28 Fuel

28 Fuel

Uploaded by

FRANCISCO JAVIER JARAMILLO MCopyright:

Available Formats

28 Fuel

28 Fuel

Uploaded by

FRANCISCO JAVIER JARAMILLO MOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

28 Fuel

28 Fuel

Uploaded by

FRANCISCO JAVIER JARAMILLO MCopyright:

Available Formats

A318/A319/A320/A321

TECHNICAL TRAINING MANUAL

M02 RAMP & SERVICING (V2500-A5)

FUEL

This document must be used for training purposes only

Under no circumstances should this document be used as a reference

It will not be updated.

All rights reserved

No part of this manual may be reproduced in any form,

by photostat, microfilm, retrieval system, or any other means,

without the prior written permission of AIRBUS S.A.S.

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

FUEL

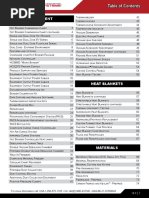

Fuel Level 2 (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

U2G05422 - U0502M0

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL TABLE OF CONTENTS Page 1

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

FUEL LEVEL 2 (2)

SYSTEM OVERVIEW

The A318, A319, and A320 share a common fuel system design.

The fuel tanks are integrated into the center fuselage area and the wings.

The center tank is part of the center wing box. The wing tanks are divided

into inner and outer cells. To reduce the structural load on the wings, the

fuel in the outer cells is not used until the fuel load in the inner cells

decreases to a low level.

Two fuel pumps are installed in the center tank and two fuel pumps are

installed in each wing tank inner cell. Fuel is supplied to the engines from

the center tank first. After the center tank is empty, fuel is supplied from

the wing inner cells.

There is no direct feed from the outer cells to the engines. Two intercell

transfer valves allow fuel to transfer from the outer cells to the inner cells

when the low level is reached.

Two engine Low Pressure (LP) valves are installed to cut off fuel to the

engines. The LP valves are closed when the engine is shut down or when

the engine FIRE pushbutton is released.

A crossfeed valve is fitted to connect or isolate the left and right sides.

It enables either engine to be fed from any available fuel pump. On the

ground, the crossfeed valve enables fuel to be transferred from tank to

tank.

U2G05422 - U0502M0 - UM28BA000000001

The fuel system also feeds the APU directly from the left side. The APU

LP valve is installed to cut off fuel to the APU. It closes when the APU

is shut down or when the APU FIRE pushbutton is released out.

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 2

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

U2G05422 - U0502M0 - UM28BA000000001

SYSTEM OVERVIEW

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 3

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

FUEL LEVEL 2 (2)

SYSTEM OVERVIEW (continued)

A321

The A321 fuel tanks are integrated into the center fuselage area and

the wings. Like the A318/A319/A320, the center tank is part of the

center wing box but unlike the A318/A319/A320, the wing tanks are

not divided. The tanks are simply called left and right wing tanks.

Two fuel pumps are installed in each wing tank. Fuel is supplied to

the engines from the wing tanks only. As the fuel level in the wing

decreases, the center tank fuel is transferred to the wing tanks until

the center tank is empty

Fuel transfer from the center tank to the wing tanks is controlled by

transfer valves. The transfer valves supply pressure for two jet pumps.

These pumps are located in the center tank and transfer the fuel from

the center to the wings.

Two engine Low Pressure (LP) valves are installed to cut off fuel to

the engines. The LP valves are closed when the engine is shut down

or when the engine FIRE pushbutton is released.

A crossfeed valve is fitted to connect or isolate the left and right sides.

It enables either engine to be fed from any available fuel pump. On

the ground, the crossfeed valve enables fuel to be transferred from

tank to tank.

U2G05422 - U0502M0 - UM28BA000000001

The fuel system also feeds the APU directly from the left side. The

APU LP valve is installed to cut off fuel to the APU. It closes when

the APU is shut down or when the APU FIRE pushbutton is released

out.

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 4

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

U2G05422 - U0502M0 - UM28BA000000001

SYSTEM OVERVIEW / A321

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 5

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

FUEL LEVEL 2 (2)

SERVICING

Automatic refueling is controlled by the Fuel Quantity Indicating

Computer (FQIC) and may be performed with normal electrical power

(External Ground Power or APU) or with battery power. With normal

power established, opening the access panel will power up the refuel

control panel automatically. To refuel on batteries, select BATT POWER

to ON.

To begin fueling in the automatic mode after the refuel panel is powered,

follow these steps:

- perform the Lights (LTS) and High Level (HIGH) test. The high level

test verifies the operation of the high-level protection system which

provides protection against overfilling and spillage.

- make sure that the REFUEL VALVE switches are in the NORM position

- set the Preselector to the required total fuel load

- set the MODE SELECT to REFUEL

There is no refuel valve indicator. The indication that the valve is open

is an increase in the fuel quantity. When the refueling is complete, the

END light will illuminate. The PRESELECTED and ACTUAL quantities

should be equal (± 100 kg.).

U2G05422 - U0502M0 - UM28BA000000001

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 6

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

U2G05422 - U0502M0 - UM28BA000000001

SERVICING

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 7

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

FUEL LEVEL 2 (2)

DAILY CHECKS

Years of operational experience have shown that regular draining of the

fuel tank water content will prevent many fuel system problems. The

Maintenance Planning Document (MPD) recommends that operators

perform this procedure every 36 hours (or less).

CAUTION: The following task summaries are presented for training

only and are not meant to be used to service an aircraft.

Always use the current Aircraft Maintenance Manual

(AMM) as the reference and adhere to ALL safety

precautions.

DRAIN WATER CONTENT

The water drain valves are installed in the center and wing tanks. All

drains should be operated to insure proper water removal from the

fuel. There are 2 drains in the center tank, 2 in each wing, and 1 in

each outer cell (A318/319/320 only).

If possible, the best time to drain the water from the tanks is prior to

refueling. If that is not possible, wait one hour after refueling.

The center tank drain valves are found in the electric hydraulic pump

compartments just forward of the wheel well in the belly fairing. The

U2G05422 - U0502M0 - UM28BA000000001

wing drain valves are accessible on the lower surface of the wing.

To operate the drain valves, use the PURGER tool and push up on

the valve. Make sure to drain at least one liter of fuel for proper water

removal. Adapting pipes are available for the PURGER tools to operate

the wing drain valves from the ground. When draining is complete

remove the PURGER tool and insure that there is no leakage at the

drain valve. If the drain valve leaks, re-seat the valve by pushing up

and releasing the drain valve.

The fuel removed may be tested for water content using a test kit.

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 8

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

U2G05422 - U0502M0 - UM28BA000000001

DAILY CHECKS / DRAIN WATER CONTENT

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 9

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

FUEL LEVEL 2 (2)

slight reduction in tank capacity if the Intercell transfer valves are

MEL/DEACTIVATION open - see AMM for tank quantities). When the desired quantity is

reached, release the plunger to close the valve. The most important

This section will cover two procedures. The first procedure involves a

thing to remember is that there is NO High Level protection when

failed refuel valve. The aircraft may be dispatched per MEL and refueling

operating the refuel valve with the manual plunger.

of the affected tank is accomplished by manual operation of the refuel

valve.

The second procedure is the use of the Magnetic Level Indicators (MLI).

The MLI's are used to verify fuel quantity in the tanks in case of an

indication malfunction or during refueling with no electrical power.

CAUTION: The following task summaries are presented for training

only and are not meant to be used to service an aircraft.

Always use the current Aircraft Maintenance Manual

(AMM) as the reference and adhere to ALL safety

precautions.

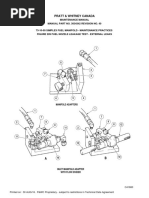

MANUAL REFUEL VALVE OPERATION

During refueling, the refuel valve solenoid is energized and fuel

pressure from the tanker/pump unit opens the valve. If the solenoid

fails or if the electrical control of the solenoid fails, the valve may be

operated manually by a plunger on the valve. There are 3 refuel valves

on the aircraft. The center tank valve is located in the R/H wheel well

U2G05422 - U0502M0 - UM28BA000000001

on the forward wall (which is actually the center tank rear spar). The

wing tank refuel valves are located on the left and right wing leading

edge near the refuel coupling.

NOTE: Remember: On the A318/A319/A320, during wing refueling

all of the fuel goes to the outer cell and spills over into the

inner cell, so only one refuel valve per wing is required.

To refuel a tank, PUSH and HOLD the manual plunger on the valve.

The fuel pressure from the tanker/pump unit will open the valve. Be

sure to monitor the fuel quantity carefully using the normal indication

system or the MLI's if electrical power is not available (there will be

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 10

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

U2G05422 - U0502M0 - UM28BA000000001

MEL/DEACTIVATION / MANUAL REFUEL VALVE OPERATION

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 11

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

FUEL LEVEL 2 (2)

MEL/DEACTIVATION (continued)

USE OF MAGNETIC LEVEL INDICATORS

Each fuel tank is equipped with one or more Magnetic Level Indicators

(MLI's). In case of an indication malfunction or during refueling

without electrical power available, the MLI's may be used to check

fuel quantity. There is one MLI in the center tank, 5 in each wing tank

on the A318/319/320 and 7 in each wing on the A321.

The aircraft attitude will determine which fuel table to use. There are

3 ways to determine aircraft pitch and roll when using the MLI's to

calculate fuel quantity. The attitude monitor located at the refueling

panel is the 'standard' method.

The attitude monitor is located in the refuel control panel compartment.

To determine aircraft attitude, check the 'bubble' on the attitude

monitor. The closest grid-square is the pitch and roll reference. The

number (1-7) is the pitch reference and the letter (A-G) is the roll

reference (ex. A2).

To use the MLI, extend the indicator rod and read the UNITS mark

nearest to the bottom skin of the wing. Each tank is checked separately.

The center and outer tanks have a single MLI each. This MLI is

enough to determine the fuel volume in that tank. The wing tanks

have multiple MLI's. To determine wing volume, use the most

U2G05422 - U0502M0 - UM28BA000000001

outboard MLI which indicates fuel in the tank. To check the total fuel

quantity on the aircraft determine the total in each tank (CTR, INNER,

OUTER) and add them together.

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 12

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

U2G05422 - U0502M0 - UM28BA000000001

MEL/DEACTIVATION / USE OF MAGNETIC LEVEL INDICATORS

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 13

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

FUEL LEVEL 2 (2)

MEL/DEACTIVATION (continued)

FUEL QTY USING MLI

Using the attitude reference, and MLI number, and MLI reading, find

the correct fuel table in the AMM and read the fuel volume. The final

step is to convert the volume to mass. Multiply the volume by the fuel

specific gravity.

For example:

RIGHT wing MLI number - 5

Attitude reference - A2

UNITS reading - 10

Volume in liters - 850

Sp. Gravity - 0.81

Fuel mass = 688.5 Kg.

NOTE: Only even-numbered MLI units are listed in the tables. To

calculate the volume of fuel for odd numbers, interpolate

(divide the difference) between the nearest even numbers

in the table.

U2G05422 - U0502M0 - UM28BA000000001

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 14

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

U2G05422 - U0502M0 - UM28BA000000001

MEL/DEACTIVATION / FUEL QTY USING MLI

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 15

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

FUEL LEVEL 2 (2)

MEL/DEACTIVATION (continued)

ALTERNATE METHODS TO DETERMINE A/C

ATTITUDE

There are 2 additional methods to determine aircraft pitch and roll

when using the MLI's to calculate fuel quantity. It is possible to use

the attitude information generated by the air data system through the

Air Data Inertial Reference Unit (ADIRU) or by the fuel system

through the Fuel Quantity Indicating Computer (FQIC). It is essential

to use the correct fuel tables based on aircraft attitude.

The air data inputs to the ADIRU can be read by using the alpha

call-up function in the Aircraft Integrated Data System (AIDS). With

the ADIRU's in the NAV position, select the AIDS menu in CFDS.

From this menu, select CALL UP PARAM ALPHA. To access roll

data, type ROLL and to access pitch data, type PTCH.

After recording the data, convert the pitch and roll references given

to the equivalent grid-square.

For example:

ADIRU PITCH (-1.5) = 1

ADIRU ROLL (+1.0) = F

Equivalent Grid-square = F1

The attitude information input to the FQIC may be accessed through

U2G05422 - U0502M0 - UM28BA000000001

the CFDS FQIC menu. The pitch and roll data can only be used if the

data is from the ADIRU. ADIRU data is identified by an 'A' after

PITCH or ROLL.

After recording the data, convert the pitch and roll references in the

same manner as the ADIRU data above.

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 16

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

U2G05422 - U0502M0 - UM28BA000000001

MEL/DEACTIVATION / ALTERNATE METHODS TO DETERMINE A/C ATTITUDE

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 17

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

FUEL LEVEL 2 (2)

MAINTENANCE TIPS

During a walk-around inspection, it is important to check the burst disc

in the OUTER cell. A white cross should be visible on a black

background. If it is not visible, it may indicate a problem with the tank

venting system.

When aircraft emergency electrical power is used, two wing fuel boost

pumps will be supplied, one in each wing. For dispatch per the MEL,

both of these pumps must be operational.

According to the AMM, during refueling operations bonding is essential,

grounding is recommended. Connect a bonding cable between the fuel

tanker and a grounding point on the aircraft, typically on the Nose or

Main gear. Connect a grounding cable from a grounding point on the

aircraft to the ground.

U2G05422 - U0502M0 - UM28BA000000001

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 18

A318/A319/A320/A321 TECHNICAL TRAINING MANUAL

U2G05422 - U0502M0 - UM28BA000000001

MAINTENANCE TIPS

M02 RAMP & SERVICING (V2500-A5) Dec 12, 2005

28 - FUEL FUEL LEVEL 2 (2) Page 19

AIRBUS S.A.S.

31707 BLAGNAC cedex, FRANCE

STM

REFERENCE U2G05422

DECEMBER 2005

PRINTED IN FRANCE

AIRBUS S.A.S. 2005

ALL RIGHTS RESERVED

AN EADS JOINT COMPANY

WITH BAE SYSTEMS

You might also like

- English Sba - Sports (On Academics)Document8 pagesEnglish Sba - Sports (On Academics)David Hall85% (13)

- A319/ A320/ A321 Technical Training ManualDocument76 pagesA319/ A320/ A321 Technical Training ManualŞevval YalınNo ratings yet

- Field Study-Learning-Experience-1Document16 pagesField Study-Learning-Experience-1Czai Lavilla83% (6)

- Aircraft High Brake Temperature IssuesDocument16 pagesAircraft High Brake Temperature Issuesv1alfred100% (1)

- AirbusDocument52 pagesAirbusKyriakos TousNo ratings yet

- Resetting of Computers - A320: Systems That Can Be Reset in The Air or On The GroundDocument8 pagesResetting of Computers - A320: Systems That Can Be Reset in The Air or On The Groundanarko arsipelNo ratings yet

- A320fam Ata29 Hydraulic PowerDocument171 pagesA320fam Ata29 Hydraulic PowerPrajwal PatidarNo ratings yet

- Single Aisle Technical Training Manual T1+T2 (IAE V2500) (LVL 2&3) APUDocument250 pagesSingle Aisle Technical Training Manual T1+T2 (IAE V2500) (LVL 2&3) APU이용일No ratings yet

- A320 FacDocument16 pagesA320 Fachhgaffadf0% (1)

- APU 320 FinishedDocument38 pagesAPU 320 FinishedGalaxy A32No ratings yet

- Docslide - Us - Airbus A319 A321 DLH Training Manual Ata 27 Flight Controls Level 3 PDFDocument179 pagesDocslide - Us - Airbus A319 A321 DLH Training Manual Ata 27 Flight Controls Level 3 PDFBrayhan Alexander Palomino100% (2)

- A320 Notes PDFDocument4 pagesA320 Notes PDFPrajwal Patidar100% (1)

- A319 A320 A321 21z Sistema Aire AcondicionadoDocument330 pagesA319 A320 A321 21z Sistema Aire Acondicionadomarcelojm7No ratings yet

- ECAM Wheel Page IndicationsDocument2 pagesECAM Wheel Page IndicationsIsmael Gonzalez100% (1)

- ATA 23 CommunicationsDocument138 pagesATA 23 CommunicationsCharles IrikefeNo ratings yet

- 23 Z CommDocument450 pages23 Z CommNizar HarbNo ratings yet

- A320 EcamDocument2 pagesA320 EcamRC Agulay0% (1)

- 21 - Air ConditioningDocument206 pages21 - Air ConditioningThông ChâuNo ratings yet

- Airbus A318/A319/A320/A321: Maintenance TrainingDocument1 pageAirbus A318/A319/A320/A321: Maintenance TrainingAnonymous QRVqOsa5100% (1)

- Circuit BreakersDocument3 pagesCircuit BreakersSuratman Bin SuparmanNo ratings yet

- A320 Displays & PanelsDocument1,752 pagesA320 Displays & PanelsOleg TysiachnyiNo ratings yet

- Fuel DescriptionDocument32 pagesFuel Descriptionsiti fatimatuzzahraNo ratings yet

- Ata 21 (Cat A)Document161 pagesAta 21 (Cat A)Kiet La100% (1)

- 31 Indication System PDFDocument512 pages31 Indication System PDFBrayhan Alexander Palomino100% (1)

- ISI Centralised - Fault - Display - SystemTroubleshooting - Guidel..Document40 pagesISI Centralised - Fault - Display - SystemTroubleshooting - Guidel..Edwar Zulmi100% (1)

- Reference A320Document34 pagesReference A320Joe FalchettoNo ratings yet

- A319/A320/A321 Technical Training Manual T1 & T2 30 Ice & Rain Protection CFM MetricDocument144 pagesA319/A320/A321 Technical Training Manual T1 & T2 30 Ice & Rain Protection CFM MetricSelcuk GuncanNo ratings yet

- Ata 38 L1 Water & WasteDocument27 pagesAta 38 L1 Water & WastejimbokhepelNo ratings yet

- A320 L3 Rev 0 ATA 00 Introduction PDFDocument16 pagesA320 L3 Rev 0 ATA 00 Introduction PDFcamilo148100% (1)

- Part 2 Out of 2Document428 pagesPart 2 Out of 2robertgabrielcarreroNo ratings yet

- A334e 31D L3 D-Ne PDFDocument54 pagesA334e 31D L3 D-Ne PDFAaron Harvey100% (1)

- ATA 24 Electrical Power L1Document40 pagesATA 24 Electrical Power L1jimbokhepel100% (1)

- NeoDocument12 pagesNeoAnurag MishraNo ratings yet

- Snapshot 3608 Air Eng 1 + 2 Bleed FaultDocument9 pagesSnapshot 3608 Air Eng 1 + 2 Bleed FaultAbil Gilang -No ratings yet

- Figure 29-00-00-13400-00-U / SHEET 4/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Document1 pageFigure 29-00-00-13400-00-U / SHEET 4/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Pankaj SrivastavaNo ratings yet

- 22 Auto FlightDocument96 pages22 Auto FlightAnonymous 298xlo3uUNo ratings yet

- A320 Ata-21Document62 pagesA320 Ata-21ROHIT KUMAR SINGHNo ratings yet

- Communication A320 PDFDocument41 pagesCommunication A320 PDFAsraf100% (1)

- Training Manual A 318: ATA 21 Air ConditionDocument17 pagesTraining Manual A 318: ATA 21 Air ConditionbnolascoNo ratings yet

- Air Conditioning ATA 21: Student Learning ObjectivesDocument115 pagesAir Conditioning ATA 21: Student Learning ObjectivesBelisario Sergio Llacchas rodas100% (1)

- A318 Diffs B1 & 2 PT 1 of 2Document216 pagesA318 Diffs B1 & 2 PT 1 of 2Mrityunjay Kumar JhaNo ratings yet

- Scribd Download - Com A320 Computer Reset Nov11Document18 pagesScribd Download - Com A320 Computer Reset Nov11hayri yilmaz100% (1)

- Airbus A320330 Panel DocumentationDocument62 pagesAirbus A320330 Panel DocumentationElias IruelaNo ratings yet

- Figure 29-00-00-13400-00-U / SHEET 1/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Document1 pageFigure 29-00-00-13400-00-U / SHEET 1/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Pankaj Srivastava0% (1)

- Airplane GeneralDocument137 pagesAirplane GeneralAdrian ScottNo ratings yet

- A320 - Ata 46 - B1-AtimsDocument30 pagesA320 - Ata 46 - B1-Atimscaptainjohnprice810No ratings yet

- Airbus NotesDocument128 pagesAirbus NotesmartinbutlerNo ratings yet

- A330Document79 pagesA330Dipendra Sen100% (1)

- Single Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) GeneralDocument8 pagesSingle Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) Generalripan thakurNo ratings yet

- 45 Onboard Maintenance SystemsDocument56 pages45 Onboard Maintenance SystemsWilliam Jaldin CorralesNo ratings yet

- A320 Ata 27 Controles de VueloDocument182 pagesA320 Ata 27 Controles de Vuelomiguel alemanNo ratings yet

- Reversers Use A320Document26 pagesReversers Use A320Maitreya Shah100% (1)

- Ata21 A320Document55 pagesAta21 A320David MoralesNo ratings yet

- A320 Neo Leap 1a Ata - 28Document43 pagesA320 Neo Leap 1a Ata - 28basid911No ratings yet

- A320 Ramp and Transit Ata 28 - Fuel Metric UnitsDocument184 pagesA320 Ramp and Transit Ata 28 - Fuel Metric UnitsCassiano CapellassiNo ratings yet

- 03 Power Plant Level 1Document226 pages03 Power Plant Level 1xuf621151No ratings yet

- Emc 3 TTM Level 1 PPDocument224 pagesEmc 3 TTM Level 1 PPPrajwal PatidarNo ratings yet

- A320 - ATA71 To 80-CFM56-5 - B1-B2 - Iss-03 - May 2016 PDFDocument388 pagesA320 - ATA71 To 80-CFM56-5 - B1-B2 - Iss-03 - May 2016 PDFKamalVirk100% (5)

- Airbus T1+T2 CFM56 Tech Doc M8 - PP1Document226 pagesAirbus T1+T2 CFM56 Tech Doc M8 - PP1doga dumanNo ratings yet

- T1 28 Sept 2020Document13 pagesT1 28 Sept 2020amr.elbashaNo ratings yet

- Ata 28 TestDocument2 pagesAta 28 TestFRANCISCO JAVIER JARAMILLO MNo ratings yet

- Fig 209 Leak TestDocument1 pageFig 209 Leak TestFRANCISCO JAVIER JARAMILLO MNo ratings yet

- Ata 21 TestDocument1 pageAta 21 TestFRANCISCO JAVIER JARAMILLO MNo ratings yet

- Ata 23 TestDocument1 pageAta 23 TestFRANCISCO JAVIER JARAMILLO MNo ratings yet

- PWC 34416 Puller PDFDocument1 pagePWC 34416 Puller PDFFRANCISCO JAVIER JARAMILLO MNo ratings yet

- EN3155 ContactsBrochureDocument4 pagesEN3155 ContactsBrochureFRANCISCO JAVIER JARAMILLO M100% (1)

- CatalogDocument124 pagesCatalogFRANCISCO JAVIER JARAMILLO MNo ratings yet

- PWC 34445 Fixture PDFDocument1 pagePWC 34445 Fixture PDFFRANCISCO JAVIER JARAMILLO MNo ratings yet

- Connectors, Contacts & ToolingDocument80 pagesConnectors, Contacts & ToolingFRANCISCO JAVIER JARAMILLO MNo ratings yet

- Pro Forma Invoice Date Pro Forma Invoice Number Page Number Customer NumberDocument3 pagesPro Forma Invoice Date Pro Forma Invoice Number Page Number Customer NumberFRANCISCO JAVIER JARAMILLO MNo ratings yet

- 900-00003-001 AM EFD1k-5c SW2.X Instl ManualDocument348 pages900-00003-001 AM EFD1k-5c SW2.X Instl ManualFRANCISCO JAVIER JARAMILLO M100% (1)

- Cdd116690-Sony Vaio - PCG - 7x2l PDFDocument7 pagesCdd116690-Sony Vaio - PCG - 7x2l PDFFRANCISCO JAVIER JARAMILLO MNo ratings yet

- P60N03LDG Niko-Sem: N-Channel Logic Level Enhancement Mode Field Effect TransistorDocument5 pagesP60N03LDG Niko-Sem: N-Channel Logic Level Enhancement Mode Field Effect TransistorFRANCISCO JAVIER JARAMILLO MNo ratings yet

- Cdd155147-Acer Aspire V5-531 - V5-571 (Petra UMA)Document103 pagesCdd155147-Acer Aspire V5-531 - V5-571 (Petra UMA)FRANCISCO JAVIER JARAMILLO MNo ratings yet

- Cdd160921-Aspire V3-471 & V3-471G PDFDocument333 pagesCdd160921-Aspire V3-471 & V3-471G PDFFRANCISCO JAVIER JARAMILLO MNo ratings yet

- A318/A319/A320/A321 Technical Training Manual M02 RAMP & SERVICING (V2500-A5) Electrical PowerDocument54 pagesA318/A319/A320/A321 Technical Training Manual M02 RAMP & SERVICING (V2500-A5) Electrical PowerFRANCISCO JAVIER JARAMILLO MNo ratings yet

- Calculation of Air Quality Index (AQI) - GMESDocument15 pagesCalculation of Air Quality Index (AQI) - GMESZay Yan HtetNo ratings yet

- AsrsDocument43 pagesAsrsmkhairi91No ratings yet

- Makalah DiphtongsDocument13 pagesMakalah Diphtongsalya khasanatulNo ratings yet

- Dvdr3455 AP Latam DVDR PhilipsDocument64 pagesDvdr3455 AP Latam DVDR PhilipsclaudiorafaelnobileNo ratings yet

- Deepak Deedy CVDocument1 pageDeepak Deedy CVlgepromoter6935624No ratings yet

- Motion in A Straight LineDocument52 pagesMotion in A Straight LineSivakumar ANo ratings yet

- WFH - Bachelor of Science in Office AdministrationDocument9 pagesWFH - Bachelor of Science in Office AdministrationAzil Nerfe Bravo LuchavezNo ratings yet

- Especificação Técnica - TD 20729-0Document39 pagesEspecificação Técnica - TD 20729-0Geovane FonsecNo ratings yet

- Release Rates From Topical Formulations Containing Drugs in SuspensionDocument8 pagesRelease Rates From Topical Formulations Containing Drugs in Suspensionpepe0% (1)

- Contemporary Arts 1st Quarter ReviewerDocument5 pagesContemporary Arts 1st Quarter ReviewerRaganayaNo ratings yet

- Three Principles Define The Sociocultural Level of AnalysisDocument1 pageThree Principles Define The Sociocultural Level of Analysischl23No ratings yet

- BPLM Spitfire White Paper 2015Document8 pagesBPLM Spitfire White Paper 2015Arumugam RajendranNo ratings yet

- HEPA Filters and ULPA FiltersDocument3 pagesHEPA Filters and ULPA FiltersSiraj AliNo ratings yet

- APSET 2014 Question Paper III CHEMICAL SCIENCESDocument20 pagesAPSET 2014 Question Paper III CHEMICAL SCIENCESyaswanthNo ratings yet

- Random Variables and Binominal Distribution With Mark SchemeDocument11 pagesRandom Variables and Binominal Distribution With Mark SchemeLATE- RADNo ratings yet

- Recent Thesis Topics in Community MedicineDocument5 pagesRecent Thesis Topics in Community Medicinemistyharrismurfreesboro100% (2)

- Cal Reform 1Document200 pagesCal Reform 1abbas zaidiNo ratings yet

- YEAR 2 Lesson Plan For PracticumDocument2 pagesYEAR 2 Lesson Plan For PracticumESWARY A/P VASUDEVAN MoeNo ratings yet

- Fall 2019 - ECO601 - 1Document5 pagesFall 2019 - ECO601 - 1Alina Shahjahan RanaNo ratings yet

- Understanding Fan Operation and Performance - W. HilbishDocument34 pagesUnderstanding Fan Operation and Performance - W. HilbishJosé Pedro Casagrande Trentín100% (2)

- Sea 235 Operator'S Manual: Digital Single Sideband RadiotelephoneDocument104 pagesSea 235 Operator'S Manual: Digital Single Sideband Radiotelephonehugo delacruzNo ratings yet

- LC FilterDocument38 pagesLC FilterDharmendra RanaNo ratings yet

- Module 1 STSDocument22 pagesModule 1 STSGinaly Pico100% (1)

- Mathematics Dissertation ExampleDocument4 pagesMathematics Dissertation ExampleWriteMyPaperApaStyleUK100% (2)

- Python Chee T SetDocument30 pagesPython Chee T SetkanuukNo ratings yet

- Module 12 - Dela Torre, Elmer J.Document3 pagesModule 12 - Dela Torre, Elmer J.Elmer Juares Dela TorreNo ratings yet

- A Parent's Guide To InstagramDocument53 pagesA Parent's Guide To InstagramCS GO TutaniccorectNo ratings yet

- Full Download Models in Microeconomic Theory She Edition Martin J Osborne PDF DOCXDocument40 pagesFull Download Models in Microeconomic Theory She Edition Martin J Osborne PDF DOCXdriestneyri100% (3)