Inconel Alloy 617 (UNS N06617) : Heanjia Super-Metals Co., LTD, Call-12068907337. Web

Inconel Alloy 617 (UNS N06617) : Heanjia Super-Metals Co., LTD, Call-12068907337. Web

Uploaded by

Josué Emmanuel Blásquez ContrerasCopyright:

Available Formats

Inconel Alloy 617 (UNS N06617) : Heanjia Super-Metals Co., LTD, Call-12068907337. Web

Inconel Alloy 617 (UNS N06617) : Heanjia Super-Metals Co., LTD, Call-12068907337. Web

Uploaded by

Josué Emmanuel Blásquez ContrerasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Inconel Alloy 617 (UNS N06617) : Heanjia Super-Metals Co., LTD, Call-12068907337. Web

Inconel Alloy 617 (UNS N06617) : Heanjia Super-Metals Co., LTD, Call-12068907337. Web

Uploaded by

Josué Emmanuel Blásquez ContrerasCopyright:

Available Formats

Inconel Alloy 617 (UNS N06617)

Inconel 617 offers high temperature strength and great oxidation resistance. Excellent

resistance to pitting and crevice corrosion and general corrosion in reducing and oxidizing

conditions. It prevents carburization, spalling and aqueous corrosion. Alloy 617 is commonly

used in aerospace and land base gas turbines, fossil fuels, catalyst grid support in acid

processing and power production plants.

The processing technology and equipment that are used in the process influence the

strength and work hardening rate of alloy. Inconel 617 provides superior heat formability

that requires comparatively large force due to its high strength at the high temperature

ranges.

Chemical Composition

Carbon (C) 0.05 to 0.15 %

Nickel(Ni) Rem %

Iron (Fe) 3%

Silicon (Si) 0.50 %

Manganese (Mn) 0.50 %

Cobalt (Co) 10 to 15 %

Chromium (Cr) 20 to 24 %

Titanium (Ti) 0.60 %

Phosphorous (P) 0.015 %

Sulfur (S) 0.015 %

Molybdenum (Mo) 8 to 10 %

Aluminum (Al) 0.80 to 1.50 %

Heanjia Super-Metals Co., Ltd, Call- 12068907337. Web: www.super-metals.com

Boron (B) 0.006 %

Copper (Cu) 0.50 %

Physical Properties

Density 0.302 lb/cubic inches or 8360 kg/ cubic

meter

Melting point 2430oF to 2510oF or 1332oC to 1377oC

Specific heat at 78oF or 26oC 0.100 Btu/lb-oF or 419 J/Kg-oC

Electrical resistivity at 78oF or 26oC 736 ohm-cir mil/ft or 1.223 aee-m

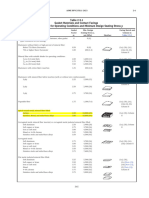

Electrical & Thermal properties

Temperature, Electrical Thermal Coefficient Specific Heat

oF Resistivity Conductivity of Expansion

ohm-circ mil/ft Btu - in/ft² - hr - oF 10(-6)in./in./oF Btu/lb-oF

78 of 736 94 - 0.100

200 of 748 101 6.4 0.104

400 of 757 113 7 0.111

600 of 764 125 7.4 0.117

800 of 770 137 7.6 0.124

1000 of 779 149 7.7 0.131

1200 of 793 161 8 0.137

1400 of 807 173 8.4 0.144

1600 of 803 185 8.7 0.150

1800 of 824 197 9 0.157

2000 of - 209 9.2 0.163

Modulus of Elasticity

Temperature Tensile modulus Shear modulus Poisson

oF oC 10(6) psi GPa 10(6) psi GPa ratio

74 of 25 oC 30.6 211 11.8 81 0.30

200 of 100 oC 30 206 11.6 80 0.30

400 of 200 oC 29 201 11.2 77 0.30

600 of 300 oC 28 194 10.8 75 0.30

800 of 400 oC 26.9 188 10.4 72 0.30

1000 of 500 oC 25.8 181 9.9 70 0.30

1200 of 600 oC 24.6 177 9.5 66 0.30

1400 of 700 oC 23.3 166 9 64 0.30

1600 of 800 oC 21.9 149 8.4 61 0.30

Mechanical Properties

Inconel 617 alloy offers large mechanical properties at the different temperature limits. It

offers high strength at the high temperatures. Its corrosion resistance property at the high

temperatures makes its strength more usable.

Heanjia Super-Metals Co., Ltd, Call- 12068907337. Web: www.super-metals.com

Temperature Test Yield Tensile Elongation Impact strength

time, strength, strength %

hours 0.2%

oF oC 10(3) MPa 10(3) MPa ft-lb J

psi psi

Room - 46.3 319 111.5 769 68 171 232

temperature

1100 of 595 100 46.5 321 111.5 769 69 213 289

oC 1000 51.8 357 116.5 803 67 223 302

4000 55.7 384 117.5 810 67 181 245

8000 59.5 410 121.5 838 61 98 133

12000 67.6 466 132 910 34 69 94

1200 of 650 100 51.8 357 114.5 789 69 191 259

oC 1000 66.6 459 133.5 920 37 35 47

3640 76.3 526 142 979 33 35 47

8000 76.5 527 144 993 28 40 54

12000 77.5 534 144 993 32 38 52

1300 of 705 100 58.7 405 126.5 872 38 57 11

oC 1000 70.5 486 138 952 33 48 65

4000 70.6 487 138 952 36 48 65

1400 of 760 100 58.3 402 126.5 872 35 56 76

oC 1000 56.3 388 126 879 37 63 85

4000 58.1 401 128.5 886 38 62 84

8000 58.5 403 130 896 40 64 87

12000 56.4 389 129.5 893 38 67 91

Creep and stress rupturing strength of Inconel 617

Inconel 617 alloy offers high scale of creep and stress rupture strength at the elevated

temperature above 1800oF. The characteristics in combination with excellent resistance to

oxidizing and carburizing atmosphere provide alloy 617 the capability to offer the

prolonged, high stress rupturing strength at the high temperatures. Inconel 617 specimen is

used in the solution annealed form prior to revelation. The strength is exhibited to carbide

production and exposing temperature at 1200oF to 1400oF to the precipitation of gamma

prime phase.

The creeping strength of Inconel 617 in the solution annealed form at the temperature of

2000oF is evaluated. The rupture capability of solution annealed material at the same

temperature is observed. The tests are conducted on bar, tubing, and sheet materials. The

design standards allowable for Inconel 617 alloy forms are received.

Inconel 617 alloy is commonly used in the annealed form that provides coarse grain

structure for the exceptional creeping resistance. It also offers high bending ductility at the

standard temperature. The solution annealing is performed at 2150oF, immediately water

or air cooling is performed. The cutting tools are sharp and they have high rake angles to

Heanjia Super-Metals Co., Ltd, Call- 12068907337. Web: www.super-metals.com

decrease the work hardening of Inconel 617 alloy. It offers excellent welding nature. Inconel

617 filler metal is used in the gas tungsten arc and gas metal arc welding though Inconel

welding 617 electrode is used for shielding metal arc welding.

Corrosion Resistance

The content of nickel and chromium in Inconel 617 alloy provides excellent resistance to

reduction and oxidation media. The corrosion resistance property of alloy improves with an

addition of aluminum. The solid solution strength is obtained by adding cobalt and

molybdenum metals. The chemical constituents of Inconel 617 alloy include nickel,

chromium and aluminum that offer large scale of resistance to oxidation and carburization

at the elevated temperatures. These elements with the molybdenum concentration also

provide strength to resist the rigorous corrosive conditions.

The resistance to carburization is compared with other Inconel alloys in the carburizing

conditions at temperatures up to 2000oF or 1095oC.

In Sulphuric Acid

Acid content % Corrosion rate

175oF or 80oC Boiling temperature

Mpy mmy Mpy Mmy

5 - - 24 0.61

10 2 0.05 28 0.71

20 32 0.81 97 2.46

30 44 1.12 464 11.89

40 40 1.02 838 21.29

50 94 2.39 - -

In Phosphoric Acid

Acid Attack rate

content % H3PO4, 175oF or 80oC H3PO4, boiling H3PO4 + 1% HF 175oF or 80oC

Mpy mmy Mpy mmy Mpy mmy

10 0.2 0.005 0.1 0.003 0.9 0.023

20 0.2 0.005 0.4 0.010 2 0.05

30 0.4 0.010 0.5 0.013 1 0.03

40 0.4 0.010 5 0.13 6 0.15

50 0.7 0.018 31 0.79 8 0.20

60 0.4 0.010 50 1.27 6 0.15

70 0.4 0.010 38 0.97 0.6 0.015

85 0.6 0.015 26 0.66 0.4 0.010

In Hydrofluoric Acid

Acid content % Attack rate

Vapour phase Liquid phase

Mpy mmy Mpy mmy

10 44 1.12 126 3.20

20 32 0.81 302 7.67

30 82 2.08 396 10.06

40 85 2.16 424 10.77

Heanjia Super-Metals Co., Ltd, Call- 12068907337. Web: www.super-metals.com

48 104 Fabrication

2.64 428 10.87

LCF fabrication factors

It is noticed that minor residue of cold processing that is obtained through mild forming, is

capable to produce significant influence on the creeping resistance of Inconel 617. The

second solution annealing is conducted at 2150oF then water cooling is performed to

prevent the cold processing results and regain the creeping resistance. The second

annealing at 2150oF develops coarse grain structure and hence reduces the LCF activity. The

low annealing temperature limits are analyzed on the 10% to 20% cold processed material.

The second annealing at 2050oF after air quenching is sufficient to get recrystallization of

the cold processed structure while not increasing the grain development in the regions that

get little or no cold processing. The subsequent analysis on the production parts has

determined the suitability of second solution annealing processing.

On the base of these factors the following suggestions are made:

Starting through mill solution annealed material, water cooling, cold processing, welding

and re solution annealing at 2050oF followed by air quenching. An approved process, when

the forging is quite large to second annealing as an assembly, would be to re-solution

annealing of the isolated components after forming but prior to assembly.

Welding Features of Inconel 617

Inconel alloy 617 comprises of superior welding character. The filler metal 617 is utilized in

the gas tungsten arc and gas metal arc welding however Inconel welding electrode 617 is

utilized for shielded metal arc welding.

The composition of filler metal resembles with the primary metal and accumulated welded

metal resembles with the wrought alloy in terms of potential and resistance to corrosion

features. The tensile characteristics at the elevated temperatures of the welded material are

evaluated. The creep rupturing potential of welded material is similar to the wrought

material.

Available Forms

Wire, Mesh, Strip, Foil, Plate, Sheet, Rod, Bars, Tubing, Pipe, Flanges

Heanjia Super-Metals Co., Ltd, Call- 12068907337. Web: www.super-metals.com

You might also like

- Hydrogen Sulfide Suicide Recipe InstructionsDocument3 pagesHydrogen Sulfide Suicide Recipe InstructionsNick ola33% (3)

- Asme Sec Viii Div.1-2023Document1 pageAsme Sec Viii Div.1-2023karthickmectrNo ratings yet

- Che1501 2023 TL 101 0 BDocument27 pagesChe1501 2023 TL 101 0 BBrandon MakamaNo ratings yet

- Infoprd-Geomet 500-gb PDFDocument2 pagesInfoprd-Geomet 500-gb PDFSannohashi MFGNo ratings yet

- Bukang Special Industry - Coalloy6, SUS316L, SUS316L BK (20180726)Document5 pagesBukang Special Industry - Coalloy6, SUS316L, SUS316L BK (20180726)ViệtNo ratings yet

- ENI Drilling Rigs PracticesDocument7 pagesENI Drilling Rigs PracticesJosué Emmanuel Blásquez ContrerasNo ratings yet

- Mechanics of Drilling PDFDocument200 pagesMechanics of Drilling PDFJosué Emmanuel Blásquez Contreras50% (2)

- How To Read A Daily Drilling: A Beginner's GuideDocument12 pagesHow To Read A Daily Drilling: A Beginner's GuideJosué Emmanuel Blásquez Contreras100% (1)

- EIGA 115-04 Condiciones en Instalaciones de ClientesDocument24 pagesEIGA 115-04 Condiciones en Instalaciones de ClientesdmpresasNo ratings yet

- Datasheet DMV 304 HCu 20081118Document4 pagesDatasheet DMV 304 HCu 20081118Anuj ShahiNo ratings yet

- Standart Cina Untuk WeldingDocument52 pagesStandart Cina Untuk Weldingandristy90No ratings yet

- (Index - HTML) : Aluminium Alloy 6082, Aluminium 6082 He30, Aluminium 6082 He30 Sheets PlatesDocument2 pages(Index - HTML) : Aluminium Alloy 6082, Aluminium 6082 He30, Aluminium 6082 He30 Sheets PlatesSamrat OMS100% (1)

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFDocument12 pages253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulNo ratings yet

- QU AL ITY: Material Data SheetDocument5 pagesQU AL ITY: Material Data SheetAlex007No ratings yet

- Weldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructuresDocument8 pagesWeldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructurestheijesNo ratings yet

- IBR - 1950 - Reg282 p1Document2 pagesIBR - 1950 - Reg282 p1ganesh82100% (1)

- Material Specification Sheet Saarstahl - 27Mncrb5-2Document1 pageMaterial Specification Sheet Saarstahl - 27Mncrb5-2rakeshNo ratings yet

- Atlantic Catalogue 2016Document34 pagesAtlantic Catalogue 2016caswel14100% (2)

- Er 100 S 1Document1 pageEr 100 S 1Oliver Quezada Inostroza100% (1)

- Weldolet Weight Table (Unit in KG)Document2 pagesWeldolet Weight Table (Unit in KG)gfd100% (1)

- 25CrMo4Document1 page25CrMo4Hans GoetheNo ratings yet

- Welding 304HDocument29 pagesWelding 304Hclaude.bouillot3566No ratings yet

- Aisi 1040 Carbon Steel (Uns g10400)Document3 pagesAisi 1040 Carbon Steel (Uns g10400)anishraobNo ratings yet

- A-80 RailrodDocument1 pageA-80 RailrodSyed AbudhakirNo ratings yet

- WPS-CS-113 Rev.1Document2 pagesWPS-CS-113 Rev.1Muhammad Bilal100% (1)

- Aladin SDocument4 pagesAladin SJeffrey BeanNo ratings yet

- John Thompson Boiler Development and Training CentreDocument2 pagesJohn Thompson Boiler Development and Training CentreMohit ComputerNo ratings yet

- Is 2708 1993Document10 pagesIs 2708 1993ghosh_ranjoyNo ratings yet

- Dupont Tefzel: Chemical Use Temperature GuideDocument12 pagesDupont Tefzel: Chemical Use Temperature GuideOscarNo ratings yet

- Dynamic and Static Balancing of Rolls - How, Why and WhenDocument2 pagesDynamic and Static Balancing of Rolls - How, Why and WhenAbolfazl KhakiNo ratings yet

- Datasheet-Safurex-En-V2017-11-15 09 - 20 Version 1Document8 pagesDatasheet-Safurex-En-V2017-11-15 09 - 20 Version 1Alejandra RendónNo ratings yet

- BSI 709 DT Fusion WeldedDocument24 pagesBSI 709 DT Fusion WeldedbonnicoNo ratings yet

- RJR PMMTDocument16 pagesRJR PMMTArun PrasadNo ratings yet

- Inconel 713CDocument20 pagesInconel 713CJSH100No ratings yet

- SB-165 - ASME BPVC 2021 Sección II Part BDocument6 pagesSB-165 - ASME BPVC 2021 Sección II Part BMohammad TaherNo ratings yet

- Specification Sheet: Alloy 800H/800HT: (UNS N08810, UNS N08811) W. Nr. 1.4958, 1.4959Document4 pagesSpecification Sheet: Alloy 800H/800HT: (UNS N08810, UNS N08811) W. Nr. 1.4958, 1.4959Abdul RehmanNo ratings yet

- 1.4313 enDocument2 pages1.4313 envesselNo ratings yet

- Clock Spring CS600 Quad Qualification Test ReportDocument7 pagesClock Spring CS600 Quad Qualification Test ReportMOHD ASHRAF MOHD ROSITNo ratings yet

- Mechanical Properties: Element Content (%)Document2 pagesMechanical Properties: Element Content (%)SANNI KUMARNo ratings yet

- Castings, Steel and Alloy, Common Requirements, For General Industrial UseDocument12 pagesCastings, Steel and Alloy, Common Requirements, For General Industrial UseIvan RamirezNo ratings yet

- Nfa 49 310 Grade Tu 52 B Tubes PDFDocument1 pageNfa 49 310 Grade Tu 52 B Tubes PDFMitul MehtaNo ratings yet

- Lecture4 - Power Density in WeldingDocument5 pagesLecture4 - Power Density in WeldingZundali Firdaus100% (1)

- (Liter) (Inch) (MM) (Inch) (MM) (Inch) (MM) (Inch) (MM) (MM) (MM) (MM) (MM) (MM) (MM) (MM) Approx. (KG)Document1 page(Liter) (Inch) (MM) (Inch) (MM) (Inch) (MM) (Inch) (MM) (MM) (MM) (MM) (MM) (MM) (MM) (MM) Approx. (KG)Sandi ApriandiNo ratings yet

- ShapeCUT Steel Hardness Conversion TableDocument2 pagesShapeCUT Steel Hardness Conversion TableVicente GarcíaNo ratings yet

- The Welding Metallurgy of HASTELLOY Alloys C-4, C-22, and C-276Document2 pagesThe Welding Metallurgy of HASTELLOY Alloys C-4, C-22, and C-276Ivan Garzon0% (1)

- Rotary JointDocument7 pagesRotary JointGlobe Star Engineers Pvt LtdNo ratings yet

- Monel 400 Data SheetDocument1 pageMonel 400 Data Sheetalextentwenty100% (1)

- BS Iso 13521-2015Document14 pagesBS Iso 13521-2015noahb110No ratings yet

- AISI 1030 Carbon SteelDocument4 pagesAISI 1030 Carbon SteelgadflovelvalvescomNo ratings yet

- Hardox 450 Data SheetDocument2 pagesHardox 450 Data SheetmatthewpincottNo ratings yet

- 277 PDFDocument15 pages277 PDFUmar MohammadNo ratings yet

- Carbon Steel Flange Rating Chart: ANSI FLANGE ASTM A105, A350 Gr. LF2/LF6 Class 1Document8 pagesCarbon Steel Flange Rating Chart: ANSI FLANGE ASTM A105, A350 Gr. LF2/LF6 Class 1sutarnoNo ratings yet

- IMIOrton MV SeriesDocument4 pagesIMIOrton MV SeriesFelipe Gamboa GálvezNo ratings yet

- En 10028 P355GHDocument2 pagesEn 10028 P355GHEvriMert RüzgArdaNo ratings yet

- WWW Wollastonalloys Com Materials 2Document8 pagesWWW Wollastonalloys Com Materials 2Mark RomeroNo ratings yet

- Welding DefectsDocument15 pagesWelding Defectsshare2sankarkNo ratings yet

- Armco Pure Iron PDFDocument12 pagesArmco Pure Iron PDFsmith willNo ratings yet

- Hastelloy C4Document4 pagesHastelloy C4titan.iran68No ratings yet

- Stainless Steel 310/310S (UNS S31000/ UNS S31008) : Element SS 310 SS 310SDocument5 pagesStainless Steel 310/310S (UNS S31000/ UNS S31008) : Element SS 310 SS 310SRajaram GanesanNo ratings yet

- FT Sifer 950iDocument2 pagesFT Sifer 950iAshik M RasheedNo ratings yet

- Incoloy A286Document4 pagesIncoloy A286zeeshan aliNo ratings yet

- 34 CR Mo 4Document2 pages34 CR Mo 4ceca nikolicNo ratings yet

- 41Cr4 Chemical PDFDocument2 pages41Cr4 Chemical PDFGayathriRajasekaranNo ratings yet

- 1.3505 100cr6 PDFDocument1 page1.3505 100cr6 PDFmcNo ratings yet

- Bus Bar CalculationDocument20 pagesBus Bar CalculationAnirban Sen100% (2)

- Annular Velocity and Hole Cleaning - MetricDocument1 pageAnnular Velocity and Hole Cleaning - MetricJosué Emmanuel Blásquez ContrerasNo ratings yet

- ESS Versus Slotted and Pre-Drilled LinerDocument1 pageESS Versus Slotted and Pre-Drilled LinerJosué Emmanuel Blásquez ContrerasNo ratings yet

- Metric Conversions: To Convert From TO Multiply by Symbol Unit Symbol Unit LengthDocument1 pageMetric Conversions: To Convert From TO Multiply by Symbol Unit Symbol Unit LengthJosué Emmanuel Blásquez ContrerasNo ratings yet

- Bit Hydraulic & ECD CalculationDocument1 pageBit Hydraulic & ECD CalculationJosué Emmanuel Blásquez ContrerasNo ratings yet

- Weight On Bit - WOBDocument10 pagesWeight On Bit - WOBJosue FishNo ratings yet

- 1.5 Humans and PollutionDocument5 pages1.5 Humans and PollutionDevkrishna KyalNo ratings yet

- Mobile Concrete Batching PlantDocument15 pagesMobile Concrete Batching PlantPaul Ticla PuenteNo ratings yet

- Applications of AlkanesDocument2 pagesApplications of AlkanesAira Jane SembranNo ratings yet

- Loctite PC 5070 Emergency Pipe Repair KitDocument2 pagesLoctite PC 5070 Emergency Pipe Repair KitNs KimNo ratings yet

- DOC022.98.80143 3edDocument388 pagesDOC022.98.80143 3edOmar BernalNo ratings yet

- Hazard Communications PPT v-03!01!17Document50 pagesHazard Communications PPT v-03!01!17Kimmy LyonsNo ratings yet

- Rayon Presentation UpdatedDocument3 pagesRayon Presentation UpdatedsaleemNo ratings yet

- Sustainable Construction and Building Materials - Select Proceedings of ICSCBM 2018 (PDFDrive) PDFDocument883 pagesSustainable Construction and Building Materials - Select Proceedings of ICSCBM 2018 (PDFDrive) PDFJoão Mendes100% (1)

- Activity For Cell Membrane YGNALAGADocument5 pagesActivity For Cell Membrane YGNALAGAdayang ranarioNo ratings yet

- Evaluation of Primary Slurry Used in Ceramic Shell Investment Casting ProcessDocument5 pagesEvaluation of Primary Slurry Used in Ceramic Shell Investment Casting ProcessAjeeth KumarNo ratings yet

- Lesson 2 - OrganellesDocument34 pagesLesson 2 - OrganellesArvin Jay Lamberte100% (1)

- 2020 Product CatalogDocument60 pages2020 Product CatalogGasim MohNo ratings yet

- MercerizingDocument38 pagesMercerizingkodigenahalli 3No ratings yet

- 3 PRE-BOARD GENERAL EDUCATION - Some College StudentsDocument10 pages3 PRE-BOARD GENERAL EDUCATION - Some College StudentsJorge Mrose26No ratings yet

- Azing Procedure Weld Copper WaterstopDocument5 pagesAzing Procedure Weld Copper Waterstopzhuxueyun55No ratings yet

- Kaiser 2004Document8 pagesKaiser 2004Dinda Dwi SeptianiNo ratings yet

- Check Mo Muna I2Document7 pagesCheck Mo Muna I2Nicole FidelinoNo ratings yet

- 4 G Mcculloch Incidents and The Regulators PerspectiveDocument39 pages4 G Mcculloch Incidents and The Regulators Perspectivemohammed ansr nmNo ratings yet

- Know The Name of The Elements and Compounds KimiaDocument73 pagesKnow The Name of The Elements and Compounds KimiaNova SinagaNo ratings yet

- Culture Media & Culture MethodsDocument60 pagesCulture Media & Culture MethodsbiochemiNo ratings yet

- Tissue Culture of Gerunggang Cratoxylum Arborescens Vahl Blume Multipurpose Native Species of Indonesian PeatlandDocument9 pagesTissue Culture of Gerunggang Cratoxylum Arborescens Vahl Blume Multipurpose Native Species of Indonesian PeatlandReni Setyo WahyuningtyasNo ratings yet

- Stock Screener, Technical Analysis ScannerDocument42 pagesStock Screener, Technical Analysis ScannerMovied AnimalsNo ratings yet

- Ward Morehouse - M. Arun Subramanian - M. Sriram - The Bhopal Tragedy - What Really Happened and What It Means For American Workers AnDocument2 pagesWard Morehouse - M. Arun Subramanian - M. Sriram - The Bhopal Tragedy - What Really Happened and What It Means For American Workers AnJacekNo ratings yet

- Unit 3Document54 pagesUnit 3Shubh AgarwalNo ratings yet

- 8bklt-Gc Ms AlgaeDocument9 pages8bklt-Gc Ms AlgaenaylaaqilahzaharaNo ratings yet

- Chapter 12 - Organic Chemistry Exercise Intext 1: Solution 1Document32 pagesChapter 12 - Organic Chemistry Exercise Intext 1: Solution 1Roshan RaikarNo ratings yet

- Bondstrengthmasonry TBRDocument8 pagesBondstrengthmasonry TBRbereket gNo ratings yet