

Dead Load

LL

Live Load

WX

Wind Load

(X-direction in the global coordinates)

XY

Wind Load

(Y-direction in the global coordinates)

EX

Seismic Load

(X-direction in the global coordinates)

EY

Seismic Load

(Y-direction in the global coordinates)

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 1. Open the model file and perform analysis

1. Open Steel pushover analysis.mgb

2. Select Works tab in the Tree Menu.

Pushover analysis is carried out in the post-processing mode

after completing elastic analysis.

3. Check the entered section data and boundary condition in

Properties and Boundaries.

4. In the tree menu, select Static Loads>Static Load Case 1

and then right click Floor Loads:3.

7

2

5. In the context Menu, select Display and then check the

applied loads.

6. By this way, check the applied seismic loads and wind

loads.

7. Click

icon to perform analysis.

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 2: Check Steel Design Code

1.

2.

3.

Design > Steel Design Parameter > Design Code

Specify the code as Eurocode3:05.

Check [OK] button.

Design Code specified in the Steel Design Code dialog is

applied to calculate the capacity of members in pushover

analysis.

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 3: Steel Code Checking

Rotation capacity at the end of steel beams

or columns depends on the class of cross

1.

Design > Steel Code Checking

section. In order for the program to

automatically determine the class of cross

section for the pushover analysis, select

Auto. For the automatic classification

Steel Code Checking should be performed

first.

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 4-1: Pushover Global Control

1.

2.

3.

4.

5.

Design > Pushover analysis > Pushover Global Control

Select DL in the combo box and click [Add] button.

Select LL in the combo box and enter the Scale Factor as 0.25.

Click [Add] button.

Click [OK] button.

In this step, we will define the initial load cases, which

will be applied prior to pushover analysis such as dead

load and live load.

2,3

2,4

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 4-2: Pushover Global Control

Reference Design code (Eurocode 8:2004) option is displayed when

the design code (in the main menu, Design > Concrete Design

Parameter or Steel Design Parameter > Design code) is specified as

Eurocode and Design code in preferences (in the main menu, Tools >

Preferences) is specified as Eurocode.

Scale Factor for Ultimate Rotation

1) Wall: In calculating the total chord rotation capacity at ultimate , u, for wall , the value is divided

by 1.6 as per EN1998-3:2004 A.3.1.1.

2) Cold-worked brittle steel: If cold-worked brittle steel is used the total chord rotation capacity is

divided by 1.6 as per EN1998-3:2004 A.3.1.1.

3) Without Detailing for earthquake resistance: In members without detailing for earthquake

resistance the total chord rotation capacity is multiplied by 0.85 as per EN1998-3:2004 .

4) Smooth longitudinal bars: in members with smooth (plain) longitudinal bars without lapping in

the vicinity of the end region where yielding is expected, the total chord rotation capacity may be

multiplied by 0.575 as per EN1998-3:2004.

MIDAS Information Technology Co., Ltd.

Gen Training Series

Pushover Analysis as per EC8:2004

Step 4-3: Pushover Global Control

Secondary Seismic Elements

In order to calculate the total chord rotation capacity at ultimate, u, the factor el is used. Since el is differently applied for primary and

secondary seismic elements (el = 1.5 for primary seismic elements, el = 1.0 for secondary seismic elements as per EN1998-3:2004

A.3.1.1), the user can define Secondary Seismic Elements group. If Secondary Seismic Elements are not defined, all the elements are

considered as Primary Seismic Elements.

In this tutorial, Secondary Seismic Elements are not defined since pushover hinge properties are assigned to primary elements only.

10

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 5-1: Pushover Load Case

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Design > Pushover analysis > Pushover Load Cases

Click [Add] button.

Enter the pushover load case name as Accel_X.

Enter the Increment Steps as 30.

Check on Use Initial Load option.

Check on Consider P-Delta Effect option.

Select Displacement Control in the Increment Method.

Select Mater Node option.

Click the entry field and click the node no. 20 with the

mouse in the model view.

Enter the Max. Displacement as 0.12m.

Check off Limit inter-Story Deformation Angle

option.

Specify the Load Pattern as Uniform Acceleration.

Specify the Direction as DX in the combo box and click

[Add] button.

Click [OK] button.

3

4

6

7

8

10

11

9

12

13

13

14

11

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 5-2: Pushover Load Case

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Design > Pushover analysis > Pushover Load Cases

Click [Add] button.

Enter the pushover load case name as EY_Y.

Enter the Increment Steps as 30.

Check on Use Initial Load option.

Check on Consider P-Delta Effect option.

Select Displacement Control in the Increment Method.

Select Mater Node option.

Click the entry field and click the node no. 20 with the

mouse in the model view.

Enter the Max. Displacement as 0.3m.

Check off Limit inter-Story Deformation Angle option.

Specify the Load Pattern as Static Load Cases.

Specify the Load Case as EY in the combo box and

click [Add] button.

Click [OK] button.

3

4

6

7

8

10

11

12

13

13

14

12

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 6-1: Define Pushover Hinge Properties for beams

1.

2.

3.

4.

5.

6.

7.

8.

Design > Pushover analysis > Define Pushover Hinge Properties

Click [Add] button.

Enter the pushover hinge properties name as Beam.

Select the Material Type as Steel / SRC(Filled)

Check on Fz & Mz components.

Click [Properties] button for My component.

Select the Class of cross section as Auto.

Click [Apply] button.

In order to check or modify the hinge properties, click [Properties]

button of the desired component.

4

9

13

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 6-2: Define Pushover Hinge Properties for Columns

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

Enter the pushover hinge properties name as Column.

Select the Material Type as Steel / SRC(Filled)

Select P-M-M in Status Determination option for Interaction Type.

Check on Fy, Fz & My components.

Click [Yield Surface Properties] button.

Click [Y-Axis] button for My component.

Select the Class of cross section as Auto.

Click [OK] button.

Click [z-Axis] button for My component.

Select the Class of cross section as Auto.

Click [OK] button.

7,10

Click [OK] button.

Click [Apply] button.

Coupled axial force-biaxial moment behavior is reflected by

calculating the flexural yield strength of a hinge considering the

effect of axial force.

6,9

2

8,11

5

12

14

13

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 6-3: Define Pushover Hinge Properties for braces

1.

2.

3.

4.

5.

6.

7.

8.

9.

Enter the pushover hinge properties name as Brace.

Select the Element Type as Truss.

Select the Material Type as Steel / SRC(Filled)

Check on Fx component.

Click [Properties] button for Fx component.

Select the Class of cross section as Auto.

Click [OK] button.

Click [OK] button.

Click [Close] button.

2

6

15

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Pushover Hinge Properties

Yield strength of Steel structures

Shear

Hinge

Eurocode3:2005, equation (6.18)

Yield rotation of Steel structures

Flexural

Hinge

Class

Class 1

Class 2

DL

1.0y

0.25 y

SD

6.0 y

2.0 y

NC

8.0 y

3.0 y

*y= MyL/6EI

Where, My: Yield moment, L: Length of a member, E: Elasticity of Modulus, I: moment of inertia

16

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 7-1: Assign Pushover Hinge Properties for columns

1.

2.

3.

4.

5.

Select column members (Material ID 1:Column) from the Tree Menu.

Design > Pushover analysis > Assign Pushover Hinge Properties

Select Hinge Properties Type as Column in the combo box.

Click [Apply] button.

Click [Close] button.

Right-click

3

4

17

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 7-2: Assign Pushover Hinge Properties for Beams

1.

2.

Select beam members (Material ID 2:Girder) from the Tree Menu.

Drag and drop the Beam hinge property from the Tree Menu to the

Model Window .

Pushover hinge properties can be simply assigned to the

selected elements by Drag & Drop.

1

Right-click

18

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 7-3: Assign Pushover Hinge Properties for braces

1.

2.

Select brace members from the Tree Menu.

Drag and drop the Brace hinge property from the Tree Menu to the

Model Window .

Pushover hinge properties can be simply assigned to the

selected elements by Drag & Drop.

Right-click

19

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 8: Check assigned hinge properties

1.

2.

3.

4.

Before assigning hinge properties (while defining hinge

Right-click B1_Column from the Tree Menu.

Select Properties from the context menu.

Check the calculated yield strength and yield strain.

Click [Detail] button to check the calculated values in detail.

properties), Yield Strength and Yield Strain are displayed

as 1. After assigning hinge properties, calculated values

for each element are displayed.

By clicking [Detail] button, the user can check the

detailed equation and values.

Right-click

Before assigning hinge properties

20

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 9: Perform pushover analysis

1.

2.

3.

Click Task Pane.

Click icon and select Analysis.

Click Perform Pushover Analysis.

Task Pane displays work procedure for

advanced

analysis

functions

and

description on input items so as to enable

the user to work more easily.

2

midas program provides 4 types of

advanced analysis features - Pushover

Analysis,

3

Nonlinear

Time

History

Analysis, Time History Analysis and

Material Nonlinear Analysis.

In addition, Task Pane data can be

saved in the html format in the User

Folder, so that the user can directly write

or add the required input items for

analysis.

21

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

2

Step 10-1: Pushover Curve

1.

2.

3.

4.

5.

6.

7.

Click Pushover Curve in the Task Pane.

Select the Pushover Load Case as Accel_X.

Select For Target Displacement

(EC8/Masonry).

Select the Spectrum Type as Horizontal Design

Spectrum.

Enter the Design Ground Acc.(Ag) as 0.5.

Enter the Behavior Factor (b) as 1.5.

Click [Draw] button.

7

For the detailed formula of the Target Displacement, refer to ANNEX B DETERMINATION OF THE

TARGET DISPLACEMENT FOR NONLINEAR STATIC (PUSHOVER) ANALYSIS, EN 1998-1:2004. The

target displacement, which is obtained from the above, corresponds to the seismic demand of the Limit State of

Significant Damage (SD). Target displacement of the Limit State of Near Collapse (NC) is taken equal to that

of SD multiplied by 1.5. Target displacement of the Limit State of Damage Limitation (DL) is taken equal to

that of SD divided by 2.5.

22

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

1

Step 10-2: Pushover Curve

1.

2.

3.

4.

5.

6.

7.

Select the Pushover Load Case as EY_Y.

Select For Target Displacement

(EC8/Masonry).

Select the Spectrum Type as Horizontal Design

Spectrum.

Enter the Design Ground Acc.(Ag) as 0.5.

Enter the Behavior Factor (b) as 1.5.

Click [Draw] button.

Click [Close] button.

4

5

For the detailed formula of the Target Displacement, refer to ANNEX B DETERMINATION OF THE

TARGET DISPLACEMENT FOR NONLINEAR STATIC (PUSHOVER) ANALYSIS, EN 1998-1:2004. The

target displacement, which is obtained from the above, corresponds to the seismic demand of the Limit State of

Significant Damage (SD). Target displacement of the Limit State of Near Collapse (NC) is taken equal to that

of SD multiplied by 1.5. Target displacement of the Limit State of Damage Limitation (DL) is taken equal to

that of SD divided by 2.5.

23

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 11-1: Hinge Status Results

Click Hinge Status Results in the Task Pane.

Select the Pushover Load Cases Name as

Accel_X.

Select Status of Yielding (EC8:2004).

Select the Components as Ry.

Check on Legend and Deform.

Specify the desired step in the combo box.

1.

2.

3.

4.

5.

6.

Clicking and scrolling

Clicking on the graph

The user can also check hinge status results for

each step by clicking on the step box and scroll

or clicking on the pushover graph which is

displayed in the black background.

4

1

5

24

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 11-2: Hinge Status Results

1.

2.

3.

4.

5.

Select the Pushover Load Cases Name as

EY_Y.

Select Status of Yielding (EC8:2004).

Select the Components as Ry.

Check on Legend and Deform.

Specify the desire step in the combo box.

25

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 12-1: Safety Verification Table

1.

2.

3.

4.

5.

6.

7.

Click Safety Verification Table in the Task Pane.

Select Show All Elements.

Click [OK] button.

Select Pushover Load Case as Accel_x.

Select Significant Damage (SD).

Check on My and Fz.

Click [OK] button.

2

3

5

Safety Verification Table displays the comparison results between the demand and

capacities of the elements as per EN1998-3:2004 Table 4.3. Safety verification shall be

conducted for both ductile and brittle elements respectively. For ductile elements,

6

verification will be conducted in terms of deformation using mean values of properties

divided by CF. For brittle elements, verification shall be conducted in terms of strength

26

using mean values of properties divided by CF and by partial factor.

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Step 12-2: Safety Verification Table

1.

2.

3.

4.

5.

Right-click on the table and select Set Safety

Verification in the Context menu.

Select Pushover Load Case as EY_Y.

Select Significant Damage (SD).

Check on My and Fz.

Click [OK] button.

1

2

3

Safety Verification Table displays the comparison results between the demand and

capacities of the elements as per EN1998-3:2004 Table 4.3. Safety verification shall be

conducted for both ductile and brittle elements respectively. For ductile elements,

4

verification will be conducted in terms of deformation using mean values of properties

divided by CF. For brittle elements, verification shall be conducted in terms of strength

27

using mean values of properties divided by CF and by partial factor.

MIDAS Information Technology Co., Ltd.

Pushover Analysis as per EC8:2004

Gen Training Series

Capacity of Steel structures for assessment in the Safety Verification Table (Eurocode8-3:2004, Annex A.3.1)

Plastic rotation

capacity

Shear capacity

Class

Class 1

Class 2

DL

1.0y

0.25 y

SD

6.0 y

2.0 y

NC

8.0 y

3.0 y

Eurocode3:2005, equation (6.18)

*For ductile elements, mean values of properties divided by CF are used. For brittle members, mean values of properties

divided by CF and by partial factor.

*y= MyL/6EI

Where, My: Yield moment, L: Length of a member, E: Elasticity of Modulus, I: moment of inertia

28

MIDAS Information Technology Co., Ltd.

You might also like

- Final Project - ML - Nikita Chaturvedi - 03.10.2021 - Jupyter Notebook100% (11)Final Project - ML - Nikita Chaturvedi - 03.10.2021 - Jupyter Notebook154 pages

- Direct Analysis and Design Using Amplified First Order Analysis2part PDFNo ratings yetDirect Analysis and Design Using Amplified First Order Analysis2part PDF27 pages

- Member Member Member Member Behavior Behavior Behavior Behavior100% (3)Member Member Member Member Behavior Behavior Behavior Behavior61 pages

- LATBSDC PEER CSSC Tall Building Design Case Study 1-05-09No ratings yetLATBSDC PEER CSSC Tall Building Design Case Study 1-05-0927 pages

- Floor Vibration Serviceability - Tips and Tools For Negotiating A Successful DesignNo ratings yetFloor Vibration Serviceability - Tips and Tools For Negotiating A Successful Design8 pages

- A Finite Element Approach To Reinforced Concrete Slab DesignNo ratings yetA Finite Element Approach To Reinforced Concrete Slab Design170 pages

- Response of Structures To Earthquake Ground Motions100% (2)Response of Structures To Earthquake Ground Motions25 pages

- CE 581 Reinforced Concrete Structures: Lecture 11: Performance Based Assessment and StrengtheningNo ratings yetCE 581 Reinforced Concrete Structures: Lecture 11: Performance Based Assessment and Strengthening131 pages

- A Practical Look at Frame Analysis, Stability, and Leaning ColumnsNo ratings yetA Practical Look at Frame Analysis, Stability, and Leaning Columns29 pages

- Seismic Behavior of Short Coupling Beams With Different Reinforcement LayoutsNo ratings yetSeismic Behavior of Short Coupling Beams With Different Reinforcement Layouts10 pages

- Reinforced Concrete Structural Walls Test Database and Modeling ParametersNo ratings yetReinforced Concrete Structural Walls Test Database and Modeling Parameters334 pages

- Bridge Foundations, Modeling Large Pile Groups - Po Lam, H.law and R. Martin100% (2)Bridge Foundations, Modeling Large Pile Groups - Po Lam, H.law and R. Martin148 pages

- 2019 04 18 Understanding The Aisc Direct Analysis Method of Design HandoutNo ratings yet2019 04 18 Understanding The Aisc Direct Analysis Method of Design Handout85 pages

- A Simplified Look at Partially Restrained Beams - GESCHWINDNER - 1991No ratings yetA Simplified Look at Partially Restrained Beams - GESCHWINDNER - 19916 pages

- SESOC - Tips For The Better Design of Low RiseNo ratings yetSESOC - Tips For The Better Design of Low Rise399 pages

- Displacement Based Seismic Design Chapter 01 (Points)No ratings yetDisplacement Based Seismic Design Chapter 01 (Points)14 pages

- Strength of High-Rise Shear Walls - Rectangular Cross SectionNo ratings yetStrength of High-Rise Shear Walls - Rectangular Cross Section28 pages

- Two-Way Flat Slabs: Direct Design MethodNo ratings yetTwo-Way Flat Slabs: Direct Design Method26 pages

- Ppt-Pushover Analysis Tutorial 6 Revised by NithilNo ratings yetPpt-Pushover Analysis Tutorial 6 Revised by Nithil23 pages

- Bülent Akbaş - Advanced Steel StructuresNo ratings yetBülent Akbaş - Advanced Steel Structures68 pages

- Hwang Et All - Analytical Model For Predicting Shear Strengths of Interior Reinforced Concrete Beam-Column Joints For Seismic100% (1)Hwang Et All - Analytical Model For Predicting Shear Strengths of Interior Reinforced Concrete Beam-Column Joints For Seismic14 pages

- Capacidades de Modelamiento No Lineal de ETABSNo ratings yetCapacidades de Modelamiento No Lineal de ETABS36 pages

- Modelling: Arrow Shows Local 2 Because of Max MOINo ratings yetModelling: Arrow Shows Local 2 Because of Max MOI10 pages

- T-05 Structural (Engineering) Evaluation of Existing Structures Based On Asce 41-13No ratings yetT-05 Structural (Engineering) Evaluation of Existing Structures Based On Asce 41-1359 pages

- Post-Tensioned Anchorage Zone - A ReviewNo ratings yetPost-Tensioned Anchorage Zone - A Review18 pages

- Structural Design Highlights of ACI 318 19 Part 1 of 2 ChaptersNo ratings yetStructural Design Highlights of ACI 318 19 Part 1 of 2 Chapters190 pages

- Pushover Analysis of Steel Frame Structu PDFNo ratings yetPushover Analysis of Steel Frame Structu PDF8 pages

- Pushover Analysis Tutorial Manual (ODOT) PDFNo ratings yetPushover Analysis Tutorial Manual (ODOT) PDF37 pages

- Structural Engineering DocumentsFrom EverandStructural Engineering DocumentsJorge de BritoNo ratings yet

- CSP00138 (GEN-Tutorial) Pushover Analysis As Per Eurocode 8 2004100% (1)CSP00138 (GEN-Tutorial) Pushover Analysis As Per Eurocode 8 200424 pages

- Tekla - Eurocode Portal Frame InformationNo ratings yetTekla - Eurocode Portal Frame Information11 pages

- Title: Structure Under A Temperature Gradient ForceNo ratings yetTitle: Structure Under A Temperature Gradient Force5 pages

- Title: Structural Geometry and Analysis ModelNo ratings yetTitle: Structural Geometry and Analysis Model5 pages

- Title: Analysis of A Structure With Nonlinear ElementsNo ratings yetTitle: Analysis of A Structure With Nonlinear Elements3 pages

- App12 - ACI Meshed Slab and Wall DesignNo ratings yetApp12 - ACI Meshed Slab and Wall Design51 pages

- Title: Structure Under A Temperature Gradient ForceNo ratings yetTitle: Structure Under A Temperature Gradient Force5 pages

- Field Work No. 8 - Determination of The Height of A Remote PointNo ratings yetField Work No. 8 - Determination of The Height of A Remote Point6 pages

- 300 C++ Programming Multiple Choice Questions and AnswersNo ratings yet300 C++ Programming Multiple Choice Questions and Answers25 pages

- CRYPTOGRAPHY AND CYBER SECURITY-CB3491(important topics)No ratings yetCRYPTOGRAPHY AND CYBER SECURITY-CB3491(important topics)1 page

- LM4875 750 MW Audio Power Amplifier With DC Volume Control and Headphone SwitchNo ratings yetLM4875 750 MW Audio Power Amplifier With DC Volume Control and Headphone Switch25 pages

- #4 recognizing_and_correcting_meg_artifacts.5No ratings yet#4 recognizing_and_correcting_meg_artifacts.510 pages

- Heat Value of Four Hardwood Species From Sudan: January 2012No ratings yetHeat Value of Four Hardwood Species From Sudan: January 20126 pages

- Expt. 1a - Density Determination Using A PycnometerNo ratings yetExpt. 1a - Density Determination Using A Pycnometer3 pages

- Chapter 6 Binomial Probability DistributionNo ratings yetChapter 6 Binomial Probability Distribution12 pages

- Final Project - ML - Nikita Chaturvedi - 03.10.2021 - Jupyter NotebookFinal Project - ML - Nikita Chaturvedi - 03.10.2021 - Jupyter Notebook

- Direct Analysis and Design Using Amplified First Order Analysis2part PDFDirect Analysis and Design Using Amplified First Order Analysis2part PDF

- Member Member Member Member Behavior Behavior Behavior BehaviorMember Member Member Member Behavior Behavior Behavior Behavior

- LATBSDC PEER CSSC Tall Building Design Case Study 1-05-09LATBSDC PEER CSSC Tall Building Design Case Study 1-05-09

- Floor Vibration Serviceability - Tips and Tools For Negotiating A Successful DesignFloor Vibration Serviceability - Tips and Tools For Negotiating A Successful Design

- A Finite Element Approach To Reinforced Concrete Slab DesignA Finite Element Approach To Reinforced Concrete Slab Design

- Response of Structures To Earthquake Ground MotionsResponse of Structures To Earthquake Ground Motions

- CE 581 Reinforced Concrete Structures: Lecture 11: Performance Based Assessment and StrengtheningCE 581 Reinforced Concrete Structures: Lecture 11: Performance Based Assessment and Strengthening

- A Practical Look at Frame Analysis, Stability, and Leaning ColumnsA Practical Look at Frame Analysis, Stability, and Leaning Columns

- Seismic Behavior of Short Coupling Beams With Different Reinforcement LayoutsSeismic Behavior of Short Coupling Beams With Different Reinforcement Layouts

- Reinforced Concrete Structural Walls Test Database and Modeling ParametersReinforced Concrete Structural Walls Test Database and Modeling Parameters

- Bridge Foundations, Modeling Large Pile Groups - Po Lam, H.law and R. MartinBridge Foundations, Modeling Large Pile Groups - Po Lam, H.law and R. Martin

- 2019 04 18 Understanding The Aisc Direct Analysis Method of Design Handout2019 04 18 Understanding The Aisc Direct Analysis Method of Design Handout

- A Simplified Look at Partially Restrained Beams - GESCHWINDNER - 1991A Simplified Look at Partially Restrained Beams - GESCHWINDNER - 1991

- Displacement Based Seismic Design Chapter 01 (Points)Displacement Based Seismic Design Chapter 01 (Points)

- Strength of High-Rise Shear Walls - Rectangular Cross SectionStrength of High-Rise Shear Walls - Rectangular Cross Section

- Ppt-Pushover Analysis Tutorial 6 Revised by NithilPpt-Pushover Analysis Tutorial 6 Revised by Nithil

- Hwang Et All - Analytical Model For Predicting Shear Strengths of Interior Reinforced Concrete Beam-Column Joints For SeismicHwang Et All - Analytical Model For Predicting Shear Strengths of Interior Reinforced Concrete Beam-Column Joints For Seismic

- T-05 Structural (Engineering) Evaluation of Existing Structures Based On Asce 41-13T-05 Structural (Engineering) Evaluation of Existing Structures Based On Asce 41-13

- Structural Design Highlights of ACI 318 19 Part 1 of 2 ChaptersStructural Design Highlights of ACI 318 19 Part 1 of 2 Chapters

- CSP00138 (GEN-Tutorial) Pushover Analysis As Per Eurocode 8 2004CSP00138 (GEN-Tutorial) Pushover Analysis As Per Eurocode 8 2004

- Title: Structure Under A Temperature Gradient ForceTitle: Structure Under A Temperature Gradient Force

- Title: Analysis of A Structure With Nonlinear ElementsTitle: Analysis of A Structure With Nonlinear Elements

- Title: Structure Under A Temperature Gradient ForceTitle: Structure Under A Temperature Gradient Force

- Field Work No. 8 - Determination of The Height of A Remote PointField Work No. 8 - Determination of The Height of A Remote Point

- 300 C++ Programming Multiple Choice Questions and Answers300 C++ Programming Multiple Choice Questions and Answers

- CRYPTOGRAPHY AND CYBER SECURITY-CB3491(important topics)CRYPTOGRAPHY AND CYBER SECURITY-CB3491(important topics)

- LM4875 750 MW Audio Power Amplifier With DC Volume Control and Headphone SwitchLM4875 750 MW Audio Power Amplifier With DC Volume Control and Headphone Switch

- Heat Value of Four Hardwood Species From Sudan: January 2012Heat Value of Four Hardwood Species From Sudan: January 2012

- Expt. 1a - Density Determination Using A PycnometerExpt. 1a - Density Determination Using A Pycnometer