0 ratings0% found this document useful (0 votes)

59 viewsUnit Planned Shutdown Operations

Unit Planned Shutdown Operations

Uploaded by

chandan mishra1. The document outlines the planned shutdown procedure for a unit including gradually reducing load through various control modes down to 5-25% load, performing turbine tests, cutting out coal mills, adjusting steam sources, and monitoring systems.

2. It then details procedures for tripping the turbine at 5% load such as closing valves and stopping oil and control systems.

3. Finally, it describes generator side shutdown including reducing MVAR with load, isolating the generator from auxiliary power, reducing the exciter, opening the generator breaker, and purging hydrogen from the system.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Unit Planned Shutdown Operations

Unit Planned Shutdown Operations

Uploaded by

chandan mishra0 ratings0% found this document useful (0 votes)

59 views3 pages1. The document outlines the planned shutdown procedure for a unit including gradually reducing load through various control modes down to 5-25% load, performing turbine tests, cutting out coal mills, adjusting steam sources, and monitoring systems.

2. It then details procedures for tripping the turbine at 5% load such as closing valves and stopping oil and control systems.

3. Finally, it describes generator side shutdown including reducing MVAR with load, isolating the generator from auxiliary power, reducing the exciter, opening the generator breaker, and purging hydrogen from the system.

Original Description:

Unit Planned Shutdown

Original Title

Unit Planned Shutdown Operations.doc

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

1. The document outlines the planned shutdown procedure for a unit including gradually reducing load through various control modes down to 5-25% load, performing turbine tests, cutting out coal mills, adjusting steam sources, and monitoring systems.

2. It then details procedures for tripping the turbine at 5% load such as closing valves and stopping oil and control systems.

3. Finally, it describes generator side shutdown including reducing MVAR with load, isolating the generator from auxiliary power, reducing the exciter, opening the generator breaker, and purging hydrogen from the system.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

59 views3 pagesUnit Planned Shutdown Operations

Unit Planned Shutdown Operations

Uploaded by

chandan mishra1. The document outlines the planned shutdown procedure for a unit including gradually reducing load through various control modes down to 5-25% load, performing turbine tests, cutting out coal mills, adjusting steam sources, and monitoring systems.

2. It then details procedures for tripping the turbine at 5% load such as closing valves and stopping oil and control systems.

3. Finally, it describes generator side shutdown including reducing MVAR with load, isolating the generator from auxiliary power, reducing the exciter, opening the generator breaker, and purging hydrogen from the system.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 3

UNIT PLANNED SHUT DOWN PROCEEDURE

1. LOAD can be reduce by 3 ways:-

a. Fully manual ( up to 5% load)

b. Load may be reduced up to 60% under CMC mode,

then change over to either Press Control Mode or

Manual Mode.

c. Load may be reduced up to 40% under Pressure

Control Mode, then change over to Manual Mode.

d. CMC (up to 60% load then either Press. Control mode

or Manual mode)

2. At 60% Load can be carried out Auto Turbine Test (ATT)

to test its availability.

3. Reduce load up to 40% Load

.

Procedure of Cutting out a coal mills:-

Reduce coal feeder position to minimum

Stop coal feeder

Wait to stop mills, till its Amps drops to

minimum e.g. no load condition.

Stop mill motor & Close all dampers.

4. Change over Pressure Control Mode to Manual Load

Control Mode

5. Cut off HP Heaters

6. Change Over DEA Pegging Steam source from

Extraction to CRH.

7. Reduce coal feeding further & reduce Load accordingly

up to 20-25%.

8. MONITOR Scanners, If required Cut in Oil support to

avoid Flame failure Protection.

9. Cut out LPHs, Change Over UAT to Station Bus and

DEA Pegging Steam from CRH to APRDS.

10 FCS to Change Over from Hi range to Low range

.

11 Put HPLP Bypass in service

.

12 Reduce Fuel & Load.

.

13 Trip Turbine at 5% load (Gen Protection can be Tested).

.

..

i.

Ensure turbine ESVs & IVs, CRH NRVs,

Extraction NRVs &Block Valve Closed.

ii.

Trip Oil= Zero, Control oil = 4.8 kg/cm2

iii.

Gen Field Breaker OPEN

iv.

AOP start auto < 2950 rpm or < 4.8 kg/cm 2

oil pressure.

v.

JOP start auto < 510 rpm

vi.

Barring Gear valve open < 210 rpm

14 Ensure opening of the following drains:-

.

15 HP casing, Seal Steam Hdr, before ESVs & Extraction

. NRVs, after CRH NRVs, before / after IV valve NRVs

16 Stop turbine barring if casing / shaft temp < 1200 C

.

17 Stop CEP at CASING TEMP OF 1000 C

.

18 Shutdown Oil System at 80 0C to 90 0C

.

Generator Side Shutdown Operations

1. REDUCE MVAR with load

2. CHANGEOVER to station supply from UAT at 20% Load

3. ISOLATE hydrogen coolers after 15 to 20 minutes of

Gen tripping.

4. REDUCE Exciter controller to minimum.

5. Open Generator Breaker at 5% load.

6. STOP stator water pump ( If Stator Cooling System is

in service )

7. OPEN line isolators.

8. PURGE H2 by filling CO2 & purge the CO2 by filling dry

compressed Air

You might also like

- Restore Power in Case of BlackoutDocument5 pagesRestore Power in Case of Blackoutadityasahay100% (2)

- Tec Specific CESSNA 172-R QuestionsDocument5 pagesTec Specific CESSNA 172-R QuestionsShaurya KhuranaNo ratings yet

- Turbine StartupDocument16 pagesTurbine StartupSakthi Murugan100% (3)

- Steam Turbine GovernorDocument25 pagesSteam Turbine GovernorMohammad Ibnul Hossain94% (17)

- Studiu de Caz Incalzire Termala - PORSCHE Bucharest West 2Document13 pagesStudiu de Caz Incalzire Termala - PORSCHE Bucharest West 2FuBashoNo ratings yet

- Procedure For Shutting Down of Turbine & EquipmentsDocument4 pagesProcedure For Shutting Down of Turbine & EquipmentsPrakash Choudhary100% (2)

- Unit Start Up Sequence ActivitiesDocument6 pagesUnit Start Up Sequence ActivitiesranjanNo ratings yet

- Unit Normal Shutdown To ColdDocument100 pagesUnit Normal Shutdown To Coldishak100% (2)

- Write Up On Turbine OperationDocument5 pagesWrite Up On Turbine OperationSarah Frazier100% (2)

- TurbineDocument11 pagesTurbineAnkush Singh BaedasNo ratings yet

- Unit Start UpDocument8 pagesUnit Start UpDebabrata TantubaiNo ratings yet

- 300 MW ThermalPower Plant Cold Start UpDocument4 pages300 MW ThermalPower Plant Cold Start Upsunil481100% (1)

- Gas Turbine StartupDocument9 pagesGas Turbine Startuppawangwl100% (5)

- 21. Low Low loadDocument2 pages21. Low Low loadPaingNo ratings yet

- Turbine SopDocument8 pagesTurbine SopDominic Daniel100% (1)

- Adani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorDocument4 pagesAdani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorBryan ScofieldNo ratings yet

- Turbine Rolling Procedure Pre Rolling ActivitiesDocument7 pagesTurbine Rolling Procedure Pre Rolling ActivitiesPrakash Choudhary100% (3)

- HP-LP Bypass FDocument16 pagesHP-LP Bypass FSolaiNo ratings yet

- Starting of ZCU 20Document5 pagesStarting of ZCU 20Usman GhaniNo ratings yet

- Adhunik Power & Natural Resources Limited 2 X 270 MW, PadampurDocument2 pagesAdhunik Power & Natural Resources Limited 2 X 270 MW, PadampurSUBHASISH MUKHERJEENo ratings yet

- G T Start Up ProcedureDocument11 pagesG T Start Up ProcedureJJ100% (3)

- Check The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001Document5 pagesCheck The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001jose Alberto uribe Minier100% (3)

- Sop TurbineDocument4 pagesSop Turbineshailendra183No ratings yet

- 72 00 00 TestDocument34 pages72 00 00 TestShrawan ShresthaNo ratings yet

- Summary of MDDocument12 pagesSummary of MDNavid NNo ratings yet

- Gas Turbine Start-UpDocument36 pagesGas Turbine Start-UpHeryanto Syam100% (4)

- Turbine Start Up ProcedureDocument3 pagesTurbine Start Up ProcedureShameer Majeed100% (1)

- Governing SystemDocument24 pagesGoverning Systemlrpatra100% (1)

- Cold Startup ProcedureDocument8 pagesCold Startup ProcedureRahul KurmiNo ratings yet

- Starting Up and Stopping of The GasplantDocument5 pagesStarting Up and Stopping of The GasplantHendra TambunanNo ratings yet

- Robinair Bombas de Vacío 15401 601Document32 pagesRobinair Bombas de Vacío 15401 601MarcWorld100% (1)

- Shutdown ProcedureDocument4 pagesShutdown ProcedureRahul KurmiNo ratings yet

- Boiler ProtDocument28 pagesBoiler ProtNikhil Mohan Goyal100% (3)

- 60 Ton Per HR Advance Empire Boiler Operation ManualDocument15 pages60 Ton Per HR Advance Empire Boiler Operation Manualrozg788152100% (1)

- Emergency Actions Code:Btpp/Turbine/011/Emergency Actions A.Actions To Be Taken in Case of Both CW Pumps TrippingDocument4 pagesEmergency Actions Code:Btpp/Turbine/011/Emergency Actions A.Actions To Be Taken in Case of Both CW Pumps TrippingPrakash ChoudharyNo ratings yet

- CCPP Cold Start ProcedureDocument3 pagesCCPP Cold Start ProcedureSahariar Bin ShafiqueNo ratings yet

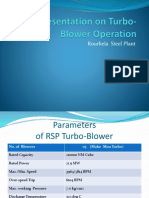

- Turbo-Blower Operation - PPSXDocument12 pagesTurbo-Blower Operation - PPSXSyed Safiur Rahman100% (1)

- Hot Startup Checklist1Document6 pagesHot Startup Checklist1Selva ManianNo ratings yet

- E39 Ahsop 06Document11 pagesE39 Ahsop 06Sanjit SinghNo ratings yet

- Turbine Shutting Down From Full LoadDocument7 pagesTurbine Shutting Down From Full Loadrohit_0123100% (4)

- Normal Shutdown Procedure: Chanar Energy Limited Tandlianwala FaisalabadDocument4 pagesNormal Shutdown Procedure: Chanar Energy Limited Tandlianwala FaisalabadMuhammadTayyab100% (1)

- 1 RC Feeder Interlock & ProtectionDocument76 pages1 RC Feeder Interlock & Protectionarvidkumar87060No ratings yet

- Powerroc T50 Start Up and Drilling Setting ProcedureDocument7 pagesPowerroc T50 Start Up and Drilling Setting ProcedurerolandNo ratings yet

- Important Things To Be Done Just After Tripping: ExplanationsDocument2 pagesImportant Things To Be Done Just After Tripping: Explanationsu yadavNo ratings yet

- Welcome: Presentation ON Boilers & AuxiliariesDocument58 pagesWelcome: Presentation ON Boilers & Auxiliariestanuja singhNo ratings yet

- Vacuum Pump Manual-2022-05VERSIONDocument8 pagesVacuum Pump Manual-2022-05VERSIONonline MNo ratings yet

- CessnaDocument33 pagesCessnaemeramusixzNo ratings yet

- Gas Turbine 5Document36 pagesGas Turbine 5anup_nairNo ratings yet

- Power Plant Emergency InsructionDocument14 pagesPower Plant Emergency Insructionbatpora100% (1)

- SHUT DOWN OF UNIT-NewDocument16 pagesSHUT DOWN OF UNIT-Newnitin PaunikarNo ratings yet

- 3.digital Electric HydraulicDocument35 pages3.digital Electric HydraulicBui Vanluong100% (1)

- Steam Power Plant Standard Operating ProceduresDocument3 pagesSteam Power Plant Standard Operating ProceduresganimechNo ratings yet

- Operation Procedures For MDBFPDocument7 pagesOperation Procedures For MDBFPJackSparrow86100% (1)

- Deh Operation InstructionDocument19 pagesDeh Operation Instructionmuhammad nasimNo ratings yet

- 10 Boiler StartupDocument2 pages10 Boiler Startupshubham vermaNo ratings yet

- X Series 2t-16t Service Manual 2021.01Document74 pagesX Series 2t-16t Service Manual 2021.01Jose ZarateNo ratings yet

- Unit Emergencies: Condensate Desk Emergencies Can BeDocument9 pagesUnit Emergencies: Condensate Desk Emergencies Can Bealoknitp04100% (1)

- Fuel Oil SystemDocument5 pagesFuel Oil SystemyattoakaiNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Mechanical Books Url LinksDocument6 pagesMechanical Books Url Linkskirankuma.jagtapNo ratings yet

- Adani Power Limited CS NECA2012 First PrizeDocument6 pagesAdani Power Limited CS NECA2012 First Prizechandan mishraNo ratings yet

- Qip Ice 19 Supercharging & TurbochargingDocument32 pagesQip Ice 19 Supercharging & TurbochargingSonusiba Bara100% (2)

- Quizzes and AssignmentsDocument130 pagesQuizzes and Assignmentschandan mishraNo ratings yet

- Write The Algorithm To Solve A Recurrence Relation by Using Generating Function - Also Give An Example With WorkingDocument1 pageWrite The Algorithm To Solve A Recurrence Relation by Using Generating Function - Also Give An Example With Workingchandan mishraNo ratings yet

- Your Electric BillDocument2 pagesYour Electric Billjailagan29No ratings yet

- 08 PSC-12 Power SupplyDocument12 pages08 PSC-12 Power SupplyHemant ParmarNo ratings yet

- B7C6A Va Tech Hydro Bulb Turbines GeneratorsDocument24 pagesB7C6A Va Tech Hydro Bulb Turbines Generatorsjoaoaugusto79100% (1)

- Does Atom Have Electromagnetic FieldDocument5 pagesDoes Atom Have Electromagnetic FieldlivingHipHop 40No ratings yet

- Industrial Attachment Report-1Document15 pagesIndustrial Attachment Report-1Purity waturiNo ratings yet

- Fresh AHU ComparisonDocument8 pagesFresh AHU Comparisonevo2oo2No ratings yet

- Chapter 4 - Steam Power PlantsDocument76 pagesChapter 4 - Steam Power Plantskenasaa GetachewNo ratings yet

- Advent Technologies Presentation 6 August 2015Document15 pagesAdvent Technologies Presentation 6 August 2015Chatzianagnostou GeorgeNo ratings yet

- Power Electronics: Chapter 4: Switch-Mode Dc-Ac InvertersDocument71 pagesPower Electronics: Chapter 4: Switch-Mode Dc-Ac InvertersAjay KumarNo ratings yet

- Serie E550Document100 pagesSerie E550Yasindu DamithNo ratings yet

- Power System-IDocument1 pagePower System-ISonu BairwaNo ratings yet

- Wireless Power Transmission: Paras JoshiDocument2 pagesWireless Power Transmission: Paras Joshikabe motumaNo ratings yet

- ISCC EU 205 Greenhouse-Gas-Emissions v4.1 January2024Document67 pagesISCC EU 205 Greenhouse-Gas-Emissions v4.1 January2024imran.teknikkimiaNo ratings yet

- IEEE STD 141-1993 (Revision of IEEE STD 141-1986) IEEE Recommended Practice For Electric Power Distribution For Industrial PDocument1 pageIEEE STD 141-1993 (Revision of IEEE STD 141-1986) IEEE Recommended Practice For Electric Power Distribution For Industrial PArafa SalemNo ratings yet

- 2023 C I Utility Ess Powercube h1Document16 pages2023 C I Utility Ess Powercube h1pafka.bNo ratings yet

- sp75 PDFDocument2 pagessp75 PDFWashington Huallpa0% (1)

- Killing Coal Time To Make Coal HistoryDocument4 pagesKilling Coal Time To Make Coal HistoryMuhammad Baharuddin Yusup SinagaNo ratings yet

- Nellore City DVP Plan 31 May 2015 (1) Presented at NELLORE NextDocument35 pagesNellore City DVP Plan 31 May 2015 (1) Presented at NELLORE NextAnumakonda JagadeeshNo ratings yet

- Renewable Power Generation Costs in 2017: Key Findings and Executive SummaryDocument16 pagesRenewable Power Generation Costs in 2017: Key Findings and Executive SummaryAyoub EnergieNo ratings yet

- Online Process Monitoring of Octane Number During Catalytic Reforming by NIRS Following ASTM D2699 and ASTM D2700Document2 pagesOnline Process Monitoring of Octane Number During Catalytic Reforming by NIRS Following ASTM D2699 and ASTM D2700hhNo ratings yet

- Causes of Water HammerDocument6 pagesCauses of Water HammeraqhammamNo ratings yet

- Unit 4 Module 2 Activity 2 PastranoDocument27 pagesUnit 4 Module 2 Activity 2 PastranoAshly Pardeñas ManlimosNo ratings yet

- Marking IECEx Equipment ExDocument1 pageMarking IECEx Equipment Exadirocks89100% (1)

- Alarms and Action List of Turbine Oil SystemDocument6 pagesAlarms and Action List of Turbine Oil SystemMuhammad Junaid Khan100% (2)

- What Is Energy Independence?Document6 pagesWhat Is Energy Independence?The American Security ProjectNo ratings yet

- DGT Chemical Thermodynamics PDFDocument20 pagesDGT Chemical Thermodynamics PDFAYUSH SHUKLANo ratings yet

- Ceramic SubstanceDocument9 pagesCeramic SubstanceIshita ChauhanNo ratings yet

- Explosive Properties of Rector Grade PlutoniumDocument18 pagesExplosive Properties of Rector Grade PlutoniumugyaNo ratings yet

- 7MBR75VB120-50: IGBT MODULE (V Series) 1200V / 75A / PIMDocument8 pages7MBR75VB120-50: IGBT MODULE (V Series) 1200V / 75A / PIMDanielle ButlerNo ratings yet