0 ratings0% found this document useful (0 votes)

Aisi410 M29002 PDF

Aisi410 M29002 PDF

Uploaded by

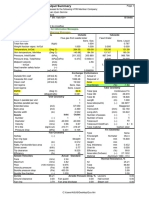

K.s. Raghavendra KumarThis document is a test certificate for a sample of AISI410 steel with a diameter of 12.2mm. It provides the results of tensile and load vs extension tests on the sample. The sample reached a maximum force of 100.38kN at 13.2mm of displacement and fractured at 19.4mm. It had a tensile strength of 858.347MPa and an elongation of 24%.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

Aisi410 M29002 PDF

Aisi410 M29002 PDF

Uploaded by

K.s. Raghavendra Kumar0 ratings0% found this document useful (0 votes)

This document is a test certificate for a sample of AISI410 steel with a diameter of 12.2mm. It provides the results of tensile and load vs extension tests on the sample. The sample reached a maximum force of 100.38kN at 13.2mm of displacement and fractured at 19.4mm. It had a tensile strength of 858.347MPa and an elongation of 24%.

Original Title

AISI410 M29002.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document is a test certificate for a sample of AISI410 steel with a diameter of 12.2mm. It provides the results of tensile and load vs extension tests on the sample. The sample reached a maximum force of 100.38kN at 13.2mm of displacement and fractured at 19.4mm. It had a tensile strength of 858.347MPa and an elongation of 24%.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

Aisi410 M29002 PDF

Aisi410 M29002 PDF

Uploaded by

K.s. Raghavendra KumarThis document is a test certificate for a sample of AISI410 steel with a diameter of 12.2mm. It provides the results of tensile and load vs extension tests on the sample. The sample reached a maximum force of 100.38kN at 13.2mm of displacement and fractured at 19.4mm. It had a tensile strength of 858.347MPa and an elongation of 24%.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1/ 1

Date : 06-03-2020 , 02:29 PM TEST CERTIFICATE

MEFT

Peenya . Bangalore

Machine : Universal Testing Machine 400 kN

:

INPUT DATA : Sample Identification : AISI410 HEAT/LOT NO:17594/M2900

Sample Type : Round solid Diameter (mm) : 12.2

C/S Area (mm2) : 116.946 Final Area (mm2) 40.73

:

Original Gauge Length (mm) : 50.0 Final Gauge Length (mm) : 62.0

Results of Load ( kN ) Vs Displacement ( mm ) Test : File : MEFT 18 , Record : 1

Maximum Force (Fm) kN

100.38

Disp. at Max. Load mm

13.20 ^

Max. Displacement mm L

19.40 o

Tensile strength (Rm) MPa a

858.347 d

Elongation %

24.00

Reduction in Area %

65.171

Results of Load Vs Extension Test , Graph : Stress MPa Vs Strain %

Youngs Modulus MPa

384172.100

0 .2 % Proof Load kN

82.900

0 .2 % Proof Stress MPa ^

708.876 s

Yield Load kN t

82.900 r

e

Yield Stress MPa

s

708.876

s

YS/UTS Ratio

0.826

Extension at Max. Load mm

1.820

Total Elongation at Fm (Agt)

3.64 % * Note : Yield Calculated By Offset method as per ASTM E8 at .2 % Strain offset

Comment

You might also like

- Test Certificate Meft: Peenya - BangaloreNo ratings yetTest Certificate Meft: Peenya - Bangalore1 page

- Test Certificate Meft Peenya - BangaloreNo ratings yetTest Certificate Meft Peenya - Bangalore1 page

- Test Certificate Meft Peenya - BangaloreNo ratings yetTest Certificate Meft Peenya - Bangalore1 page

- Test Certificate MVGR Mech: Results of Tension TestNo ratings yetTest Certificate MVGR Mech: Results of Tension Test1 page

- Test Certificate Sant Longowal Institute of Engineering and Technology (Mech. Engg. Deptt.) SlietNo ratings yetTest Certificate Sant Longowal Institute of Engineering and Technology (Mech. Engg. Deptt.) Sliet1 page

- Rashmiranjan Si-716CE3008 (Group-7) TensileNo ratings yetRashmiranjan Si-716CE3008 (Group-7) Tensile9 pages

- Test Certificate Meft Peenya - BangaloreNo ratings yetTest Certificate Meft Peenya - Bangalore1 page

- Technical Specification For GD TC435077 2021 OPGW 24B1 100 (82 71)No ratings yetTechnical Specification For GD TC435077 2021 OPGW 24B1 100 (82 71)2 pages

- Construction Materials: Monsoon Semester 2021No ratings yetConstruction Materials: Monsoon Semester 20215 pages

- BH-04(2 A1) UCS (Modulis) 24-000345-PJ - (Depth 1.50~3.00)No ratings yetBH-04(2 A1) UCS (Modulis) 24-000345-PJ - (Depth 1.50~3.00)2 pages

- One-Way Slab (CONTINOUS) - ACI - Code - Good OKNo ratings yetOne-Way Slab (CONTINOUS) - ACI - Code - Good OK18 pages

- ASLH-D (S) BB 48 NZDSF (AL4 108 - 18,9) : Optical Ground Wire (OPGW)No ratings yetASLH-D (S) BB 48 NZDSF (AL4 108 - 18,9) : Optical Ground Wire (OPGW)1 page

- OPGW Cable Cross Section and Technical Data Type OPGW-48B1-90 (115 42.1)No ratings yetOPGW Cable Cross Section and Technical Data Type OPGW-48B1-90 (115 42.1)1 page

- Mechanical Stopper - Structure CAlculationNo ratings yetMechanical Stopper - Structure CAlculation9 pages

- EC - Max 30 30 MM, Brushless, 60 Watt: Part NumbersNo ratings yetEC - Max 30 30 MM, Brushless, 60 Watt: Part Numbers1 page

- Jordan University of Science and Technology Faculty of EngineeringNo ratings yetJordan University of Science and Technology Faculty of Engineering8 pages

- Strength of Materials-Ii Experiment 3 "To Perform Tension Test On Mild Steel Bars and Determine Principal Stresses Using Analytical Method"No ratings yetStrength of Materials-Ii Experiment 3 "To Perform Tension Test On Mild Steel Bars and Determine Principal Stresses Using Analytical Method"13 pages

- Simulation:1: Project Info (Iproperties)No ratings yetSimulation:1: Project Info (Iproperties)76 pages

- M.E.Forge Tech: Ultrasonic Inspection ReportNo ratings yetM.E.Forge Tech: Ultrasonic Inspection Report1 page

- M.E.Forge Tech: Ultrasonic Inspection ReportNo ratings yetM.E.Forge Tech: Ultrasonic Inspection Report1 page

- Revised Asme Items: SL - No PO No. Material No. Po. SL No. WO. No Material Qty InspectionNo ratings yetRevised Asme Items: SL - No PO No. Material No. Po. SL No. WO. No Material Qty Inspection1 page

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedNo ratings yetM.E.Forge Tech: Customer:M/s L & T Valves Limited1 page

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedNo ratings yetM.E.Forge Tech: Customer:M/s L & T Valves Limited1 page