Vacuum Pulling 1. Preliminary Checks:: SM6 & SM7

Vacuum Pulling 1. Preliminary Checks:: SM6 & SM7

Uploaded by

Shaon majiCopyright:

Available Formats

Vacuum Pulling 1. Preliminary Checks:: SM6 & SM7

Vacuum Pulling 1. Preliminary Checks:: SM6 & SM7

Uploaded by

Shaon majiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Vacuum Pulling 1. Preliminary Checks:: SM6 & SM7

Vacuum Pulling 1. Preliminary Checks:: SM6 & SM7

Uploaded by

Shaon majiCopyright:

Available Formats

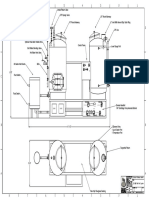

Vacuum pulling

1. PRELIMINARY CHECKS :

Ensure that TPRDS is charged condition from main steam line (10-12 kg/cm2 pr. & 2600C

temp.) i.e. turbine auxiliary steam is available up to ejector steam pressure control station.

Ensure that the following valves are OPENED condition :

i) Condenser air off-take line manual isolating valves (SM6 & SM7).

ii) Isolating valve for valves gland sealing from DMSW pump discharge (DM48).

iii) Condensate isolating valve (CD54) for valves gland sealing from CEP discharge.

iv) Condensate isolating valves for the gland sealing of all the individual valves operating

under vacuum.

iv) All the CEPs gland sealing valves.

v) CEP suction relief valve discharge isolating valves (CS7, CS8 & CS9).

vi) Isolating valves for condenser normal DM make up supply line (DM52 & DM54).

viii) Main ejectors drip line isolating valves (DR41 & DR42).

ix) Steam line drain valves between ejector steam pressure control station and starting or

main ejectors (situated at just below the ejector floor)

Ensure that the following valves are CLOSED condition :

i) CEP suction strainers vent valves.

ii) CEP suction drain valves (CS101 to CS108).

iii) Main ejectors loop filling isolating valves (No Nos.).

iv) Main ejectors loop drain valves.

v) Combined HP & LP Flash Tank drain manifold drain valves (DR116 & DR117).

vi) CRH line drain open to atmosphere valve at minus floor (near BFP-C Booster pump

side).

vii) Boiler side reheater vent valves.

Vacuum breaker (MAG11001) should be kept “OPEN” & “Manual” mode. Its manual

isolating valve (SM15) should be on Open condition.

Ensure that at least one CEP is running on recirculation.

Ensure that auxiliary steam is available up to turbine initial gland sealing steam supply

control station from TPRDS by opening motorized isolating valve (AS-9). Before that

drain valves at this station (upstream of GS supply valve) CRH-105 open to atmosphere

should be kept open to achieve the required gland steam supply temperature (minimum

2200C).

2. LINE – UP OF STARTING EJECTOR :

Open the starting ejector steam line drain valve (DR130).

MCC of starting ejector steam valve and air valve (AS19 & SM14 respectively) should be

“ON” & “Normal” selection. Lock out switches of AS19 and SM14 should be “Released”

condition.

MCC of ejector steam pressure controller bypass valve (AS15) should be ‘ON’ & ‘Normal’

position. L.O.S. of this valve should be released.

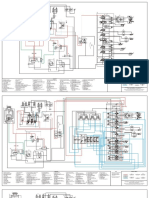

3. LINE – UP OF MAIN EJECTORS :

Put MCC of steam valves (AS17 & AS18) and air valves (SM12 & SM13) ‘ON &

‘Normal’ selection. L.O.S. of these valves should be released i.e. normal position.

Open the ejector drip to condenser isolating valves.

Close the ejector loop drain valves.

Open the ejector loop filling overflow valve. After that fill up the ejector loops from CEP

discharge by opening loop filling valves (CD61 / CD62). After sufficient water coming out

through the overflow valve, close the loop filling valve and overflow valve.

6

Ejector loop filling is required to prevent air / non-condensable gas ingress into the

condenser through the ejector drip line which is to be released to atmosphere through the

orifices.

4. VACUUM PULLING - UP OPERATION :

Auxiliary steam line (from ejector steam pressure control station behind Deaerator FST to

Ejectors) is warmed up by slowly opening the ejector steam pressure controller bypass

motorized valve (AS15). Before that steam trap assembly bypass valve (AS212) of drain

line from auxiliary steam line to ejectors (which leads to the LPFT manifold) should be

fully opened.

Open the ejector steam pressure controller (AS12) manual isolating valves (AS11 &

AS13).

After sufficient warming up of the above aux. steam line, close the valve AS15 and

subsequently close the drain valve AS212.

Bring the ejector steam pressure control valve (AS12) in operation to maintain the

downstream pressure at about 6.5 – 8.0 kg/cm2 (g). Put the AS12 on “AUTO” mode.

Put the Starting Ejector into service, firstly by opening steam side motorized valve (AS19)

and then opening air side motorized valve (SM14).

After the condenser vacuum reaches more than 15 mmHg , open the gland steam supply

valve (MAW11AA002). Fully close the Vacuum Breaker (MAG11AA001) after gland

sealing steam pressure increases more than 200 mmAq. and put the Vacuum Breaker into

“AUTO”.

Set the gland sealing steam controller at “AUTO” mode to maintain the gland steam

pressure approx. 670 mmAq.

When the condenser vacuum reaches 500 mmHg , bring one of the two main ejector (A/B)

into service by firstly opening the respective steam side motorized valve (AS17 or AS18)

and then opening the respective air side motorized valve (SM12 or SM13).

When the condenser vacuum reaches above 650 mmHg , withdraw Starting Ejector from

service firstly by closing its air side valve (SM14) and then closing the steam side valve

(AS19).

When the condenser vacuum reaches designed value (680 mmHg , practically vacuum

reaches above 700 mmHg) and maintain this vacuum as steady state, vacuum pulling up

operation is then completed.

Note 1 : Out of two main ejectors, one ejector is selected as working and the other as standby.

Practically steam side valve of the standby ejector is kept as “Opened” condition (i.e.

steam line is charged) during vacuum pulling up operation. After reaching of designed

condenser vacuum, close the steam side valve of the standby main ejector. If the

condenser vacuum falls, the standby main ejector can be brought into service by

opening its steam side valve and air side valve step by step.

Note 2 : If condenser vacuum tends to fall, check the following main items :-

• Ejector loops are perfectly filled with water.

• All the valve glands operating under vacuum are perfectly sealed.

7

You might also like

- Refrigerant Charging ProcedureDocument3 pagesRefrigerant Charging Procedurenagarajasarma80% (10)

- Aban Ejector TrainingDocument39 pagesAban Ejector TrainingChiranjeet Jena100% (1)

- SECTION 07 Hydraulics2 9020-9030Document16 pagesSECTION 07 Hydraulics2 9020-9030Vjz10997100% (2)

- E RwerewrDocument35 pagesE RwerewrMARK LESTER REALNo ratings yet

- 883BakreswarO& M WithFiguresDocument151 pages883BakreswarO& M WithFiguresShaon maji0% (1)

- Hydraulic Schematic For 580M Series 3 With Mechanical ControlsDocument8 pagesHydraulic Schematic For 580M Series 3 With Mechanical ControlsJesus Perez100% (1)

- C: P: D: Factory Acceptance Test Procedure For Control Valve C - D N .: - Ptcs D N .: FCS-SOP-001. R 01 S: 1 10Document13 pagesC: P: D: Factory Acceptance Test Procedure For Control Valve C - D N .: - Ptcs D N .: FCS-SOP-001. R 01 S: 1 10Hicham BelmaatiNo ratings yet

- Air Cooled Condenser (Acc) and Air Evacuation SystemDocument4 pagesAir Cooled Condenser (Acc) and Air Evacuation SystemCo-gen Manager100% (1)

- Unit Sart Up 800mwDocument12 pagesUnit Sart Up 800mwVamsiKrishnaNo ratings yet

- Emergency Actions Code:Btpp/Turbine/011/Emergency Actions A.Actions To Be Taken in Case of Both CW Pumps TrippingDocument4 pagesEmergency Actions Code:Btpp/Turbine/011/Emergency Actions A.Actions To Be Taken in Case of Both CW Pumps TrippingPrakash ChoudharyNo ratings yet

- Unit Start Up ProcedureDocument14 pagesUnit Start Up ProceduredineshmehtaNo ratings yet

- Code: Btpp/Turbine/007/Vacuum Raising Guidelines For Condenser Vacuum Raising PreconditionDocument5 pagesCode: Btpp/Turbine/007/Vacuum Raising Guidelines For Condenser Vacuum Raising PreconditionPrakash Choudhary100% (2)

- Cold Startup ProcedureDocument8 pagesCold Startup ProcedureRahul KurmiNo ratings yet

- Date: 04/10/2007: Area - TG UNIT - 3/4/5/6Document3 pagesDate: 04/10/2007: Area - TG UNIT - 3/4/5/6netygen1No ratings yet

- Operation Procedures For MDBFPDocument7 pagesOperation Procedures For MDBFPJackSparrow86100% (1)

- Indiabulls Power Limited: Sop/Opns/ Operations DepartmentDocument2 pagesIndiabulls Power Limited: Sop/Opns/ Operations Departmentarvidkumar87060100% (1)

- Precheck Before Light-Up: Drum Metal Temp. DiffDocument12 pagesPrecheck Before Light-Up: Drum Metal Temp. DiffAhemadNo ratings yet

- Boiler Startup ProcedureDocument9 pagesBoiler Startup ProcedureKUNALJAYNo ratings yet

- Cold Start Up ProcedureDocument18 pagesCold Start Up ProcedurerahulNo ratings yet

- Hot Startup Checklist1Document6 pagesHot Startup Checklist1Selva ManianNo ratings yet

- Operator QuestionsDocument4 pagesOperator Questionskalosha917No ratings yet

- Manual Pump Down On An Air ConditioningDocument7 pagesManual Pump Down On An Air ConditioningRay Ravel100% (1)

- Cold Startup 1Document51 pagesCold Startup 1Vel MuruganNo ratings yet

- Express orDocument36 pagesExpress orkr_abhijeet72356587100% (1)

- 4E GUIDE How To Write Valve OperationDocument7 pages4E GUIDE How To Write Valve Operationomegamon619No ratings yet

- 3 Mekg Aug 2023Document15 pages3 Mekg Aug 2023Meghanath AdkonkarNo ratings yet

- Write Up On Turbine OperationDocument5 pagesWrite Up On Turbine OperationSarah Frazier100% (2)

- Operator Questions - Docx Version 1Document5 pagesOperator Questions - Docx Version 1MOHIT TIWARINo ratings yet

- Well Control Equipment Maintenace and Inspection C 240429 190658Document19 pagesWell Control Equipment Maintenace and Inspection C 240429 190658hayam.aarefNo ratings yet

- Plant Compressed Air SystemDocument4 pagesPlant Compressed Air SystemgodwinNo ratings yet

- To Carry Out Cleanup ActivityDocument4 pagesTo Carry Out Cleanup Activitysarojdubey0107No ratings yet

- Test Bench For Safety ValveDocument8 pagesTest Bench For Safety ValvekhairurNo ratings yet

- Unit Start UpDocument8 pagesUnit Start UpDebabrata TantubaiNo ratings yet

- Ammonia Unloading Sop ZaclDocument2 pagesAmmonia Unloading Sop ZaclHARRY SINGHNo ratings yet

- Air Conditioning SystemDocument45 pagesAir Conditioning SystemLeonardo Gómez BernigaNo ratings yet

- Safety Valve FloatingDocument15 pagesSafety Valve FloatingAmitava PalNo ratings yet

- 4.condenser & Feed Water SystemsDocument62 pages4.condenser & Feed Water SystemsAjit Kumar100% (1)

- Activities After Unit Shutdown (Short Shutdown 8Hrs To 72 HRS) Stage-1Document2 pagesActivities After Unit Shutdown (Short Shutdown 8Hrs To 72 HRS) Stage-1Shiftinchargeengineer dadri coalNo ratings yet

- Cargador 920 & 930 Sistema HidraulicoDocument19 pagesCargador 920 & 930 Sistema Hidraulicojulio100% (1)

- Rtaa SB 4 - 10011991Document6 pagesRtaa SB 4 - 10011991alcomech100% (3)

- Introduction To Practical PneumaticsDocument28 pagesIntroduction To Practical PneumaticsAjay PesadoNo ratings yet

- Sporlan Adlse-2Document12 pagesSporlan Adlse-2Serrefriair Garcia RefriNo ratings yet

- Preparation and RequirementDocument2 pagesPreparation and RequirementAdy FardyNo ratings yet

- Lesson 09 Relief Valve Sizing Part 02 1724308647Document23 pagesLesson 09 Relief Valve Sizing Part 02 1724308647fahadNo ratings yet

- 51 Ther MostDocument2 pages51 Ther Mostjasmin45No ratings yet

- Centrifugal Comp PDFDocument7 pagesCentrifugal Comp PDFmsaroladanNo ratings yet

- 300 MW ThermalPower Plant Cold Start UpDocument4 pages300 MW ThermalPower Plant Cold Start Upsunil481100% (1)

- Pur-15-02 - Air Purger Type PurDocument4 pagesPur-15-02 - Air Purger Type PurAnderson Giovanny Herrera DelgadoNo ratings yet

- Air Conditioning SystemDocument51 pagesAir Conditioning SystemMoaed KanbarNo ratings yet

- Air Dryer Ad-9 InstallationDocument24 pagesAir Dryer Ad-9 InstallationLuciano Luiz Vadallares100% (1)

- Treadle ValveDocument8 pagesTreadle ValveBOB100% (1)

- Prestartup ChecksDocument3 pagesPrestartup ChecksPrudhvi RajNo ratings yet

- Cooling Down Operation Prior ArrivalDocument3 pagesCooling Down Operation Prior Arrivalpvukovic91No ratings yet

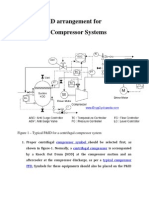

- Typical Compressor ArrangementDocument2 pagesTypical Compressor ArrangementkaitokidH3MNo ratings yet

- Aus SystemDocument4 pagesAus SystemsarahNo ratings yet

- Procedure For Shutting Down of Turbine & EquipmentsDocument4 pagesProcedure For Shutting Down of Turbine & EquipmentsPrakash Choudhary100% (2)

- Indonesia Medan Industrial Park 2 ×: November 2015, ChengduDocument5 pagesIndonesia Medan Industrial Park 2 ×: November 2015, ChengduNashruNo ratings yet

- 5 HRSG 11 12Document7 pages5 HRSG 11 12M Moarraf Naeem100% (3)

- Evans Install Procedure 2011 Navistar Max Force 13L Ver 05nov2012Document9 pagesEvans Install Procedure 2011 Navistar Max Force 13L Ver 05nov2012Veterano del CaminoNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- F HarleyDocument4 pagesF HarleyShaon majiNo ratings yet

- Ajmani OfferDocument2 pagesAjmani OfferShaon majiNo ratings yet

- RCCPRDocument4 pagesRCCPRShaon majiNo ratings yet

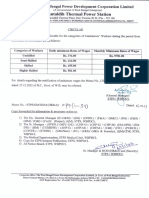

- Minimum Rates of WagesDocument1 pageMinimum Rates of WagesShaon majiNo ratings yet

- CRITICAL STATUS OF 05.08.2020: Santaldih Thermal Power StationDocument16 pagesCRITICAL STATUS OF 05.08.2020: Santaldih Thermal Power StationShaon majiNo ratings yet

- Spots Name of Operator Coverage Min Max PriorityDocument3 pagesSpots Name of Operator Coverage Min Max PriorityShaon majiNo ratings yet

- Corporation Limited Santaldih Power Station: The West Bengal Power DevelopmentDocument1 pageCorporation Limited Santaldih Power Station: The West Bengal Power DevelopmentShaon majiNo ratings yet

- Empanelment of HospitalsDocument3 pagesEmpanelment of HospitalsShaon majiNo ratings yet

- Manual Pump Down On An Air ConditioningDocument7 pagesManual Pump Down On An Air ConditioningRay Ravel100% (1)

- Ce 271-Fluid Mechanics Venturimeter Experiment: - PurposeDocument2 pagesCe 271-Fluid Mechanics Venturimeter Experiment: - PurposesssssNo ratings yet

- Fuel SystemDocument10 pagesFuel SystemFrancis MartinezNo ratings yet

- How To Order: 095LM 160CQ45EHUR R38MDocument2 pagesHow To Order: 095LM 160CQ45EHUR R38MJuan Enrique Perez VillanuevaNo ratings yet

- HydacDocument4 pagesHydacmarkoNo ratings yet

- Degree of ReactionDocument24 pagesDegree of ReactionKrishna SinghNo ratings yet

- Maintenance Checklist Land Mud CoolerDocument1 pageMaintenance Checklist Land Mud CoolerApneryanus LepingNo ratings yet

- Chapter 02 - Pipeline FeaturesOCR OKDocument8 pagesChapter 02 - Pipeline FeaturesOCR OKfabioalves8No ratings yet

- 980H Wheel Loader KZL00001-UP - General Information (Steering System)Document4 pages980H Wheel Loader KZL00001-UP - General Information (Steering System)Andri YuliantoNo ratings yet

- 4 Oil Discharge Monitoring Equipment-Final DrawingDocument92 pages4 Oil Discharge Monitoring Equipment-Final DrawingAung SquNo ratings yet

- Isolation Valve: Factory Tested For Leaks Mounted Between Pump and Receiver TankDocument1 pageIsolation Valve: Factory Tested For Leaks Mounted Between Pump and Receiver TankdigecaNo ratings yet

- Inova Connection Plates SCDocument2 pagesInova Connection Plates SCSympatyagaNo ratings yet

- Logo Logo: Kettle Drain Pump Out WhirlpoolDocument1 pageLogo Logo: Kettle Drain Pump Out WhirlpoolchinsiNo ratings yet

- Ec 310: Hydraulics Lecture NotesDocument14 pagesEc 310: Hydraulics Lecture NotesChileshe Mulenga PhiriNo ratings yet

- CPS CPD Vinatesco Series1Document6 pagesCPS CPD Vinatesco Series1adamkecuuroinhanloaiNo ratings yet

- Pompa Kuras Overflow GWT 12,6 m3h @8mDocument2 pagesPompa Kuras Overflow GWT 12,6 m3h @8mAndreas B KresnawanNo ratings yet

- Releasable Check Valve Type RHC and RHCE: Product DocumentationDocument26 pagesReleasable Check Valve Type RHC and RHCE: Product DocumentationVic CastilloNo ratings yet

- Venturi Type Flow Meter: SubmittalDocument1 pageVenturi Type Flow Meter: SubmittalrajuNo ratings yet

- Turbo Expander CompressorDocument8 pagesTurbo Expander CompressorSaidFerdjallahNo ratings yet

- JXZZ38-5.16HP: Data SheetDocument2 pagesJXZZ38-5.16HP: Data SheetkckhoaNo ratings yet

- Ballast PP2Document1 pageBallast PP2Jano GoñiNo ratings yet

- Model 300S Technical Data 300 GPM: Dimensions and WeightsDocument4 pagesModel 300S Technical Data 300 GPM: Dimensions and WeightsKarina MedinaNo ratings yet

- Hydraulic/Hydrostatic Schematic With High Flow Option 863 (S/N 514440001-41938) (S/N 514640001-40147)Document2 pagesHydraulic/Hydrostatic Schematic With High Flow Option 863 (S/N 514440001-41938) (S/N 514640001-40147)Ataa AssaadNo ratings yet

- CL8552-23 4263443Document40 pagesCL8552-23 4263443Heran Gonzalez100% (1)

- Belts Right-HandDocument2 pagesBelts Right-HandValentinNo ratings yet

- List of Equipments: P & ID IPAL DomestikDocument1 pageList of Equipments: P & ID IPAL DomestikMohammad SyafiiNo ratings yet

- GTG - Know How Training 27 Feb 2013 - 1Document30 pagesGTG - Know How Training 27 Feb 2013 - 1aden mng100% (1)

- UNIT3L1-2S - Lubrication Systems and OilDocument24 pagesUNIT3L1-2S - Lubrication Systems and OilMedo SowarNo ratings yet