0 ratings0% found this document useful (0 votes)

215 viewsWPS Format For AWS D1.1 - WPS - SAW

WPS Format For AWS D1.1 - WPS - SAW

Uploaded by

The Welding Inspections CommunityWelding procedure specification format

ASME IX, AWS D1.1, BS EN ISO 15614-1

Read more: http://bit.ly/31v9NSh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

WPS Format For AWS D1.1 - WPS - SAW

WPS Format For AWS D1.1 - WPS - SAW

Uploaded by

The Welding Inspections Community0 ratings0% found this document useful (0 votes)

215 views1 pageWelding procedure specification format

ASME IX, AWS D1.1, BS EN ISO 15614-1

Read more: http://bit.ly/31v9NSh

Original Title

WPS format for AWS D1.1 - WPS - SAW

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

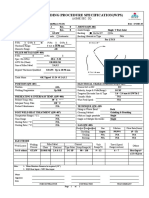

Welding procedure specification format

ASME IX, AWS D1.1, BS EN ISO 15614-1

Read more: http://bit.ly/31v9NSh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

215 views1 pageWPS Format For AWS D1.1 - WPS - SAW

WPS Format For AWS D1.1 - WPS - SAW

Uploaded by

The Welding Inspections CommunityWelding procedure specification format

ASME IX, AWS D1.1, BS EN ISO 15614-1

Read more: http://bit.ly/31v9NSh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

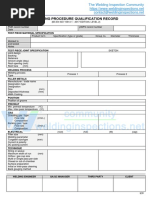

The Welding Inspections Community

https://www.weldinginspections.net

contact@weldinginspections.net

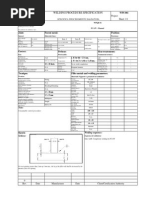

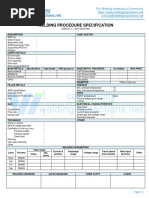

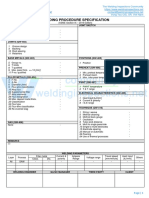

WELDING PROCEDURE SPECIFICATION

(AWS D1.1 – 2015 EDITION)

DESCRIPTION JOINT SKETCH

WPS no. :

Date of issue :

Applicable code :

Welding process/Type :

Supporting PQR no. :

Position :

JOINTS DETAILS

Groove type :

Groove angle :

Root opening :

Root face :

Back gouging :

Method :

BASE METALS Specification Type/Grade AWS group no. BASE METAL THICKNESS As welded With PWHT

Base material - - I or II CJP Groove welds - -

Welded to - - I or II CJP Groove w/CVN - -

Backing material - - - PJP Groove welds - -

Other: - Fillet welds - -

DIAMETER 100mm and over

FILLER METALS PREHEAT

AWS classification : Min. preheat temperature : ºC

Filler metal diameter : Max. inter-pass temperature : ºC

Electrode / Flux classification : PWHT

Manufacturer/Trade name : PWHT temperature : None

Supplemental filler metal : Time at temperature range :-

T limits :-

SHIELDING GAS ELECTRICAL CHARACTERISTICS

Composition : Max. heat input: :-

Flow rate : Transfer mode :-

Nozzle size : Current type & polarity: :-

A & V range :-

Power source type :-

TECHNIQUE

String or weave : Oscillation (GTAW mech./Auto.) :

Multi to single pass/side : Traverse length :

Number of electrodes : Traverse speed :

Longitudinal spacing of arcs : Dwell time :

Angle of parallel electrodes : Peening :

Angle of electrode (Mech./Auto.) : Inter-pass cleaning :

Normal to directions of travel : Other :

WELDING PARAMETERS

Filler metal Wire

Current & Travel speed Heat input

Layer Process Amp. Volt. feed Other

Class. Dia. polarity [mm/minute] [kJ/mm]

speed

All SAW

WELDING ENGINEER QA/QC MANAGER THIRD PARTY CLIENT

Page | 1

You might also like

- Dantherm VAM 40 Army Heater Service Manual VA-M 40 MK II - ServiceM - 2.2 - en - 971145 - 92sDocument92 pagesDantherm VAM 40 Army Heater Service Manual VA-M 40 MK II - ServiceM - 2.2 - en - 971145 - 92sRichardNo ratings yet

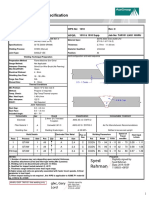

- WPS Format For ISO 15614-1 PQRDocument3 pagesWPS Format For ISO 15614-1 PQRThe Welding Inspections Community100% (2)

- Cajon-001 WPSDocument2 pagesCajon-001 WPSDanem HalasNo ratings yet

- 2019 Product Catalog WebDocument104 pages2019 Product Catalog WebIan Niko100% (1)

- WPS Format For ISO 9606-1 WelderDocument2 pagesWPS Format For ISO 9606-1 WelderThe Welding Inspections Community100% (1)

- WPS Format For AWS D1.1 - WelderDocument1 pageWPS Format For AWS D1.1 - WelderThe Welding Inspections Community100% (1)

- WPS Format For ASME IX - PQR-AllDocument3 pagesWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Leseprobe Guidelines For XRF Analysis1Document12 pagesLeseprobe Guidelines For XRF Analysis1faheemqc100% (1)

- STOICHIOMETRY (Yield, Conversion, Selectivity)Document4 pagesSTOICHIOMETRY (Yield, Conversion, Selectivity)kennethmsoriano67% (3)

- VILTER - Cool Compression Operation ManualDocument96 pagesVILTER - Cool Compression Operation ManualDiego Trinidad100% (1)

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNo ratings yet

- Procedure Qualification Record (PQR) : JointDocument2 pagesProcedure Qualification Record (PQR) : JointBalkishan DyavanapellyNo ratings yet

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi Jerbi100% (1)

- Ncpfirst - X-Form - PDF Example: (Epc - Dedicated Front Cover Sheet Here)Document11 pagesNcpfirst - X-Form - PDF Example: (Epc - Dedicated Front Cover Sheet Here)mohammed shaffi abdul rahman0% (1)

- Wps 7018 SmawDocument1 pageWps 7018 SmawErick VazquezNo ratings yet

- WPS - 020Document15 pagesWPS - 020MAT-LION100% (2)

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PQR (GMAW) - NotesDocument3 pagesPQR (GMAW) - Notesbibianamercado02No ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- Sujan Das WQTDocument2 pagesSujan Das WQTMD Shadikul Huq ShezanNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- PQR FormatDocument2 pagesPQR FormatBE GNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

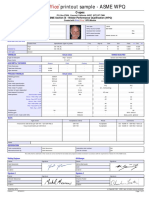

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan Vel100% (1)

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- Welding Procedure Specification: Neo StructoDocument2 pagesWelding Procedure Specification: Neo Structohareesh13hNo ratings yet

- Weld Log PDFDocument1 pageWeld Log PDFDeniz AydinNo ratings yet

- WPS + PQR (Aws D1.1)Document1 pageWPS + PQR (Aws D1.1)adiNo ratings yet

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- Bohler Fox N Ev48-1Document1 pageBohler Fox N Ev48-1brayanNo ratings yet

- Doosan Power Systems Indai PVT Limited: System CalibrationDocument3 pagesDoosan Power Systems Indai PVT Limited: System CalibrationBalkishan DyavanapellyNo ratings yet

- Welding Procedure Specification: Material / Joints QualifiedDocument2 pagesWelding Procedure Specification: Material / Joints Qualifiedmurshid badshahNo ratings yet

- Welder Certificate UpdatedDocument25 pagesWelder Certificate Updatedm.aljhany18No ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- 25 Tack Welder - ABSDocument7 pages25 Tack Welder - ABSvudinhnambrNo ratings yet

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaNo ratings yet

- Sample PQR Form (GTAW & SMAW - Page 1) Procedure Qualification Record (PQR)Document2 pagesSample PQR Form (GTAW & SMAW - Page 1) Procedure Qualification Record (PQR)Luis Carlos Clericci LimonNo ratings yet

- WPS - 016Document11 pagesWPS - 016MAT-LIONNo ratings yet

- WPS - 006Document13 pagesWPS - 006MAT-LIONNo ratings yet

- WPS ListDocument2 pagesWPS ListAdeel OmerNo ratings yet

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocument1 pageWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- Mechanical Test 1Document21 pagesMechanical Test 1Manoranjan sharmaNo ratings yet

- MTC TubeDocument1 pageMTC TubeLUIZ CALROSNo ratings yet

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Flux Baking RegisterDocument4 pagesFlux Baking RegistersurwaneNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- WPS Form - A - ENGDocument1 pageWPS Form - A - ENGdavidemolNo ratings yet

- WPS PQR FormatsDocument22 pagesWPS PQR Formatsmdharmaraj28No ratings yet

- QW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Document3 pagesQW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Alesol EquipmentNo ratings yet

- PQR FC-19-23.1Document2 pagesPQR FC-19-23.1cycsi02No ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- WPS106 6010 WPS 107 7024 Secondary and Post SecondaryDocument1 pageWPS106 6010 WPS 107 7024 Secondary and Post SecondaryahmedNo ratings yet

- Awsd1 191019041556 PDFDocument1 pageAwsd1 191019041556 PDFBiswasNo ratings yet

- WPS Format For AWS D1.1 - WPS - SMAWDocument1 pageWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNo ratings yet

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipNo ratings yet

- WPS Format For ISO 15614-1 WPSDocument1 pageWPS Format For ISO 15614-1 WPSThe Welding Inspections CommunityNo ratings yet

- WPS Format For AWS D1.1 - WPS - SMAWDocument1 pageWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNo ratings yet

- WPS Format For Asme Ix - Wps - GtawDocument1 pageWPS Format For Asme Ix - Wps - GtawThe Welding Inspections Community50% (2)

- WPS Format For ASME IX - WQTDocument1 pageWPS Format For ASME IX - WQTThe Welding Inspections CommunityNo ratings yet

- WPS Format For ASME IX - WPS - SAWDocument1 pageWPS Format For ASME IX - WPS - SAWThe Welding Inspections CommunityNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- WPS Format For Asme Ix - Wps - SmawDocument1 pageWPS Format For Asme Ix - Wps - SmawThe Welding Inspections CommunityNo ratings yet

- WPS Format For AWS D1.1 - PQR - SMAWDocument3 pagesWPS Format For AWS D1.1 - PQR - SMAWThe Welding Inspections Community100% (3)

- WPS Format For Asme Ix - Wps - Gtaw SmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SmawThe Welding Inspections Community100% (1)

- WPS Format For Asme Ix - Wps - Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocument1 pageWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- Steam Room Construction & Generator Sizing GuideDocument2 pagesSteam Room Construction & Generator Sizing GuideasdthuNo ratings yet

- Electric HeatingDocument34 pagesElectric HeatingRamanujam O SNo ratings yet

- Manufacturing President COO CFO in Saginaw MI Resume Charles LangeDocument1 pageManufacturing President COO CFO in Saginaw MI Resume Charles LangeCharles LangeNo ratings yet

- Listado de Estándares de ASHRAEDocument7 pagesListado de Estándares de ASHRAECarlos VINo ratings yet

- Smacna Duct LeakageDocument3 pagesSmacna Duct Leakageanton7786No ratings yet

- Brake System: SectionDocument34 pagesBrake System: Sectiontomallor101No ratings yet

- Leather Tanning Process Using AluminiumDocument13 pagesLeather Tanning Process Using Aluminiumanon_632703628No ratings yet

- Sor CivilDocument33 pagesSor CivilYugal Pandey Sonu100% (1)

- Partes Fso-4305 PDFDocument10 pagesPartes Fso-4305 PDFcheolllNo ratings yet

- Uniflair SDA0601: Equipment Computech Close Control A/C Units (Main Data Centre)Document6 pagesUniflair SDA0601: Equipment Computech Close Control A/C Units (Main Data Centre)Arnold MokuaNo ratings yet

- 2015 Structure and Electrical Behaviors of 0.36BiScO3-0.64PbTiO3 Ceramics With Overdosing Bi and PB Starting MaterialsDocument6 pages2015 Structure and Electrical Behaviors of 0.36BiScO3-0.64PbTiO3 Ceramics With Overdosing Bi and PB Starting MaterialsAnaghaNo ratings yet

- Rasistor Color Code-1103Document2 pagesRasistor Color Code-1103Sadanand DubeyNo ratings yet

- NitridesDocument30 pagesNitridesOsvaldo Lopez VelaNo ratings yet

- 4 Absorption PDFDocument36 pages4 Absorption PDFHoongNo ratings yet

- Psebm150 ADocument45 pagesPsebm150 AMohamedElsawiNo ratings yet

- Coal Feeder BlockageDocument1 pageCoal Feeder BlockageMuhammad luqmanNo ratings yet

- E-Waste Management Scenarios in Malaysia: September 2014Document9 pagesE-Waste Management Scenarios in Malaysia: September 2014Pravin PeriasamyNo ratings yet

- Crack Width Calculation: MaterialsDocument2 pagesCrack Width Calculation: MaterialsIrfan AliNo ratings yet

- Casting TheoryDocument22 pagesCasting TheoryJairam Atluri100% (1)

- Minor Project For Civil EngineeringDocument52 pagesMinor Project For Civil EngineeringRupesh GenesisNo ratings yet

- Public Disclosure Report Pakistan Jul 2023Document13 pagesPublic Disclosure Report Pakistan Jul 2023Amer ZeeshanNo ratings yet

- TDS Oscar Zircon Starlight SAE 10W40 15W40 API CI 4 SL ACEA E7Document1 pageTDS Oscar Zircon Starlight SAE 10W40 15W40 API CI 4 SL ACEA E7901shahzadNo ratings yet

- 888 Product Tech Data SheetDocument1 page888 Product Tech Data SheetPowerGuardSealersNo ratings yet

- Radioactive Waste ManagementDocument15 pagesRadioactive Waste Managementrickymartin23No ratings yet

- Self Healing ConcreteDocument4 pagesSelf Healing ConcreteAvilayyina ANo ratings yet

- Review of Recent Progress in Solid-State Dye-Sensitized Solar CellsDocument25 pagesReview of Recent Progress in Solid-State Dye-Sensitized Solar CellsDenis NegreaNo ratings yet