Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Uploaded by

MD Shadikul Huq ShezanCopyright:

Available Formats

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Uploaded by

MD Shadikul Huq ShezanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Uploaded by

MD Shadikul Huq ShezanCopyright:

Available Formats

Page 1 of 4

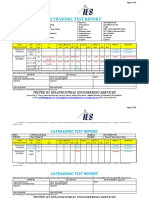

Inspection Date :16 July 2020 Report no : IES-ARBAB-UT-01

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

ULTRASONIC TEST REPORT

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-01 06 - - - - 73.1 - - - - - Accepted Satisfactory

Rafter Joint no -02 06 - - - - 73.1 - - - - - Accepted Satisfactory

Joint no-3 06 - - - - 73.1 - - - - - Accepted Satisfactory

Joint no-4 06 - - - - 73.1 - - - - - Accepted Satisfactory

T** LEGEND: X = Circumferential distance from datum, Y= Distance from weld C/L to probe index. BPL = Beam path length, y = Calculated distance from probe index, L = Length, a = Indication level, d = Indication

rating,

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shadikul huq Shezan Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 16/07/2020 Date: 16/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

Page 2 of 4

ULTRASONIC TEST REPORT

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-05 06 60 mm left ward To left 13.24 33.19 100% 66.1 A 40.00 2.31 13.00 0.24 Repair Find the defect IP,SL

Rafter

Joint no -06 06 80 mm left ward To left 15.43 37.14 100% 66.1 A 90.00 3.41 15.43 0.00 Repair Find the defect IP,SL

Joint no-07 06 75 mm left ward To left 22.05 36.98 100% 66.1 A 40.00 2.45 22.05 0.00 Repair Find the defect IP,SL

Joint no-08 06 210 mm left ward To left 24.09 45.38 100% 66.1 A 120.00 2.67 24.09 0.00 Repair Find the defect IP,SL

Joint No-09 06 - - - - 66.1 - - - - Accepted Satisfactory

-

ULTRASONIC TEST REPORT

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shadikul huq Shezan Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 16/07/2020 Date: 16/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

Page 3 of 4

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-10 06 - - - - 66.1 - - - - - Accepted Satisfactory

Rafter Joint no -11 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint no-12 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint no-13 06 70 mm left ward To left 22.14 42.18 100% 66.1 A 50.00 2.30 22.10 0.04 Repair Find the defect IP,SL

Joint No-14 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint no -15 06 80 mm left ward To left 12.10 45.18 100% 66.1 A Full 2.80 12.10 0.00 Repair Find the defect IP,SL

ULTRASONIC TEST REPORT

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shadikul huq Shezan Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 16/07/2020 Date: 16/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

Page 4 of 4

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Rafter Joint No-16 06 60 mm left ward To left 10.14 36.18 100% 66.1 A 80.00 3.10 10.00 0.14 Repair Find the defect IP,SL

Joint no -17 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint no-18 06 - - - - 66.1 - - - - - Accepted Satisfactory

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shadikul huq Shezan Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 16/07/2020 Date: 16/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

You might also like

- Sasha Fierce - The Book of ShadowsDocument98 pagesSasha Fierce - The Book of Shadowssina dfard100% (4)

- Warrior Engineering PaperDocument14 pagesWarrior Engineering PaperangusNo ratings yet

- Ir - L1904-32 17apr19-Mt (Sfjt-E)Document5 pagesIr - L1904-32 17apr19-Mt (Sfjt-E)Alleyson Akin100% (1)

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesAmit HasanNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Gpti Qicl 032Document2 pagesGpti Qicl 032uselessinstaid52No ratings yet

- 1-UT-Pot Shell 615Document2 pages1-UT-Pot Shell 615Azhar GulzarNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Gpti Qicl J931 Mut 004Document3 pagesGpti Qicl J931 Mut 004uselessinstaid52No ratings yet

- CCTC 17.07.2024 Ut RN 48727Document2 pagesCCTC 17.07.2024 Ut RN 48727eravijitdebnathNo ratings yet

- Ut AmrDocument1 pageUt AmrbalaNo ratings yet

- Scip2 TGXDocument6 pagesScip2 TGXKarthikeyan Ganesan100% (1)

- Content 20240115185834Document2 pagesContent 20240115185834BLY YEDEKPA NOEL BENITONo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- Ut Report - 018 - Fab Tech Abudhabi LLC 19.04.2018Document2 pagesUt Report - 018 - Fab Tech Abudhabi LLC 19.04.2018ADOBEENo ratings yet

- Amir Construction & Company Ltd. Manlift UT Report-14 (06.10.22)Document3 pagesAmir Construction & Company Ltd. Manlift UT Report-14 (06.10.22)sumit singhNo ratings yet

- CB-043 Mpi Exp-02 Apr 2024Document1 pageCB-043 Mpi Exp-02 Apr 2024Ahmed Abu EleninNo ratings yet

- Coil # 09 Inlet C-Scan ReportDocument5 pagesCoil # 09 Inlet C-Scan ReportdrakeNo ratings yet

- Ultrasonic Inspection Report: REPORT NO.-UT-HB-1003723Document1 pageUltrasonic Inspection Report: REPORT NO.-UT-HB-1003723Ahmed GomaaNo ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Coil # 01 Inlet C-Scan ReportDocument5 pagesCoil # 01 Inlet C-Scan ReportdrakeNo ratings yet

- Doosan Power Systems Indai PVT Limited: System CalibrationDocument3 pagesDoosan Power Systems Indai PVT Limited: System CalibrationBalkishan DyavanapellyNo ratings yet

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- Report TemplateDocument3 pagesReport TemplatePretech Anand100% (1)

- Coil # 25 Inlet C-Scan ReportDocument5 pagesCoil # 25 Inlet C-Scan ReportdrakeNo ratings yet

- Ut Report-1 PDFDocument1 pageUt Report-1 PDFsureshrathod2No ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Ultrasonic Examitation Report: Probe DetailsDocument5 pagesUltrasonic Examitation Report: Probe DetailsMarcus AntoniusNo ratings yet

- Paut 16Document4 pagesPaut 16maroof m100% (1)

- Liquid Penetrant Testing Report: Sievert Emirates Inspection LLCDocument1 pageLiquid Penetrant Testing Report: Sievert Emirates Inspection LLCAvijit DebnathNo ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Coupler Plate DP TestDocument1 pageCoupler Plate DP Testshindemitesh17No ratings yet

- UT Report J-5R XH45Document3 pagesUT Report J-5R XH45Marcus ImagweNo ratings yet

- ACS GW 24 001 AR029 Gose Neck ThreadDocument1 pageACS GW 24 001 AR029 Gose Neck Threadarehmanmirza1990No ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Radiography OfferDocument1 pageRadiography OfferRavi patelNo ratings yet

- EWPR01,EWSB03 (30.10.2024)Document1 pageEWPR01,EWSB03 (30.10.2024)Quality Inspection videosNo ratings yet

- Report No - 038 - NFT Specialized - 20.11.2018Document1 pageReport No - 038 - NFT Specialized - 20.11.2018ADOBEENo ratings yet

- Liquid Penetrant Examination Report: Jasa Perbaikan Silincer & Dinding Dalam Gas Duct Mi GT 1.1 MUARA KARANG 2020Document4 pagesLiquid Penetrant Examination Report: Jasa Perbaikan Silincer & Dinding Dalam Gas Duct Mi GT 1.1 MUARA KARANG 2020Riesky Firdyan100% (1)

- Liquid PenetrantDocument2 pagesLiquid PenetrantabdiNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Sievert Emirates Inspection L.L.C.: Magnetic Particle Testing ReportDocument1 pageSievert Emirates Inspection L.L.C.: Magnetic Particle Testing ReportAvijit DebnathNo ratings yet

- Ut ProcedureDocument2 pagesUt ProcedureJJ WeldingNo ratings yet

- CAT-ECI-19-035 Pad Eyes On M 310B Fan Room (AFT) Rigging Locker #7Document3 pagesCAT-ECI-19-035 Pad Eyes On M 310B Fan Room (AFT) Rigging Locker #7Komang Triwahyudi100% (1)

- NDT Request Mes-454 (Mpi)Document1 pageNDT Request Mes-454 (Mpi)khotravi28No ratings yet

- Client:: Olectra Greentech LTDDocument1 pageClient:: Olectra Greentech LTDnareshNo ratings yet

- Method Statement For Inst Cable LayingDocument24 pagesMethod Statement For Inst Cable LayingMallikarjun Devarapalli0% (1)

- Coil # 21 Inlet C-Scan ReportDocument5 pagesCoil # 21 Inlet C-Scan ReportdrakeNo ratings yet

- Coil # 14 - Top - Outlet C-Scan ReportDocument4 pagesCoil # 14 - Top - Outlet C-Scan ReportdrakeNo ratings yet

- 30-11-2021 UT ReportDocument3 pages30-11-2021 UT ReportMD Shadikul Huq ShezanNo ratings yet

- MD - Akibur Sheikh PT Test ReportDocument2 pagesMD - Akibur Sheikh PT Test ReportMD Shadikul Huq ShezanNo ratings yet

- Sujan Das WQTDocument2 pagesSujan Das WQTMD Shadikul Huq ShezanNo ratings yet

- Sujan Das PT Test ReportDocument2 pagesSujan Das PT Test ReportMD Shadikul Huq ShezanNo ratings yet

- MD - Akibur Sheikh WQTDocument2 pagesMD - Akibur Sheikh WQTMD Shadikul Huq ShezanNo ratings yet

- IES PadDocument1 pageIES PadMD Shadikul Huq ShezanNo ratings yet

- Tested by Ies-Industrial Engineering Services: Data and Test SpecimenDocument7 pagesTested by Ies-Industrial Engineering Services: Data and Test SpecimenMD Shadikul Huq ShezanNo ratings yet

- Ies-Industrial Engineering Services: Hydraulic Test ReportDocument7 pagesIes-Industrial Engineering Services: Hydraulic Test ReportMD Shadikul Huq ShezanNo ratings yet

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDocument2 pagesMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ies-Industrial Engineering Services: Ultrasonic Thickness Test ReportDocument3 pagesIes-Industrial Engineering Services: Ultrasonic Thickness Test ReportMD Shadikul Huq ShezanNo ratings yet

- Acute GlomerulonephritisDocument14 pagesAcute GlomerulonephritisMochaLoverNo ratings yet

- Lecture 20 m23 Karr120 10e PPT c23Document31 pagesLecture 20 m23 Karr120 10e PPT c23Milan MišićNo ratings yet

- SLOKADocument80 pagesSLOKAlovenetNo ratings yet

- SENTRI ManualDocument30 pagesSENTRI ManualalbeertoNo ratings yet

- HSE Perfomance Report Jan-21Document2 pagesHSE Perfomance Report Jan-21Bassam HSENo ratings yet

- Kvalitet I Bezbednost Hrane Iz Ugla Korisnika: Conference PaperDocument9 pagesKvalitet I Bezbednost Hrane Iz Ugla Korisnika: Conference Papermilica sivcevicNo ratings yet

- Phase Diagram of Mixture Solution: A A B B A A B B A A B BDocument6 pagesPhase Diagram of Mixture Solution: A A B B A A B B A A B BAldrichsyah Yoga PratamaNo ratings yet

- As 2855-2004 Paints and Related Materials - Micaceous Iron Oxide PigmentDocument8 pagesAs 2855-2004 Paints and Related Materials - Micaceous Iron Oxide PigmentSAI Global - APACNo ratings yet

- 2022 Chevrolet Corvette Owners ManualDocument338 pages2022 Chevrolet Corvette Owners ManuallinseysabrinaNo ratings yet

- Indian Minerals Yearbook 2020: (Part-III: Mineral Reviews)Document7 pagesIndian Minerals Yearbook 2020: (Part-III: Mineral Reviews)k_pareshNo ratings yet

- HDFC Securities Retail Research Dabur India LTD Initiating CoverageDocument28 pagesHDFC Securities Retail Research Dabur India LTD Initiating CoverageDCDC DCNo ratings yet

- Intensity-Modulated Radiation Therapy (Imrt) in The Treatment of Anal Cancer - Toxicity and Clinical OutcomeDocument8 pagesIntensity-Modulated Radiation Therapy (Imrt) in The Treatment of Anal Cancer - Toxicity and Clinical OutcomejunfangokuNo ratings yet

- Salary Slip Naveen Feb 24Document1 pageSalary Slip Naveen Feb 24Amit LakhnotraNo ratings yet

- Activity Sheet PEH Q2 Week 3 4Document2 pagesActivity Sheet PEH Q2 Week 3 4Elsa Lailani SadangNo ratings yet

- 9 Health LM - Mod.1.v1.0Document52 pages9 Health LM - Mod.1.v1.0totChing82% (11)

- 10 Simple Things That Make Seafarers Happy On Board ShipsDocument17 pages10 Simple Things That Make Seafarers Happy On Board ShipsvdevivNo ratings yet

- Solid Groung CuringDocument16 pagesSolid Groung Curingselva_raj215414100% (2)

- General Construction Rules FOR Underground SystemsDocument25 pagesGeneral Construction Rules FOR Underground Systemsaegean227No ratings yet

- Proposed House Rules For PPPI MarketDocument29 pagesProposed House Rules For PPPI MarketCesareo Angelo BanolNo ratings yet

- Plain Bearing Failure Foreign Matter Wiping FatigueDocument1 pagePlain Bearing Failure Foreign Matter Wiping FatigueSatyabrat GaanNo ratings yet

- Deep Vein ThrombosisDocument33 pagesDeep Vein ThrombosisWisnu Cahyo100% (2)

- Nithyananda Yoga - Shastra Pramanas PDFDocument39 pagesNithyananda Yoga - Shastra Pramanas PDFJhuma Debnath100% (1)

- ENMIND EN-S7 INSTRUCTION MANUAL. Manufactured by - Shenzhen Enmind Technology Co., Ltd. ENMIND PDFDocument65 pagesENMIND EN-S7 INSTRUCTION MANUAL. Manufactured by - Shenzhen Enmind Technology Co., Ltd. ENMIND PDFjavier100% (2)

- Santosh DevDocument45 pagesSantosh Devdevdsantosh100% (1)

- Foundational Tao Alchemy MeditationsDocument6 pagesFoundational Tao Alchemy MeditationsTechnical PhantomNo ratings yet

- 1) Introduction 2) Features 3) Diagrams/description 4) Operation 5) Flow Chart 6) ConclusionDocument5 pages1) Introduction 2) Features 3) Diagrams/description 4) Operation 5) Flow Chart 6) ConclusionSanjay YadavNo ratings yet

- 060378en - General Reachstacker Forklift - SCANIA ENGINE DC13 (74A AND 76A)Document11 pages060378en - General Reachstacker Forklift - SCANIA ENGINE DC13 (74A AND 76A)MohamedSalahNo ratings yet

- TNRI Final Design Report R01Document48 pagesTNRI Final Design Report R01Bunyamin SelimogluNo ratings yet