1008V

1008V

Uploaded by

Raju SkCopyright:

Available Formats

1008V

1008V

Uploaded by

Raju SkOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

1008V

1008V

Uploaded by

Raju SkCopyright:

Available Formats

FLOW INDICATOR TOTALISER 1008V masibus

Ref No: m18V/om/101

Issue No: 07

Operator’s Manual

F L O W I N D I C A T O R T O T A L I S ER 1 0 0 8 V

Masibus Automation And Instrumentation Pvt. Ltd.

B/30, GIDC Electronics Estate,

Sector-25, Gandhinagar-382044, Gujarat, India.

Ph: 91 79 23287275-79

Fax: 91 79 23287281/82

Email: support@masibus.com

Web: www.masibus.com

Operator’s Manual Page 1 of 14

FLOW INDICATOR TOTALISER 1008V masibus

Ref No: m18V/om/101

Issue No: 07

CONTENTS

1. TECHNICAL DETAILS

2. SPECIFICATIONS

3. DIMENSIONS & PANEL CUTOUT

4. FRONT FASCIA

5. CONNECTIONS DETAIL

6. USER GUIDE

7. MODE OF OPERATION

8. MODBUS PROTOCOL

Operator’s Manual Page 2 of 14

FLOW INDICATOR TOTALISER 1008V masibus

Ref No: m18V/om/101

Issue No: 07

1. TECHNICAL DETAILS The unit has following optional features.

1) Flow Alarms /Batch

This is a versatile micro controller Relays Output(Factory

based Flow Indicator Totaliser unit. Set)

With very high performance to price Two High/low alarm

ratio. relays with one

changeover contact type

The features offered in this product are having 2A/230 VAC

better than any other Totaliser available Contact rating.

in similar price range. 2) Rs-232/485 serial port.

3) 24V DC power supply.

The instrument is made in 144 x 72 x 4) 4-20 mA Retransmission

175 mm³ size with standard cutout of Output

138 x 68 mm². Front is sealed

membrane type to withstand dusty

environment. On back plate, detachable

terminals are provided for easy

connections. The programming of the

instrument is done by a 6-button

keypad, equipped with two independent

displays for flow rate and integrated

total. Status of alarm relays are

displayed by 3 mm red LED.

The operation of the instrument is

menu- driven with user-friendly

prompts. For protecting programmed

data password protection facility is

provided. Integrated total is stored in

NVRAM and can be erased from using

specific password.

The product is made to accept the

standard inputs, 4 - 20mA, 0- 20mA,

1-5 Volt, 0- 5 volt ,0- 10 volt and 0-

10kHZ pulse inputs. It is available as a

single input version only. The

calibration of the unit is done through

trim pots.

There are four relays, which can be used

either as Hi, Lo alarms for process

variable and Prewarn, End of program

set point for batch total.

Provision for zero and span setting is

made to restrict range of usage and

programming. This restricts accidental

wrong setting of set-point beyond the

range of interest. Outside this range the

display will start flashing process

variable. This zero and span setting is

Operator’s Manual Page 3 of 14

FLOW INDICATOR TOTALISER 1008V masibus

Ref No: m18V/om/101

Issue No: 07

2. SPECIFICATIONS • On load resistance: 500E or

less

• Output accuracy: ± 0.25% of

DISPLAY

full scale +1 count

• Resolution: 12 bits (5mA)

• 4 digit 0.56" Red LEDs for Flowrate

• 8 digit 0.36" Red LEDs for

C. Communication

Integrated total.

• Protocol: Modbus RTU serial

• Four individual discrete 3 mm Red

• Standard: EIA RS-485 / RS -

LEDs to indicate relay status of

232.

batch & Alarm relays.

• Max. Communication

distance: ≤1200 mtrs. (For

INPUT (Factory Set)

9600 bps RS 485)

• Communication rate:9600,

• 0-20 mA, 4-20mA.

19200 bps

• 0-5V, 1-5V, 0-10V.

• Max. Connectable

• 0-10kHz pulse input.

controllers/Indicator: 32

• Accuracy: • Address range: 1 to 99

± (0.25% of F.S + 1Digit) - For

I/P signal D. Digital input

• Usage : To start a new

± (0.45% of reading + 1Digit) - batch.

Integrated / Batch total GENERAL

# for pulse input low voltage level: • Power supply:

0-5Volt and high voltage level 110V/230V +/-10% AC 50Hz

5-15 Volt. (Jumper selectable on Terminals)

• Transmitter Power supply:

CALIBRATION 24VDC +/- 5% @ 50mA

• Ambient Temperature:

• Zero and Span adjusted by trim pot 0 to 55 °C

only. • Humidity:

Up to 95% RH non-condensing

CONTROL KEYS AND TERMINALS • Power consumption:

Less than 10 VA

• Index, Enter, Digit Select (→), Warm-up time: 10 minute

Increment (↑) START & STOP for

operation, programming and PHYSICAL

calibration.

• Case:

OPTIONAL FEATURES M.S. powder coated with ABS

molded bezel

A. Contact Output: • Terminals:

• Usage: Flow alarm & batch Detachable PCB type terminal

(Factory Set) block can accept up to 2.5 mm²

• Number of relay contact wire

outputs: • Bezel size:

• Two High/low alarm relays. 144(H) X 72(W) mm²

• Relay contact rating: • Depth behind Panel:

• 250VAC/2Amps. 175 mm maximum including

• Relay contact terminal: 3 terminals

• Panel cutout:

B. Retransmission Output: 138(H) X 68(W) mm²

• Number of output points: 1 • Weight:

• Output Signal: 4 to 20 mA DC Approximately: 1.58 kg.

Operator’s Manual Page 4 of 14

FLOW INDICATOR TOTALISER 1008V masibus

Ref No: m18V/om/101

Issue No: 07

3. DIMENSIONS & . 4. FRONT FASCIA

PANEL CUTOUT

• Process Variable : Process Value

• Integrated total: indicates

integration of process value.

• AL1: Low Alarm(for PV)

• AL2: High Alarm(for PV)

• WP: Pre warn process indication (for

batch process).

• EP: End of process indication (for

batch process)

• INDEX: Indexing Parameter in

Various Modes

• ENTER: Saves Desired Parameter in

Various Modes.

• Digit Select (→): Select next digit

and also can be used as START key

while batching.

• Increment (↑): Increment the

Selected Parameter Value to Desired

Value.

• RXD&TXD: Indication of

communication.

FLOW RATE

BATCH TOTAL/INTEGRATED TOTAL

RXD

INDEX

TXD

AL1

ENTER

AL2

WP

START STOP

EP

m asibus 1008V

Operator’s Manual Page 5 of 14

FLOW INDICATOR TOTALISER 1008V masibus

Ref No: m18V/om/101

Issue No: 07

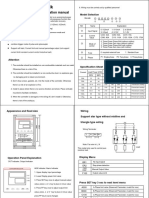

5. CONNECTIONS read the instructions carefully before

altering any configuration.

DETAIL

6.2 INSTALLATION GUIDE

The description of the Back Panel

terminals is as follows:

Unpack the instrument from the packing

box carefully.

Low Flow Analog Input/ Mount the instrument in the panel cut-

Alarm Relay: TPS out of 138 mm X 68mm. Fix the

AL1 instrument with the panel using side

1: NO 15: Analog input 1 brackets.

+VE

2: COMMON 16: +24VDC@ All the electrical connections to be done

50mA (TPS) at the back panel of the unit using spade

3: NC 17: Input/TPS -VE lugs. Refer the manual for back panel

High Flow Serial Interface connections.

Alarm Relay:

AL2 Make sure that no wire is connected

4: NO 18: RXD/RxTxA loosely to avoid generation of spark and

5: COMMON 19: TXD/RxTxB RFI.

6: NC 20: GND (Digital)

Batching Mains +24VDC Connect mains cord on the back panel

Relay: WP Input Supply on the P,N and E terminals.

7: NO 21 N2:

Neutral Before connecting the mains, check the

8: COMMON 22 N1: +VE mains configuration inside the

9: NC 23 L2: -VE instrument.

Batching 24 L1:

Relay: EP Phase Earth the instrument properly.

10: NO 25 : Earth

11: COMMON For 230VAC Supply: short Some of the contacts are powered.

L2 & N1 Hence don’t touch any terminal directly

12: NC (22&23)

when power is applied to the instrument.

Retransmissio For 115VAC Supply: short

L1&L2(21&22) short Whenever any connection is to be made

n

N1&N2(23&24) or removed from the unit, always switch

13: Output –VE off the power.

14: Output +VE I/P TYPE SELECTION

JUMPER PULSE mA

J1 1-2 2-3 6.3 DISPLAY & KEY BOARD

J2 2-3 1-2

Display on top row is organized as 4

digit 0.56" Red LEDs for Flowrate

6. USER GUIDE variable. The second group of display is

eight digits it indicates integration of

process variable. In normal mode of

6.1 INTRODUCTION

operation, it displays integrated / Batch

total. While in EDIT mode, parameters

1008V is flow indicator totaliser user-

are displayed in this window.

friendly key-pad and display for guiding

the user with programming and

There are six keys for operation of the

calibration operation. The levels of

instrument. For understanding the

protections decide access to set-points,

operation first let us see the operation of

configuration and calibration. The

keys.

manual covers all aspects of operation of

the instrument. Users are requested to

Unit has 6 key membrane keypad

organized as 6 x 1 matrix.

Operator’s Manual Page 6 of 14

FLOW INDICATOR TOTALISER 1008V masibus

Ref No: m18V/om/101

Issue No: 07

List of keys and their functions: Press ‘Index’ key to enter into edit

mode.

KEYS FUNCTION

Index Enter into Entry/Verification mode First three parameter displayed in Lower

select parameter

display window with each depression of

Enter Save New Data and terminate

Edit mode. If ‘Enter’ key is ‘Index’ Key is: Integrated Total, Batch

pressed twice, unit comes out of Total & Roll count. These are non-

EDIT mode. (i.e. comes to normal editable parameters.

mode)

Digit Shift (™) Select Digit

Increment (↑) Increment selected digit value

Fourth Parameter is Password. When

Start Clear Batch Total (to be use with ‘Index’ Key is pressed after third

Batching) parameter, lower display window will

Stop Stop/Reset Batch (to be use with show ‘PASS’ for a moment and then it

Batching)

will start displaying ‘0000’ with flashing

Left most digit .The unit is prompting

When Instrument is in Edit mode, for Password. Password is a four digit

Increment and Digit Select will be used as no. There are two different passwords.

data entry keys and when the instrument

is in Normal mode of operation the keys Operator's Password: 0101

will be Batching (START / STOP) Key.

Engineer's Password: 1234

7. MODE OF Enter any one of the above password

OPERATION using data entry keys. When ‘Enter’ key

is pressed, the validity of Password is

checked. If wrong password is entered

There are following modes of operations. the unit comes out of edit mode and

• Normal mode displays engineering value.

• Edit mode

Press ‘Index’ key again if you want to

7.1 NORMAL MODE enter into edit mode.

When ever mains is switched on to If correct password is entered, then also

The unit, engineering value Proportional the unit starts Indicating Engineering

to the input signal will be displayed as value of input. Now press ‘Index’ key,

Process variable. Decimal point is the display will show name of the

displayed at selected position. parameter to be modified and its value

after a moment.

Last saved integrated/batch total

will also be displayed on the lower Now press ‘INDEX’ key to go to any one

window as per selection in “Different of the listed parameters as below. When

Display” parameter. the parameter is selected its current

value is being displayed in the totaliser

7.2 EDIT MODE field of display.

In this mode user can verify or modify: The data field of the display will show

Calibration zero, Calibration span, Zero, parameter one by one. The various

Full scale, decimal point, Time base and parameters that will appear on the

Conversion mode settings. Integrated display with successive pressing of the

total can also be cleared to Zero using a ‘INDEX’ Key are:

command from this mode. Entry into

Edit mode is protected by Password. It Integrated Total

bt Batch Total

Press ‘Index’ key to enter into edit rC Roll count

mode. PS Password

Operator’s Manual Page 7 of 14

FLOW INDICATOR TOTALISER 1008V masibus

Ref No: m18V/om/101

Issue No: 07

CALZ Calibration Zero/Offset Press ‘INCREMENT’ key the no. at the

CALS Calibration Span selected digit position will increment and

bd Baud Rate rolls back to ‘0’ when it reaches at ‘9’.

(19200,9600,4800)

dP Decimal Point Once desired digit is set, press digit

Un Unit Number select key (→) to select next digit. The

FS Full Scale next selected digit will flash. Set it to

Id Unit Identification No. desired value as per the above step.

In Input Type (4-20mA,

0-20mAPULSE,0-5V,0-10V) Once all the digits are set, press ‘ENTER’

F1 Flow Alarm 1 key. The display will stop flashing.

F2 Flow Alarm 2

INDICATION

Pr Pre warm

SP Set Point

In normal mode of operation, input is

CF Conversion Factor

converted to frequency using V to F

CI Clear Integrated Total and

converter.

Roll Over Count

The same is measured by the unit. Full

d.d Default display (Integrated

scale value of frequency is 10 KHz.

Total & Batch Total)

In linear indication mode (Unit no. 1 to

Following the above process, one can 4), the measured input current is

select any of the above listed converted to engineering value as per

parameters. When the parameter is the following equation using the set

selected its current value is being values of FS.

displayed in the totaliser field of display

and display will start flashing, indicating Flow Rate Indication =

that you can modify the digit. (I/P current – 4) * FS / 16

Use ‘Digit shift’ and ‘INCREMENT’ key to Re-transmitted output current will be

modify the selected parameter. linearly proportional to calculated flow

rate.

Once new data is set for the particular

mode, press ‘ENTER’ Key to save that Output will be 4.00mA DC for Zero and

data in NVRAM. Otherwise it will not 20.00mA for full scale.

save. On pressing ‘ENTER’ key will stop

display flashing. Integration is done as per the set time

base (unit) and conversion factor.

By pressing ‘START’ key in between. the

display shows flow rate and batch total. SQUARE ROOT EXTRACTION:

If no key is pressed for more than 25 This is a built-in feature of this unit.

seconds, the Data entry/programming Indication can be linear or square root of

mode is terminated automatically and input.

display will show flow rate and

Integrated / batch total. Square root extraction when unit no. is

set from 5 to 8.

ENTER/MODIFY PARAMETER VALUE:

For square root extraction mode:

Use Digit shift (→), increment ( ↑), and Indication = N * Full scale

‘ENTER’ key to enter or modify any N= square root ((input current – 4)/16)

numeric data.

Where in data entry/edit mode, the

selected digit will be flashing.

Operator’s Manual Page 8 of 14

FLOW INDICATOR TOTALISER 1008V masibus

Ref No: m18V/om/101

Issue No: 07

UNIT No. SETTING IS INTERPRETED

AS PER FOLLOWING TABLE. The value of ‘It’ depends on FS, Time

base (Unit), Conversion Factor and

UNIT NO TIME BASE SCALING Decimal Point settings. If these

1 Second Linear parameters are changed, the stored

value of ‘It’ will not be correct. Before

2 Minute Linear

making any change in FS, Unit,

3 Hour Linear

Conversion Factor (CF) and/or DP,

4 Day Linear Integrated total should be cleared using

5 Second Square root ‘CI’ function.

6 Minute Square root

7 Hour Square root For updating it value, the flow rate is

8 Day Square root divided by value of conversion factor

(CF).

REMOTE OPERATION: (Optional)

Conversion factor is a six digit no. with

Normally the parameter values are two digits after decimal point. Format is

set/Verified using membrane keypad on XXXX.XX.

the front.

CLEAR INTEGRATED & BATCH

But for applications when unit is to be TOTAL:

housed in Explosion proof enclosure or

some other enclosure, parameter setting In edit mode, select parameter CI.

and verification can be done using Enter value of ‘654321’.

remote keypad. The It & bt will be reset to Zero; Roll

over count (rC) will also be reset to

On Back panel of the unit, parallel Zero.

connections to the membrane keypad

are provided for remote keyboard wiring WARM-UP-TIME:

is on a 9-pin D-type connector.

Once you switch – on your instrument, it

For remote keyboard wiring is to be need 10 minutes for warm up. Wait for

done by following schematic. It should this period before getting correct

be a 4 x 2 matrix. indication. Once unit is switched on, it

shows actual flow rate. Integration is

INCR DIGIT ENTER INDEX START also performed as per flow rate and

STOP other related settings. In normal

operation, batch total (bt) is indicated.

Return line (RL)

K1 K2 K3 K4 K5 K6 ALARM RELAYS:

INTEGRATED TOTAL (It): There are two alarm relays available

with the unit (F1 & F2). Value of both

As per the selected time base (unit), Full the alarms is settable. Alarm F1 is

scale (FS) and Conversion Factor (CF) configurable for low alarm and alarm F2

setting, integrated total is updated. This is configured for High Flow alarm. When

is an eight no. If the number rolls over, flow is lower then F1 setting, Relay F1

the roll over count (rC) will be will switch On, LED on front also will

incremented by one. This total is non glow. When flow is more then F1, the

reset able. relay F1 is switched off.

It is stored in serial NVRAM, which does If flow is greater then F2 setting,relay

not need battery back up. On power for Alarm F2 is switched On, LED on

down, current data is stored on NVRAM front also glows. During normal flow

by early sensing of power failure.

Operator’s Manual Page 9 of 14

FLOW INDICATOR TOTALISER 1008V masibus

Ref No: m18V/om/101

Issue No: 07

condition, F1<Flow<F2, no alarm relay INPUT TYPE (In):

will be on.

Type of process input to instruments is

Change over contacts from both the keyboard selectable. Through edit mode,

relays is available on the back panel. select appropriate input type

(0-20mA/4-20mA/0-5V/1-5V/0-10V/

BATCHING OPERATION: pulse) as per your process. Apply your

process input between terminal no. as

This unit has two batching relays. With shown in back plate connection table.

help of this batching operation can be

performed. It supports two stage There is two input type. It is selectable

batching control. There are two relays: through jumper inside the CPU card

pre warn and set point. One can set PCB.

value for each relay (Pr and SP). These INPUT 1: In case of pulse input short

are six digit settings including decimal jumper J1.

point. Using Edit mode one can set value INPUT 1: In case of 4-20mA Dc short

of Pr and SP. Value of Pr should be less jumper J2.

then SP. If Pr is set more than SP, it is

truncated to SP. CALIBRATION:

To start batch operation, press ‘START’ CALIBRATION PROCEDURE:

Key. Value of ‘bt’ is reset to zero. Relays

for both Pr and Sp are switched On. The Instrument is duly calibrated at the

When integrated total for current batch factory. For any reason, if re-calibration

i.e. ‘bt ‘reaches to set value of Pr, relay is required follow the procedure as

of Pr is switched Off. Once Batch total defined below.

(bt) crosses set point (sp) value, relay As explained earlier, One can do

for SP is switched OFF. calibration thro' the keyboard itself, no

trimming of potentiometer is required.

Contacts for Both the relays are The Zero and Full-scale values are stored

available on the back panel. LED in NVRAM. The calibration is allowed

Indications are available on the front. only in Engineer's Password mode.

One can terminate the batch by pressing

‘Stop’ key. If stop key is pressed, both 1. Switch on the instrument and allow 15

the relays are switched off. If you press minutes of warm up time before starting

stop key again batch will start from the calibration.

same value where it has been stopped. 2. Take a standard source. Set it’s

One can start new batch by pressing output at desired Zero (CALZ) value.

Start key again. Apply output of the source to the input

terminals (1 & 3) of the indicator.

If mains power goes OFF during 3. Go to EDIT mode:

batching is going. On, the status of Enter engineers: Password '1234'.

batching stored in NVRAM. When Power Press INDEX key after entering

comes, batching is resumed from the this Password.

point it has stopped. The parameter 'CALZ ' for Zero

will be displayed.

IDENTIFICATION No. (ID) Actual row counts will be

displayed.

When the FIT is connected on RS485 Allow the reading to settle, press

multi-drop environment, is to be 'Enter' Key.

addressed by this identification code This count will be stored as

(unit no.) Zero/Offset reading.

4. Now apply input equal to Full

scale/Span (CALS):

Press 'Index' key again.

Operator’s Manual Page 10 of 14

FLOW INDICATOR TOTALISER 1008V masibus

Ref No: m18V/om/101

Issue No: 07

‘CALS' for Span calibration will be

displayed. CONVERSION FACTOR (CF):

Row counts of VFC will be

displayed. It is a constant which simply divides

Allow the reading to settle and process value by the factor set.

Press ' Enter' key. Usually, it is set as ONE (1).

This reading will be stored as For example, if process value is 100

Span/Full scale. liters/minute & conversion factor is

1 then it will simply integrate

Now the instrument is calibrated. process value as it is. If we change

conversion factor = 2, then it will

For again entering into calibration mode, divide process value by that factor

you have to wait till the instruments go i.e. 100/2 = 50 & it integrates that

to normal mode. After that go to EDIT value (in both integral and batch

mode thro' Engineers' Password and total) but on the display it shows

perform calibration. original process value.

An OPEN msg. will appear in Upper DEFAULT DISPLAY (d.d):

Display window, when input is 5% less Depending up on selection of

than its minimum value. “Default Display” parameter in menu

as batch total or integral total the

An OVER msg. will be displayed, when respective value of the parameter

input is 5% higher than its maximum (batch total/integral total) will be

value. displayed in normal mode.

If input terminals are open, then also

upper window will show ‘OPEN’

message.

Operator’s Manual Page 11 of 14

FLOW INDICATOR TOTALISER 1008V masibus

Ref No: m18V/om/101

Issue No: 07

8. Modbus Protocol

REGESTERS TABLE

DIGITAL PARAMETERS READ:

HEX ADDRESS Register No. Parameter Function

00 00001 Lo alarm Status Relay Status 1

01 00002 Hi alarm Status Relay Status 2

02 00003 Pre-warn Status Relay Status 3

03 00004 Set-point Status Relay Status 4

MSB 3 2 1 ISB

WP: Pre warn process (for batch process) Relay4 Relay3 Relay2 Relay1

EP: end of process (for batch process) (EP) (WP) (AL12) (AL1)

Bit will be ‘0’ if relay is off

Bit will be ‘1’ if relay is on

DIGITAL PARAMETER WRITE:

Hex Address Register No. Parameter Function

00 00005 Start/stop Start/Stop Batching

If Data=0000 Start batch

Data= 0001 toggle batch status

Between start/stop

ANALOG PARAMETERS:

Hex Register Parameter Function

Address No.

00 40001 Batch Total L5W (2 Byte) Read the Batch Total Value

01 40002 Batch Total MSW (2 Byte) (4 Byte)

02 40003 Integrated Total L5W(2 Byte) Read the Integrated Total Value

03 40004 Integrated Total MSW(2 Byte) (4 Byte)

04 40005 Set Point L5W (2 Byte) Read/Write the Set Point Value

05 40006 Set Point MSW (2 Byte) (4 Byte)

06 40007 Pre warn L5W (2 Byte) Write the Pre warn value

07 40008 Pre warn MSW (2 Byte) (4 Byte)

08 40009 Conversion Factor L5W Read/Write conversion factor

(2 Byte) value (4 Byte)

09 40010 Conversion Factor MSW

(2 Byte)

OA 40011 Flow Rate (2 Byte) Read the Flow Rate Value

OB 40012 Full Scale (2 Byte) Read/Write the Full Scale Value

OC 40013 Low Alarm (2 Byte) Read/Write the Low Alarm Value

OD 40014 High Alarm (2 Byte) Read/Write the High Alarm

Value

OE 40015 RC + Null Read the RC (roll count)

OF 40016 DP Value + Null Read/Write the DP Value

(0,1,2,3)

10 40017 Unit No. + Null Read/Write the Unit No. (0001

to 0008)

Operator’s Manual Page 12 of 14

FLOW INDICATOR TOTALISER 1008V masibus

Ref No: m18V/om/101

Issue No: 07

How to Test: -

To test this all parameters in MODSCAN32 application, do the following settings:

1. Set Device Id to1 for all.

2. Set Length according to requirements.

3. Set Modbus point Type according to the parameter type.

a). For Analog parameters READ: Set the Modbus point Type to HOLDING

REGISTER and

Address from 0001 to 0017 in Modbus application.

For Example1:

Suppose the Batch total Value displayed is 562017 (or 56201.7), To read

it, Set address to 0001 and Modbus point Type to HOLDING REGISTER.

(Length -for displaying only batch total could be to 2).

Its hex value will be 0x00089361. Four bytes are used to display batch

total (bt) in serial application according to the table shown above.

So, the modscan32 will show at address

40001 [9361](lower 2 byte)

40002 [0008](higher 2 byte)

Example2:

If Full-scale value (FS) = 800.0(hex will be 1F40, converted according to

8000, no decimal point consideration) Two bytes for full scale (FS).

Then the modscan32 will show at address

40012 [1F40]

Note: In serial decimal point is not taken into consideration.

b). For Digital parameters READ:

To read the relay status, set the Modbus point Type to COIL STATUS

and Address to 0001 to 0004

Example1:

If Lo alarm relay is on , Modbus application will show at Address:

00001 [1].

00002 [0] (Hialarm led is off)

Operator’s Manual Page 13 of 14

FLOW INDICATOR TOTALISER 1008V masibus

Ref No: m18V/om/101

Issue No: 07

Example2:

If start is given then Loalarm, SP and WP relay will be on and Hialarm

relay will be off .Set Address to 0001 and Length to 4. So, Modbus App.

will show:

00001 [1]. (Lo alarm relay will be off)

00002 [0]. (Hi alarm relay will be off)

00003 [1]. (PreWarn relay will be on)

00004 [1]. (SP relay will be on)

c). For digital /Analog parameters WRITE:

We can only do START and STOP function from serial Application.

For this the address should be displayed in the application first. Then double click

on the address to be modified and then a screen will be opened with name

1. Write coil (for digital parameter –start -stop)

2. Write Register (for analog parameter –for all)

Change the status or value according to parameter (for start stop on off is to be

done, but for analog parameters value should be entered) and click on UPDATE

icon. The value will be updated.

Operator’s Manual Page 14 of 14

You might also like

- Dashcam Pro ManualDocument15 pagesDashcam Pro ManualShipra AroraNo ratings yet

- Electrical Wiring Material List With PicturesDocument140 pagesElectrical Wiring Material List With PicturesMuhammad Azri67% (3)

- Sample Calibration CertificateDocument2 pagesSample Calibration CertificateRaju Sk67% (3)

- How To Crack AutoCAD 2014 FreeDocument1 pageHow To Crack AutoCAD 2014 FreeBenj Binoya50% (2)

- Accuvar PDFDocument4 pagesAccuvar PDFbmsingh100% (1)

- SEW Brak Coil ResistancesDocument8 pagesSEW Brak Coil ResistancesVictorNo ratings yet

- ALSTOM Instntneous Voltage Relay VAGM HighResDocument4 pagesALSTOM Instntneous Voltage Relay VAGM HighResMorgan Brooks0% (1)

- Calibration WorksheetDocument4 pagesCalibration WorksheetRaju SkNo ratings yet

- TankDocument480 pagesTankduelsky100% (2)

- Pid - 5030 Digital Pid Controller: Operator's ManualDocument22 pagesPid - 5030 Digital Pid Controller: Operator's Manualஇராம் பாபு100% (1)

- Operational Manual For 85Xx: Technical DetailsDocument16 pagesOperational Manual For 85Xx: Technical DetailskpbaijuNo ratings yet

- Elmeasure Pricelist All Products 2023 v3 0123Document68 pagesElmeasure Pricelist All Products 2023 v3 0123Ashish Rawat100% (1)

- 8204 User ManualDocument41 pages8204 User ManualDhaniraj SinghNo ratings yet

- 1008S User ManualDocument38 pages1008S User ManualHardev Singh100% (1)

- Cautoni Swastik: SCR Power Regulator Operation ManualDocument2 pagesCautoni Swastik: SCR Power Regulator Operation ManualMaulik PatelNo ratings yet

- 802P Universal Indicator Manual 350Document15 pages802P Universal Indicator Manual 350Davesh JadonNo ratings yet

- Masibus Digital Controller 5002uDocument20 pagesMasibus Digital Controller 5002uSOURISH100% (2)

- VS070-1614MDR1 Integrated Machine Quick Start User ManualDocument7 pagesVS070-1614MDR1 Integrated Machine Quick Start User ManualEdsonNo ratings yet

- Sequential Timer Modul ST6M1Document3 pagesSequential Timer Modul ST6M1Ricky Ocktavi RizkyNo ratings yet

- MA10..I With RS232 MIDAS User's ManualDocument81 pagesMA10..I With RS232 MIDAS User's ManualMostafAliNo ratings yet

- Roboox Ac DriveDocument4 pagesRoboox Ac DrivejaahironlineNo ratings yet

- Multispan TC-19Document4 pagesMultispan TC-19Karan SolankiNo ratings yet

- NHR Industrial Furnace Temperature ControllerDocument10 pagesNHR Industrial Furnace Temperature ControllerAhmed AliNo ratings yet

- 11 KV 200 Amp 3 Pole AB Switch Technical Specification: ScopeDocument4 pages11 KV 200 Amp 3 Pole AB Switch Technical Specification: ScopeVIKRAM DESAINo ratings yet

- Masibus-8208 Manual PDFDocument36 pagesMasibus-8208 Manual PDFfaisal2106No ratings yet

- Electronic Speed SwitchDocument1 pageElectronic Speed SwitchSudipto MajumderNo ratings yet

- WL-WC4400, WL4405 Basic MFMDocument6 pagesWL-WC4400, WL4405 Basic MFMRohit Kumar0% (2)

- Instruction Manual: Energy MeterDocument2 pagesInstruction Manual: Energy MeterIshwar ranawatNo ratings yet

- Automatic Power Factor Controller Relay: Operating InstructionsDocument7 pagesAutomatic Power Factor Controller Relay: Operating InstructionsKatty MenaNo ratings yet

- Controller User Manual - 12-24 Steps - RG1A-12Document91 pagesController User Manual - 12-24 Steps - RG1A-12ashNo ratings yet

- LVM PDFDocument8 pagesLVM PDFBALAJI UNo ratings yet

- TOKY SV Series Sensor Meter User ManualDocument6 pagesTOKY SV Series Sensor Meter User ManualAS LO ProveedoresNo ratings yet

- Emfis PlusDocument24 pagesEmfis PlusPrabhu Natarajan100% (2)

- ABB Catalogue For LT MotorDocument6 pagesABB Catalogue For LT MotorNavneet Singh0% (1)

- Masibus-1008V R2 0110 Flow-Indicator-TotalizerDocument2 pagesMasibus-1008V R2 0110 Flow-Indicator-TotalizerSAYAK KUMAR DUTTANo ratings yet

- Universal Calibrator 3001m PDFDocument19 pagesUniversal Calibrator 3001m PDFKrishnaraj DhavalaNo ratings yet

- Smartcon 4000Document20 pagesSmartcon 4000செல்வமாரியப்பன் சீனிவாசன்No ratings yet

- Catalogue For TFM-FR-TZ-TX-B PDFDocument15 pagesCatalogue For TFM-FR-TZ-TX-B PDFGuru Vaga50% (2)

- Acrux Three Phase Energy Meter PDFDocument12 pagesAcrux Three Phase Energy Meter PDFManoj Shah0% (1)

- EM3360Document4 pagesEM3360antonyamnr100% (1)

- Gic SM 301Document3 pagesGic SM 301srinivasgate100% (1)

- Masibus Tcs 4050m - Loop Calibrator - Cb-2 - tcs4050m - r2 - 0110Document2 pagesMasibus Tcs 4050m - Loop Calibrator - Cb-2 - tcs4050m - r2 - 0110kazishahNo ratings yet

- Operating Manual: Technical Specification Technical SpecificationDocument4 pagesOperating Manual: Technical Specification Technical SpecificationKaran Solanki100% (1)

- Tuc 6 WF Manual PDFDocument92 pagesTuc 6 WF Manual PDFDhananjay MahakudNo ratings yet

- Adr141c PDFDocument11 pagesAdr141c PDFNamrata Shetti100% (1)

- Notes On Belt WatchDocument8 pagesNotes On Belt WatchManasJadavNo ratings yet

- Operating Manual Pid Temperature Controller UTC-1202, 2202Document4 pagesOperating Manual Pid Temperature Controller UTC-1202, 2202pawar darshanNo ratings yet

- 3de e (Bocr) ManualDocument6 pages3de e (Bocr) ManualNaveen Gupta100% (1)

- Addmas: "ADDMAS" Make Electro-Magnetic Flow MetersDocument22 pagesAddmas: "ADDMAS" Make Electro-Magnetic Flow Metersinfo -ADDMAS100% (1)

- Microsoft Word - AK-62 4 To 20maDocument2 pagesMicrosoft Word - AK-62 4 To 20maNisar Ahmed100% (4)

- L&T MN RelaysDocument6 pagesL&T MN RelaysArun Kumar100% (1)

- EM 231 TC 8AI eDocument4 pagesEM 231 TC 8AI eJaime Saldias0% (1)

- Condensate Recovery Meter CRM 485R: Energy Conservation - Environment - Process EfficiencyDocument6 pagesCondensate Recovery Meter CRM 485R: Energy Conservation - Environment - Process Efficiencyaftab0% (1)

- Ain Alpha Meter: High Accuracy MeteringDocument2 pagesAin Alpha Meter: High Accuracy Meteringmareymorsy282250% (2)

- Pic101 User ManualDocument2 pagesPic101 User Manualசசி குமார்No ratings yet

- Abb Acs 355: Access Parameter ListDocument3 pagesAbb Acs 355: Access Parameter ListBoulos Nassar100% (1)

- NX Series VFDDocument36 pagesNX Series VFDASHISH KUMARNo ratings yet

- Combined Catalogue - AuXC-2000, ATS, ACCLDocument68 pagesCombined Catalogue - AuXC-2000, ATS, ACCLmangalelectric CorporationNo ratings yet

- Pic152 User ManualDocument4 pagesPic152 User ManualCak Rony100% (2)

- Numerical Protection PDFDocument14 pagesNumerical Protection PDFDrashti PatelNo ratings yet

- Power Factor Controllers PFR-X R / PFR-M T: Because Excellent Capacitors Are Not EnoughDocument3 pagesPower Factor Controllers PFR-X R / PFR-M T: Because Excellent Capacitors Are Not EnoughMarvin RaxónNo ratings yet

- Pegasus D232 ERROR CORD LISTDocument1 pagePegasus D232 ERROR CORD LISTWasantha PeirisNo ratings yet

- 2940 Ast3pDocument3 pages2940 Ast3pPirooz MakooeiNo ratings yet

- C628 AWESOME Rate Meter: Dynapar Veeder-RootDocument1 pageC628 AWESOME Rate Meter: Dynapar Veeder-RootnayhatNo ratings yet

- Moglix Remarks Model: 409 With 2 Relay Alarm + 4-20 MADC RX O/pDocument3 pagesMoglix Remarks Model: 409 With 2 Relay Alarm + 4-20 MADC RX O/pyashNo ratings yet

- LC 5296 atDocument2 pagesLC 5296 atRohit BerwalNo ratings yet

- Speed SensorDocument1 pageSpeed SensorRaju SkNo ratings yet

- Excitation & Avr SystemDocument32 pagesExcitation & Avr SystemSreeram PanigrahiNo ratings yet

- PositionerDocument13 pagesPositionerLeonidas Petrou100% (2)

- AVR Dini XiDocument27 pagesAVR Dini XiAnonymous IN80L4rRNo ratings yet

- 2009 4 18 West e PDFDocument4 pages2009 4 18 West e PDFRaju SkNo ratings yet

- 1800R 8Document8 pages1800R 8Raju SkNo ratings yet

- PseDocument107 pagesPseAshutosh TiwariNo ratings yet

- Desuperheater PDFDocument14 pagesDesuperheater PDF3obaydoofNo ratings yet

- SP Am3 enDocument1 pageSP Am3 enRaju SkNo ratings yet

- Formula For Linear Ma To Square Root Ma ConversionDocument2 pagesFormula For Linear Ma To Square Root Ma ConversionRaju SkNo ratings yet

- Asme BPV PDFDocument59 pagesAsme BPV PDFRaju SkNo ratings yet

- Example of 3-15 Psi To 4-20ma ConversionDocument3 pagesExample of 3-15 Psi To 4-20ma ConversionRaju SkNo ratings yet

- Formula For Linear % To Square Root % ConversionDocument2 pagesFormula For Linear % To Square Root % ConversionRaju SkNo ratings yet

- Sa 352Document8 pagesSa 352Raju SkNo ratings yet

- Sa 320 PDFDocument13 pagesSa 320 PDFRaju SkNo ratings yet

- Sa 203 PDFDocument4 pagesSa 203 PDFRaju SkNo ratings yet

- Sa 204Document4 pagesSa 204Raju SkNo ratings yet

- Mantenimiento Maquina de TraccionDocument23 pagesMantenimiento Maquina de TraccionGustavo ZambranoNo ratings yet

- Aldila Nia Widya Pangestika - 40030218060026 Izzati Afina Risahan - 40030218060051Document22 pagesAldila Nia Widya Pangestika - 40030218060026 Izzati Afina Risahan - 40030218060051RaiNo ratings yet

- 2020 SampleRecommendationDocument3 pages2020 SampleRecommendationDauda Baba0% (1)

- LKPD SMK Analytical Exposition TextDocument5 pagesLKPD SMK Analytical Exposition Texthendra khoNo ratings yet

- A Review of Program Theory (Sharpe, 2011)Document4 pagesA Review of Program Theory (Sharpe, 2011)Gaby MerinoNo ratings yet

- Naca 101Document12 pagesNaca 101Joseph MuhoroNo ratings yet

- Business OneDocument3 pagesBusiness OneVikram AnandNo ratings yet

- Calculations Using Tanabe-Sugano DiagramsDocument7 pagesCalculations Using Tanabe-Sugano DiagramsFANDOMNo ratings yet

- Catalogo Baccara Dos Filtros T e yDocument2 pagesCatalogo Baccara Dos Filtros T e yEli VerliNo ratings yet

- Test Results: VersionDocument4 pagesTest Results: VersionCristian CotgNo ratings yet

- AV Control Receiver SA-XR15: Operating InstructionsDocument20 pagesAV Control Receiver SA-XR15: Operating InstructionsrockamkdNo ratings yet

- Steps in Crafting SK PlansDocument28 pagesSteps in Crafting SK PlansDistor, Jane F.No ratings yet

- Seminar #5. Speaking Part 1 Introduction & InterviewDocument21 pagesSeminar #5. Speaking Part 1 Introduction & InterviewOyun-erdene ErdenebilegNo ratings yet

- JMJ Marist Brothers Notre Dame of Marbel University: Alunan Avenue, City of Koronadal 9506 South Cotabato, PhilippinesDocument4 pagesJMJ Marist Brothers Notre Dame of Marbel University: Alunan Avenue, City of Koronadal 9506 South Cotabato, PhilippinesKurt Ryan JesuraNo ratings yet

- Cellsecure E12 Nuska Product User ManualDocument30 pagesCellsecure E12 Nuska Product User ManualCellSecure IndonesiaNo ratings yet

- IC Construction Project Charter 8556 WORDDocument3 pagesIC Construction Project Charter 8556 WORDTomi ReyesNo ratings yet

- NRRC-SG-07-Application For Authorization of Radioisotope Production Using AcceleratorsDocument39 pagesNRRC-SG-07-Application For Authorization of Radioisotope Production Using AcceleratorsESTSS TrainingNo ratings yet

- GEC 3 WorksheetsDocument26 pagesGEC 3 WorksheetsRodnie Flores BaguioNo ratings yet

- Appendix 3 - The Written DocumentDocument29 pagesAppendix 3 - The Written DocumentNaomi Liang100% (1)

- Accord Fire Alarm Check ListDocument6 pagesAccord Fire Alarm Check ListFaruque SathiNo ratings yet

- BGS OwnersManualDocument66 pagesBGS OwnersManualSoporte centralNo ratings yet

- Psikologi Ulayat: Sarlito Wirawan SarwonoDocument6 pagesPsikologi Ulayat: Sarlito Wirawan SarwonoArin taradipaNo ratings yet

- Jma 53126Document492 pagesJma 53126christos1157No ratings yet

- BrandlDocument21 pagesBrandlSaqib M GorayaNo ratings yet

- C50 Operating-Instructions INT enDocument36 pagesC50 Operating-Instructions INT enBrian ByengaboNo ratings yet

- Marine & Offshore Catalog Channel Tray SystemsDocument34 pagesMarine & Offshore Catalog Channel Tray SystemssivakumarNo ratings yet