Parallel Operation of Two Single Phase Transformers: Experiment No: 05

Parallel Operation of Two Single Phase Transformers: Experiment No: 05

Uploaded by

Bhanoth MohanCopyright:

Available Formats

Parallel Operation of Two Single Phase Transformers: Experiment No: 05

Parallel Operation of Two Single Phase Transformers: Experiment No: 05

Uploaded by

Bhanoth MohanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Parallel Operation of Two Single Phase Transformers: Experiment No: 05

Parallel Operation of Two Single Phase Transformers: Experiment No: 05

Uploaded by

Bhanoth MohanCopyright:

Available Formats

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

EXPERIMENT NO: 05

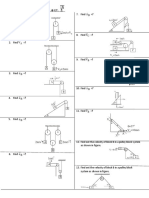

PARALLEL OPERATION OF TWO SINGLE PHASE TRANSFORMERS

AIM: Parallel operation of two dissimilar (2 KVA, 3 KVA) single phase transformers and

determination of load sharing and analytical verification given the short circuit test details.

NAME PLATE DETAILS:

EQUIPMENTS REQUIRED:

S.No Name of the Type Range Quantity

Equipment

1 Ammeter MI 0 -10 Amp 02

2 Ammeter MI 0 – 20 Amp 01

3 Voltmeter MI 0 – 600 Volt 01

4 Voltmeter MI 0 – 75 Volts 01

5 Wattmeter UPF 75 V / 10 Amp 01

6 Resistive Load NA ---- 01

PROCEDURE :

a) Make connections as per circuit diagram; keep the Load switch (DPST) and SPST(S1) switch

open.

b) First, Perform polarity test on each of the units and note down terminals with the same

polarity.

c) Switch ON the main supply, see the voltmeter reading of V connected across SPST switch, if

this reading double the secondary voltage of both the transformers then switch OFF main

supply and interchange the connections of secondary of any transformers.

d) If it reads zero which confirms that two transformers are connected correctly and parallel

then switch SPST(S1)can be closed, this way the polarity can be checked.(since wrong

polarity will short circuit the transformer if operated in parallel).

e) Also, confirm that no load voltages of both the transformers match in magnitude.

(It is important to perform both these tests before attempting the parallel operation).

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

f) As we are not applied load on the Transformers, the ammeters shows zero readings.

g) Start applying the load on transformers, then T/F-1 and T/F-2 starts drawing the

corresponding currents as per their ratings.

h) Note down the corresponding current readings I1 , I2 & IL .

i) As we increase the load the corresponding values of currents I1 , I2 & IL increases.

j) Repeat the procedure for 4 to 6 readings by applying load stepwise.

k) Once the readings are noted down switch off the loads gradually, open SPST switch and

switch OFF the main supply.

l)

TABULATION OF READINGS OF LOAD TEST :

S.No PRACTICAL VALUES THEORETICAL VALUES

I1 (Amp) I2 (Amp) IL (Amp) I1 (Amp) I2 (Amp) IL (Amp)

1

2

3

4

5

6

FOR THEORETICAL VALUES :

Procedure for conducting SC tests to determine Z1 & Z2 :

a) Connections are made as shown in the circuit diagram for SC test for each Transformer.

b) Keeping the auto transformer at zero output position close the supply switch.

c) Vary the auto transformer till the ammeter reads the rated full-load current of the

Transformer under test.

d) Note down the ammeter, voltmeter and wattmeter readings.

e) Bring the auto transformer to zero output position and open the supply switch.

f) Tabulate the readings, disconnect the windings.

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

THEORETICAL CALCULATION OF CURRENT SHARING BY EACH TRANSFORMER :

(Note : Impedance calculating should be in (a+jb) rectangular form and load sharing shall be

reported in the tabular column in a+jb form.)

𝑍2 𝑍1

I1 = I L X (Amp) ; I2 = I L X (Amp)

𝑍1 +𝑍2 𝑍1 +𝑍2

SHORT CIRCUIT TEST FOR EACH TRANSFORMER TO DETERMINE Z1 & Z2 :

SC TEST TO BE CONDUCTED INDIVIDUALLY ON EACH TRANSFORMER :

S.No Vsc (Volts) Isc (amp) Wsc (watts) COS ⍉sc R01 (Ω) X01 (Ω)

T/F-1

T/F-2

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

Calculation of Z1 and Z2 by conducting SC Test :

𝑊𝑠𝑐

1. R01 = 2 (Ω)

𝐼𝑠𝑐

𝑉𝑠𝑐

2. Z01 = (Ω)

𝐼𝑠𝑐

3. X01 = √𝑍01

2 2

− 𝑅01 (Ω)

CONCLUSION : The load sharing between the two transformers connected in parallel is studied

theoretically and verified practically.

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

EXPERIMENT NO: 03

SUMPNER’S TEST (or) BACK TO BACK TEST

AIM : To conduct Back to Back test on two identical transformers and to determine the efficiency

and regulation of Transformer.

APPARATUS :

S.No Name of the Type Range Quantity

Equipment

1 Ammeter MI 0 -20 Amp 01

2 Ammeter MI 0 – 2 Amp 01

3 Voltmeter MI 0 – 75 Volt 01

4 Voltmeter MI 0 – 300 Volts 01

5 Voltmeter MI 0 – 600 Volts 01

6 Wattmeter LPF 300 V / 2.5 Amp 01

7 Wattmeter UPF 75 V / 20 Amp 01

NAME PLATE DETAIS :

1. Transformer ratings : 1.2 KVA

2. Primary Voltage : 240 V

3. Secondary Voltage : 120 V

THEORY :

1. In OC test we find :

a) Core loss (Wo)

b) Core Parameter (Ro & Xo)

2. In SC test we find :

a) Copper loss (Wcu)

b) Winding Parameters (R01 & X01)

3. From Sumpner’s test we find :

a) all the four parameters can be find (i.e. Ro, Xo, Ro1 & Xo1)

b) In addition to above we can also find temperature rise of transformers.

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

4. Advantage of this test :

a) To find Ro, Xo, Ro1 & Xo1 need to conduct two separate test (i.e. OC and SC test)

and consumes time and extra power.

b) In one attempt we can conduct OC test as well as SC test and we can find all four

quantities at a time.

c) The Power required to conduct this test is less when compare to OC and SC test.

d) We can also perform the Heat run test on a same test.

5. We required two identical transformers to conduct this test.

PROCEDURE :

1. Make circuit as per given circuit diagram.

2. Two primaries of Transformers are connected in parallel.

3. Two secondaries of transformers are connected in series opposition.

4. Give rated primary voltage to the transformer by varying auto transformer gradually.

5. According to that emf’s will induce in the primary and secondary winding.

6. Net voltage across secondaries becomes zero due to series opposition which shows

voltmeter (V) connected across A & B terminals.

7. Means the secondary of the transformers acting like a open circuit.

8. Under this condition source will supply No-load current (io) and No-load power (Wo).

9. Note down the readings of ammeter A1 and W1.

10. Wattmeter reads No-load power loss (i.e Wo= Core loss or Iron loss) and ammeter

reads No-load current (Io).

11. Keep the primary supply as it is and close switch (S1-polarity switch) and apply

voltage towards secondary side through auto transformer until rated current flows

through Primary and secondary, just like short circuit test.

12. Small amount of voltage is enough ( say 30% of full load voltage) to get rated current

in primary and secondary.

13. Current will flow through primary terminals (C-D-E-F-G) not through ammeter (A1)

and wattmeter (W1).

14. W1 reading will not change, W2 reads copper loss (from short circuit test)

15. Note down the readings of A2 and W2. ( short circuit current and copper losses of both

the transformers respectively)

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

TABULATION :

OC TEST :

2*Io 2* Wo

Vo (Volts) Ro (Ω) Xo (Ω) Zo (Ω)

(Amp) (Watts)

SC TEST :

2*Vsc (Volts)

Isc (Amp) (Across auto 2*Wsc Req (Ω) Xeq (Ω) Zeq (Ω)

transformer output)

CALCULATIONS PER EACH TRANSFORMER :

𝑊𝑂

1. COS ⍉O = 𝑉𝑂∗ 𝐼𝑂

𝑉𝑂 𝑉𝑂

2. Zo=√𝑅𝑜2 + 𝑋𝑂2 3) Ro = 𝐼 Ω 4) Xo = 𝐼 Ω

𝑂 𝑋 𝐶𝑂𝑆⍉𝑂 𝑂 𝑋 𝑆𝑖𝑛 ⍉𝑂

Wsc Vsc

5. Req = Ω 6) Zeq = Ω 7) Xeq=√𝑍𝑒𝑞

2 − 𝑅2

𝑒𝑞

(Isc)2 Isc

TABULATION FOR CALCULATION OF % REGULATIONAT FULL-LOAD :

S.No Load PF % Regulation @ Lagging PF % Regulation @ Leading PF

1

2

3

4

5

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

𝐼𝑠𝑐 {𝑅𝑒𝑞 ∗𝐶𝑂𝑆⍉ ± 𝑋𝑒𝑞 ∗𝑆𝑖𝑛⍉ }

% REGULATION = x 100

𝑉𝑜

CALCULATION OF COMBINED EFFICIENCY AT DIFFERENT LOADS AND INDIVIDUAL

EFFICIENCY IS CALCULATED :

S.No FRACTION OF FULL LOAD EFFICIENCY @ PF =1 EFFICIENCY @ PF =0.8

X

1 0.25

2 0.50

3 0.75

4 1.0

(𝑋∗𝐹𝑈𝐿𝐿 𝐿𝑂𝐴𝐷 (𝐾𝑉𝐴)∗𝐶𝑂𝑆∅ )∗ 1000

%ɳ= x 100

(𝑋∗𝐹𝑈𝐿𝐿 𝐿𝑂𝐴𝐷 (𝐾𝑉𝐴)∗𝐶𝑂𝑆∅∗1000)+𝑊𝑜+𝑋 2 ∗𝑊𝑠𝑐

RESULT: The characteristic curve of efficiency at different loads and % Regulation at full-load at

different power factors are drawn.

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

EXPERIMENT NO: 04

SCOTT CONNECTION (or) T-CONNECTION ON TRANSFORMERS

AIM : To obtain two single phase (1-∅) supplies from a three phase (3-∅) supply by scott

connecting the two transformers and further study the loading on the three phase side

due to loading on the two single phase & determination of efficiency of the combined set

(2 x 1.2 KVA).

APPARATUS :

S.No Name of the Type Range Quantity

Equipment

1 Ammeter MI 0 -20 Amp 03

2 Voltmeter MI 0 – 300 Volts 02

3 Voltmeter MI 0 – 600 Volts 01

4 Wattmeter UPF 300 V / 20 Amp 02

THEORY :

Here we are using two transformers (T/F-1 & T/F-2 )

a) Transformer-1 called as -------- Main Transformer

b) Transformer-2 called as -------- Teaser Transformer

c) Transformer-1 in which used 86.6 % of secondary tappings, whereas

d) Transformer-2 in which used 50 % of secondary tapping.

PROCEDURE :

1. Make the connection as per circuit diagram.

2. The supply is given to the secondary of both the transformers.

3. Loads are connected to primaries of main transformer and teaser transformer.

4. Use wattmeters (W1 & W2) to measure power taken by the two transformers.

5. Connect two voltmeters and two ammeters towards load side to measure voltage and

current by each load.

6. Before going to start main supply confirm that the auto transformer kept at zero

position.

7. After confirming the Auto-transformer at zero position, switch on the supply.

8. Now gradually vary the auto-transformer till the voltmeters V1, V2 connected across load

should shows 240V.

9. Once the rated voltage are applied then vary the load in steps.

10. First apply balanced load for main transformer and teaser transformer.

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

11. Switch ON one equal loads to the T/F-1 and T/F-2.

12. Note down the corresponding values of wattmeters, ammeters and voltmeters

(i.e. W1,W2,I1,I2,V1,V2).

13. The loads are applied step wise ( equal loads need to apply for each transformer and take

the corresponding readings of the meters)

14. The same procedure will be repeat by applying the unequal loads to the main

transformer and teaser transformer.

15. The corresponding values of W1,W2,I1,I2,V1,V2 are noted down.

TABULAR COLUMN :

BALANCED LOAD READINGS :

S.No W1 W2 INPUT V1 V2 I1 I2 OUTPUT %ɳ

UN-BALANCED LOAD READINGS :

S.No W1 W2 INPUT V1 V2 I1 I2 OUTPUT %ɳ

CALUCULATION :

1. Input = W1+W2 (watts)

2. Output = (V1 x I1) + (V2 X I2)

𝑂𝑈𝑇 𝑃𝑈𝑇

3. %ɳ = X 100

𝐼𝑁𝑃𝑈𝑇

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

EXPERIMENT NO: 08

REGULATION OF ALTERNATOR BY USING SYCHRONOUS IMPEDANCE METHOD

AIM : To find the regulation of a 3-⌀ alternator by using synchronous impedance method.

APPARATUS REQUIRED :

S.No Equipment Type Range Quantity

1 Voltmeter MI 0-300/600V 1

2 Ammeter MI 0-5/10A 1

3 Ammeter MI 0- 2.5/5A 1

4 Rheostat Wire-wound 145Ω/2A 2

5 Rheostat Wire-wound 400Ω/1.7A 1

6 Tachometer Digital -------- 1

7 Connecting wires ------------ --------- required

NAME PLATE DETAILS:

DC Motor (Prime mover) Rating 3-⌀ Alternator Rating

KW 7.5 hp Power rating

Voltage 230v PF

Current Line Voltage

Speed 1500 rpm Speed 1500 rpm

Excitation Shunt Excitation Voltage 230 V (DC)

Voltage 230 V (DC) Rated Current

Field Current

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

CIRCUIT DIAGRAM:

PROCEDURE :

OPEN CIRCUIT TEST :

1. Make the connection as per the circuit diagram.

2. Before starting the experiment, the potential divider network in the alternator field circuit

and field regulator rheostat of motor circuit is set minimum resistance position.

3. Switch ON the supply and close the DPST switch. The DC motor is started by moving starter

handle.

4. Adjust the field rheostat of DC motor to attain rated speed (equal to synchronous speed of

alternator)

5. By decreasing the field resistance of alternator, the excitation current of alternator is

increased gradually in steps.

6. Note the readings of field current, and its corresponding armature voltage in a tabular

column.

7. The voltage readings are taken up to and 10% beyond the rated voltage of the machine.

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

SHORT CIRCUIT TEST :

1. For short circuit test, before starting the experiment the potential divider is brought back to

zero output position, i.e. resistance should be zero in value.

2. Now close the TPST switch.

3. The excitation of alternator is gradually increased in steps until rated current flows in the

machine and note down the readings of excitation current and load current (short circuit

current)

4. Switch OFF the supply.

OBSERVATIONS :

OC TEST S.C.TEST

S.N S.N

Field Current (Amp) OC Voltage/phase (Vo) Field Current If (Amp) SC Current Isc (Amp)

Procedure to find Armature resistance of alternator:

1. Connections are made as per the circuit diagram.

2. Switch ON the supply. By varying the rheostat, take different readings of ammeter and

voltmeter in a tabular column.

3. From the above readings, average resistance Ra of a armature is found out.

OBSERVATIONS :

𝑽

S.No Armature Current (amp) Armature Voltage (volts) Rdc = (Ω)

𝑰

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

Connection Diagram to find Ra :

Procedure to find synchronous impedance from OC and SC test:

1. Plot open circuit voltage, short circuit current verses field current on a graph sheet.

2. From the graph, the synchronous impedance for the rated value of excitation is calculated.

3. The excitation emf is calculated at full load current which is equal to the terminal voltage at

no-load.

4. The voltage regulation is calculated at rated terminal voltage.

MODEL CALCULATIONS:

𝑉𝑜𝑐

𝑍𝑠 = for the same If and speed : 𝑋𝑠 = √𝑍𝑆2 − 𝑅𝑎2 [Ra Rdc ]

𝐼𝑠𝑐

Generated emf of alternator on no load is :

𝐸𝑂 = √(𝑉 𝐶𝑂𝑆 ∅ + 𝐼𝑎 𝑅𝑎 )2 + (𝑉 𝑆𝐼𝑁 ∅ ± 𝐼𝑎 𝑋𝑠 )2

+ for lagging p.f

- for leading p.f

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

The percentage regulation of alternator for a given p.f is :

𝐸𝑜− 𝑉

% Reg = X 100

𝑉

Where Eo = Generated emf of alternator.

V = Full-load, rated terminal voltage per phase.

MODEL GRAPH :

Draw the graph between If (vs) Eo per phase and If (vs) Isc

PRECAUTIONS :

1. Connections must be made tight.

2. Before making or breaking the circuit, supply must be switched off.

RESULT :

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

EXPERIMENT NO: 07

DIRECT LOAD TEST ON ALTERNATOR

AIM : To conduct direct load test on Alternator and obtain voltage regulation.

APPARATUS REQUIRED :

S.No Equipment Type Range Quantity

1 Voltmeter MI 0-300/600V 1

2 Ammeter MI 0-5/10A 1

3 Ammeter MI 0- 2.5/5A 1

4 Rheostat Wire-wound 145Ω/2A 2

5 Rheostat Wire-wound 400Ω/1.7A 1

6 Tachometer Digital -------- 1

7 Connecting wires ------------ --------- required

NAME PLATE DETAILS:

DC Motor (Prime mover) Rating 3-⌀ Alternator Rating

KW 7.5 hp Power rating

Voltage 230v PF

Current Line Voltage

Speed 1500 rpm Speed 1500 rpm

Excitation Shunt Excitation Voltage 230 V (DC)

Voltage 230 V (DC) Rated Current

Field Current

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

CIRCUIT DIAGRAM :

PROCEDURE:

1. Make the connection as per the circuit diagram.

2. Before starting the experiment, the potential divider network in the alternator field circuit

and field regulator rheostat of motor circuit is set minimum resistance position.

3. Switch ON the supply and close the DPST switch. The DC motor is started by moving starter

handle.

4. Adjust the field rheostat of DC motor to attain rated speed (equal to synchronous speed of

alternator)

5. Increase excitation current of alternator gradually until we get rated terminal voltage by

decreasing the field resistance.

6. Note the readings of line current, and its corresponding armature voltage under no load

condition in a tabular column.

7. Now close TPST switch to apply load on alternator.

8. Apply load on alternator step wise and note the readings of line current, armature voltage for

corresponding load values in a tabular column.

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

DIPLOMA IN ELECTRICAL AND ELECTRONICS ENGINEERING (DEEE)

9. Increase load up to rated current and take the values of terminal voltage, line current and

calculate regulation of alternator at different load conditions.

10. Remove load gradually from the alternator and switch off the power supply.

OBSERVATIONS :

S.No Armature Current (amp) Armature Voltage (volts) % Regulation

1

2

3

4

5

VIJAY RURAL ENGINEERING COLLEGE – II SHIFT POLYTECHNIC, DASNAGAR-NIZAMABAD

You might also like

- Experiment 02Document2 pagesExperiment 02micu100% (1)

- 4.circle Diagram of Three Phase Induction Motor From No Load & Blocked Rotor TestsDocument4 pages4.circle Diagram of Three Phase Induction Motor From No Load & Blocked Rotor Testsmandadi_sailesh67% (3)

- Study of StartersDocument6 pagesStudy of StartersGANESH KUMAR B eee2018No ratings yet

- Types of ForcesDocument10 pagesTypes of ForcesAbdulrahman RadeefNo ratings yet

- Study of Over Current RelayDocument6 pagesStudy of Over Current RelayDarshana ChathurangaNo ratings yet

- Experiment No.5-Determination of XD and XQ of Synchronous Machine by Slip TestDocument3 pagesExperiment No.5-Determination of XD and XQ of Synchronous Machine by Slip Test61EEPrabhat PalNo ratings yet

- Speed Control of Three Phase Slip Ring Induction Motor at Variable Load ConditionDocument3 pagesSpeed Control of Three Phase Slip Ring Induction Motor at Variable Load Conditionhi100% (1)

- 2.sumpner's Test On A Pair of Single Phase TransformersDocument5 pages2.sumpner's Test On A Pair of Single Phase Transformerschandrakanth100% (3)

- EM-I Lab Viva Questions Updated OnDocument6 pagesEM-I Lab Viva Questions Updated OnNagamohan BilluNo ratings yet

- 5.locus Diagram RL PDFDocument4 pages5.locus Diagram RL PDFRaghapavani C100% (1)

- Light Intensity ControlDocument8 pagesLight Intensity ControlRaman GargNo ratings yet

- Electrical and Electronics Measurements and Instrumentation-77-Đã Chuyển ĐổiDocument9 pagesElectrical and Electronics Measurements and Instrumentation-77-Đã Chuyển ĐổiNguyên Nguyễn SơnNo ratings yet

- EE592 Lab Manual Power Sytem LabDocument48 pagesEE592 Lab Manual Power Sytem LabCiczmockingbird TsvkAdmNo ratings yet

- Electrical Machines and Drives Year Question PaperDocument2 pagesElectrical Machines and Drives Year Question PapersivaeinfoNo ratings yet

- CH-1 - DC Generator Q.bank PDFDocument2 pagesCH-1 - DC Generator Q.bank PDFjaythakar8887No ratings yet

- Experiment No.3-Voltage Regulation of A 3-Phase Alternator by ZPF and ASA MethodDocument6 pagesExperiment No.3-Voltage Regulation of A 3-Phase Alternator by ZPF and ASA Method61EEPrabhat Pal100% (2)

- Swinburne S Test On DC Shunt MotorDocument5 pagesSwinburne S Test On DC Shunt Motortamann2004No ratings yet

- 2 - To Study The Speed Control of DC Shunt Motor by Armature Control and Field Control MethodDocument4 pages2 - To Study The Speed Control of DC Shunt Motor by Armature Control and Field Control Methodbhavesh1863100% (1)

- Hopkinson Test On DC Shunt MotorDocument5 pagesHopkinson Test On DC Shunt MotorVarun VadluriNo ratings yet

- Magnetization Characteristics of A D.C. Shunt Generator: Exp. No: DateDocument60 pagesMagnetization Characteristics of A D.C. Shunt Generator: Exp. No: DateSuyash SinghNo ratings yet

- Chapter 3-Ac Machines FundamentalsDocument40 pagesChapter 3-Ac Machines FundamentalsnehmeNo ratings yet

- DC Series Motor Single Phase Half & Full Controlled DrivesDocument11 pagesDC Series Motor Single Phase Half & Full Controlled DrivesUjjal Dey100% (1)

- Experiment# 10: Measure The Power and Power Factor by Three Ammeter MethodDocument10 pagesExperiment# 10: Measure The Power and Power Factor by Three Ammeter MethodFarwa MunirNo ratings yet

- Brake Test On DC Shunt MotorDocument5 pagesBrake Test On DC Shunt MotorkudupudinageshNo ratings yet

- Experiment-5: Aim: To Measure Active and Reactive Power in Single Phase Ac Circuit. Apparatus RequiredDocument4 pagesExperiment-5: Aim: To Measure Active and Reactive Power in Single Phase Ac Circuit. Apparatus RequiredAMIT SINGHNo ratings yet

- Electrical Machines I Lab Twisted QuestionsDocument4 pagesElectrical Machines I Lab Twisted QuestionsPranav MenonNo ratings yet

- Brake Test On 3 Phase Slip Ring Induction MotorDocument5 pagesBrake Test On 3 Phase Slip Ring Induction MotorRajeev Sai0% (1)

- Experiment No - 04 To Study DC MachineDocument4 pagesExperiment No - 04 To Study DC MachineRaviNo ratings yet

- Parallel Operation of AlternatorDocument13 pagesParallel Operation of AlternatorChirag Bafna0% (1)

- V and Inverted V Curves of Synchronous MotorDocument7 pagesV and Inverted V Curves of Synchronous Motorkarthikeyan249No ratings yet

- 6.v-Curve & Inverted V-Curve For Three Phase Syncronous MotorDocument6 pages6.v-Curve & Inverted V-Curve For Three Phase Syncronous Motormandadi_sailesh100% (1)

- Representation of Power System ComponentsDocument14 pagesRepresentation of Power System ComponentsRume EmujekarohwoNo ratings yet

- Power Factor Meters - Electrodynamometer Type Power Factor MeterDocument4 pagesPower Factor Meters - Electrodynamometer Type Power Factor MeterNh Chuminda Yapa0% (1)

- Single Phase TransformerDocument31 pagesSingle Phase Transformerpranay639100% (1)

- Study of Bridge Rectifier: ObjectivesDocument3 pagesStudy of Bridge Rectifier: ObjectivesDeepak KumbharNo ratings yet

- Experiment No.2-Voltage Regulation of A 3-Phase Alternator by Emf and MMF MethodDocument7 pagesExperiment No.2-Voltage Regulation of A 3-Phase Alternator by Emf and MMF Method61EEPrabhat PalNo ratings yet

- 1.o.c & S.C T Test On Single Phase TransformerDocument6 pages1.o.c & S.C T Test On Single Phase Transformermandadi_saileshNo ratings yet

- Electrical Machines-III Question BankDocument9 pagesElectrical Machines-III Question BanksanthiNo ratings yet

- Static V-I Characteristics of A ThyristorDocument3 pagesStatic V-I Characteristics of A Thyristorsrikaanth06No ratings yet

- Sreekavithaengineerig College: Scott Connection of TransformersDocument4 pagesSreekavithaengineerig College: Scott Connection of Transformersmandadi_saileshNo ratings yet

- Speed Torque Characteristics of 3 Phase Induction MotorDocument4 pagesSpeed Torque Characteristics of 3 Phase Induction MotorAdi Adnan100% (1)

- Load Test of Single Phase Transformer Phase: Expt. No: DateDocument11 pagesLoad Test of Single Phase Transformer Phase: Expt. No: Datesameerpatel15770No ratings yet

- Power Electronics & Drives: Unit: 1 Power Semiconductor DevicesDocument24 pagesPower Electronics & Drives: Unit: 1 Power Semiconductor DevicesTapobroto ChatterjeeNo ratings yet

- Power Electronics - 2 MARKSDocument30 pagesPower Electronics - 2 MARKSkarthik kumar50% (4)

- Presentation - Presentation: DC To DC ConverterDocument20 pagesPresentation - Presentation: DC To DC ConverterDev Kumar100% (2)

- Exp. No: Date: Formation of Y-Bus Matrice by Direct Inspection Method Aim: To Determine The Admittance Matrices For The Given Power System NetworkDocument5 pagesExp. No: Date: Formation of Y-Bus Matrice by Direct Inspection Method Aim: To Determine The Admittance Matrices For The Given Power System NetworkSnehil ChandraNo ratings yet

- Load Test On DC Shunt MotorDocument6 pagesLoad Test On DC Shunt Motorsanju0% (1)

- UNIT-2 Three Phase TransformerDocument24 pagesUNIT-2 Three Phase Transformerkaran nirmala gajanan shinde0% (1)

- 9.speed Control of DC Motor Using Chopper DriveDocument8 pages9.speed Control of DC Motor Using Chopper DriveDhivya N100% (2)

- Chapter 3Document26 pagesChapter 3Belayneh TadesseNo ratings yet

- Electric Drive Lab Laboratory Manual: Dev Bhoomi Institute Chakrata Road, Navgaoun Manduwala, UttarakhandDocument15 pagesElectric Drive Lab Laboratory Manual: Dev Bhoomi Institute Chakrata Road, Navgaoun Manduwala, Uttarakhandjaya mishraNo ratings yet

- Electrical Machines-II QuestionsDocument2 pagesElectrical Machines-II QuestionsHari Reddy50% (2)

- Questions & Answers On Three Phase TransformersDocument26 pagesQuestions & Answers On Three Phase Transformerskibrom atsbha50% (2)

- Exp3 Star-Delta ConnectionDocument9 pagesExp3 Star-Delta Connectionpijechad0% (2)

- 5.fault Analysis (LG, LLG) On A Three Phase Unloaded AlternatorDocument4 pages5.fault Analysis (LG, LLG) On A Three Phase Unloaded Alternatorarjuna430650% (2)

- Parallel Operation of Two Single Phase Transformers: Experiment No: 05Document31 pagesParallel Operation of Two Single Phase Transformers: Experiment No: 05Bhanoth MohanNo ratings yet

- Sr. No. Name of Experiment: Load Test On 3 Phase Squirrel Cage Induction MotorDocument40 pagesSr. No. Name of Experiment: Load Test On 3 Phase Squirrel Cage Induction MotorSagar G ReddyNo ratings yet

- BeeeDocument66 pagesBeeejaydeep gudetiNo ratings yet

- O.C & S.C Test On Single Phase Transformer.: Siddhartha Institute of Engineering & TechnologyDocument6 pagesO.C & S.C Test On Single Phase Transformer.: Siddhartha Institute of Engineering & Technologyal imranNo ratings yet

- Em Lab-II ManualDocument45 pagesEm Lab-II Manualrkadiraj701160% (5)

- 1.O.C. & S.C. Tests On Single Phase TransformerDocument6 pages1.O.C. & S.C. Tests On Single Phase Transformerchandrakanth100% (3)

- Design of Electrical Circuits using Engineering Software ToolsFrom EverandDesign of Electrical Circuits using Engineering Software ToolsNo ratings yet

- Condenser MicrophonesDocument4 pagesCondenser MicrophonesKarthik NarayananNo ratings yet

- Edexcel IAL Mechanics MDocument28 pagesEdexcel IAL Mechanics MDima MurjanNo ratings yet

- Phys 111 Final Exam Formulas - Fall 2011: DT DWDocument1 pagePhys 111 Final Exam Formulas - Fall 2011: DT DWVenkataramanan SureshNo ratings yet

- Chapter 25Document134 pagesChapter 25Tejas SharmaNo ratings yet

- Strain Gage-WhatDocument16 pagesStrain Gage-WhatAshok JoshiNo ratings yet

- Topics Problem Set 5 - Dynamics of Rigid Bodies (Final) 2nd Term 2020-2021Document1 pageTopics Problem Set 5 - Dynamics of Rigid Bodies (Final) 2nd Term 2020-2021Franz SantosNo ratings yet

- Can An Ohmmeter Test Thyristor and TriacDocument2 pagesCan An Ohmmeter Test Thyristor and Triacmr.sanyNo ratings yet

- Phy 12345Document33 pagesPhy 12345Jameel MalikNo ratings yet

- Miniature Circuit Breaker Index ABBDocument108 pagesMiniature Circuit Breaker Index ABBsquelcheNo ratings yet

- LDS LMS LHS FRDocument84 pagesLDS LMS LHS FRМихаил МолокотинNo ratings yet

- Electrical Energy and PowerDocument8 pagesElectrical Energy and Powerrudiskw456No ratings yet

- Panasonic Th-42pz77u CH Gp10dhuDocument167 pagesPanasonic Th-42pz77u CH Gp10dhuRaskipusNo ratings yet

- Fuse and Types of FusesDocument5 pagesFuse and Types of FusesYasir JamilNo ratings yet

- Newton's First LawDocument22 pagesNewton's First LawJayPee BasiñoNo ratings yet

- Lecture 2 - Coulomb's Law and Electric Field IntensityDocument20 pagesLecture 2 - Coulomb's Law and Electric Field IntensitySir AsherNo ratings yet

- Basic PPT For PFDocument39 pagesBasic PPT For PFsrichander50% (2)

- Simulation Study of Dynamic Fault Recovery Performance of VSC-HVDC SystemDocument5 pagesSimulation Study of Dynamic Fault Recovery Performance of VSC-HVDC Systemkra_amNo ratings yet

- PROBLEM SET AP Projectile MotionDocument2 pagesPROBLEM SET AP Projectile MotionmariniabrahanNo ratings yet

- Performance Analysis and Comparison of Conventional and Interleaved DC/DC Boost Converter Using MULTISMDocument10 pagesPerformance Analysis and Comparison of Conventional and Interleaved DC/DC Boost Converter Using MULTISMIam AbdiwaliNo ratings yet

- Photovoltaic Array / Solar Panel: Design, Analyze & Operate Solar Farms With ETAPDocument3 pagesPhotovoltaic Array / Solar Panel: Design, Analyze & Operate Solar Farms With ETAPamitNo ratings yet

- Operation, Maintenance and Repair of Auxiliary GeneratorsDocument125 pagesOperation, Maintenance and Repair of Auxiliary GeneratorssabrahimaNo ratings yet

- Balluff Bes 516 326 G s4cDocument2 pagesBalluff Bes 516 326 G s4cРома ВоронковNo ratings yet

- Solution 1167965Document10 pagesSolution 1167965Nabaratna BiswalNo ratings yet

- ASTM - D - 1456 Test Method For Rubber Property - ElongationDocument4 pagesASTM - D - 1456 Test Method For Rubber Property - ElongationElaine HuangNo ratings yet

- B A 2m/s V: DPS Constraint Motion at ETDocument2 pagesB A 2m/s V: DPS Constraint Motion at ETsanjibnandaNo ratings yet

- Helicopter StabilityDocument13 pagesHelicopter Stabilitymanikandan_murugaiahNo ratings yet

- Cable Sizing Design Basis - DraftDocument11 pagesCable Sizing Design Basis - DraftIman Mukherjee100% (1)

- Course Outline MM103 2022Document10 pagesCourse Outline MM103 2022Manshika LalNo ratings yet