Astm C656

Astm C656

Uploaded by

alokjha_03Copyright:

Available Formats

Astm C656

Astm C656

Uploaded by

alokjha_03Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Astm C656

Astm C656

Uploaded by

alokjha_03Copyright:

Available Formats

Designation: C 656 – 07

Standard Specification for

Structural Insulating Board, Calcium Silicate1

This standard is issued under the fixed designation C 656; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

--``,`,,,`,````,`,```,,,`,,,,`,-`-`,,`,,`,`,,`---

1. Scope C 165 Test Method for Measuring Compressive Properties

1.1 This specification covers structural insulating board for of Thermal Insulations

general thermal insulating, fire-resistive, and marine bulkhead C 168 Terminology Relating to Thermal Insulation

applications. The rigid, preformed structural insulating board is C 177 Test Method for Steady-State Heat Flux Measure-

for use at temperatures up to 1700°F (927°C). For specific ments and Thermal Transmission Properties by Means of

applications, the actual temperature limit shall be agreed upon the Guarded-Hot-Plate Apparatus

between the manufacturer and the purchaser. C 203 Test Methods for Breaking Load and Flexural Prop-

1.2 The structural insulating board maintains its structural erties of Block-Type Thermal Insulation

integrity after immersion in water. C 303 Test Method for Dimensions and Density of Pre-

1.3 Rapid cycling over a wide temperature range is not formed Block and Board−Type Thermal Insulation

recommended because of potential damage due to thermal C 356 Test Method for Linear Shrinkage of Preformed

shock. High-Temperature Thermal Insulation Subjected to Soak-

1.4 The values stated in inch-pound units are to be regarded ing Heat

as the standard. The approximate SI equivalents of inch-pound C 390 Practice for Sampling and Acceptance of Thermal

units are given in parentheses. Insulation Lots

1.5 This standard does not purport to address all of the C 411 Test Method for Hot-Surface Performance of High-

safety concerns, if any, associated with its use. It is the Temperature Thermal Insulation

responsibility of the user of this standard to establish appro- C 447 Practice for Estimating the Maximum Use Tempera-

priate safety and health practices and determine the applica- ture of Thermal Insulations

bility of regulatory limitations prior to use. C 518 Test Method for Steady-State Thermal Transmission

1.6 When the installation or use of thermal insulation Properties by Means of the Heat Flow Meter Apparatus

materials, accessories and systems, may pose safety or health C 1045 Practice for Calculating Thermal Transmission

problems, the manufacturer shall provide the user appropriate Properties Under Steady-State Conditions

current information regarding any known problems associated C 1058 Practice for Selecting Temperatures for Evaluating

with the recommended use of the company’s products, and and Reporting Thermal Properties of Thermal Insulation

shall also recommend protective measures to be employed in D 1037 Test Methods for Evaluating Properties of Wood-

their safe utilization. The user shall establish appropriate safety Base Fiber and Particle Panel Materials

and health practices and determine the applicability of regula- E 136 Test Method for Behavior of Materials in a Vertical

tory requirements prior to use. Tube Furnace at 750°C

2. Referenced Documents 3. Terminology

2.1 ASTM Standards: 2 3.1 Definitions—The definitions in Terminology C 168 shall

apply to the terms used in this specification.

4. Classification

1

This specification is under the jurisdiction of Committee C-16 on Thermal 4.1 The structural insulating boards shall be of the following

Insulation and is the direct responsibility of Subcommittee C16.20 on Homogeneous

Inorganic Thermal Insulations. types:

Current edition approved Sept. 1, 2007. Published September 2007. Originally 4.1.1 Type I—Maximum use temperature 1400°F (760°C).

approved in 1970. Last previous edition approved in C 656 – 94a(2001).

2

4.1.2 Type II—Maximum use temperature 1700°F (927°C).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.2 The structural insulating boards shall be of the following

Standards volume information, refer to the standard’s Document Summary page on grades:

the ASTM website. 4.2.1 Grade 1—Typical density 36 lb/ft3 (577 kg/m3).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Provided by IHS under license with ASTM Licensee=Technip La Defense/5931917103

No reproduction or networking permitted without license from IHS Not for Resale, 12/10/2007 11:28:18 MST

C 656 – 07

4.2.2 Grade 2—Typical density 46 lb/ft3 (737 kg/m3). 10. Qualification Requirements

4.2.3 Grade 3—Typical density 60 lb/ft3 (961 kg/m3). 10.1 Unless otherwise specified, the following requirements

4.2.4 Grade 4—Typical density 14 lb/ft3 (224 kg/m3). shall be employed for the purpose of initial material or product

4.2.5 Grade 5—Typical density 18 lb/ft3 (288 kg/m3). qualification.

4.2.6 Grade 6—Typical density 28 lb/ft3 (449 kg/m3). 10.1.1 Compressive strength,

4.2.7 Grade 7—Typical density 40 lb/ft3 (641 kg/m3).

10.1.2 Screw holding strength,

4.2.8 Grade 8—Typical density 60 lb/ft3 (961 kg/m3).

10.1.3 Linear shrinkage and temperate of use,

5. Ordering Information 10.1.4 Apparent thermal conductivity, and

10.1.5 Combustion characteristics.

5.1 The type, grade, and dimensions shall be specified by

the purchaser.

11. Sampling

5.2 When a certification or test report, or both, are required,

it shall be specified by the purchaser. 11.1 Calcium silicate structural insulating boards shall be

sampled in accordance with Practice C 390. Specific provisions

6. Materials and Manufacture for sampling shall be agreed upon between the purchaser and

6.1 Calcium silicate structural insulating board shall be the supplier.

composed of hydrated calcium silicate with natural or man-

made fibers or fillers, or a combination thereof. Asbestos shall 12. Test Methods

not be used as an ingredient or component of the product. 12.1 Dimensions and Density—Use Test Method C 303,

except that specimens shall be full-size sheets for determina-

7. Other Requirements tion of length and width and at least 12-in. (300-mm) square

7.1 Calcium silicate structural insulating board shall con- for determination of thickness and density.

form to the physical and mechanical requirements specified in 12.2 Flexural Strength—Use Test Methods C 203 on a 1-in.

Table 1. (25-mm) thick specimen.

12.3 Compressive Strength—Use Test Methods C 165.

8. Dimensions and Permissible Variations Specimen thickness shall be 11⁄2 in. (38 mm). Compress

8.1 Calcium silicate structural insulating board is typically specimen to 10 % deformation and calculate on maximum load

available in lengths 48 or 96 in. (1219 or 2438 mm), widths of value.

24 or 48 in. (610 or 1219), and thicknesses from 1⁄2 to 3in. (13 12.4 Screw Holding Strength—Use Test Methods D 1037,

to 76 mm). Direct Screw Withdrawal Test. Test at least three specimens,

8.2 Dimensions shall be within the following tolerances of 31⁄2-in. (89-mm) square, and 1 in. (25 mm) or more in thickness

specified values: after drying to constant weight from 215°F (102°C) to 250°F

Length Width Thickness (121°C). Drill a hole at least 1 in. (25 mm) deep, normal to the

61⁄8 in. (3 mm) 61⁄8 in. (3 mm) 61⁄16 in. (1.5 mm) surface at the center of each specimen, with a No. 29 drill.

Install a No. 8, Type A, self-tapping screw at least 7⁄8 in. (22.2

9. Workmanship, Finish, and Appearance mm) in length such that 33⁄8 in. (18.8 mm) of the screw

9.1 Calcium silicate structural insulating boards shall not penetrates the board.

have visible defects, such as major cracks, lumps, or excessive 12.5 Apparent Thermal Conductivity—Use Test Methods

departure from planeness, which adversely affect service quali- C 177 or C 518. Test Method C 518 shall not be used at

ties. temperatures other than those in the range of calibration.

TABLE 1 Physical and Mechanical Requirements

Type I Type II

Grade 1 Grade 2 Grade 3 Grade 4 Grade 5 Grade 6 Grade 7 Grade 8

Temperature of use, max, °F (°C) 1400 (760) 1400 (760) 1400 (760) 1700 (927) 1700 (927) 1700 (927) 1700 (927) 1700 (927)

Density, typical, lb/ft3(kg/m3) 36 (577) 46 (737) 60 (961) 14 (224) 18 (288) 28 (449) 40 (641) 55 (881)

Flexural strength, min, psi (kPa) 350 (2413) 550 (3792) 900 (6206) 100 (690) 200 (1379) 350 (2413) 800 (5516) 1200 (8274)

Compressive strength, min, psi (kPa) 900 (6206) 1000 (6895) 2000 (13 790) 200 (1379) 300 (2069) 600 (4137) 2000 (13 790) 4000 (27 580)

Screw-holding strength, min, lb (N) 80 (356) 120 (534) 150 (667) NA NA 20 (89) 150 (667) 200 (890)

Linear shrinkage, 24 h at max use 2.0 2.0 3.0 2.0 2.0 2.0 2.0 2.0

temp, max.%

Apparent thermal conductivity, max,

Btu·in./h·ft2°F (mW/m·K):

Test Conditions Approximate DT

Mean Temperature Recommended

200°F (93°C) 100°F (56°C) 0.71 (102) 0.92 (133) ... 0.42 (61) 0.54 (78) 0.61 (88) 0.73 (105) ...

400°F (204°C) 100°F (56°C) 0.74 (107) 0.89 (128) 1.26 (182) 0.52 (75) 0.61 (88) 0.66 (95) 0.75 (108) 0.97 (140)

600°F (316°C) 100°F (56°C) 0.80 (115) 0.87 (125) 1.28 (185) 0.67 (97) 0.67 (97) 0.73 (105) 0.78 (113) 0.99 (143)

800°F (427°C) 200°F (111°C) 0.88 (127) 0.90 (130) 1.29 (186) 0.87 (125) 0.73 (105) 0.80 (115) 0.84 (121) 1.05 (151)

Combustion characteristics, Test Method E 136: Passing Passing Passing Passing Passing Passing Passing Passing

--``,`,,,`,````,`,```,,,`,,,,`,-`-`,,`,,`,`,,`---

Copyright ASTM International 2

Provided by IHS under license with ASTM Licensee=Technip La Defense/5931917103

No reproduction or networking permitted without license from IHS Not for Resale, 12/10/2007 11:28:18 MST

--``,`,,,`,````,`,```,,,`,,,,`,-`-`,,`,,`,`,,`---

C 656 – 07

12.5.1 Temperature of test shall be in accordance with the lot after removal of that portion not conforming to the

Practice C 1058. specified requirements.

12.5.2 Conduct the final analysis of the thermal data in

accordance with Practice C 1045 to generate a thermal con- 15. Certification

ductivity versus temperature relationship for the specimen. 15.1 When specified in the purchase order or contract, the

12.6 Combustion Characteristics—Use Test Method E 136. manufacturer’s or seller’s certification shall be furnished to the

12.7 Maximum Use Temperatures—Use Practice C 447, purchaser stating that samples representing each lot have been

which references Test Method C 411. Linear shrinkage (length manufactured, tested, and inspected in accordance with this

or width, or both) should not exceed 2 % at maximum use specification and the requirements have been met. When

temperature. See Test Method C 356. specified in the purchase order or contract, a report of the test

13. Inspection results shall be furnished.

13.1 Unless otherwise specified, the following requirements 16. Packaging and Package Marking

shall be employed for purposes of acceptance sampling of lots

or shipments of qualified insulation: 16.1 Packaging—Unless otherwise specified, the manufac-

13.1.1 Density, turer’s standard packaging system shall be used.

13.1.2 Flexural strength, 16.2 Marking:

13.1.3 Dimensions, and 16.2.1 Unless otherwise specified, each package shall be

13.1.4 Workmanship, finish, and appearance. marked with the manufacturer’s name, the product name,

13.2 Inspection of the material shall be agreed upon be- quantity, nominal dimensions, and manufacturer’s lot or date-

tween the purchaser and the supplier. code identification.

16.2.2 When specified in the purchase order or contract,

14. Rejection and Rehearing each container shall be marked with the appropriate ASTM

14.1 Failure to conform to the requirements in this specifi- C656 type and grade, or other special designations.

cation shall constitute cause for rejection. Rejection shall be

reported to the producer or supplier promptly and in writing. 17. Keywords

14.2 In case of rejection, the manufacturer or supplier shall 17.1 calcium silicate; fire-resistive; marine; structural insu-

have the right to reinspect the rejected shipment and resubmit lation; thermal insulation

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright ASTM International 3

Provided by IHS under license with ASTM Licensee=Technip La Defense/5931917103

No reproduction or networking permitted without license from IHS Not for Resale, 12/10/2007 11:28:18 MST

You might also like

- Astm F2170Document7 pagesAstm F2170AhmedNo ratings yet

- Aerius VB1115 Parts Manual Rev BDocument13 pagesAerius VB1115 Parts Manual Rev BNicola BattaglinoNo ratings yet

- Clay Roofing Tiles and Fittings - Product Definitions and SpecificationsDocument32 pagesClay Roofing Tiles and Fittings - Product Definitions and Specificationschwkim38No ratings yet

- Astm c717 - SelantesDocument13 pagesAstm c717 - SelantesJavier VianaNo ratings yet

- Astm E119Document36 pagesAstm E119Mirha FathimaNo ratings yet

- MIL02 - Site 44: Datacenter Italy Caleppio Di Settala Strada Prov. 415Document1 pageMIL02 - Site 44: Datacenter Italy Caleppio Di Settala Strada Prov. 415Gino FilosaNo ratings yet

- Packaged, Dry, Rapid-Hardening Cementitious Materials For Concrete RepairsDocument4 pagesPackaged, Dry, Rapid-Hardening Cementitious Materials For Concrete RepairsJesús Luis Arce GuillermoNo ratings yet

- Monokote Mk6 - Hy TdsDocument2 pagesMonokote Mk6 - Hy TdsEngTamerNo ratings yet

- A741Document3 pagesA741solrac4371100% (1)

- ASTM E761 - 92 Reapproved 2011Document3 pagesASTM E761 - 92 Reapproved 2011Trà Trần SơnNo ratings yet

- Svensk Standard SS-EN 13813: Fastställd 2002-10-25 Utgåva 1Document11 pagesSvensk Standard SS-EN 13813: Fastställd 2002-10-25 Utgåva 1Arvin Bhurtun100% (1)

- Testing Application Standard 203-94Document6 pagesTesting Application Standard 203-94Shawn DeolNo ratings yet

- 2260Document16 pages2260rayNo ratings yet

- Astm C591 - 22Document10 pagesAstm C591 - 22sgjsevenpNo ratings yet

- Mineral Wool Roof Insulation Board: Standard Specification ForDocument4 pagesMineral Wool Roof Insulation Board: Standard Specification ForMina RemonNo ratings yet

- ISO 16163 - (2012) - (Continuos HDG-Dimensional and Shape-Tolerances) - 10pgsDocument10 pagesISO 16163 - (2012) - (Continuos HDG-Dimensional and Shape-Tolerances) - 10pgsdpfloresNo ratings yet

- ASTM D5147 - Sampling and Testing Modified Bituminous Sheet Material1Document5 pagesASTM D5147 - Sampling and Testing Modified Bituminous Sheet Material1jothi vel muruganNo ratings yet

- Orientação ISO 11600Document6 pagesOrientação ISO 11600sahcristine3968No ratings yet

- Abuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement PanelsDocument7 pagesAbuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement PanelsAlejandroNo ratings yet

- En Iso 1183-3Document12 pagesEn Iso 1183-3aeotomasyonNo ratings yet

- 32 31 13.53 - FinalDocument13 pages32 31 13.53 - Finalnauris.ezerlicisNo ratings yet

- Astm A 956Document7 pagesAstm A 956Joshua Surbakti100% (1)

- Iso 11925Document1 pageIso 11925A MahmoodNo ratings yet

- D 828 - 97 Rdgyoc05nw - PDFDocument7 pagesD 828 - 97 Rdgyoc05nw - PDFomar alvaradoNo ratings yet

- Aama 2605-02Document10 pagesAama 2605-02Aniket InarkarNo ratings yet

- Fire Test Report 60 Non-Load-MEC21-LYX SHERA PRO F1 2021Document24 pagesFire Test Report 60 Non-Load-MEC21-LYX SHERA PRO F1 2021Phú NguyễnNo ratings yet

- M o S For Grouting-01Document6 pagesM o S For Grouting-01civil.godfatherNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07250-1 FireproofingDocument4 pagesITCC in Riyadh Residential Complex J10-13300 07250-1 FireproofinguddinnadeemNo ratings yet

- EN 12390-3 - 2019 Compressive Strength of Test Specimens (Concrete)Document20 pagesEN 12390-3 - 2019 Compressive Strength of Test Specimens (Concrete)Nick Androulakis0% (1)

- Gas-Fired Storage Water Heaters For The Production of Domestic Hot WaterDocument138 pagesGas-Fired Storage Water Heaters For The Production of Domestic Hot WaterAbey VettoorNo ratings yet

- (BS en 1015-2-1999) - Methods of Test For Mortar For Masonry. Bulk Sampling of Mortars and Preparation of Test MortarsDocument8 pages(BS en 1015-2-1999) - Methods of Test For Mortar For Masonry. Bulk Sampling of Mortars and Preparation of Test MortarsYole AvilaNo ratings yet

- AASHTO M300 Inorganic Zinc-Rich PrimerDocument8 pagesAASHTO M300 Inorganic Zinc-Rich Primer1.202056100% (2)

- FprEN 14188-2 (2017) (E)Document6 pagesFprEN 14188-2 (2017) (E)narendar.1100% (1)

- Non-Asbestos Fiber-Mat Reinforced Cement Substrate Sheets: Standard Specification ForDocument4 pagesNon-Asbestos Fiber-Mat Reinforced Cement Substrate Sheets: Standard Specification ForNicolas FernandezNo ratings yet

- BS 3900 Pull Off Test PDFDocument9 pagesBS 3900 Pull Off Test PDFAvinash LalNo ratings yet

- Astm 795Document7 pagesAstm 795djfreditoNo ratings yet

- Astm d412 Testing FixtureDocument6 pagesAstm d412 Testing FixturePallab Jyoti DasNo ratings yet

- Volume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Document8 pagesVolume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Ahmad Saadeldin100% (1)

- BS en Iso 10545-5-1998 (1999)Document14 pagesBS en Iso 10545-5-1998 (1999)Layna PontesNo ratings yet

- Sae Ams 225 - 8aDocument5 pagesSae Ams 225 - 8aNelsonAguilar100% (1)

- Ufgs 09 97 13.15Document43 pagesUfgs 09 97 13.15Tim KearneyNo ratings yet

- BS en 12543 2 1999 PDFDocument14 pagesBS en 12543 2 1999 PDFkimNo ratings yet

- C 636 - 04 Installation of Metal Ceiling Suspension Systems ForDocument4 pagesC 636 - 04 Installation of Metal Ceiling Suspension Systems ForJavier Salinas SepúlvedaNo ratings yet

- BS 6399 PDFDocument22 pagesBS 6399 PDFTeoh ChunliNo ratings yet

- PDS Hempafire Optima 500Document3 pagesPDS Hempafire Optima 500Tanmay GorNo ratings yet

- A325 PDFDocument8 pagesA325 PDFGHULAM NABINo ratings yet

- Astm C 864 - 05 (2015)Document3 pagesAstm C 864 - 05 (2015)alexanderhdez100% (1)

- 0192-En 13948-2008Document9 pages0192-En 13948-2008Borga ErdoganNo ratings yet

- Design No. XR736: BYBU - XR736 Fire-Resistance Ratings - ANSI/UL 1709 Design/System/Construction/Assembly Usage DisclaimerDocument2 pagesDesign No. XR736: BYBU - XR736 Fire-Resistance Ratings - ANSI/UL 1709 Design/System/Construction/Assembly Usage DisclaimeredoNo ratings yet

- Jis G3466Document9 pagesJis G3466魏雨辰No ratings yet

- BS en 14891-2017 - TC - (2020-08-27 - 08-52-57 Am)Document87 pagesBS en 14891-2017 - TC - (2020-08-27 - 08-52-57 Am)梁山伯No ratings yet

- Reva ASTM-A500-A500M-23Document4 pagesReva ASTM-A500-A500M-238nb9kdwg2mNo ratings yet

- BS-2571 For Waterbar PDFDocument8 pagesBS-2571 For Waterbar PDFminhhuan0101No ratings yet

- Astm e 774Document4 pagesAstm e 774Zahoor Ahmed MohsanNo ratings yet

- Technical Submittal: Product Name Nitoflor EPU100Document14 pagesTechnical Submittal: Product Name Nitoflor EPU100rayNo ratings yet

- ASTM E84 ACP Test Report PDFDocument10 pagesASTM E84 ACP Test Report PDFaziz hNo ratings yet

- Comparison of E84 and BS 476 Part 7Document3 pagesComparison of E84 and BS 476 Part 7fahadNo ratings yet

- Preprufe 300R & 160R PDFDocument6 pagesPreprufe 300R & 160R PDForlandomcortezNo ratings yet

- Astm E736Document3 pagesAstm E736Diego NeiraNo ratings yet

- 17.4 PH Material SpecificationDocument2 pages17.4 PH Material SpecificationDevendra BangarNo ratings yet

- Astm C267Document6 pagesAstm C267Hà KhểnhNo ratings yet

- ASTM C547 Mineral Fiber Pipe InsulationDocument7 pagesASTM C547 Mineral Fiber Pipe InsulationMike DukasNo ratings yet

- Excavation, WAH, ScaffoldingDocument30 pagesExcavation, WAH, ScaffoldingManohar KumarNo ratings yet

- Inline Filter With Basket: 16/40 FKE 25/400 - 16 FKE 500/2500 16/40 FFE 25/400 - 16 FFE 500/2500Document4 pagesInline Filter With Basket: 16/40 FKE 25/400 - 16 FKE 500/2500 16/40 FFE 25/400 - 16 FFE 500/2500Matteo BiondiNo ratings yet

- Hilti Expansion Bolts - CapacityDocument9 pagesHilti Expansion Bolts - CapacitykevinisonlineNo ratings yet

- Fatigue and Fracture MechanicsDocument77 pagesFatigue and Fracture MechanicsrunondiveshNo ratings yet

- Century Exterior Cladding HPL SheetDocument71 pagesCentury Exterior Cladding HPL Sheetlalith raj jaiswalNo ratings yet

- Thermoanalytical Instruments ListDocument2 pagesThermoanalytical Instruments ListHui Yuan YeonNo ratings yet

- Thermoelectric CoolingDocument5 pagesThermoelectric CoolingDraganNo ratings yet

- Gum or Resin: A Valuable Resin, Called Manila Elemi or Breabianca', Is Used As An Ingredient in The Manufacture ofDocument3 pagesGum or Resin: A Valuable Resin, Called Manila Elemi or Breabianca', Is Used As An Ingredient in The Manufacture ofKrisma BananiNo ratings yet

- E-PFbCorTrolOS5614 ENDocument1 pageE-PFbCorTrolOS5614 ENPraveen KumarNo ratings yet

- Extreme How-To Magazine - April 2014 PDFDocument92 pagesExtreme How-To Magazine - April 2014 PDFAndre nichols100% (1)

- Homework Assignment 1: - Review Material From Chapter 2 - Mostly Thermodynamics and Heat TransferDocument43 pagesHomework Assignment 1: - Review Material From Chapter 2 - Mostly Thermodynamics and Heat TransferIppiNo ratings yet

- WWW .Abs Fir E.it: Vertical Foam Bladder TankDocument4 pagesWWW .Abs Fir E.it: Vertical Foam Bladder TankJorge InostrozaNo ratings yet

- Survey of Precast Concrete Method and Cast-in-Situ Concrete MethodDocument4 pagesSurvey of Precast Concrete Method and Cast-in-Situ Concrete MethoderpublicationNo ratings yet

- 6000 StructuresDocument79 pages6000 Structuresahong100No ratings yet

- W415-1730 CEFL32-100FH CeCf 08.29.18Document56 pagesW415-1730 CEFL32-100FH CeCf 08.29.18thumbsuppaintNo ratings yet

- Energy Efficiency WorksheetDocument3 pagesEnergy Efficiency Worksheetsupratik30No ratings yet

- Dos PDFDocument4 pagesDos PDFRaj Jamariya50% (2)

- Cem-FIL GRC Technical DataDocument91 pagesCem-FIL GRC Technical Datacbler100% (1)

- Project Report On Artificial/synthetic Marble ProductionDocument5 pagesProject Report On Artificial/synthetic Marble ProductionEIRI Board of Consultants and Publishers100% (1)

- Module 2 Rebar DetailingDocument16 pagesModule 2 Rebar DetailingMae LozanoNo ratings yet

- ME-341A - Heat and Mass TransferDocument34 pagesME-341A - Heat and Mass TransferMukul ChandraNo ratings yet

- Case StudyDocument33 pagesCase StudyMir Hasib Ul LatifNo ratings yet

- Direct CoatingDocument5 pagesDirect Coatingtanzeel.ayoubNo ratings yet

- Room Data Sheet Pour La MRiDocument2 pagesRoom Data Sheet Pour La MRiCarole CaronNo ratings yet

- Linex Solutions GuideDocument22 pagesLinex Solutions GuideJanus AntonioNo ratings yet

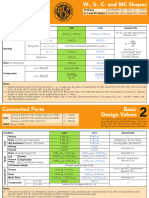

- Manual Card AISC Ver.16Document4 pagesManual Card AISC Ver.16Phanathon OunonNo ratings yet

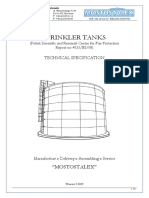

- Mostostalex - Sprinkler TanksDocument8 pagesMostostalex - Sprinkler TanksVanja Ivkovic100% (1)